Ice cream maker redesign

From DDL Wiki

Contents |

Executive Summary

Since the previous update of our progress, we have done significant market research and testing to determine the major design problems with the current ice cream maker on the market. The largest problem found was that the entire process of making ice cream took far too long and users soon grew frustrated or impatient. Furthermore, there was a large dependence on other appliances, such as blenders, pots, and pans. Considering these consumer complaints, we went ahead with three main design changes that could solve these problems.

In the three possible solutions, each solution addresses our main customer need, to expedite the process of making ice cream. With our first redesign option, the idea is to change the shape of the bowl. The changed shape will increase contact surface area, so the ingredients will cool faster, which results in ice cream being made quicker. This design will reduce the amount that the ice cream maker is actually running.

Our second redesign option combines the functionality of other products that are used in the process of making ice cream. If the device had the ability to blend, then this would cut down on the preparation time because the ingredients would not have to be transferred from one mixing place to another. Additionally, the consumer would have to spend less time cleaning, since they would have fewer pieces of equipment to clean.

Our third redesign option incorporates a new, innovative idea. The ingredients are extruded through a freezing tube using a small compressor to generate pressure. Since there is more surface area where the ingredients will contact the tube, the ice cream will theoretically be ready faster. Additionally, agitators will be placed inside of the tube to facilitate proper mixing of the ingredients to form an ice cream structure. Some research still needs to be done to verify the feasibility of this idea.

The next step in our design process was to identify the pros and cons for each of the three concepts as compared to the currently existing base model ice cream maker. A standard Pugh Chart was used to establish and weigh criteria that consumers would find important. Through the Pugh Chart analysis, it was found that each of the three design concepts were significant improvements over the currently existing model. Since the feasibility of pursuing our third design concept is still in question, we have decided to currently move forward with our first two design ideas. This will likely include somehow merging the concepts into one idea. By both attaching a whisking arm to expedite the preparation process and increasing the surface area of the mixing bowl to reduce the run time of the ice cream maker, the overall experience of making ice cream can be enhanced significantly. The exact layout of how this combination ice cream maker will look still needs to be designed. Therefore, design ideas one and two are discussed separately in this report.

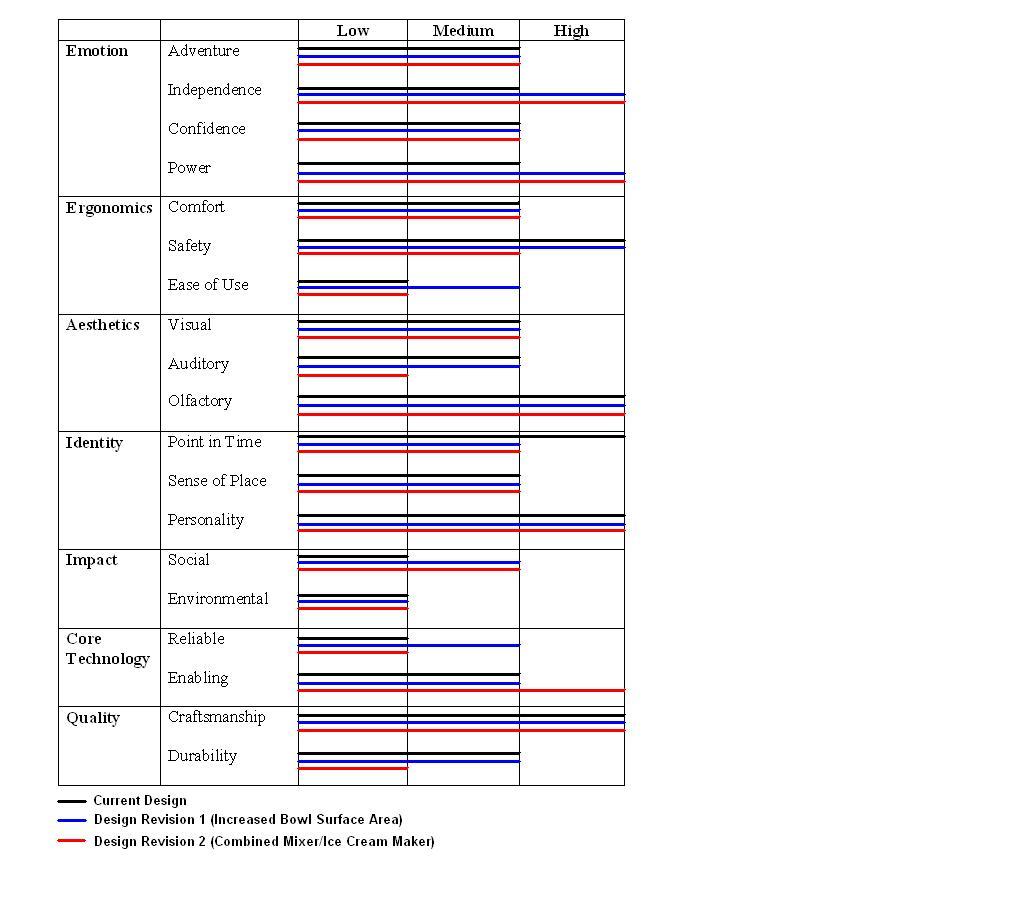

A value opportunity analysis (VOA) chart of design ideas one and two was constructed to compare these concepts with the currently existing model, from the user’s point of view. It was found that the ice cream maker creates a good deal of emotion and identity in the user. This is because the user is free to be creative and independent in making a variety of different flavors of ice cream. It was also found that both of the redesign ideas discussed in the VOA will make the user feel more independent and empowered. It was also found that both design concepts will increase the social impact of ice cream makers. The ideology behind this is that by reducing the amount of time required to make ice cream and making the entire process more efficient, more people will purchase ice cream makers and they will have a larger impact in society.

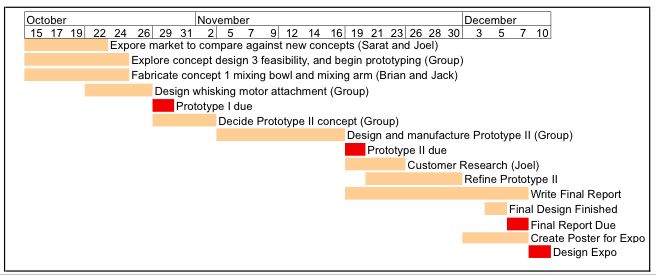

Finally, a Gantt chart was created to plan out the remainder of project and establish concrete timelines and goals for further testing and prototyping. Specific tasks were handed out to each team member. The biggest goal for the immediate future is to explore the existing market to confirm that our design concepts have not already been created. After this we can create a design merging ideas one and two and then begin prototyping. Once our first prototype is finished, the goal for the remainder of the project is to refine this prototype into a second, more detailed model and then eventually into a final product. With a specific timeline for the goals of the project, we will be able to provide a report of our final model for Initech by December 7 and be prepared to present our findings at the design expo on December 10.

Research and Observations

We have observed the ice cream maker in use and have noticed many processes that can be improved. The process that is currently used in today’s industry is a bit extensive and a consumer may grow tiresome of the long waiting process. In one of the trials, the users had to wait for approximately three hours before deciding to give up and put the mixed product into the freezer.

Our other trials were much more successful. The users were able to add the ingredients into the bowl and create ice cream in the advertised time. However, since there is extensive preparation time, this elongates the process of actually making ice cream. If you need to prepare the ingredients for an hour before placing them in the bowl, then the actual time needed to make ice cream becomes one and a half hours.

When observing the subjects interacting with the ice cream maker, it was evident that there was difficult with the clean up with the mixing arm. Since some of the spots were difficult to reach and the ice cream was sticking onto the arm, the cleaning of the mixing arm became frustrating. Also, since the mixing bowl is not dishwasher safe, this had to be cleaned manually.

Another observation that we observed is that the user has very little interaction with the actual device. Once the ingredients are properly mixed and prepared, then this is placed into the bowl and the user will turn the switch from the “Off” position to the “On” position. For a user to be able to produce all of the desired products (sorbet, sherbet, shushes, frozen drinks), they need the use of other products. The user has more interaction with other products, which include blenders, pots, pans, etc. Without these other products, it is not possible to make these other desserts.

Design Problem and Possible Solutions

The main problem that we would like to address is the excess preparation time. This includes the time it takes to prepare the ingredients to make ice cream along with the time required to leave the mixed ingredients in the mixing bowl. If we are able to significantly shorten this process, then the consumer will be able to enjoy their dessert without all of the waiting.

With the current process, if a consumer would like to enjoy dessert after dinner, they would have to prepare the ingredients before dinner and then make the ice cream while they eat dinner. This may not be optimal because the consumer is already preparing dinner, and adding another process may be confusing or stressful.

Some possible solutions to alleviate this problem are to redesign the bowl, redesign the process to make the ice cream, or to create a multi-functional bowl. The first solution, to redesign the bowl, is aimed to lower the preparation time of the ice cream after the ingredients have been mixed. This is aimed at lowering the half hour of mixing time that the bowl needs to make the ice cream. Since the bowl is freezing the ice cream as it is being made, if we increase the contact surface area, then there will be increased heat transfer between the walls of the bowl and the ice cream. We will have to do further research if the increased surface area significantly decreases the time required to make the ice cream.

The second possible solution is to create a multi-functional device that would incorporate the other processes in one appliance. This would shorten the cleaning up process because the consumer wouldn’t have to use other products such as a mixing bowl or blender. Our proposed solution is to include a dual speed motor with interchangeable whisking and mixing arm attachments that the user could switch based on need. The whisking arm would be in place for the preparation process and the mixing arm would be in place for ice cream making process. One major change from the current design is that the bowl itself would not rotate. Instead, the motor would rotate either the whisking or mixing arm. If we created an all-in-one device, the consumer would not have to clean the other devices after use, since only one container was used in the process.

The third possible solution is to redesign the process of making ice cream. The current process requires a bowl and some arm that is used to mix the ingredients to allow for consistency. A new process that would be able to expedite the process is to extrude the ice cream through a tube. The tube will have a small cross-section, and its wall will be cooled with a cooling mechanism. Then, the ingredients will be pushed through the tube until it forms into ice cream. Some research that needs to be done with this process will be the effectiveness of the tube. What will be the cross-sectional diameter of the tube? Depending on the cross-section, how long will the tube need to be to create the proper consistency of ice cream? Also, a major factor will be the length of time that is needed to make the ice cream. Will this new idea cut down the preparation time significantly? Lastly, cost will be a factor into this equation. Will the cost of this device be more expensive or cheaper? What parts will be used to make this redesign and how much will they cost?

Proposed Design Concept 1

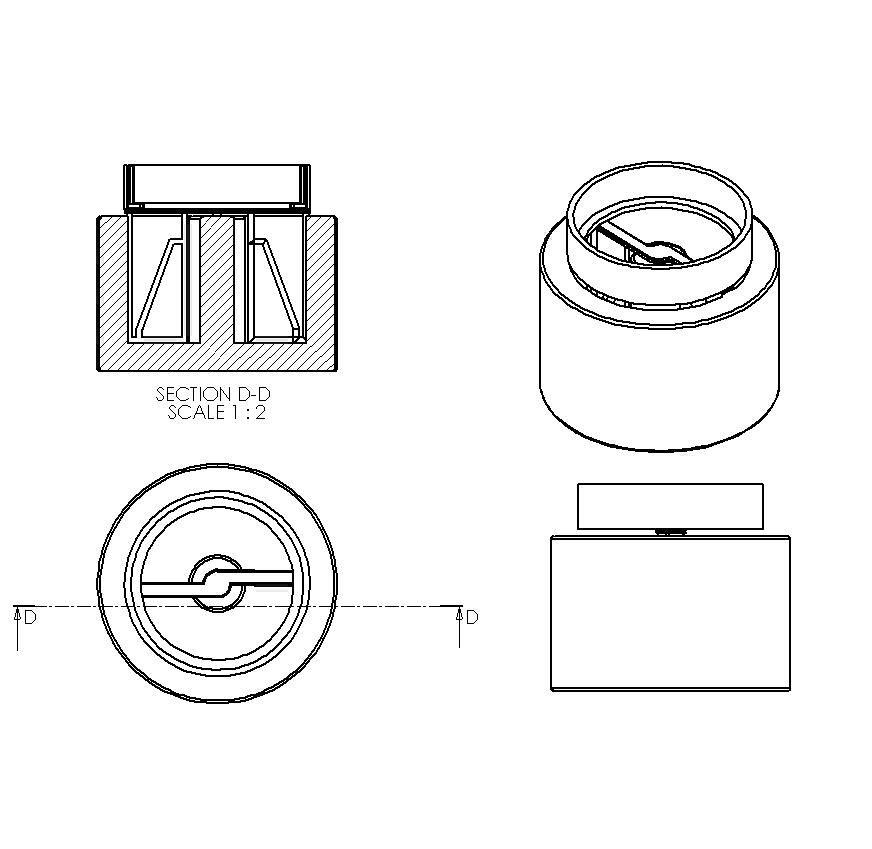

Increase Surface Area of the Freezer Bowl:

The overall concept for this idea is to increase the surface area where the ingredients contact the bowl. If there is more contact between the ingredients and the bowl, then the contents of the bowl will cool quicker. This will result in a shorter preparation time for the end product.

In order to implement this idea, we added a fixture in the middle of the bowl that works on the same principle as the outer bowl. When you place the bowl into the freezer, the middle tube will also have a liquid inside of it that will freeze. In the current design by Cuisinart, the ice cream freezes unevenly. It is evident that the product hardens faster at the edge of the bowl than in the middle. With this redesign of the mixing bowl, we plan on eliminating the consistency problem of the product.

Due to the redesign of the bowl, there also needs to be a redesign of the mixing arm. Since the bowl shape has altered, we have designed a new mixing arm. The mixing arm will consist of two separate arms, as shown in the diagram. They will be suspended from a beam and will remain stationary as the ingredients are rotated around it. The freezer bowl will act similarly to the current design, which will rotate and have the “Easy Lock Lid” to hold the mixing arm in place.

Proposed Design Concept 2

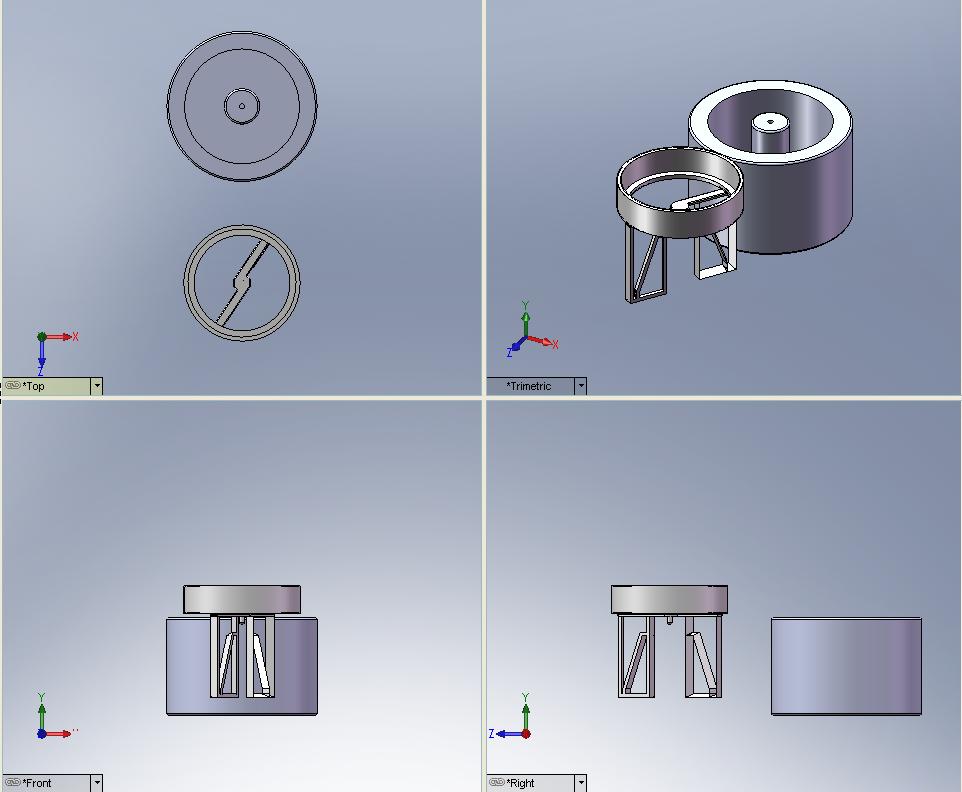

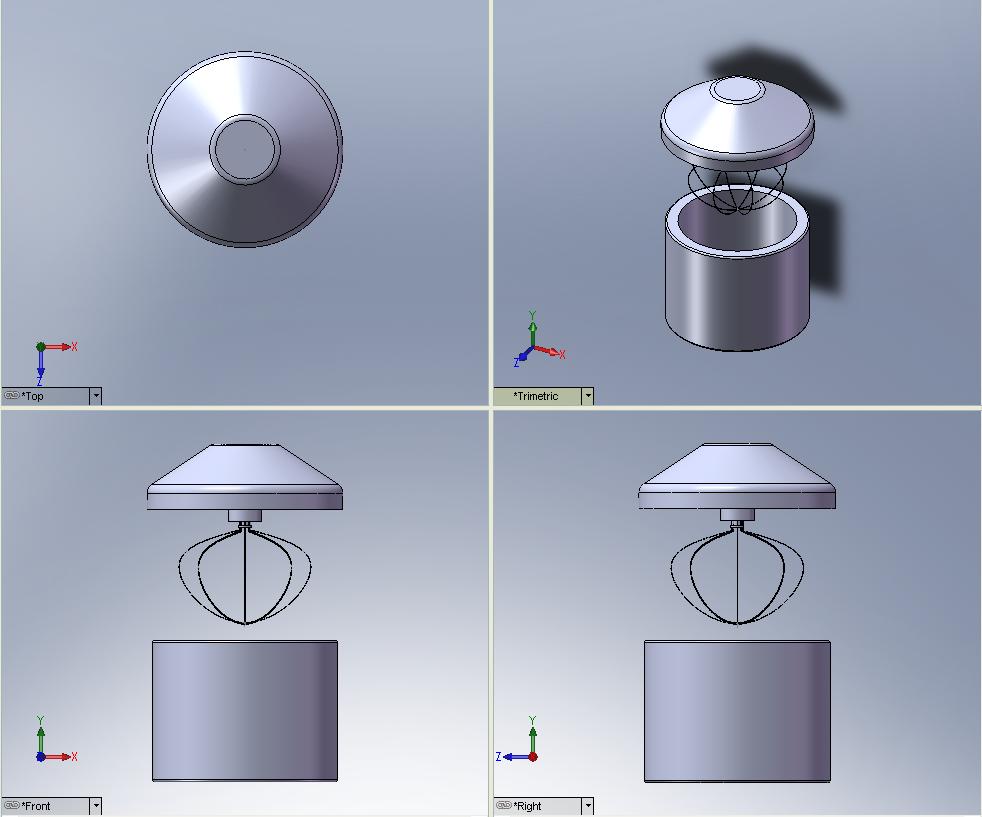

Combined Mixer/Ice Cream Maker:

The purpose of this design is to shorten the preparation time by including more processes in the mixing bowl. If there are fewer procedures involved in the process, the preparation time should be reduced. The added feature that we would like our device to have is the ability to whisk the ingredients together.

In order to accomplish this new task, we had to change the idea on how to whisk the ingredients while still maintaining the ability to mix the ingredients to form the proper ice cream structure. We placed the motor mechanism so that it is located over the bowl, with a couple of different arm attachments. These attachments clip onto the motor with spring loaded locking mechanisms, which are similar to the ones that are commonly found on household electric mixers.

Since the whisking process requires a faster rotation from the motor, we would have to design the motor so that there are multiple speed options. The faster option is necessary to whisk the ingredients together, while the slower option is needed to churn the ingredients into ice cream.

Proposed Design Concept 3

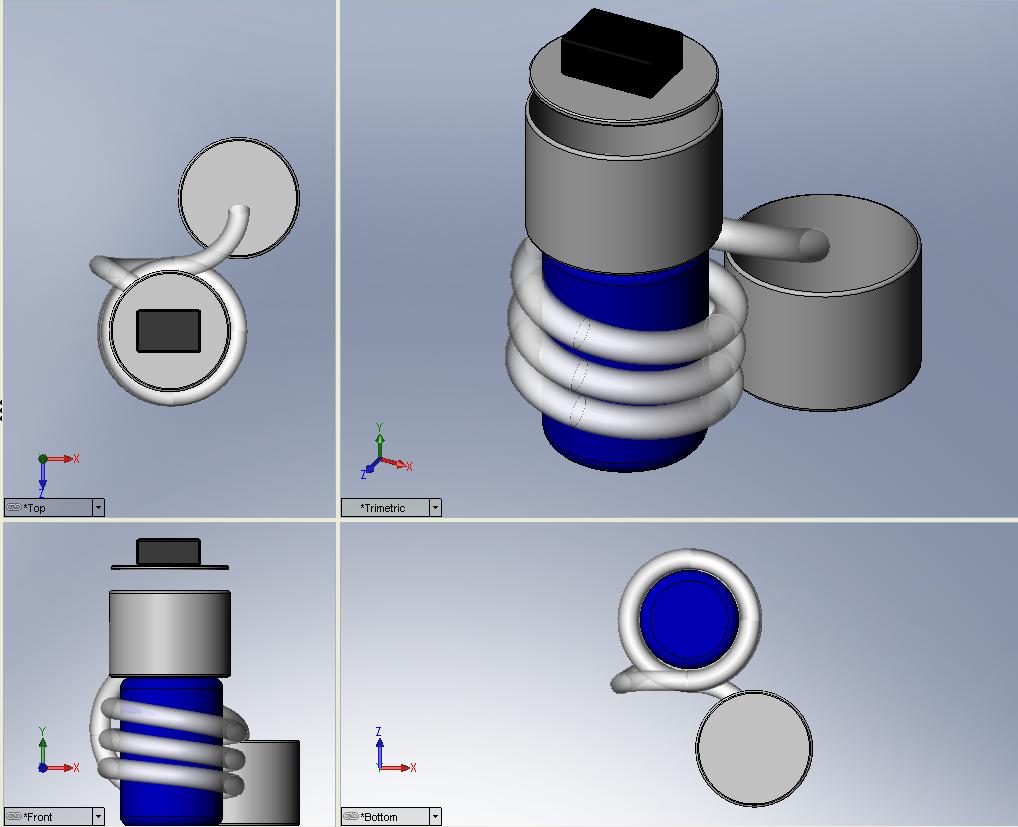

Freezing Tube:

This innovative design concept is challenging how commercial ice cream makers have operated. This idea is similar to our first design concept in that we are trying to increase the surface area between the ingredients and the frozen component. The ingredients would be extruded from a tube, which is coiled around two freezing units. Because the tube will be long and have a small diameter (relative to the mixing bowl), there will be a significant increase in the amount of heat transfer that will take place.

The two freezing units that are involved are the outer casing and the inner cooling cylinder. The outer casing, which is not shown, will surround the device, to keep it cool. The inner cooling cylinder (which is represented by the blue cylinder in the diagram) will also have the freezing fluid inside of it, which will ensure that the tubes will remain cold.

In order to get the ingredients to go through the tube, we would need a small compressor to engage and pump air through the system. This process has a few benefits because the pumped air can aerate the ice cream mixture to add to its texture, and also push the ice cream through the entire freezing tube. When the ice cream leaves the tube, it will be in a semi-hard soft serve state, where the ice cream can be consumed or can be put into the freezer to make the more traditional ice cream.

Pugh Chart

A Pugh Chart, or design selection matrix is a useful tool for comparing several design concepts against each other. The key component is to compare several qualities of different concepts against a currently existing design, notated as the datum.

Pugh Chart Criteria

To first explain our Pugh Chart, we will give a description of the different criteria and weighting. Many of these criteria were used because they were identified as key improvement areas from our market research and brainstorming sessions

- Bowl Freeze Time - This is the time it takes for the freezing apparatus to freeze. In most cases this is the freeze time of the bowl, specifically the fluid inside. In the case of the third design, this would be the freeze time of the freezing element that the hose wraps around.

- Prep Time - Preparation time is a key element because it determines how much effort the user must put in before even using the ice cream maker. Designs that reduce preparation time are the most desirable (hence a weight of 3) because it is the most cumbersome step for the user.

- Run Time - This is defined as the time that the product is running on its own, starting from pouring the prepared ingredients into the mixing apparatus to the time the ice cream is served. If the ice cream requires additional freezing in a freezer, this is part of the run time also. Once again this is weighted strongly because it is the limiting step in the process, and the most important function of the ice cream maker itself.

- Bowl Size - This determines how much ice cream can be made in a single use. Products that allow for more ice cream to be made will receive higher scores. This received a low weighting because at the current time we do not know the bowl specification sizes of two of the products and therefor the final design may allow for the same amount of created ice cream as the datum.

- Additional Equipment - Users who buy an ice cream making will want to use a little additional equipment as possible because they already invested in the ice cream maker, and because more equipment means longer prep and clean up time. If the home ice cream making process can be streamlined into a single process with one device, then it will be very beneficial for users. Therefor, it receives moderate weighting.

- Cost - Ice cream makers are a luxury item, and therefor do not receive high weighting. Nevertheless, because all three design concepts require improvements and additional parts, it is important to note that the price in all likelihood will go increase.

Pugh Chart Analysis

- Design 1 receives high marks for run time because the increased surface areas means that the ice cream will freeze more quickly. Additionally, because more of the ice cream is in contact with the cold surface, the finished product will have a more uniform temperature. Design 1 receives low marks for freeze time because increased surface means more time to freeze. Additionally product room is sacrificed to increase surface area.

- Design 2 receives high marks for both prep time and additionally equipment because of its ability to streamline the ice cream making process. It allows for users to do all prep inside the bowl meaning less kitchen supplies and no transferring of mixtures. The design receives low marks only for cost because other than adding an additional component, all other aspects of the datum are kept the same.

- Design 3 receives high marks in several categories. Since there is no bowl to freeze, it receives high marks in this category. Since the tube allows for more freezing element contact, the run time is also decreased. Finally the process is now continuous, and there is no limit to how much cream can be made in one batch. However, this design is complex and as a result may see a large price increase.

Pugh Chart Conclusions

Clearly from the net scores, all three ideas are improvements on the datum. Design 2 and Design 3 both score the highest with a score of six. However, it is possible to combine design 1 and 2 into a single product, which would receive an even higher net score. Ultimately it will be up to our group to decide which idea is the most feasible and then move on from there.

Value Oppurtunity Analysis (VOA)

A value opportunity analysis (VOA) of the ice cream maker designs described above can give valuable insight into what the user hopes to gain from using the product. By looking at the product designs from the user’s point of view, one can compare the worth of a new design compared to the existing base model. A VOA chart is broken down into seven main categories: Emotion, Ergonomics, Aesthetics, Identity, Impact, Core Technology, and Quality.

Each of these categories is further broken down into sub-categories which are rated from low to high for each design. We have limited the scope of our value opportunity analysis to only two of our three design concepts. The third design idea of using a pressure system to extrude ingredients through a chilled tube to make ice cream is not yet concrete enough at this point to proceed with a VOA. Further research needs to be done on the feasibility of this idea. For now, we intend to pursue a possible combination of design concepts one and two. It is feasible to increase the surface area of the mixing bowl while having a combination mixer/ice cream maker. The exact layout of how this will be achieved has yet to be worked out, so the the VOA chart below analyzes the first two design concepts individually. It shows how the first two design concepts rate in comparison with the current base model that is out on the market. A further explanation of each category follows as well.

Emotion

Ice cream is a product that has a variety of flavors but consumers are usually dependent on professional ice cream parlors or restaurant to provide ice cream. Therefore, the biggest emotional impact that users can gain from an ice maker is that it allows them to be creative and independent in making their own ice cream. Both of the re-designs described in the VOA chart essentially allow the user to make ice cream more efficiently by saving time in some phase of the ice cream making process. This gives users more independence in that they don’t have to depend on as many extra components, such as a blender, and that they don’t have to spend as much time. Users also don’t have to depend on professional ice cream parlors for different flavors of ice cream, leading to a high level of independence. For this reason, we also feel that users will feel more empowered. The confidence and feeling of adventure the user will gain will be similar for the current design and both design concepts since the process of making ice cream and the quality of ice cream made will largely remain the same. Security and sensuality are also commonly used sub-categories in a VOA chart; however, they do not really apply to ice cream makers and have been omitted from this analysis.

Ergonomics

Since an ice cream maker is a very hands-on product, the ergonomics of it are very important to users. Ergonomics has been further broken down into comfort, safety, and ease of use. The comfort for all three designs analyzed is essentially the same since the user essentially interacts with the ice maker redesigns in the same fashion as in the base model. The on/off switch will remain the same, except in the case of re-design concept two, which will have a whisk/mix/off switch. However, the comfort of using the switch will be the same. The current ice cream maker on the market is quite safe since the mixing arm is made of plastic and there is a locking lid that makes it difficult to accidentally place body parts into the ice cream while it’s running. The design concept with the increased surface area bowl will have the same lid and also have a plastic mixing arm so the safety of the product has also been given a high rating. For design concept two, the whisking attachment will almost certainly be made of metal so it could be more unsafe. Furthermore, if the user accidentally bumps the on switch while interchanging components, safety issues could occur. For this reason, design three has been given a lower safety rating. For ease of use, the current design has been given a lower rating due to the additional components required to make ice cream. Although the ice cream maker itself is easy to use, the entire process can be quite frustrating at times. The second design concept is similar in that other components will be required, but it has been given a higher ease of use rating because the run time for the ice cream maker will be shorter. Design concept three removes the use of most additional components but can be confusing to use in that the user may have trouble deciding when to switch from whisking to mixing. Therefore, it has been given a low easy to use rating as well.

Aesthetics

The aesthetics of an ice cream maker are very important to the user, especially because it is a unique product that most households do not own. This is especially important during possible dinner parties when users are showing the product to friends or family. The aesthetics category is further broken down into visual, audio, and olfactory. Although the three designs compared will look different, it is difficult to tell which one, if any, is more visually appealing to the user. Therefore, all three designs have been given a medium rating since there is likely a way to make an ice cream maker look more appealing, but the designs discussed still look quite modern and pleasing. From an auditory standpoint, much of the noise generated by ice cream makers comes from resistance in the gears of the motor. Design concept one and the current design will both utilize the same motor-gear assembly so the noise factor will be similar for both. Design concept three will likely need a more powerful motor or a different gear assembly that will likely cause more noise so it has been given a lower auditory rating. All three design concepts have been given high olfactory ratings since it is clearly possible to smell the ice cream while it is being made and it has been noted that this smell is satisfying to the user.

Identity

Ice cream makers are very unique products and therefore, in general, have a high level of identity associated with them. Identity is broken down into point in time, sense of place, and personality. Since all three designs discussed in this value opportunity analysis have the same goal of allowing the user to independently and creatively make ice cream and other frozen desserts, they have been given equal ratings for all three identity categories. The personality category has been rated highly for all three designs since the user is encouraged to be creative in making different flavors of ice cream and the user's personality can come out in this process.

Impact

The ice cream maker currently on the market now does not have a large social impact because it is not a very popular product. Because of this, the current model has been given a low social impact rating. However, by improving the design and making it easier and faster to make ice cream, we hope that ice cream makers will have a larger social impact. As a result of this reasoning, both of the re-design concepts have been given medium social impact ratings. From the LCA analysis in report one ([1]), it is evident that ice cream makers have a very low environmental impact rating. Much of the emissions from ice cream makers are either through electricity use or through the manufacturing process, but these are still quite low. Although concept two will likely use more electricity, it is not significant enough to achieve a higher environmental impact rating. Concept one will likely use less electricity since it will run for a shorter amount of time, but again this is negligible in terms of environmental impact.

Core Technology

The core technology of a product is important to the user so that they can be confident that the product will work as advertised. The current product is quite unreliable in that it takes a long time to make the ice cream. This is our largest reason for our re-design concepts. Design concept one will reduce the amount of time that the product must run, leading to more reliability in the product. Design concept three has a much more complicated design and has more components that could possible fail. With a great deal of product testing and more specific design details, this idea could be harnessed into a more reliable product. For now, we have given it a low reliability rating simply because there are more complicated components involved. The second part of the core technology category is the level at which the product is enabling to the user. The current design and design concept one have been given medium ratings for “enabling” since they allow users to make their own ice cream but also have a dependence on other appliances (blender). The third design concept aims to remove this dependence on other appliances and will enable the user even more so it has been given a high rating for enabling.

Quality

The quality of the product is perhaps the most important category for the user. The craftsmanship of the current ice cream maker design is of good quality and there are very few if any places that it can be improved. For a further discussion of this, please see the design for manufacture and assembly section from report one ([2]). The current ice maker is also quite durable if used correctly since there are not many moving parts. Since the working mechanism is the same for design concept one, it has also received a high durability rating. Design concept two has more working parts and is more complicated and is more likely to fail so it has received a lower durability rating.

Gantt Chart

A Gantt Chart provides a visual representation of a time for tasks to be completed for a project.

The Gantt Chart above shows tasks to be completed and length of tasks in light beige. The red areas are critical points and deadlines. Red points must be completed before moving on to tasks that follow them.

In the next two weeks the team will divide into two groups to explore the newly designed concepts. We will explore the market of available ice cream makers to make sure our concepts are not similar to existing products. Additionally we will explore the feasibility of our third design concept and brainstorm the key element of moving the fluid through the tube.

It should be noted that if design 3 is found to be unfeasible, the task will be cut off, and all focus will be put on the first two design concepts, and possibly combining the two.

After we submit our first prototype, all time will be dedicated to improving it for the second prototype deadline. After the second deadline the team will focus on refining the prototype, with a personal deadline to have a finished product by December 5. We will additionally perform customer research with the new prototype while writing the final report and creating a poster for the design expo