Automatic card shuffler 2

From DDL Wiki

Report 1: Competitor Product Analysis

Executive Summary

A standard automatic card shuffler was analyzed as a preliminary investigation into developing a device that automatically separates different decks of cards. We identified the stakeholders and their priority requirements, analyzed the operation of the product and conducted user studies. (This included dissecting the product to more clearly understand its functioning and to formulate a bill of materials). Research was also done to understand the design for manufacturing, causes and effects of failure, and design for environment.

The specific model of card shuffler used for these analyses was determined to be more suited for the needs of individuals as opposed to professional casinos, including its affordability, portability and ease of use. The product was designed to be mass produced, with its high percentage of plastic parts and relatively low tolerances. These features cause it to be fast and easy to manufacture and assemble, however they negatively affect the performance of the shuffler and constitute the main points of failure of the product. The most important of these is the gear system, which is made completely from mass produced plastic parts which can easily cause misalignment in the system and inexact teeth on individual gears.

Our main conclusion in terms of the environmental impact of the product is that while it does not have a large environmental effect individually, the life cycle of the device is short, causing a larger cumulative effect over time. The main component of the device's environmental effect is battery use, which we would attempt to decrease in a redesign.

The main areas for improvement for this product are redesigning the gear system to be more effective and exact and to redesign the battery system to require less batteries in order to operate the product.

Major Stakeholders and Needs

There are four main stakeholders for this product: Families/Individuals, Casinos, Retail Stores, and Shipping Companies. Each of these stakeholders has different needs, although most of these needs align nicely with each other. The resulting needs are summarized below.

Families/Individuals

Families and individuals are the main users for this product. As such, these users have the most and most well-defined needs in regard to a card shuffler. Their needs are as follows:

- Low cost

- Appealing aesthetics

- Small, lightweight, and portable

- Able to be operated by adults and children age 8+

- Should not jam easily

- Shuffle at least 2 decks of cards

- Fast, should be faster than shuffling by hand

- Minimal/no assembly required

- Child-proof (no sharp edges, little to no risk of fingers getting pinched)

- Uses standard batteries

- Easy to store

- Quiet (so as to not disturb conversation)

- Accident-proof/Waterproof

- Cordless/battery-operated

- Easy to clean

- Sit flat/balance on table

Casinos

Casinos make up the second set of stakeholders in this product. While it is more likely that these establishments would purchase higher end card shufflers, it is possible that they would use our product as a low cost alternative. Their needs are as follows:

- Very Reliable (cards don’t jam)

- Appealing Aesthetics

- Shuffle at least 2 (potentially more) decks of cards

- Very Fast

- Small/doesn’t take up a lot of space

- Cordless/battery-operated (so that patrons don’t trip on cord)

- Sit flat/balance on table

- Easy to clean

Retail Stores

Retail stores are the ones who will be stocking our product and serve as the middle-man between production and the end user. As such they have a special set of needs in regards to our product, which are as follows:

- Small and lightweight

- Easy to store and stack

- Appealing packaging

- Reliable/high quality

- Low wholesale cost

Shipping Companies

Shipping companies make up the final main stakeholder in our analysis. Their needs are similar to the retail store, but they also have several differences. Their needs are as follows:

- Small/compact packaging

- Easy to stack/fit in standard boxes without wasted space

- Lightweight

Product Operation

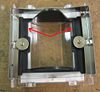

Upon being removed from its packaging, the competitor card shuffler must be equipped with 4 C batteries (not included). Two batteries are placed in each side of the base by opening two plastic tabs that lift two flaps to reveal the respective battery locations (see Figure 1). It is interesting to note that the springs for each negative terminal twist and bend, thus providing only marginal contact between them and the batteries.

After inserting the batteries and closing the flaps, the entire shuffler can then be equipped with decks of playing cards on each side of the clear plastic top. Note that according to the competitor's description, up to 2 decks can be placed on either side, though for the operation illustrated in the figures, only one deck was placed on either side. Figure 2 illustrates this first step of operation. Also, the loose clear plastic tray should be situated snugly within the alcove prior to operation of the shuffler.

To begin shuffling the decks of cards, a plate labeled "Press Down to Operate" is pushed. The plate must be held down continuously until both decks are completely processed through the shuffler. Cards are shuffled by being shot forward via a circulating wedge that is driven by the internal gears and motor. The wedge regularly breaks the surface of the deck-holding area, thrusting the card in contact with it towards a narrow crevice underneath the clear plastic top. Cards then fall onto the plastic tray. At the end of this report, a link to a video of the card shuffler in use can be seen.

Since the wedges on either side of the card collection cache move out of sync, the cards from either deck enter at alternating times. Sporadically during any given run, some cards from either side get caught along the side walls of the collection cache and do not fall onto the other cards accumulating on the plastic tray.

Once all the cards have been thrown into the cache, removal is performed by clasping the edges of the plastic tray and sliding it out. Care has to be taken on the user's part to ensure cards in a large stack (i.e. when more than 2 decks are shuffled) are not accidentally shaken off. Once fully removed from the shuffler cache, the cards themselves can be removed from the tray and used for play. The plastic tray is then re-inserted in the cache.

Post-operation maintenance and storage is very simple. The biggest detriment to the shuffler's useful life-span is the accumulation of dust over not just the entire surface, but upon the exposed gear assemblies. Over an extended period of time, dust and dirt accumulation on the gears can lead to destruction of the teeth (exacerbated during operation while not clean), which will wear down or loosen due to the minuscule (but growing) obstructions. Therefore, some cleaning must be done regularly if the shuffler is used often (once a week, for example) and kept out in the open. A dry cloth or rag will suffice in order to remove the majority of the superficial dust. However, for long-term survival, storing the shuffler in the box that it came packaged in is a viable and cost-effective option for the user. Note that while these care and maintenance suggestions have been discussed, they are no where to be mentioned in any documentation that came with the shuffler, no doubt signaling the manufacturer's intent to merely create and sell a "bare bones" model that is intended to be thrown away upon the first failure not attributable to dead batteries.

User Studies

Engineer's Analysis

Before we tested this product with a random user to see how they would use the shuffler, we conducted our own user study to see how we thought that it performed from an engineering standpoint. Our results can be seen below.

Good Points:

- Cheap (~$16)

- Small size

- Portable

- Easy to store

- Easy to clean

Areas for Improvement:

- Loud (could scare pets, children, unsettling to adults)

- Uses C batteries (not conventional AA or AAA), does not indicate on box what type of batteries are required, needs 4 batteries total

- Cards occasionally get stuck/jammed with 2 decks of cards (because shuffler takes too many cards at once from one side)

- Cards almost always get stuck with 3+ decks of cards (advertised as able to handle 4 decks)

- Have to hold button down entire time, cannot just press once

- Dangerous for finger pinching

- No directions or safety guidelines provided

- Battery springs deform very easily

- Does not shuffle particularly well, cards “clump”

These findings indicate much of what we suspected from the start, which is that you get what you pay for. This card shuffler is designed to be a cheap alternative to shuffling cards by hand, where quality is not always the highest priority. The main issue that we found with this product pertains to the main function, which is its ability to actually shuffle cards. For one or two decks, the product performs relatively well, with both sides finishing at almost the same time. Once additional decks are added, the performance drops drastically, with the product frequently jamming or having one side finish several seconds before the other. The main issues involve the fact that the shuffler is loud and the button to shuffle the cards needs to be held down the entire time the cards are being shuffled. While these issues do not affect the usability of the product, they are definite areas for improvement to improve the general product experience for the user.

General Consumer's Analysis

To get an outside opinion on the product and its usability, we got a volunteer to use the product and tell us their general opinions and impressions about the product. No instructions were given to the volunteer about how to use the product so that we could observe the thought process of how users approach such a product. This would also simulate the experience of actually buying the product and using it for the first time since no instructions were included with the product. The volunteers thoughts are summarized below:

- Thought product was cool (hadn’t seen before)

- Did not find button immediately

- Hesitated when pushing button which caused a jam

- Noise shocked her

The results of this experiment also confirmed our thoughts about the product. While this user didn’t analyze the product from an engineering perspective, most of her observations echoed our thoughts in a less scientific sense. She did point out that some type of instruction card would have helped and she would be much more likely to continue using the product if it were quieter. This provides us a little bit of insight into the minds of the general consumer and what aspects we should focus on for future improvement.

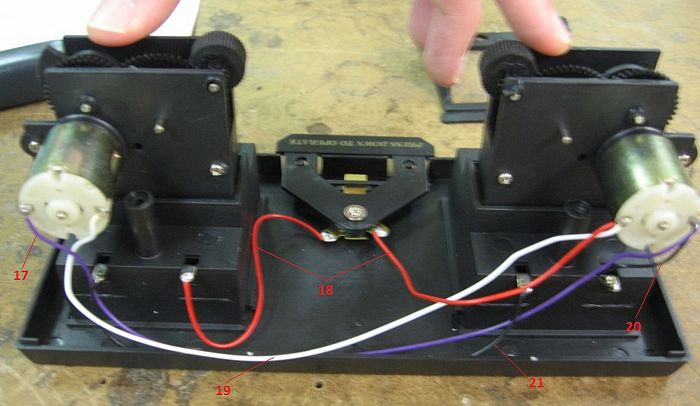

Mechanical Operation

Inside the main assembly housing are identical mechanical assemblies on either side of the main operation button. Atop each battery housing are plastic cases that hold both the motor and the various gears and rollers. Wires go between the operation button contacts and the battery contacts, as well as between the motors and their respective battery contacts.

When the button is pressed, the two copper contacts meet and allow electricity to flow from the two sets of batteries into their respective motors. The motors then spin at a very high RPM and turn a gear that not only rotates the wedge that makes contact with the bottom card in each deck, but also a rubber roller that guides the card smoothly through the aluminum gateway and into the card collection cache.

The motor, which has a gear attached to its shaft, drives the gear furthest to the left in Figure 8. On the same shaft as that gear is a much smaller one that drives the large, central gear, which in turn drives the small gear and roller on the third and and final shaft. Most importantly, the first shaft also holds the wedge that hits the bottom of the card deck periodically during rotation. A video is included as a link below to illustrate how the motor drives the gears and thus controls the speed of the card shuffling.

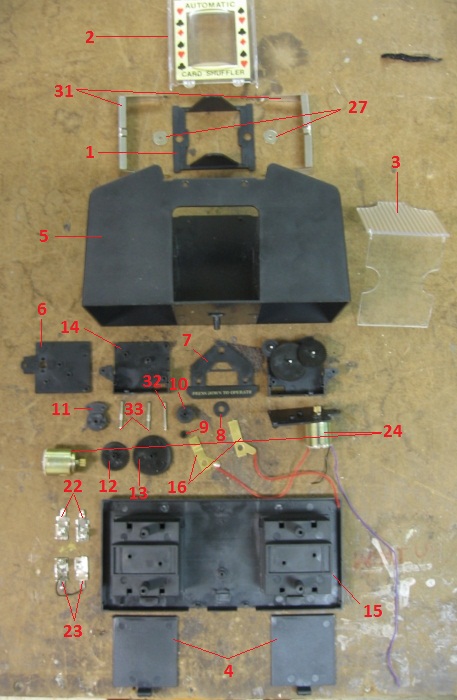

Bill of Materials

A dissection of the automatic card shuffler was completed and the device was found to include 33 different parts. These parts were easily divided into the categories of plastics, electrical components, fasteners, and miscellaneous metal components, with the bulk of the materials falling under the plastics category.

Table 1: Bill of Materials

Design for Manufacturing and Assembly (DFMA)

Design For Manufacturing

This product was designed with the ease of manufacturing in mind, but it was not without flaws according to our analysis. The areas of this design done well and the potential areas to be improved are summarized below with respect to manufacturing.

Good points:

- Design is simple

- Almost every part is made out of plastic

- Almost no really tight tolerances

- Minimal secondary and finishing operations

- Color could be incorporated into injection molding since almost the entire product is black plastic

- Standard motor that could be inexpensively purchased

- Aluminum parts could be stamped and then bent to avoid costly manufacturing procedures

Areas of Potential Improvement

- High part count

- Lot of screws, no standard size between screws

- Extra gears added so that cheaper, faster motor could be used

- Almost all parts were unique, could only be used in one place

- Tolerances might have been too loose, product jammed, more precise gears might have reduced noise level

There are many areas of this design that are done well in regards to design for manufacture. The first part is that the design is fairly simple in nature, meaning that the individual parts that it consists of are no too difficult or complex. This is important because this will simplify the manufacturing of the individual parts and the overall product as a whole. Additionally, almost the entire product is made out of plastic, which makes it easier to manufacture because you could use the same plastic to make almost any part within the product. The tolerances within the product are not very tight, so precise machining or injection molding is not required. While this is an advantage for this style of design, it did become an issue in performance because the cards would sometimes get jammed or one side would not shuffle the cards with the other side, which could have been prevented if the tolerances were tighter. Another advantage is that almost the entire product is black, so the black color could be incorporated into the injection molding process, reducing the amount of secondary process such as coloring the product. The motor is a standard part, which is used in many other simple toys, can be purchased separately to decrease the amount of manufacturing necessary. Finally, the aluminum parts can easily be stamped and bent into the correct shape. This is a fairly inexpensive and quick manufacturing process compared to some of the other processes available, which will save both time and money.

Despite the many portions that were done well with regard to manufacturing, there are some definite areas for improvement. The first area is the fact that there are many parts and they are almost all unique. This will be inconvenient for manufacturing because the machines need to be changed or separate machines need to be used to manufacture each of the individual parts. Making some of the parts interchangeable may help reduce manufacturing costs. Another area that could be improved is the fact that several extra gears are used in order to facilitate the use of a cheaper motor. While this may be advantageous overall for cost effectiveness, it is not convenient for manufacturing because additional gears of different sizes need to be made to get the desired speed of the final product. Additionally, there are a lot of screws involved in fastening the product together, of which almost none of them are the same size. Most of these screws are probably purchased separately, so the burden on manufacturing is not that high, but it is inconvenient, especially because they are not all the same size. If the screws were all the same size, it would standardize the buying process and ease assembly. Finally, while the tolerances being loose is advantageous for manufacturing, the tolerances on this product might have been a little too loose because the product did jam a lot if the cards were not placed perfectly or if three or more decks were being shuffled. Tighter tolerances might have helped to have the final product function better, but it would put an additional burden on manufacturing.

Design For Assembly

This product was also designed well for assembly. The main issues come into play with the high part count and the non-standardization of screws. The results of our findings are summarized below.

Good Points:

- Don’t need many tools to assemble (really only need screwdrivers and pliers)

- Only 5 main sub-assemblies to assemble (2 gearboxes, base, main housing, decorative top)

- Gearboxes could be assembled and tested separately, decorative top could be assembled separately

- Most parts had size-specific slots that would only allow the correct part to be assembled in that location

- Battery flaps didn’t need an additional fastener

- Most fasteners could be inserted in the vertical direction so minimal handling is necessary

- Assembly can be done in one essentially one direction, from bottom to top

- Can get to almost any part by unscrewing 1-2 screws, nothing is incredibly difficult to get to so replacing parts is fairly straightforward and easy.

- Chamfers allowed for easier installation of screws.

Areas of Potential Improvement:

- No standard screw size means that you potentially would need multiple size screwdrivers

- Gearbox uses multiple gears in order to slow down the motor speed, can be time consuming to make sure that all the gears line up correctly.

- Lots of fasteners/screws, some of the parts such as the decorative top potentially could have been fastened another way, such as a snap-fit

Just as in the case for manufacturing, the design certainly took into account ease of assembly. One of the best features of this product in regards to assembly is the fact that it doesn’t take many tools to assemble. In our minds, the only tools that you really need are screwdrivers and pliers. This makes it easier to assemble because you are not constantly switching tools, which streamlines the assembly process. Another great feature of this product is that the product could be assembled in a bottom to top fashion because the product consists of five main sub-assemblies that are not entirely dependent on each other. This is advantageous because each of the subassemblies can be made separately and then put together at the end. Additionally, the gearboxes can each be made separately and tested independently, which helps in assembly because it makes the process move quicker because testing could occur instantly after each gearbox is made. The product is also designed well because, for the most part, all of the slots where the parts go are unique, only allowing the correct part to be inserted. This is very good because it eliminates most of the errors in putting parts in the wrong places. The fact that most of the holes for screws have chamfers allows for easier installation of the screws, which helps with assembly. Finally, the assembly is greatly aided by the fact that almost all parts can be accessed by unfastening one or two screws, so if an error is made, it can quickly be corrected.

This product does still have several areas that could be improved with respect to assembly. The first, most prominent area that was noticed was the fact that all of the screws were different sizes. This is advantageous for knowing where they need to go, but it can be very inconvenient in terms of using different screwdrivers to assemble the product. As mentioned in the previous section on manufacturing, the gearbox does have several additional gears to gain the correct final speed. If the correct speed motor were obtained, several of the additional gears might be able to be eliminated. Finally, there are a lot of fasteners and screws involved in the assembly process. This could potentially be improved by making some of the connections snap-fits or some other assembly process. This might not be advantageous for manufacturing but would certainly help in assembly.

Failure Modes and Effects Analysis (FMEA)

This table lists the different failure modes, its effects, and recommended solutions to the design in order to minimize or remove these failures. The numbers represent on a scale of 1 to 10, the severity of failure (S), occurrence of failure(O) and ease of detection of failure(D). The basis for the scale used here comes from the following textbook reference: Dieter, George E., and Linda C. Schmidt. "Chapter 14 - Risk, Reliability, and Safety." Engineering Design . 4th ed. New York: McGraw-Hill Higher Education, 2009. Pg 670-671. Print.

Table 2: FMEA Analysis

| Item and Function | Failure mode | Effects of Failure | S | Causes of Failure | O | Design Controls | D | RPN | Recommended Actions | |

|---|---|---|---|---|---|---|---|---|---|---|

| Wire – makes electrical connections | Wires come unattached | The system won’t operate | 5 | Dropping, wearing out or repeated use | 2 | The motor won’t turn on while testing | 2 | 30 | Have more spaces between contacts, make stronger connections, longer wires | |

| Gears – drive cards through shuffler | The gears can be loosely assembled or misaligned; the lubricant on the gear could dry out | Whole assembly stops moving, it causes more noise or can break | 7 | Poor manufacturing – inexact teeth, overuse | 3 | can see the irregular motion of the cards; they do not move in the right direction | 1 | 21 | Requires higher precision manufacturing | |

| Plastic – casing holding the parts together | Cracks, pieces breaking off | All parts will come apart, therefore it will not shuffle the cards correctly | 4 | high impact caused by dropping the product | 4 | cracking sound of plastic | 1 | 16 | use better quality plastic; provide some kind of rubber covering at the corners | |

| Motor – runs the gears | Motors burn out or stop working | The gear system will stop working | 5 | Usually occurs due to overuse | 5 | Object stops working entirely when tested | 1 | 25 | The motor has to be replaced or requires service. | |

| Plastic Card catcher | It is not attached properly therefore can be easily lost | Easy to lose and harder to remove cards | 3 | Lost in transportation | 5 | If you don’t see it then you know its lost | 1 | 25 | Have some kind of groove to slide it in instead of it just sitting in the space. |

FMEA Conclusion

The most significant failure of our products is that of the gear system which could result due to improper manufacturing. Most of the other modes of failure are due to improper use or over use. We will address these failures in our new part based on the recommended solutions listed in the table above.

Design For Environment (DFE)

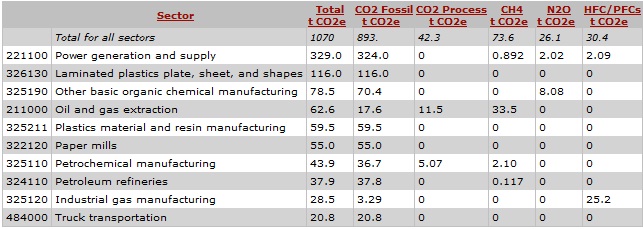

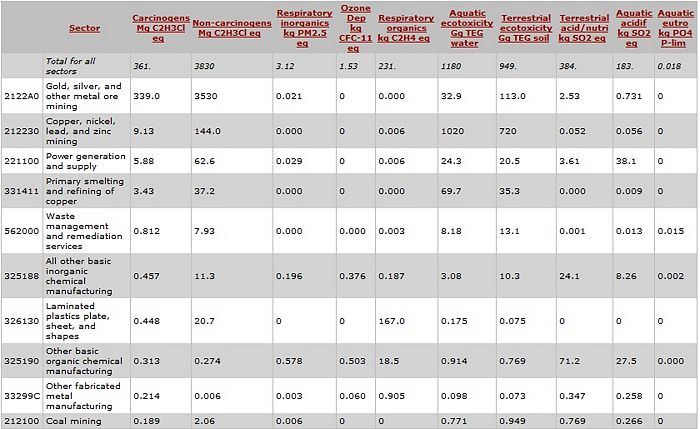

Especially in today’s society, designing products while keeping in mind the environmental impact that they are having is extremely important. In order to obtain a first level analysis of the environmental impact of our card shuffler, we used the EIO-LCA software from the Carnegie Mellon Website.

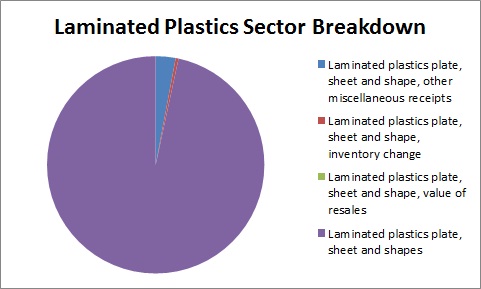

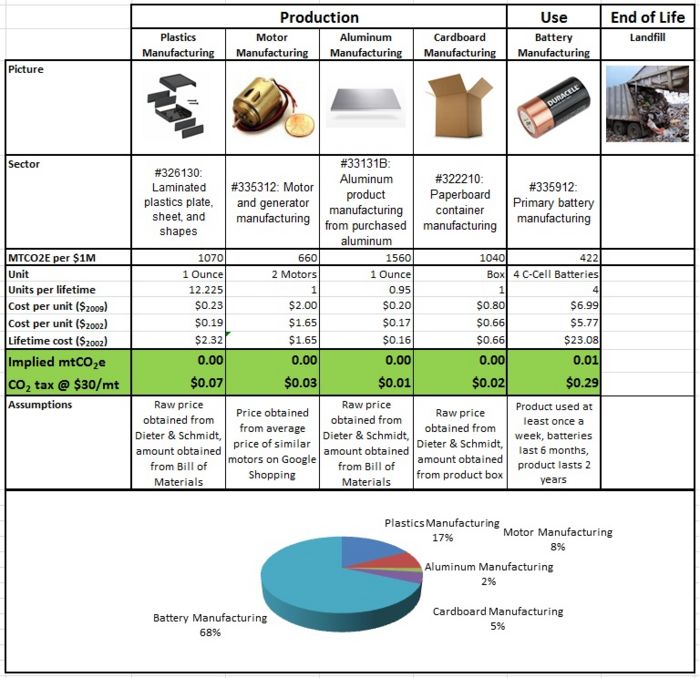

Sector Breakdown

In order to analyze the effect that the manufacture of this product has on the environment, it was necessary to determine what sectors were relevant to card shufflers since no one sector covers card shuffler manufacturing. In order to do this, we broke the product down into 5 main categories: plastic manufacturing, motor manufacturing, aluminum manufacturing, cardboard manufacturing, and battery manufacturing. While this is helpful, each of these sectors needed to be analyzed to make sure that they actually fit with our product. To do this, we looked at what type of operations and processes fell into each sector, and those results are summarized below.

The first sector analyzed was the laminated plastics sector. As can be seen in the graph, the vast majority of this sector is devoted to laminated plastic plate, sheet, and shapes. This validates our decision to use this sector as the primary sector for our product because our plate is almost entirely a rigid, plastic plate, which takes up a large part of this sector.

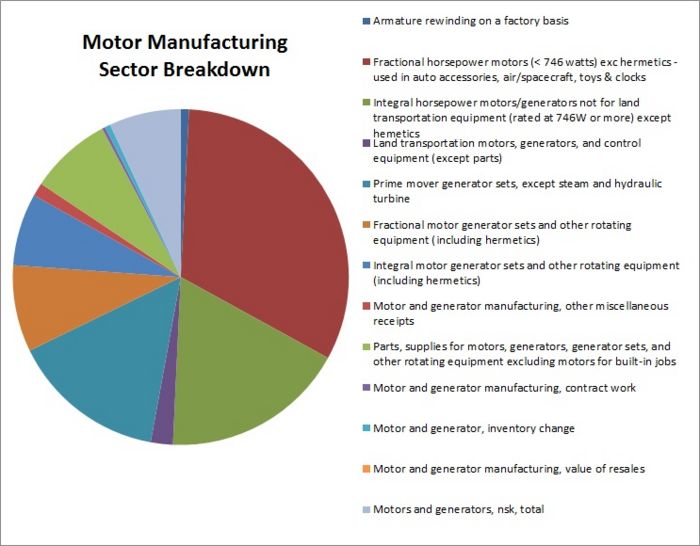

The second sector that was analyzed was motor manufacturing. The graph shows that the largest portion of this sector is devoted to small motors rated at less than 746 W which can be put in, among other items, toys. This is the section that our motor would fall into, which means that this sector is valid to use for our analysis.

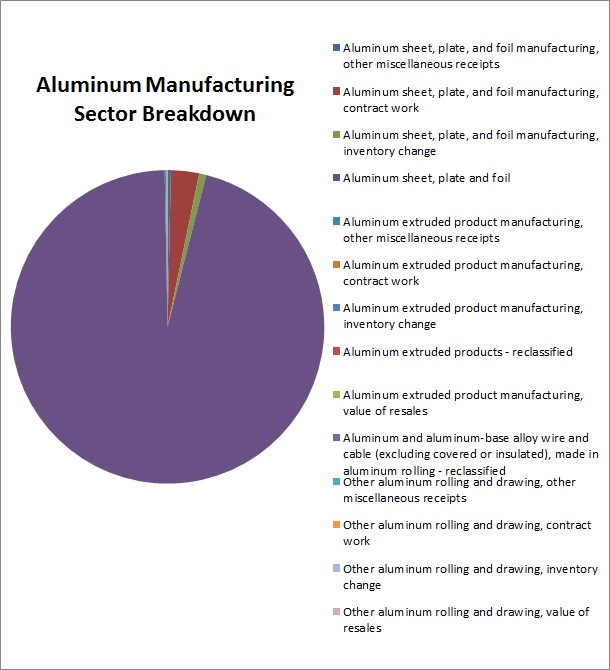

The third sector that was looked into was the aluminum manufacturing sector. In this sector, a very large amount of its focus is spent on aluminum sheet, plastic, and foil. This validates our decision to use this sector because the aluminum in our product was almost entirely formed from aluminum sheet.

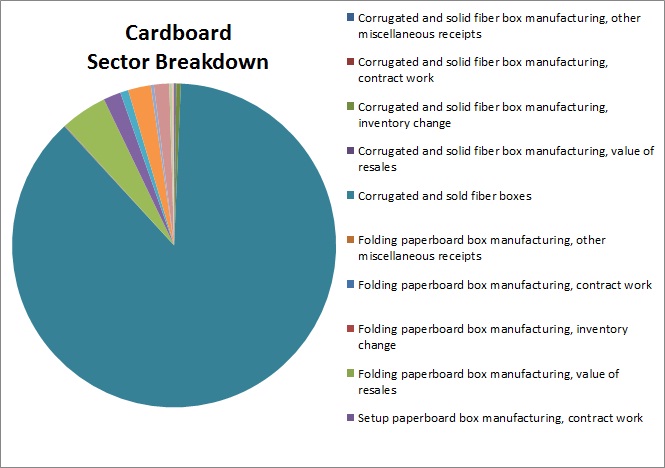

The fourth sector that was analyzed was the cardboard manufacturing sector. As can be seen in the graph, a lot of the focus of this sector is on corrugated and solid fiber boxes. This is exactly the type of box that we have for our product so it is logical to use this sector in our analysis.

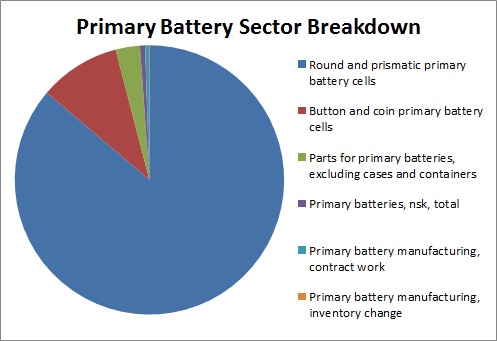

The final sector that was analyzed was the primary battery manufacturing sector. This sector primarily focuses on round and prismatic primary battery cells. Once again, this aligns well with our product and confirms our decision to use this sector in our analysis.

Primary Sector Analysis

Due to the fact that almost the entire shuffler is made out of plastic, we decided to look at the plastic manufacturing sector in more detail in terms of its environmental impact. The first area that was looked at was the economic impact of the manufacture of card shufflers. The top ten sectors in terms of economic activity related to the plastics sector are summarized below. The results of this table are encouraging, because the area that is most related to our product turns out to be the most impacted. The surprising result of this analysis is that power generation rates so low in terms of economic activity. Due to the fact that power generation is necessary for almost every step of the process, we expected this to be higher on the list. Overall, though, nothing is entirely unexpected regarding the economic activity.

The next area that was looked at was the effect of the laminated plastics sector on the emission of greenhouse gases. This analysis yielded results that were entirely expected. Here, the main offender is the process of power generation. While this process is, for the most part, out of our control, it is a little discouraging because large impacts in terms of greenhouse gas emission reduction will be difficult to achieve. Knowing this, however, we went through the other top sectors to see which of them could potentially lead to decreases in emissions if design changes were made. The most obvious solution would be to use less plastic, because the actual plastic sector is the next biggest offender. This is something that will need to be considered in terms of our potential redesign.

The third area that was looked at was which areas of the laminated plastics sector produced the most toxic releases. This area is important to look at because these emissions could be very dangerous. The largest offender in this area involves actually obtaining some of the materials that go into the manufacture of plastic and not the process itself. Power generation once again plays a large role in these emissions, but not nearly as large as some of the other processes. While most of these processes are out of our control, their impact should be taken into consideration to see if anything can be done to reduce them.

Environmental Impact

Finally, all of the preceding factors need to be looked at as a whole to see what type of overall environmental impact the production of card shufflers will have and what type of carbon tax would apply to this product. The results of this were computed using the EIO-LCA software on the Carnegie Mellon Website. The template used to summarize all of the results was taken from the Coffeemaker Example spreadsheet that was distributed by Professor Michalek. The results are summarized below.

The most interesting note from the environmental impact analysis is that the most of the emissions are related to the use phase of the life cycle of the card shuffler. The product itself produces negligible emissions during use, but the batteries, which will need to be replaced several times over the life of the product, account for the vast majority of the emissions. This is important to note because it tells us that finding a way to reduce the number of batteries while still maintaining system performance will be one of the major priorities of the redesign phase. In terms of the other sectors, it makes sense that plastic manufacturing would produce the next most emissions because almost the entire product is made out of plastic. Reducing the amount of materials may also be a high priority in the next phase in order to reduce our negative impact on the environment. Overall, this product did do a good job of keeping the environment in mind, with only a $0.43 carbon tax on a $16 card shuffler assuming a $30 tax per mtCO2e. This amounts to only a 2.7% tax, which is not unreasonable.

DFE Resources

"Battery (electricity)." Wikipedia. Web. 1 Feb. 2011. <http://en.wikipedia.org/wiki/Battery_(electricity)#Life_of_primary_batteries>.

Carnegie Mellon University Green Design Institute. (2011) Economic Input-Output Life Cycle Assessment (EIO-LCA) US 2002 (428) model [Internet], Available from: <http://www.eiolca.net/> [Accessed 1 Feb, 2011]

Dieter, George E., and Linda C. Schmidt. Engineering Design . 4th ed. New York: McGraw-Hill Higher Education, 2009. Print

"Small DC Motor." Google Shopping. Web. 1 Feb. 2011. <http://www.google.com/prdhp?hl=en&tab=wf>.

Team Member Roles

- Alexander Harber - Team Leader

- Alana Yoel - Safety Lead

- Paul Wagner - Environmental Lead

- Tanvi Bubna - Manufacturing Lead

Roles in the team formed more so than they were selected. With each exercise in class regarding DFMA, FMEA, and DFE, a different person naturally took to over-seeing its completion not just in class, but during our own reunions for the sake of writing this report. A couple of us had worked together before on previous projects, so there was a spark of familiarity that promoted thorough collaboration right from the start.