Paper towel dispenser redesign

From DDL Wiki

Contents |

Executive Summary

Paper towel dispensers are used in the majority of public restrooms, the main alternative being a hot air blower. There are several types of dispensers available. The three most common types are infrared sensor dispensers that lowers a length of paper when it detects a hand motion, hand-lever-powered dispensers that lower a length of paper for each pull of a mechanical lever and lastly, the most common on the Carnegie Mellon Campus, is a dispenser where the user pulls on a hanging paper towel and a sheet is cut and available for hand drying.

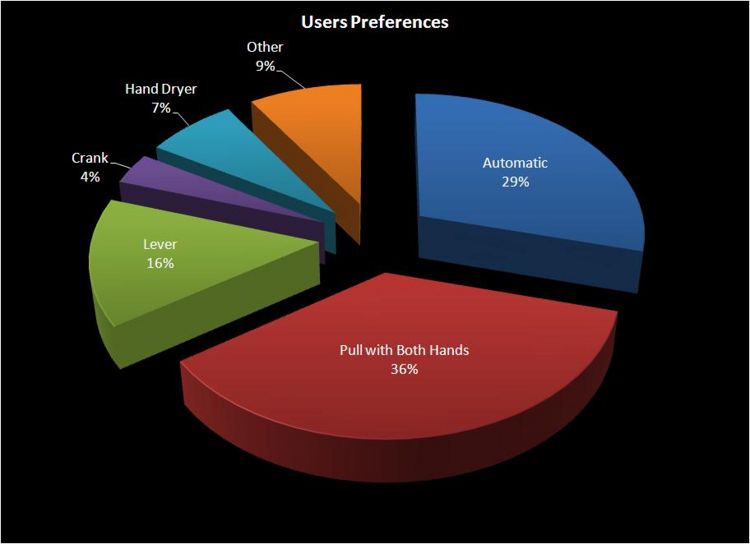

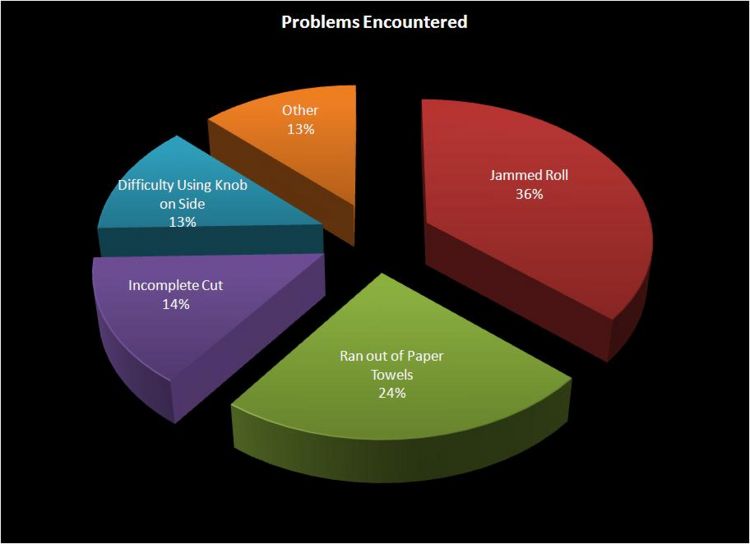

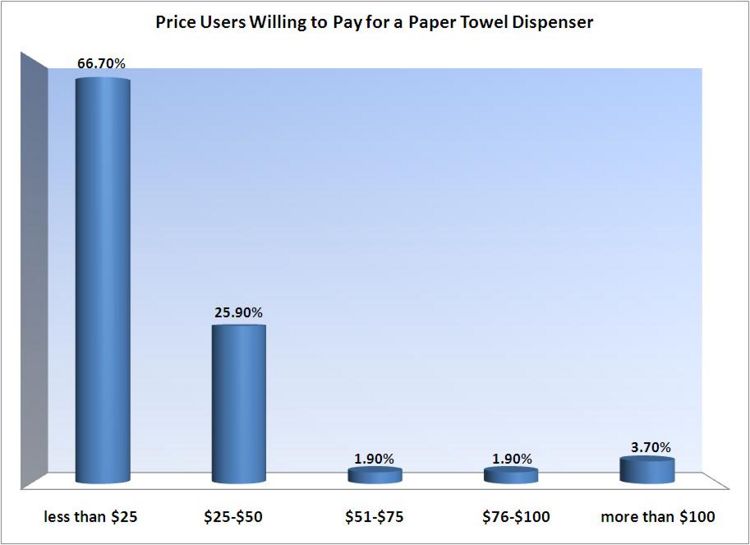

For our market research, we conducted two interviews maintenance workers from Carnegie Mellon University. We concluded that neither worker had any significant problems with replacing the paper towel roll. We also went around a few restrooms on the Carnegie Mellon campus with most user traffic for our observations. As as result, we found only a small number of users that experienced paper jamming and about a fifth of the users encountered the inconvenience of having the paper towel roll back into the machine. For our last user study, we created an online survey to gain some more insight about user preferences, user problems, and prices users are willing to pay for a paper towel dispenser. From our evidence, we found that they preferred dispensers where a user pulls a hanging paper towel. They had most problems with encountering a jammed roll and the majority were only willing to pay less than $25 for a unit.

Our report also includes the top five sketches and descriptions of idea concepts that we selected from after brainstorming one hundred ideas. The new designs are to implement a side roll, paper quantity sensor, clear windows on side housing, free standing dispenser with recycle bin, or a foot pedal.

To meet our stakeholders' needs, we identified relevant competitor products from searching through patents and the internet. We gathered advantages, disadvantages, price of the product, and cost per use of each competing product. A Pugh chart was drafted to compare the pros and cons of our concepts and to benchmark them against relevant competitors.

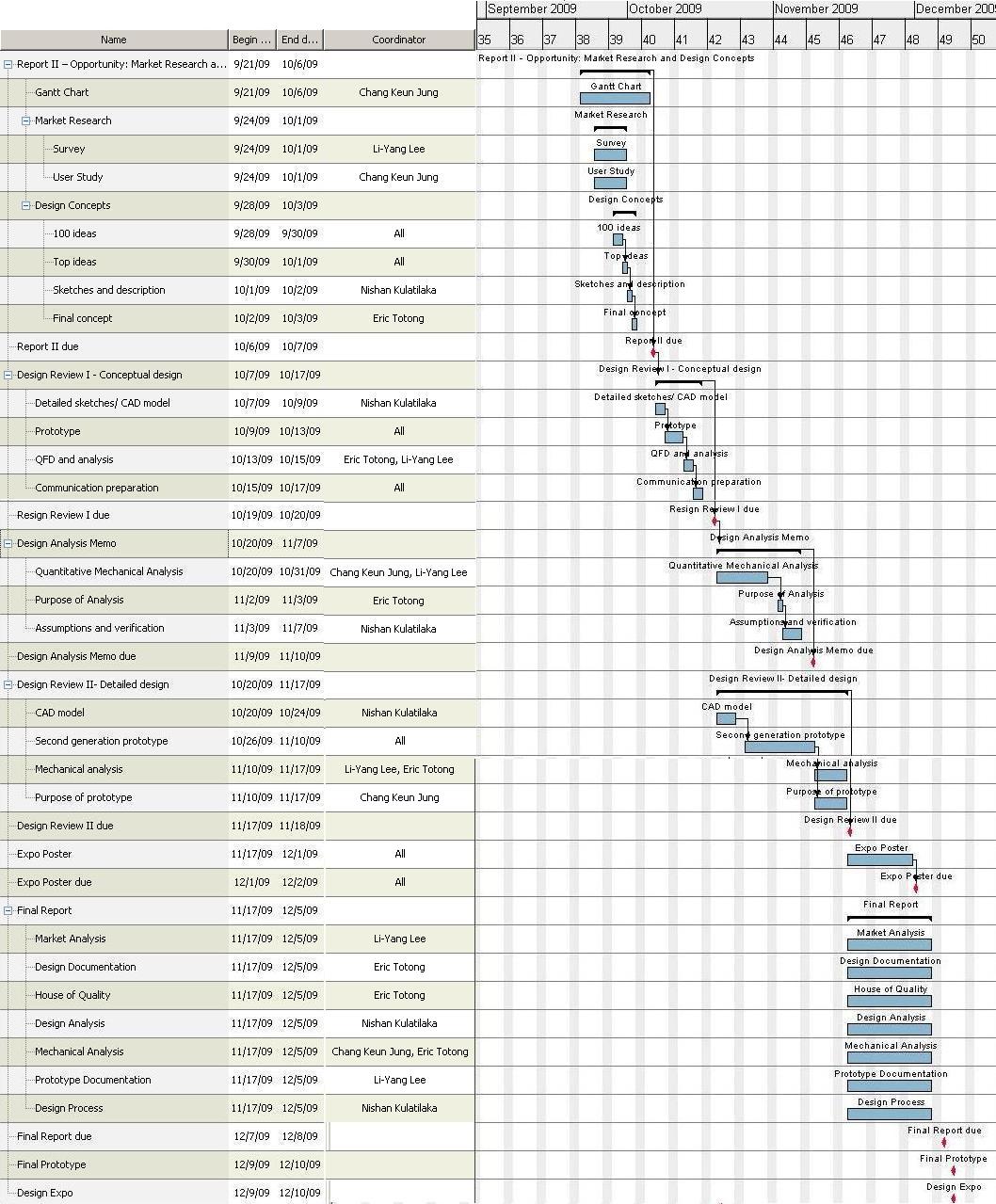

At times, it was difficult keeping track of our progress. Therefore, to delegate our work and to meet upcoming deadlines, we provided a Gantt chart to map out our team plan for design and prototyping for the rest of the semester. The Gannt chart also helped us to establish team member roles.

Market Research and Observations

In this section, we conducted different surveys and interviews to gain as much information as possible for primarily two stakeholders: the users and maintenance workers. We spoke with maintenance workers, observed users in bathrooms, and surveyed users as well. Another note, is that we spoke to Facilities Management Services at Carnegie Mellon to find out why they used these models of Kimberly-Clark paper towel dispensers. What we found was that CMU has a contract with Kimberly-Clark and this was the newest model at the time of purchase. The results below reflect our observations.

Consultation with Maintenance Workers

We interviewed two maintenance workers employed by Carnegie Mellon’s ISS, who are responsible for the cleaning and maintenance of facilities on campus. The importance of these interviews was to find out what types of issues or problems they had when replacing a paper towel roll. Also, we wanted to know if they used two rolls in one machine as listed on the Kimberly-Clark website. As we did not discuss that their identities would be disclosed online, we will refer to them as Respondent 1 and Respondent 2.

Respondent 1

We asked Respondent 1 about any issues he had with replacing the roll. He stated that he never had a problem replacing it, since it was pretty straightforward procedure. To identify an empty roll, he said he looked through the front of the housing and popped open the dispenser with a key. With regards to the two rolls, he said he never put both rolls in the machine at once. As for the old roll, if it had any paper left on it, he said he would take it and use it for other cleaning purposes. He did not have any suggestions on how to improve the design.

Respondent 2

We asked Respondent 2 similar questions regarding the replacement of rolls and the empty roll. He had similar answers, stating that he never had a problem replacing the roll. He did note that the cutting edge was sharp and he did note that that could be an issue, but as long as you are safe, it is not a problem. Another thing he did mention was that there should be an easier way to see if the paper towel dispenser needed to be refilled. Respondent 2 stated that he also would take the almost spent roll with him, but he said sometimes he would leave it in the bathroom for people to use.

Summary

We noted that neither worker had any significant problems with replacing the paper towel roll. One aspect that we could improve upon could be the ability to see if the paper towel roll is empty or close to empty. Another option we may consider is mounting a vertical rod on the PTD that would allow the smaller roll to be mounted there. This way the user could use either roll dispenser.

Observations

Porter Hall

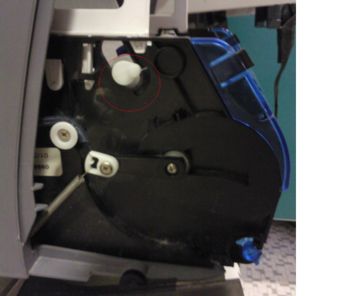

While observing different bathrooms, we found one particular case where the paper towel was not being cut correctly.

We were able to find the reason for this error by experimenting with the dispenser. We noticed that a spring was missing.

As you can see circled in red, the spring that is supposed to be there forces the white rod above the paper towel, down onto the spindle. This inturn, produces a resisting force for when you pull. Once that resistance force is applied, the cutter will strike through the taut paper towel.

Bathroom Observations

In order to understand behaviors of users and causes of inconveniences, we observed 60 users and collected data from restrooms in Doherty hall first floor, Porter hall first floor, University Center first floor and Wean hall fifth floor. Note that the observations could be biased because data are only collected from men's room.

1. Doherty Hall First Floor

- Data

| Legend |

|---|

| √: Yes/ Occurred |

| -: No/ Not occurred |

| No. of user | Use | No. of paper | One hand pull | Paper ready | Turning wheel used | Malfunction |

|---|---|---|---|---|---|---|

| 1 | - | - | - | √ | √ | - |

| 2 | √ | 2 | √ | √ | √ | - |

| 3 | √ | 3 | - | √ | √ | - |

| 4 | √ | 2 | - | √ | - | - |

| 5 | √ | 2 | √ | - | - | - |

| 6 | - | - | - | - | √ | - |

| 7 | √ | 3 | - | √ | - | - |

| 8 | √ | 1 | √ | √ | √ | - |

| 9 | - | - | - | √ | √ | - |

| 10 | √ | 3 | - | √ | - | - |

| 11 | √ | 2 | √ | √ | √ | - |

| 12 | √ | 1 | √ | √ | - | - |

| 13 | √ | 2 | √ | √ | √ | - |

| 14 | √ | 3 | - | √ | - | - |

| 15 | - | - | - | √ | √ | - |

- Description

The paper towel dispenser in Doherty Hall first floor was brand-new and seems to have no broken component. No unusual feature of machine has been observed. User #5 used turning wheel first without pulling, then tore paper. As a result the paper was not cut properly and not ready for the next user.

- Summary of data

| - | Number | Percent |

|---|---|---|

| Total observations | 15 | - |

| Use | 11 | 73.3% |

| Average paper towel used | 1.533 | - |

| One hand pull | 6 | 40.0% |

| Paper towel ready | 13 | 86.7% |

| Turning wheel used | 5 | 33.3% |

| Malfunction | 0 | 0.0% |

2. Porter Hall First Floor

- Data

| No. of user | Use | No. of paper | One hand pull | Paper ready | Turning wheel used | Malfunction |

|---|---|---|---|---|---|---|

| 1 | √ | 2 | - | √ | - | - |

| 2 | √ | 2 | - | √ | - | - |

| 3 | √ | 3 | - | √ | √ | - |

| 4 | √ | 2 | √ | √ | - | - |

| 5 | √ | 2 | - | √ | √ | - |

| 6 | √ | 1 | √ | √ | - | - |

| 7 | √ | 2 | - | √ | - | - |

| 8 | √ | 3 | √ | √ | - | - |

| 9 | - | - | - | - | √ | √ |

| 10 | √ | 2 | √ | √ | √ | - |

| 11 | √ | 2 | - | √ | - | - |

| 12 | - | - | - | - | - | - |

| 13 | √ | 3 | √ | - | - | - |

| 14 | √ | 2 | √ | √ | - | √ |

| 15 | - | - | - | - | - | - |

- Description

There were 2 paper towel dispensers analyzed separately.

i. The first paper towel dispenser(PTD1)

While pulling PTD ourselves, we experienced a lot of friction. The spindle did not rotate smoothly. Users had to pull harder than usual while using the PTD1. Most of users used PTD1.

ii. The second paper towel dispenser(PTD2)

Only user # 9 and 14 used PTD2. PTD2 was further away from the faucets which was why there were less users. The only case that we observed was that a roll was not hanging out and the user attempted to use the red knob but ultimately gave up and left. When we used PTD2 ourselves, we noticed that the PTD did not cut. We opened the unit up and realized that there were springs missing that held the white tube guide in place. As the spindle rotates the cutter comes out and cuts the paper towel. The white tube guide provided a force on the paper towel which made the paper towel touch the spindle. This force is necessary so that the cutter was in close contact to the paper towel.

- Summary of data

| - | Number | Percent |

|---|---|---|

| Total observations | 15 | - |

| Use | 12 | 80.0% |

| Average paper towel used | 1.733 | N/A |

| One hand pull | 6 | 40.0% |

| Paper towel ready | 11 | 73.3% |

| Turning wheel used | 4 | 26.7% |

| Malfunction | 2 | 13.3% |

3. University Center First Floor

| No. of user | Use | No. of paper | One hand pull | Paper ready | Turning wheel used | Malfunction |

|---|---|---|---|---|---|---|

| 1 | √ | 3 | √ | √ | - | - |

| 2 | √ | 3 | √ | - | √ | - |

| 3 | - | - | - | - | - | - |

| 4 | √ | 3 | √ | √ | √ | - |

| 5 | √ | 1 | √ | √ | √ | - |

| 6 | - | - | - | √ | - | - |

| 7 | √ | 2 | √ | √ | √ | - |

| 8 | √ | 1 | √ | - | - | - |

| 9 | √ | 2 | - | √ | √ | - |

| 10 | - | - | - | √ | - | - |

| 11 | √ | 1 | √ | √ | √ | - |

| 12 | √ | 2 | √ | √ | - | - |

| 13 | √ | 3 | √ | √ | - | - |

| 14 | √ | 1 | √ | √ | √ | - |

| 15 | √ | 2 | - | √ | - | - |

- Description

The paper towel dispenser in University Center first floor was brand-new and seems to have no broken component. No unusual feature of machine has been observed.

- Summary of data

| - | Number | Percent |

|---|---|---|

| Total observations | 15 | - |

| Use | 12 | 80.0% |

| Average paper towel used | 1.6 | N/A |

| One hand pull | 10 | 66.7% |

| Paper towel ready | 12 | 80.0% |

| Turning wheel used | 7 | 46.7% |

| Malfunction | 0 | 0.0% |

4. Wean Hall fifth Floor

| No. of user | Use | No. of paper | One hand pull | Paper ready | Turning wheel used | Malfunction |

|---|---|---|---|---|---|---|

| 1 | √ | 3 | √ | √ | - | - |

| 2 | √ | 2 | √ | √ | √ | - |

| 3 | √ | 1 | - | √ | √ | - |

| 4 | √ | 1 | √ | √ | √ | - |

| 5 | √ | 1 | √ | √ | - | - |

| 6 | √ | 2 | √ | √ | - | - |

| 7 | √ | 1 | √ | - | - | - |

| 8 | √ | 2 | √ | √ | √ | - |

| 9 | - | - | - | √ | - | - |

| 10 | √ | 2 | √ | √ | √ | - |

| 11 | √ | 1 | - | - | - | - |

| 12 | √ | 3 | √ | √ | √ | - |

| 13 | √ | 1 | √ | √ | √ | - |

| 14 | √ | 1 | √ | - | - | - |

| 15 | - | - | - | - | - | - |

- Description

The paper towel dispenser was missing one of the even hooked spring(component #11) but still worked without failure.

- Summary of data

| - | Number | Percent |

|---|---|---|

| Total observations | 15 | - |

| Use | 13 | 86.7% |

| Average paper towel used | 1.4 | - |

| One hand pull | 11 | 73.3% |

| Paper towel ready | 12 | 80.0% |

| Turning wheel used | 7 | 46.7% |

| Malfunction | 0 | 0.0% |

Common User Errors

We noted some of the common errors users depicted: using one hand, using one hand and turning the wheel, tearing the paper. We re-enacted the actions because we did not think it would be appropriate to take pictures of users while in the bathroom.

Using one hand.

Using one hand and turning the wheel at the same time. This gives the user two sheets without the paper being cut all the way through.

Using one hand and tearing the paper towel instead of pulling straight down.

Summary of Observations

From the observations, it can be concluded that most (about 80.0%) of restroom users use paper towel dispensers and only a small number (approximately 3.3%) of users experience paper jamming. However, about 21.7% of the users encountered the inconvenience of having the paper towel roll back into the machine due to the momentum and were not ready to be used. This occurred when people used one hand (about 55.0%), pulled too hard, or ripped out the paper. The most people used turning wheel to solve this problem, some put their fingers to pull out papers, and a small number of people just gave up and left. But there were also some people who used the turning wheel even when the paper was ready. These people summed up to be 38.3% of the whole users. Most users used more than one paper towel (about 1.57 towels) and thus it can be concluded that they do not seem to be satisfied with current length or thickness of paper towel.

The result of 60 user data is summarized as follows:

| - | Number | Percent |

|---|---|---|

| Total observations | 60 | - |

| Use | 48 | 80.0% |

| Average paper towel used | 1.57 | - |

| One hand pull | 33 | 55.0% |

| Paper towel ready | 47 | 73.3% |

| Turning wheel used | 23 | 38.3% |

| Malfunction | 2 | 3.3% |

Survey of Users

Description

All user data was collected from a personal survey created on www.surveymonkey.com. We received and analyzed 55 user responses. The survey was created to find more information about user preferences, user problems, price users are willing to pay for a paper towel dispenser, and improvements that can be made.

Statistical Analysis

Summary and Conclusion

- Most users like using the paper towel dispenser where you pull down with both hands. Since most of the paper towel dispensers on the Carnegie Mellon campus consists of this type, we also surveyed users outside of campus to deter any biases. The second most preferred paper towel dispenser is the automatic hands free kind with an infrared sensor to detect motion.

- The major problem that most users experienced when using a paper towel dispenser is encountering a jammed roll. Running out of paper towels was the second greatest problem. We could fix this problem and improve the design by creating a 'networked PTD system'. Each paper towel dispenser will have a circuit board that could transmit information to a server where the user can track each dispenser. The system will tell the user the percentage of paper towels left.

Note: this finding only applies to the dispenser where you pull with both hands

- Another question in our survey allowed us to see how much users are willing to pay for a paper towel dispenser. From our findings, 67% would only pay less than $25 for a unit. In actuality, we purchased our single unit for $75, which is the same unit that is prevalent on our campus. Had users known this fact, we might have received different results.

Sketches and Descriptions of New Designs

After brainstorming 100 ideas, we needed to narrow it down. As a team we determined 5 designs that we feel are the top choices and have outlined them in this section.

All new designs should include an extra spring on the white spindle to ensure the cutters work.

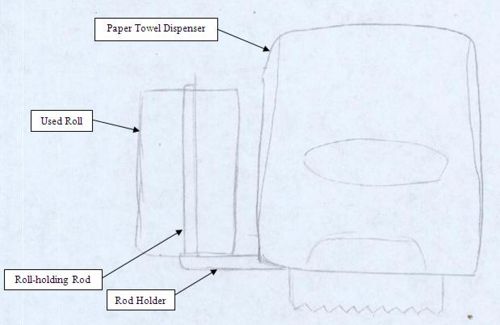

Side Roll

The main idea behind this design is to conserve paper towels and not let them go to waste. Custodial workers replace paper towel rolls when there is little paper left, but often there is a decent amount of paper left on the roll.

Front view of Side Roll design

Top view of Rod Holder (Isolated)

The main idea behind this design is to accommodate a used paper towel roll on the side of the main paper towel dispenser unit. When a custodial worker is replacing a roll that is running out of paper, they can remove the used roll and place it on the rod on the side. The old roll can now be used by people who would like to use more paper than the sheet cut by the dispenser. There are also instances where someone will spill a liquid in their office, hall or classroom and will go to the bathroom to retrieve paper towels to clean up the mess. The side roll will allow the user to use any desired length of paper towel to clean up the mess.

Paper Quantity Sensor

Custodial workers raised the issue of it being difficult to determine how much paper was left in the roll. To attend to this problem, we have come up with a design that incorporates a mechanical meter that shows how much paper is left on the roll. A sketch diagram of the design is included below.

Side view of Paper Quantity Sensor design

Top view of Paper Quantity Sensor design

As you can see, the springs on the front and back of the paper towel hold the meter at the height caused by the thickness of the paper towel roll. The meter is read by comparing the position of the protruding plastic with the position of the center of the paper towel roll (which is marked on the housing).

Clear Windows on Sides of Front Housing

As mentioned earlier, custodial workers raised the issue of it being difficult to determine how much paper was left in the roll. Having clear windows on the sides of the front housing will allow the custodial workers to physically see the remaining thickness of the paper towel roll.

Side view of Side Windows design

Also included next to the window is a ruler printed onto the side of the housing that will allow the custodial workers to make a more educated decision when deciding whether a roll needs to be replaced without opening any of the housings.

Free Standing Dispenser with Recycling Bin

Situations arise when a paper towel user needs to use several paper towels somewhere other than a restroom (such as a classroom, office, barbeque, special event, etc.). The design shown below is our sketch for a free standing dispenser. Included in this design is a recycling bin (or waste bin if the owner chooses) which decreases the negative environmental impact of using paper towels.

The frame can be constructed out of hollow metal tubes which would decrease the weight and increase the ease transporting the dispenser. Additional weight should not be an issue as a plastic waste bin and the dispenser itself are not too heavy for an average user to carry.

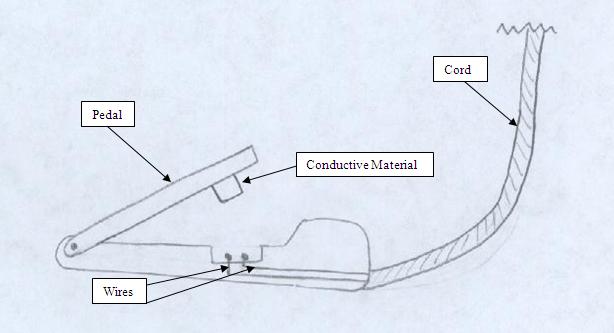

Foot Pedal

A major advantage of not touching the dispenser during use is it reduces the possibility of spreading germs. The design shown below allows the user to press down on a pedal with one of their feet which causes a motor to turn the spindle.

Top of design

Bottom of pedal design

As seen above, pressing down on the pedal completes the circuit for the motor. Releasing the pedal will cause the motor to shut off. While the spindle is turning, paper is released down towards the user. There is a serrated blade just inside the housing and above the paper towel. The user can cut the paper towel into their desired length by pulling the towel at an angle against the serrated blade (This is a similar cutting method to the Lever Arm Dispenser in the Competitors section).

Competitors and Pugh Chart

Current Product

- Two-hand Pull Down Dispenser<ref name="Two-hand Details">http://www.restockit.com/In-Sight-Sanitouch-Roll-Towel-Dispenser-12-1116w-x-10-316d-x-16-12h-Smoke--(KIM09990).html</ref>

Kimberly-Clark In-Sight Sanitouch 09990 Touchless Hard Roll Paper Towel Dispenser

This paper towel dispenser requires the user to use two hands on either side of the paper to advance the roll. It perforates a 12" sheet with each pull and allows a new sheet to fall into a "ready position" after each use. It is fairly hygienic because the user only has to touch the paper. It can jam or fail, thus causing the user to use the knob on the right to advance the paper.

Pros: Generally works relatively well with no jams. Hygienic, user only touches paper towel. Quick and easy to use.

Cons: Can jam or paper can recede into the machine. Knob on right does not always work. Must use two hands. Paper waste.

Price: $75

Cost per use (2 sheets at 8" x 12" apiece): $0.01667 per use.

Using $40 per carton of 12-8" x 400' rolls.<ref name=" Paper roll Details">http://www.restockit.com/Recycled-Nonperforated-Paper-Towel-Rolls-8-W-x-400-ft-White-12-RollsCarton--(KIM02068).html</ref>

Competitors

Looking at other products, we found that the main competitors to the Kimberly-Clark In-Sight Sanitouch 09990 to be other designs of paper towel dispensers and air dryers since the main goal for the user is the dry his or her hands in a quick and hygienic manner. Below we listed the most significant models and also what we deemed the best competitors.

- Lever Arm Dispenser<ref name="Lever Arm Details">http://www.restockit.com/Dispenser-Insight-Roll-Towel-Smoke-Gray--(09736KIM)---TOP-SELLER!.html</ref>

Kimberly-Clark In-Sight Lev-R-Matic II 09736 Roll Paper Towel Dispenser

This lever-operated paper towel dispenser requires the user to pull down on the lever to advance the paper. To increase the length of the paper, the user must use the lever more than once. There are some variations on this design, where some of the levers are along the bottom of the dispenser. This can allow the user to use their arm or elbow to advance the towel, instead of using their hands. Overall, these are dispensers are fairly reliable and do not jam.

Pros: Translucent, smoked plastic makes it easier to see when paper towel is almost empty. Works relatively well with no jams.

Cons: Must touch lever to advance paper (not hygienic). If you want a long sheet, you must pull down the lever several times. Paper costs.

Price: $53

Cost per use (2 sheets at 8" x 12" apiece): $0.01667 per use.

- Touchless Electronic Dispenser<ref name=" Touchless Electronic Details">http://www.restockit.com/Smart-Roll-Towel-Electronic-Dispenser-(SANT1400TBK).html</ref>

San Jamar T1400TBK Black Smart System with iQ Electronic Sensor

This dispenser is an electric dispenser that releases paper from a sensor to detect hand motion. It is powered by four D-sized batteries. The advantage of using a sensor, is that the user does not need to touch anything on the machine to advance the paper, and only has to touch the towel that he/she is using. The dispenser also has a variety of advanced features.

Pros: Hand sensor (hygienic). Paper length and delay adjustment. Replaceable drive module. Downloadable data usage to PDA. Relatively few jams. Break-resistant plastic.

Cons: Electric sensor may not "see" hand at first. Battery life. May take long to get multiple sheets. Paper costs.

Price: $126

Cost per use (2 sheets at 8" x 12" apiece): $0.01667 per use.

- XLerator Hand Dryer<ref name="Xlerator Details">http://www.exceldryer.com/Products/xlerator.asp</ref>

Excel Dryer - XLerator

The XLerator hand dryer is a heated hand dryer that uses an infrared optical sensor to detect hand motion. When the user wants to use it, the user puts his/her hands under the dryer and the XLerator blows air at a speed of 14,000 LFM (linear feet per minute) at the hands. The dryer uses a 900W heating element to produce a temperature up to 135°F at the hands. Excel Dryer claims you can dry hands completely in 10-15 seconds.

Pros: Cleans hands without touching machine (hygienic). Relatively quick. Warm air helps drying. No paper towel costs. No "empty" paper roll or maintenance needed.

Cons: Loud when operating. Electricity costs.

Price: $440

Cost per dry: Using average electricity cost per kWh in United States, $0.115/kwH <ref name="Electricity Cost">http://www.eia.doe.gov/cneaf/electricity/epm/table5_6_b.html</ref>

Using a drying time of 15 seconds and 0.9kW for the dryer, we have an average of 0.00375 kWh per use. This results in $4.3125e-4 per use.

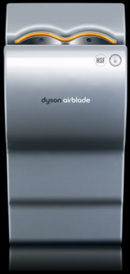

- Dyson Airblade<ref name="Dyson Details">http://www.dysonairblade.com/homepage.asp</ref>

The Dyson Airblade uses a unique design that is similar to a windshield scraping water off glass. The Airblade uses ambient room temperature air that it cleans through a HEPA filter. It uses less energy since it is not heating up the air and is hygienic since it filters the air. To use it, the user places his/her hands into the device where an infrared sensor activates the device. Air blows on the hands and the user pulls them out, allowing the water to be scraped down into the dryer. Dyson claims that the airspeed at the nozzle is 400mph and you can dry your hands in 12 seconds.

Pros: Quick drying. No heat use. No paper towel use. Hygienic due to infrared sensor.

Cons: Costly. Slightly noisy. Uses electricity. Mounting height may be more difficult. Can only dry hands (not face).

Price: $1,300

Cost per dry: Electricity cost per kWh in United States, $0.0115/kwH. And 0.00468 kWh used per dry at 1.4kW and a 12 second drying time. This results in $5.382e-4 per use.

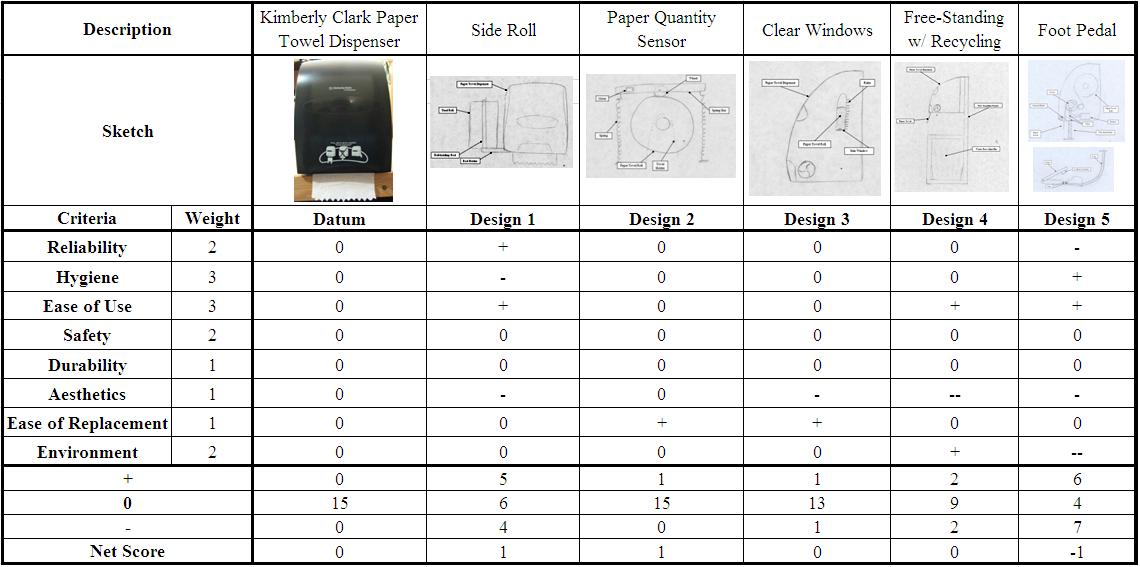

Pugh Chart

The Pugh chart is used to compare the pros and cons of different design ideas against our current model. The datum is our benchmark, against which we are comparing the other ideas. If an aspect of a design is better than the datum's, it receives a "+" sign. If it is worse, it receives a "-" sign. The Net Score measures the overall product against the datum. It should be noted that these numbers are subjective and by no means an exact science.

In this Pugh chart, we found the Side Roll and Paper Quantity Sensor to be the best ideas. The Clear Windows and Free-Standing models were neutral and the Foot Pedal design scored below the datum.

Existing Patents

There are many ideas that have been patented in relation to paper towel dispensers and their function. Below are a list of some of the most notable patents relating to paper towel dispensers.

Electronic Control of Paper Towel<ref name="Electronic Patent">http://www.google.com/patents/about?id=bUkJAAAAEBAJ&dq=paper+towel+dispenser</ref>

This patent was written by inventors at the Georgia-Pacific Corporation. Many of the ideas they have in the patent are in use today. Some ideas were having an electronic system sense the presence of the user to activate the system, also controlling the amount of paper towel that is dispensed. Another idea was to have a paper towel in the ready position and once it was torn off, another one would be advanced by the motor.

Dual Roll Paper Towel Dispenser<ref name="Dual Roll Patent">http://www.google.com/patents/about?id=3WZqAAAAEBAJ&dq=paper+towel+dispenser</ref>

This patent was written in 1966 by William J. Craven Jr. His idea was to have a two roll paper towel dispenser in which the second roll would begin feeding once the first roll was depleted.

Center Pull Paper Towel Dispenser<ref name="Center Pull Patent">http://www.google.com/patents/about?id=Hu4jAAAAEBAJ&dq=paper+towel+dispenser</ref>

This patent is for a center pull paper towel dispenser. In this design, the paper towel stands upright within the housing and does not have a core. The paper towel is dispensed from the center of the roll and out of the dispenser. The roll must be perforated for this application.

Musical Towel Dispenser<ref name="Musical Patent">http://www.google.com/patents/about?id=MMNjAAAAEBAJ&dq=paper+towel+dispenser+music+box</ref>

This patent involves combining a music box and paper towel dispenser. The idea is that when a person removes a paper towel, the roll that spins is connected to a music box, which causes it to play music.

Combined Liquid and Paper Towel Dispenser<ref name="Combined Patent">http://www.google.com/patents/about?id=VpICAAAAEBAJ&dq=paper+towel+dispenser+free+standing</ref>

This patent comes from the idea of combining a dispenser for a liquid and paper towel. The example is a cleaning solution with a roll set around it into one unit.

Top Stakeholders' Needs

Following Report I, we have come up with an updated list of the stakeholders with a focus more on the post-production aspect. Also we have narrowed down the most important stakeholders by impact and interaction with the paper towel dispenser.

User

- Reliability - the user wants a product that will provide paper towels and will be ready for use without jams

- Hygiene - users want to make sure that once their hands are clean, they stay clean. This involves making sure the consumer only touches the paper towel following washing

- Ease of Use - whether it is a pull down or IR sensor paper towel dispenser, the user wants something that is simple and quick to use

- Safety - no sharp edges should be exposed and if temperature is involved, it should not burn the person's hands

- Durability - the user wants something that won't fall apart on them while they are using it

- Aesthetics - the PTD should be visibly pleasing and simple

Maintenance Worker

- Identifying need for replacement - there should be a simple, clear way of notifying a maintenance worker that the paper towel needs to be replaced

- Safety - the worker wants to be able to open up and change a roll without any issues of sharp edges or pieces

- Ease of replacement - It should not take very long to set up a new paper towel roll and should not be complicated

Customer

- Reliability - the customer does not want a product that will need more maintenance than necessary and wants something that has a low failure rate

- Conservation - the customer wants a product that can limit the paper towel used in order to reduce the cost and time of refilling the paper towel roll

- Safety - the customer does not want to be responsible for one of their patrons getting hurt from this device

- Aesthetics - the product should be pleasing to the eye and may also want to match with the decor/theme of the customer's business

Society

- Paper Use - there should be a way to reduce the amount of paper used and/or increase the recycling of this paper

- Electricity Use - if the dispenser uses electricity, it should be of minimal impact to the environment

Gantt Chart

The Gantt chart displays the division of labor as well as the overview of how our project will progress. We have set deadlines and goals in order to complete our design project on time. The Gantt chart allows all of the team members to see what sections they should be working on and what dates they are due.

Findings and Recommendations

Findings

From interviews with maintenance workers, we found out that they do not have any particular problems with replacing the paper towels, but have inconvenience of having to open up the housing every time they want to check if the paper towel dispenser needs refill or not.

The studies of users showed that most people use one hand instead of both in order to get paper towel out. This caused biased force concentrated along the point of grasp, and caused paper towel to be ripped or not cut properly. People often had paper towels rolled into the machine, when previous user had pulled too hard, or ripped out the paper manually.

According to the survey, other than those problems, most users seem to be satisfied with the paper towel dispenser where you pull down with both hands. Some respondents preferred automatic hands free paper towel dispenser because they do not require users to turn the knob to pull out papers for hygienic reason, and this machine has very low chance of paper towel rolling back in.

Recommendations

Having studied paper towel dispensers for the last few weeks we have seen that there is still a lot of opportunity for improvement and we have determined that we would like to pursue a paper towel dispenser redesign.

Based on the analysis of the five designs we chose earlier, our team recommends adopting a mixture of the Side Roll design and the Clear Windows design.

By analyzing the Pugh chart, we can see that the top two designs (using the net score as a measurement) are the Side Roll design and the Paper Quantity Sensor design. The Clear Windows design accomplishes the same goal as the Paper Quantity Sensor design because both allow someone replacing a paper towel roll too have an accurate measurement of how much paper is left on the roll inside the dispenser. Having clear side windows on the housing would be significantly easier and cheaper to manufacture and we feel that, because it accomplishes the same goal as the quantity sensor with only a small aesthetic downgrade, it is an acceptable replacement.

The Side Roll design will help deal with the problem of throwing away paper towel rolls when there is still perfectly usable paper left. While it is true that some custodial and maintenance workers will take the used roll with them to clean up other spills or messes, there are still rolls being thrown away. This is unnecessary and allowing the user of the dispenser to have access to the old roll will reduce the waste of paper.

In conclusion, we recommend a combination of our Side Roll and Clear Windows designs. These designs can be easily used together as the designs do not conflict physically and do not have the same purpose. A combination of the designs will allow for paper towel dispensers to be greener by saving paper and will allow for easier maintenance by custodial workers.

Hypothetical Scenario

Jay Jung is a 20 year old international student from Korea that loves to spend his spare time playing computer games such as Starcraft and eat soup afterwards. However this has always been a problem for Jay. After touching his keyboard and mouse, Jay always needs to wash his hands. After washing his hands, he has always been scared to use the paper towel dispenser because of the possibility of catching germs.

At the Carnegie Mellon University Engineering Design class, several bright students came up with the idea to obtain a paper towels. Jay spilt his soup while playing games and had to run to the bathroom to get paper towels quickly. Now with the roll on the side, he was able to get a long sheet of paper towels quickly and clean up his spill.

After cleaning, Jay went back to the bathroom, washed his hands and was able to dry his hands by pulling down on the hanging paper towel, with a redesign that is more reliable.

With this new design, Jay Jung can now enjoy playing Starcraft and eating soup without the fear of catching germs and diseases.

Team Member Roles

Chang Keun Jung - Market Research/Observations, Gantt Chart, Findings

Nishan Kulatilaka - Concept Sketches, Descriptions of opportunities, Recommendations

James Li-Yang Lee - Executive Summary, User Survey, Hypothetical Scenario

Eric Totong - Interviews, Stakeholders, Competitors, Existing Patents, Pugh Chart

References

<references/>

Appendix

Our 100 Freewheeling Ideas

1. Triangle cut (hole in center) towel

2. Triangle cut (either side cuts to create triangle in center)

3. Engraved instructions

4. Rectangle cut towel

5. Clap sensor

6. Motor powered moving slicer

7. Handle cutter, cuts hole in towel to use as handle

8. Punch cutter

9. Use weights instead of springs for spindle motion

10. Using air damper to prevent towel from receding into housing

11. Infrared sensor

12. Smile sensor

13. Rotational damper that limits initial pulling speed

14. Put weighted gears in spindle to increase friction

15. T-shape front housing, to prevent the use of one hand

16. Increase the number of springs

17. Housing can hold two paper towel rolls

18. Wet sensor, i.e. hands have to be wet to use it

19. Combined paper towel/air dryer

20. Cut paper towel in different sized sheets

21. Turn on water, paper towel comes out

22. Voice sensor say, “paper”

23. Instead of red turning wheel, use a crank

24. Deeper key hole on top to open it

25. To prevent graffiti, make housing with grooves

26. Dry erase board housing

27. Chalkboard housing

28. Frame in front housing to provide a place to provide advertisements

29. Front screen with LCD screen for ads or news

30. Paper towel meter, to determine how much paper is left

31. Sensor that pops up when paper towel reaches a certain diameter

32. Networked system that can detect levels of paper towels in different locations (eSuds)

33. Mirror on front cover

34. Make cover open up, instead of down

35. Make cover swing open sideways

36. Writing on paper towel to be “Eco-friendly”

37. Advertisement on paper towel roll, before paper towel dispenser

38. Paper towel dispenser stamps out ads or sayings

39. Every time pull, a different message comes up (like a clickable pen)

40. Put TV on front screen

41. Recycling bins instead of garbage bins

42. Energy storage device in spindle for when it turns (dynamo) to power LEDs or LCD

43. Clock on front screen (digital)

44. Foot pedal to dispense paper

45. Hologram on front housing with instructions on how to use paper towel dispenser (PTD)

46. Sensor to detect jammed paper towel

47. Press a button when paper towel is jammed to notify management

48. After a certain number of pulls, it dispenses an air freshener spray

49. Q-tip dispenser

50. Paper towel dispenser on sliding track to move horizontally

51. Button to open door with paper towel

52. Combine PTD with hand sanitizer dispenser

53. Walls on outside (left and right) to prevent people from tearing paper sideways

54. Blow air into mic, then paper towel comes out

55. Polling system to gauge consumer responses on front housing

56. LCD screen that has sports, weather, news, stocks

57. PTD shoots out paper with a small pull

58. Musical box that plays tune when you spin

59. Totally clear housing

60. Donation box towards green societies, research for diseases

61. Change cover material to steel

62. Hair gel/wax dispenser

63. Photobooth/PTD

64. Dispenses sideways folded paper, easier to grab

65. Cookie cutter shaped paper towel

66. Remove back housing except for mounting points

67. Remove spindle housing, replace with less material

68. Corkboard on front housing

69. Make it look better to match bathroom décor

70. For kids, Playskool-looking towel dispenser

71. Hole to replace paper towel without having to open it

72. Thermometer on paper towel dispenser

73. Use lever in place of wheel to lower paper towel when stuck/not low enough

74. Use flat rectangular plate with one serrated edge that rotates along long dimension in place of spindle (increases tension, decreases material)

75. Have the whole PTD system sideways, i.e. you pull horizontally

76. Shatter or break-proof plastic

77. Sensor to detect if paper towel is not in ready position and a motor to make the paper move down

78. Mechanism where one pull brings out two sheets connecting with a perforation, possibly using two blades

79. Free-standing recycling bin and paper towel stand. No need for a wall to mount onto

80. Talking robot responsive PTD "How is your day? Did you use soap?"

81. Alarm system if opened without key or knocked off wall

82. Use springs from the inside of the spindle to push up the cutter to decrease frequency of missed cuts.

83. Decrease width of slot that paper leaves through to reduce possibility getting stuck on the sides

84. Spring load the top paper towel roll to ensure tension

85. Use a coil (similar to the turning wheel's one) to prevent top roll from rotating back

86. Alter release angle in housing to be horizontal so user can reach in and grab if it is slightly jammed

87. Laser cutter

88. Weight powered rotating and cutting mechanism. Step on a scale, and it works

89. Holder on sides of PTD if person takes an extra sheet, they can leave it for the next person

90. Long lever arm coming from side, to advance paper so a person can use their arm instead of hands

91. Heat sensor to detect body heat and release paper

92. Noise-insulated housing walls to reduce noise

93. Have embroidery roller spindle to give paper towel sheet a unique design

94. Implement a game with the PTD such as a slot machine.

95. Automatic paper towel loader. Just have to stick the new roll in

96. Mint dispenser

97. Smoke detector integrated with the PTD and is kept low profile

98. Downloadable usage statistics to computer

99. Separate paper towel holder for when the roll gets small. This could be mounted outside of the PTD.

100. Dispenser that can hold 10 or so rolls and reload itself when a roll runs out.