Soda gun opportunity

From DDL Wiki

Contents |

Executive Summary

Soda guns serve a very specific purpose for restaurants and bars alike: provide a compact, easy-to-use device to fill a variety of beverage types from a single source in a reliable and cost-effective manner. For the purpose of the opportunity study, this usage has been examined and extended into new environments to drive the creation of a new product or the improvement of an existing product on the market. Through anthropological studies, interviews, and background research, different strengths and weaknesses of the device have been identified. Additionally, our team has gathered information about how the device is used in different settings, what typical users think about the device, and a greater understanding of how the system works mechanically. This information was gathered by visiting bars and restaurants in the area, talking to users of the soda guns, observing the use of the device, interviewing companies and employees in the beverage and soda dispensing industries, and extensively reading product reviews, user forums, and online discussions related to soda fountains, soda guns, and bar equipment.

One potential area we have examined as a key market opportunity is home users that may want to use a home soda gun or home soda dispensing system to entertain guests or improve their own home bar setup. The main design challenge identified is finding a low-complexity solution that attracts buyers to the product, without losing the authentic feeling that a soda gun provides. We also determined there are key improvement areas with current soda gun designs including dispensing speed, maintenance procedures, installation, and overall usability.

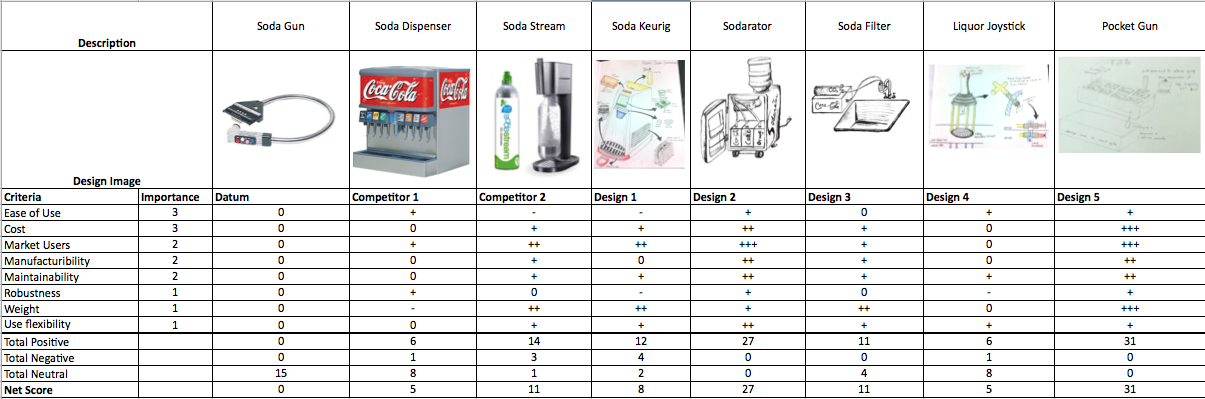

During the concept generation phase, our group generated many ideas related to the problem then refined the ideas into potential design solutions appropriate for the course. Our ultimate five ideas include an adapted refrigerator design for soda, a home sink soda attachment, a counter top home soda dispensing system, a hand-held syrup dispensing system for travelling bartenders, and a multi-directional joystick drink dispenser for commercial use in bars and restaurants. These ideas were passed around the group and modified and discussed until complete understanding of the product could be achieved.

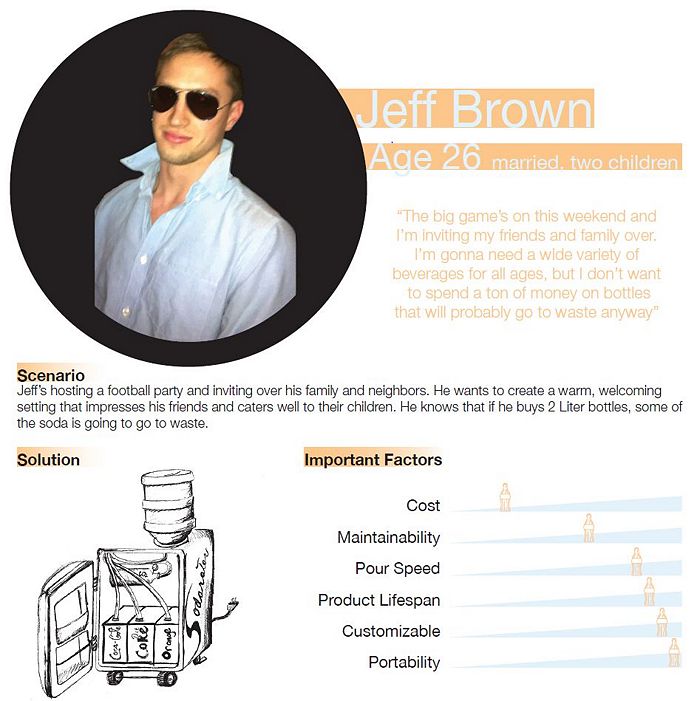

These ideas were also compared using benchmarking from current patents, Pugh charts for determining strengths and weaknesses, and potential user interviews. We found that although each idea had positives and drawbacks, the "sodarator" concept, or a modification of it, provides the best opportunity for further design in the class. We identified a user scenario that would benefit from the product, namely a younger, male homeowner who would like to entertain guests of all ages with a cheap, authentic style dispensing device, without spending large amounts of money or wasting a large amount of space with many different 2 liter soda bottles. The product is low-cost, easy to install , maintain, and use, and provides the authenticity of a soda dispensing system or bar gun without complicated components or expensive hardware. Additionally, it allows the user to save money in bulk distribution of soda, customize which beverages he would like to use (even across brands like coca-cola/pepsi), and the system is portable and compact.

Finally, we set the groundwork for future work in the group, assigned roles, and set up a schedule to help guide further actions on the project.

Market Research

Conducting research on the soda gun was an interesting task because it is not a common consumer product. We visited local restaurants and bar areas to conduct anthropological research, as well as call and email a variety of companies and maintenance corporations.

Product reviews and secondary research were also conducted, which provided us with a variety of information ranging from homemade soda guns to intricate bar set up reviews.

We geared away from surveys and use studies because the soda gun is an uncommon consumer product. Often, users receive waitress or bar tending training before using the product and are instructed on how it functions. Use studies would be difficult to set up because the full system is very difficult to acquire. It is important to note these inconveniences when developing new opportunities. Perhaps our new product could function without the need of training. Perhaps we could condense the system, making it more transportable.

Stakeholder Needs

Users:

- Fast gun

- Appropriate syrup ratio

- Easier to maintain without outsourcing

- More flexible gun leash

- Durable gun

Consumers:

- Fast gun

- Delicious soda

- correct syrup ratio

- appropriate carbonation

Retailers:

- Easy/cheap to maintain

- Easy to set ratios

- Easily manufacturable

- Aesthetically appealing

- Broad market

- Brand marketing

- Make customers desire soda

Manufacturers:

- Easy to manufacture

- Repeatable parts

- Low tolerances

- Common materials

- Common repeatable manufacturing processes

Maintainers:

- Easy to maintain

- Cheap to maintain

- Durable and doesn't break often

- Simple to install

- Straightforward bar adaptability

- Obvious labels

Anthropological Study: Friday Afternoon

Two of our group members walked to Oakland on Friday afternoon to visit bars (Hemingway's) and restaurants (Noodles & Co. and Fuel & Fuddle) during off hours. The goal of this study was to interview bartenders, and get insider opinions on how a user interacts with a soda gun system.

We learned that the plastic pieces on the soda gun are colored either red (if the establishment sells Coke) or blue (if the establishment sells Pepsi). Further, the decision of which brand to sell is based mostly on customer demand.

We also learned that almost none of the restaurant owners/bartenders knew how to fix the gun if there was a problem. All maintenance was handled by an outside maintenance man even for problems as simple as a leaky O-ring or bad syrup ratio. Also, all the ratios are set by the installer.

Specifics to Hemingway's:

There are two stations behind the bar with three soda guns each: juices, sodas, and red bull. This is so the bartender can make a mixed drink pitcher more quickly by using two soda guns at once (say to combine cranberry juice and sprite).

The CO2 tanks and syrup boxes were located underneath a trapdoor behind the bar.

There was also a soda dispenser that was used mostly by the waiters. The bartender said she also preferred to use the soda dispenser to get cups of soda because it filled glasses faster than the soda gun.

Bartenders were responsible for changing the syrup boxes out (which happened on average once a week). The biggest problem was that the soda syrup boxes were incredibly heavy for the bartender to lift onto the rack. The syrup was siphoned out by a vacuum system so there was almost no waste. Each box made around 10,000 glasses of soda and cost around $4. The large 50-liter CO2 tanks were refilled by the distributor about every two weeks.

Likes: Can Duel-Wield Soda Gun, Stations set up to quickly fill shot pitchers

Dislikes: Very slow compared to soda machine, Pushing multiple buttons at once doesn't work, Short Leash, Metal tube is sometimes too stiff and causes the gun to twist out of the holster

Specifics to Fuel & Fuddle:

There are two stations with one 12-button gun, both for soda. This is a smaller bar and the soda gun was liked much less by everyone who worked there. It was very slow, and the syrup ratios were off. In general, the entire bar/waiting staff would prefer a soda dispenser for its speed and ease of use.

Anthropological Study: Saturday Night

Two of our group members walked down to Shadyside on Saturday night to visit bars(Mario's) and restaurants (Steel Cactus) during prime hours. The goal of this study was to observe how bartenders and waiters/ waitresses used the soda gun in a high stress environment.

Unfortunately, because the bartenders and waitresses were very busy, we could not conduct an interview with them. To continue the study, we sat close to the soda guns and made observations on how the employees interacted with the product.

We learned that longer bars have more than one gun attached. Steel Cactus serves Pepsi products, which we could notice through the blue plastic nozzle and handle. When the bar tender utilized the soda gun, he seemed to understand what buttons produced each syrup, even though they weren't labelled with brand names or icons. We assumed this intuitive state of thinking came from experience. We also noticed that only one button was pressed at a time. The bartender would often combine carbonated soda and a juice. To do so, he had to press the carbonated soda button, release it, then press the juice button.

On average, a drink would take 4-5 seconds to pour. Before mixing a drink, the bartender would grab the liquor bottle, walk over to the soda gun, use one hand to release the soda and the other hand to pour the liquor. This maximized the bartender's efficiency so he wasn't standing idle waiting for the glass to fill with soda. It is also important to note that the bartender would walk to the gun. He never fully utilized the extension of the gun. This occurred because the soda gun was re-holstered after every use. We were curious as to why the bartender would walk half way around the bar to utilize the soda gun instead of pulling it towards them. When we leaned closer, we realized the holster multi-functioned as a draining device. Any residue from the soda nozzle would drip into the holster down into a drain. The bartenders walked to the gun to maximize cleanliness, even if it cost them an extra five seconds.

On a busy night, bartenders utilize the soda gun 4-5 times per minute. Assuming busy hours at a bar in Shadyside to be between 11pm and 2am, the soda gun is used roughly 800 times per night. Rapid use and durability are significant factors to consider during design.

Anthropological Study: Soda Fountains

Our team also explored the soda gun's brother- the soda fountain. We visited a Carnegie Mellon University dining hall to explore how the soda fountain works and is utilized.

We spoke with one of the employees at Skibo Cafe, who took us behind the counter to see how the soda fountain is set up. The syrup boxes are aligned on shelves next to several Carbon Dioxide tanks. Only one tank is connected to the system, but there are extra tanks sitting idle in case the current tank runs out before another order is placed. All of the syrups are attached to tubes with a plastic nozzle and clamp very similar to those seen on the soda gun. We wonder if these are the same parts? This would reduce part numbers sold by the fountain manufacturer.

The syrup tubes run on extremely long line. The tubes are gathered together and filtered through a long piece of PVC that runs up the wall, through the ceiling, and down another wall. The tubes exit right below the soda fountain. At this point, the tubes containing syrup run directly up into the soda machine and are connected to their labeled taps. The carbon dioxide and water tubes run into the carbonator where the carbonated soda is made. This is then pumped through the larger, clear tube into the fountain.

After speaking with the employees at Skibo Cafe, we uncovered these key points

- Pepsi Co. installed this entire system. They also maintain the system, replace damaged parts, and restock syrups and carbon dioxide tanks. Skibo employees only responsibility is to call in when they need refills or if a part is damaged.

- Employee has been working in the cafe for over a year and has never seen a part malfunction

- Employee doesn’t know how to regulate the flow of syrup- Pepsi company takes care of that as well

- Employee didn’t have any significant complaints about the product

- Non-carbonated beverages run out faster than carbonated ones (could be a CMU statistic)

- Ice container chills syrup and soda in tubes only

- Cold plate on bottom of ice container

- It’s easy to screw on the nozzle to the syrup containers

- Pump is activated entirely through pressure because there are no wires

After observing students use the soda machine, we recorded:

- The tray under the nozzles isn’t connected to a drain- it’s just a collection bin that must be emptied out every evening

- Soda comes out of a fountain much faster than it comes out of a soda gun

- More carbonation is produced from a soda fountain than a soda gun

- Users can fill their cup with one hand, but cannot leave the machine unattended

- It is difficult to multitask when filling a drink at a soda fountain

- Multiple sodas can be pressed at a time

Stakeholder Interviews

The purpose and intent of the stakeholder interviews was to call different companies selling soda gun systems as well as maintenance companies servicing these soda guns as suggested on wunderbar.com to gain understanding of their specific role with soda gun systems, as well as ask for feedback about potential strengths and weaknesses of the soda guns.

Strategies adopted on the phone while calling on Feb 7

First, we identified ourselves to the interviewees as students in Mechanical Engineering doing a project involving a soda gun. This approach was not successful, as most people only wanted to talk to potential customers, not students.

After a few failed calls, we posed as potential customers in hopes of staying on the line longer. At that point, we were able to get some answers, but most answers were framed as sales pitches, which may have misrepresented the actual quality and usability of the products. To even further gain new information, we even posed as a potential bar manager to ask technical questions about the gun in a commercial bar setting.

Summary

The complete notes gathered during this research can be found in the appendix. The key findings are the following :

- Most of the bars rent the system and therefore have a contract with the company regarding the maintenance : if they have a problem, they just call and they fix it.

- The gun itself is pretty reliable : o-rings and valves are the only things that generally need replacement. The flow rate of the gun is commonly found to be rather poor compared to a soda fountain.

- The other parts of the system (carbonator, pumps, ...) may be subject to failure during normal operation, as expected.

- The lifespan of a system can be from 10 to 30 years depending on the level of maintenance.

- A common reason for bars to call a service company is because of a wrong syrup ratio !

- The system sellers emphasize the fact that the system can be repaired and maintained by anyone. The service companies say it’s impossible to do it yourself.

Product Reviews

Key Points:

- There appears to be some demand for in-home soda dispensing systems

- Average annual consumption of carbonated soft drinks in America is 44.7 gallons per person, per year. (http://www.huffingtonpost.com/2011/06/27/americans-soda-beer_n_885340.html)

- There are current products in the market that allow for the adaptation of a Wunderbar system into a home system (Bar Bandit)

- Uses 2-liter bottles and CO2 to power soda through a Wunderbar gun, allowing for off-counter storage of bottles

- Benefits include portability, integrate-ability into current CO2 line set ups, low cost, increased work space, and professionalism (http://www.youtube.com/watch?v=ZE9kaeB_Bd4)

- Wholesale distributors allow you to buy soda syrup directly (http://www.markpowers-and-company.com/Wunder-Bar%20Setup.htm)

- A home user may not drink a 2L bottle of soda fast enough to prevent it from going flat, adding a CO2 component to preserve carbonation is attractive to consumers

- Purchasing the equipment (gun) especially new, is expensive and requires some know-how of how the set-up should work

- Bar guns should be cleaned daily to prevent contamination in the lines

- Our dissection product was a hydraulic post-mix gun, but most home consumers prefer pre-mix because it is easier and there is no syrup mixing involved (brixing etc.) (http://www.homebrewtalk.com/f51/soda-gun-anyone-used-one-these-35702/)

- The presence of a bar gun gives a bar, both in commercial and home settings, a sense of authenticity, a desired trait for many (http://www.hometheaterforum.com/topic/295421-should-i-get-a-soda-gun/)

- The bar gun allows users to “custom-set” their own preferences for brixing based on how they think the soda should taste

- Syrup attracts flies, ants, etc.

- Pre-mix guns can dispense beer, but post-mix guns can’t (all foam, wrong carbonation levels, mixer in gun prevents it) (http://www.homebrewtalk.com/f11/can-soda-bar-gun-dispense-beer-259425/)

- Financially, you will save money buying syrup and CO2 rather than soda itself (http://www.city-data.com/forum/house/579747-home-soda-fountain.html)

- Commercially, soda guns/fountains are preferable to bottles, but when maintenance and portability are brought into the picture, the advantage is reduced (http://www.roadfood.com/Forums/Coke-Dispensing-Machine-m551245.aspx)

General Impression:

- Many users express interest in a home soda gun for a variety of purposes, but the complexity of the set-up, the maintenance required, and the cost of commercial systems are major deterrents

Relevant Competitor Products

- Soda Stream

- Light-weight, smaller CO2 bottles

- Uses tap water and soda syrups to carbonate soda in the home

- Counter top device, no hoses or expected know-how

- Must be set-up for each serving/use

- Easy to clean

- Relatively low up-front costs ($79-$200)

- PUR Flavor Options

- Uses tap water with a small amount of flavoring to lightly flavor water (4 flavor options sold separately)

- Also Filters water

- Biggest Problem = falling off the faucet

- Customers complained of cheap manufacturing by P&G

- Easy to Install

- No electricity necessary

- Attaches to any faucet

- $40-$100

- Everpure Exubera Chiller/Carbonator

- Faucet system that dispenses chilled carbonated or still water

- Amount of fizz is adjustable

- Complicated installation

- Difficult to Remove

- Must also buy custom faucet ($600)

- Very Expensive ($2000)

Patent Searches

Listed below are the most relevant patents found for each concept. It should be noted that, except for the Soda Keurig, the patents are not exactly the same as our design ideas. For example, the closest patent for the Sodarator includes a carbonation tank and pump to create the sparkling water, patent US 20040206244 A1 for the Soda Filter doesn't specify how the syrup would be added to the sparkling water and the patents listed for the Liquor Joystick don't include the Joystick concept. No patent has been found at all for the Pocket Gun, the listed one is just a liquid dispenser.

- Sodarator :

- US 20130277394 A1 : Moveable roll around self-contained ice cooled beverage dispensing apparatus [1]

- Soda Filter :

- US 20040206244 A1 : Kitchen mixing faucet for producing soda water [2]

- DE 102012102467 A1 : Device for enriching drinking water stream with carbon dioxide, for use in e.g. house, has control valve that adjusts differential pressure between gas and liquid stream, and gas pipe that supplies gas stream to liquid stream in mixer [3]

- Soda Keurig :

- Liquor Joystick :

- Pocket Gun :

- US 20130206791 A1 : Portable handheld liquid dispenser [9]

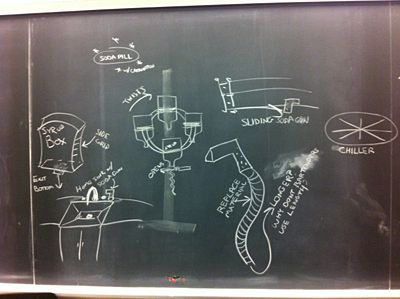

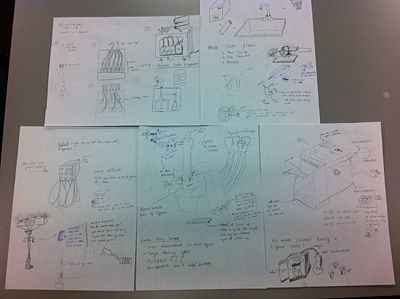

Design Concepts

After multiple brainstorming sessions, our team sat down to sketch out our top 5 designs. We then passed our designs around the group to add details and features, making the design complete. Below you will find a sketch of each design and a short description on how it works.

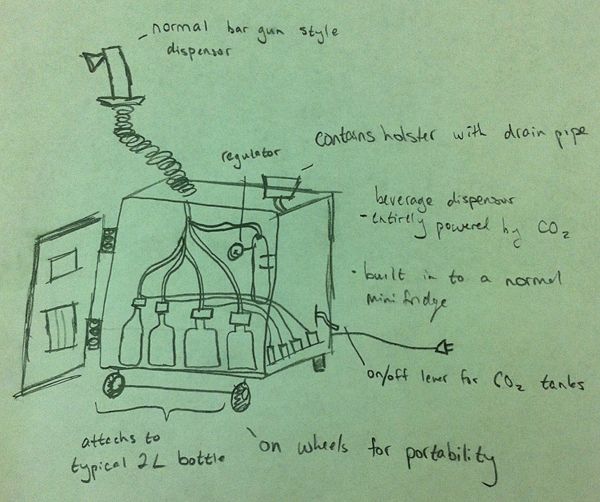

SODARATOR

The sodarator is a modification of a conventional mini-refrigerator designed for home use or small, private parties. The motivation of the design is the discovery of a desire to maintain the authenticity of a soda gun or soda fountain without complicating the system with large scale commercial components and intricate systems. Additionally, the sodarator helps minimize large up-front capital costs that a home bar owner may experience when purchasing his own system by relying on easily replaceable, cheap, common parts. The system allows standard 2 liter bottles to retain carbonation much longer than typically seen, which allows users to purchase soda in economical levels, even if they drink it at a slower pace that may result in flat soda. Finally, the sodarator design is based in a refrigerator, which allows the user to control temperatures.

Mechanically, the sodarator works with simple components and tubing, and relies on a current soda gun handheld dispenser. The user attaches 2 liter bottles onto valves that screw-on to the tops, and then carbon dioxide, stored in a tank and pressure-regulated, is added to the lines. This pressure causes the soda to dispense when each drink style is selected, and does not rely on any electric pumps or motors. Additionally, the constant presence of carbon dioxide in each bottle retains carbonation.

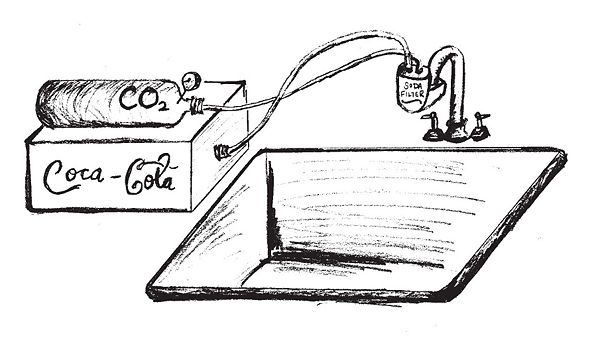

SODA FILTER

The basic concept behind this design is: Faucet + CO2 Tank + Box of Syrup = Cup of Inexpensive Soda. The soda filters allows home users to make a cup of cheap soda from a box of syrup. The main engineering design challenge will be finding out how to carbonate continuously flowing water without installing an expensive system that is ifficult to install and confusing to maintain. To do this, we plan on using pipe flow to create a highly pressurized. turbulent flow region where the water and the CO2 can

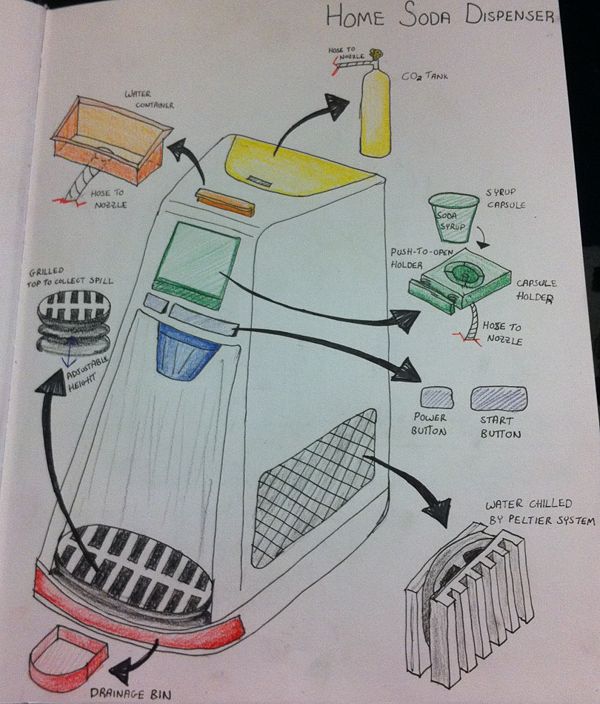

HOME SODA DISPENSER

The Home Soda Dispenser is a combination of a Keurig and a Soda Stream with some added features. The dispenser is loaded with water and a soda syrup capsule is placed in the compartment. When the start button is pressed, the capsule will be pierced, ejecting the syrup from the device. Simultaneously, the start button will activate the pump and carbonator. The carbonator carbonates the water as it flows through the pump and out the nozzle. As long as the button is pressed, the pump and carbonator will remain running. Letting go of the button closes the carbonator and shuts off the pump. The water and syrup flow through two separate tubes which are connected in the nozzle and mixed at the end of the process. There is also a cooling system in the device to chill the water, making it easier to carbonate and tastier to drink. A 4"x4" Peltier cooling system will be sufficient to cool 1/2 gallon of water. Finally, there is an adjustable drain (stand in drain has several clamps that lock in place when the drain is moved up/down) so cups of all heights can mount correctly. There is a drainage bin at the bottom of the device to collect soda leakage.

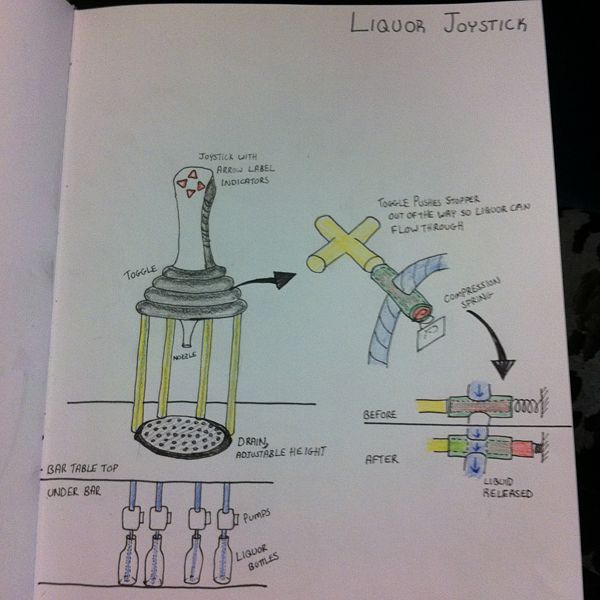

LIQUOR JOYSTICK

During our anthropological study, we noticed that the bartenders always had to walk to the liquor bottles and come back before being able to mix the drink with the help of the soda gun. This was the starting point of the Liquor Joystick concept, which could reduce the time spent and thus increase efficiency of a bartender. The glass would be placed under the dispenser, and the bartender could chose the needed liquor by tilting the joystick in the appropriate direction while dispensing the soda with the other hand at the same time, to ensure a perfectly mixed drink. Mechanically speaking, tilting the joystick would open the correct spring loaded valve, allowing the liquid to flow either due to gravity (bottles above the dispenser, visible to the customers) or with the help of pumps (CO2 pumps for example) if the bottles are stored under the bar. This concept could be brought to another level with the addition of easily accessible buttons on the joystick, which could, for example, allow the bartender to dispense coke when tilting the gun to the left and pour rum when pressing on a particular button at the same time. Many different combinations could be achieved with this concept : the direction of the joystick and the buttons could determine the type of liquid (soda , liquor, both) or a fixed standardized amount of liquid.

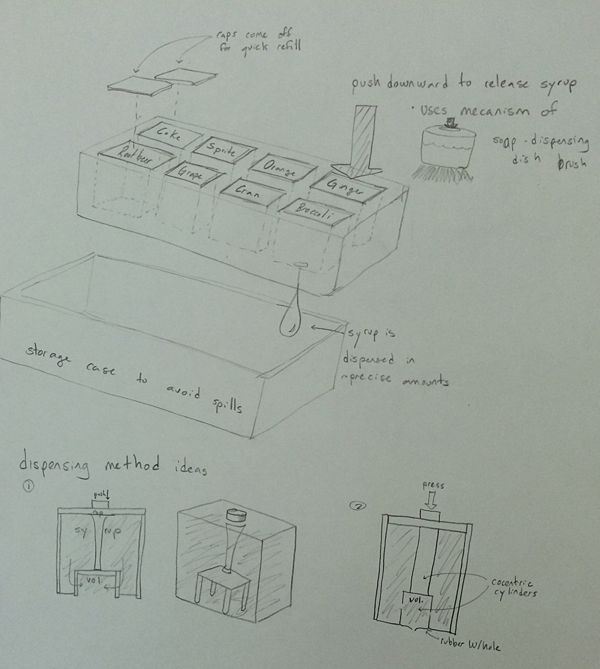

POCKET GUN

The idea here is to have a handheld device that would contain a large variety of soda syrups that could be easily dispensed by hand. Each time the action button was pushed, an appropriate and precise amount of the chosen syrup would exit the device and could be mixed with carbonated water to create a full-sized glass of soda.

Pugh Chart

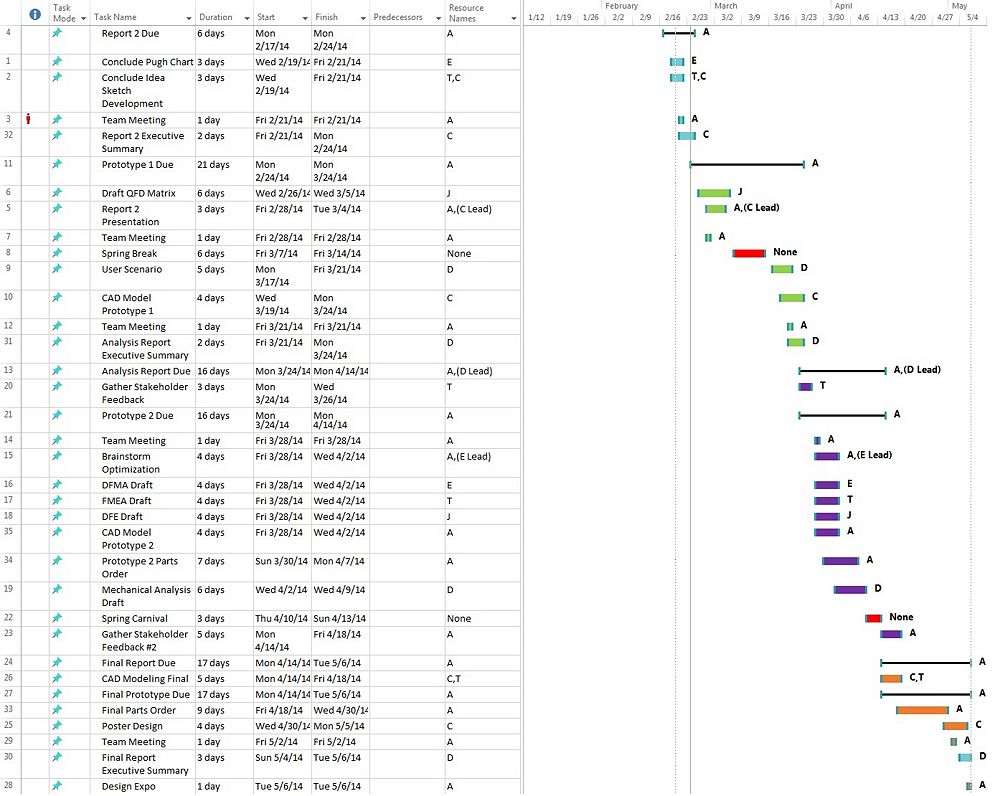

Gantt Chart

The Gantt chart shows a tentative outline for the expected workloads and deadlines for the completion of this project. Each design phase has been outlined in a different color for readability, and the events have been ordered from closest in time to furthest away. Additionally, we have outlined spring break and carnival as times where we expect to not work on the project, which is important for planning and for meeting deadlines that occur after those events.

The chart has been coded with first initials to make the chart more compact where:

- A = All

- C = Christy

- D = Dan

- E = Elle

- J = Julien

- T = Taryn

The chart is designed to give each member an opportunity to lead parts of the report, as well as switch to different areas that may interest them as we modify the schedule. Initially, assignments are based on a self-declared strengths and weaknesses that our group put together at the start of the semester. Specifically, Christy is strong in organizational skills, administration, and concept sketching. Dan is strong in technical writing, editing, and report writing. Elle is strong in machining and design critiquing. Julien is strong in theoretical background and perspective generation. Taryn is strong in concept sketching, modeling, and aesthetic design. The Gantt chart reflects these skills, but our group also wants to focus on allowing multiple people to work in different areas over the remainder of the project.

Team Members

Elle Allen- Stakeholder Interviews, Pugh Charts, Sketching

Julien Locher- Expert Interviews, Benchmarking/Patent Research

Taryn Monteleone- Anthropological Studies, Product Reviews, Sketching, User Scenarios

Dan Murby- Anthropological Studies, Gantt Chart, Executive Summaries, Sketching

Christy St. John- Stakeholder Interviews, Product Reviews, Sketching, Powerpoint

Throughout this design phase, our team worked well together to develop ideas and move forward on 5 of them. We began with market research, where our group divided to conduct a series of anthropological studies, stakeholder interviews, and product reviews. We met after the weekend to discuss our findings and begin our first round of brainstorming. We conducted two separate brainstorming sessions, where we gathered and came up with our top 75 ideas. After gathering these ideas, we picked out our top 25 ideas/ key issues we wanted to solve. With this information, we were able to begin benchmarking, patent searching, and researching current competitor products. All of this was done in a group dynamic, where we equally contributed ideas. We gathered a week later to conduct more brainstorming, where we implemented the round robin sketching technique. Based on brainstorming and benchmarking, each team member sketched their favorite idea and other team members added to it. These concepts were then discussed and combined to create our final 5 concepts for the class. We worked as a team to put together the report and powerpoint presentation presented in class.

Conclusions

User Scenario

Concept to Pursue

SODARATOR

When returning to our original market research, we see that the four main modifications we want to focus on are: faster flow rate, cheaper soda, preventing soda from going flat, and an easily-installed home system. From this market research, we decided to combine ideas and create a Sodarator, which mixes pre-carbonated water and syrup from a box. This portable system allows users to cheaply buy name brand sodas, fixes the problem of sodas going flat, and allows us to adjust the flow rate by controlling the pressure of the CO2.

Appendix

List of Interview Questions for the User

- What do you like about your soda gun?

- What don’t you like about your soda gun?

- Has your soda gun ever broken? If so, how?

- What parts of the soda gun are tedious?

- Have you ever lost a customer because of soda gun malfunction?

- Have you ever used the shut off screw?

- What’s the most creative way you use the soda gun?

- Are there any quick fixes you have applied to the device to make it easier?

- How often does the product require maintenance?

- How easy is the product to maintain?

- How often do you clean the product? How? Issues?

- Can you personally maintain or do you need to call for assistance?

- Do you know how to adjust the soda ratio?

- Can you notice the difference between fountain soda and pre-bottled soda?

- Is the gun long enough to reach the full bar?

- Are the buttons hard to press?

- Are the buttons intuitive?

- Do you know how to refill the syrups?

- Where is the product from?

- What is the lifespan of the product?

- Is the product owned or licensed?

List of Interview Questions for Stakeholders and Experts

- What part of this product is the most difficult to produce?

- What part of this product is the easiest to produce?

- Where do you see the most failures in the product?

- Where do you see the least amount of failures in the product?

- Can you reduce part numbers?

- What part of this product is the most difficult to maintain?

- What part of this product is the easiest to maintain?

- How often are you called in to maintain the product?

- What replacement parts are purchased the most?

- What parts can be replaced individually? What failures require full system replacement?

- What is the lifespan of the product?

- Is the system transferable? Is the system worth transferring?

Notes from the phone calls

Random companies found on the internet :

- sodadispenserdepot.com

- Call : no answers

- Live chat : first ended by the agent because I wasn't a customer. Later, I pretended to be a potential customer : System lasts “several years”. Weak points are o-rings and syrup pumps that don’t last forever. Flow rate is rather poor vs fountain. Everything is easy to repair, they provide guides, videos, etc.

- sodadispensers.com : no answer

- sodabarsystem.com : they don’t do maintenance

- Willtec Home Soda : he doesn't do any maintenance but he has a system at home for 10 years w/o a problem. “Damn reliable”. Sometimes o-ring or valve have to be changed. He says bars have several guns to change them if there’s a problem.

- Kint : can’t join a technician, “time is money”.

Service companies from Wunder-bar website :

- R.S. Sales : don’t do soda guns -> Recommended to get in contact with Philadelphia Extract (215-548-5225)

- Philadelphia Extract : 99% of bars rent the system from them. They usually call once every month / 3 months for a problem, depending on the place. If maintained, system -> 20 years. Syrup pumps -> 5,6 years. Every system is likely to leak/break, but it’s less about the gun itself.

- Kapco Service : no answers

- Cameron Supply : What can fail : carbonator, pump. Problems : leaks on gun, connectors are bad. Most occurring problem : wrong syrup ratio. Lifespan up to 30 years.

- Polar Bear : can’t get through the answering machine w/o leaving my coordinates and detailing the problem.

- Glen Carbonic : they don’t do Coke/Pepsi and he doesn’t want to answer my questions anymore.

Additional notes :

The system sellers emphasize the fact that the system can be repaired and maintained by anyone. The service companies say it’s impossible to do it yourself.

100 Brainstorming Ideas

1. Single soda dispenser

2. Add carbonator to tumbler cup

3. Octopus nozzle

4. Carbonated Ice Cube

5. Inject CO2 into soda with needle

6. Roulette Wheel for 2-liter bottle soda dispenser

7. Regulator next to connection to box

8. Hydra Nozzle (Three Heads for Multiple Use)

9. Rail Across Bar

10. Single Serving Hose

11. Put soda stuff on top of bar (Gravity increases flow rate)

12. All in one carbonator/soda maker/water – multiple nozzles for multiple users

13. Ability to push two buttons at once

14. Second button to soda gun (one for syrup/one for carbonated water)

15. Doubling the buttons to control the flow

16. Beer tap soda tap

17. Add alcohol speed rack for common drinks

18. Based on the direction the tap was flipped, a different mixed drink would come out

19. LIQUOR JOYSTICK!!!

20. Replacing Button with Trigger

21. Water Meter Sensor in Nozzle for Flow Stop

22. Connection to Cup

23. Laser Point Field to Sense the Bottom of the Cup

24. Drink Monitor System for Bar (Home Security System)

25. Drink Agitator for mixing stagnant drinks

26. Magnetic Hands Free Stirrer (Replace Cocktail Shaker)

27. Easy Home Soda System (simplified)

28. Home System to Combine Seltzer with Syrup

29. Soda Keurig

30. Exact Soda Ratio Dispenser

31. Add Soda Steam to Syrup

32. Make a faster soda gun

33. Sensor to know when soda cup is full

34. Buttons for Small, Medium, and Large

35. Replace buttons with Touch screen

36. Indicator for soda ratios being off

37. More Easily Adjustable Syrup Ratio

38. Detection of Empty Soda Syrup Boxes

39. Ice gun

40. Conveyer Belt Bar Top

41. Self Serve Alcoholic Drink Machine

42. Magnet That Released Once You Pay

43. Magnet System that Is Connected To Your Tab

44. Pour from the Bottom of the Cup (Soda Geysers)

45. Make Gun More Ergonomically Friendly

46. Dragons that Spit Soda

47. Decorative Soda Gun Heads

48. Fire Breathing Soda Gun

49. Soda Gun could Be Used By Customer

50. Soda Gun on Tables

51. Soda Nozzle that You Can Turn and Get different Spray Patters (Shower Head Style)

52. Wine Aerator Gun

53. Healthier Soda – Is this possible mechanically?

54. Box redesign (Easier to Lift)

55. Mechanical Racking System for Boxes

56. Better System for Bar Bandit

57. Cap that Allows Soda to Retain Carbonator

58. Re-carbonation Station

59. Cup Under Pressure to Retain Carbonation

60. Sliding Library Soda Gun

61. Soda Gun/Soda Fountain Hybrid

62. Retractable Soda Machine Nozzles

63. Soda Pill (Turns Flat Water into Soda)

64. Soda Filter

65. Connect to a Pressurized Line for Home System

66. Combine a Water Dispenser with Soda Gun

67. Flavored Water

68. Make Filling Water Faster

69. Separate Water Gun

70. Syrup Box has a Side Grip

71. Replacing Metal Sleeve With Something more Moveable

72. Expandable Hose

73. Efficient Chiller Plate Re-Design

74. Filter for Faucet with two options: Soda, water

75. Soda Water Balloons

76. Handheld Soda Syrup Dispenser

77. Retractable Soda Gun Handle

78. Portable Soda System

79. Home Use Soda System

80. Home System with Drainage

81. Spring Loaded Release Valves

82. Single Serving Soda Syrup Dispenser

83. Cheap Soda System

84. Adjustable Floor for Cup

85. Better Leakage Drainage

86. Attachment to Existing Water Source in Homes

87. 2-Liter Kegerator

88. Cheap Carbonator

89. Soda Water Bubbler

90. Cheap Cooling System

91. Tube Chiller/Insulator

92. Personal Soda System

93. Cheap Pump

94. Attachment to Existing Syrup Boxes

95. Childproof Soda Gun

96. Soda Filter

97. Keurig Soda Stream

98. Liquor Joystick

99. Soda Joystick

100. “Sodarator”

Brainstorming Sketches

References

User Studies

Personal Interview: Skibo Cafe Employee

Personal Interview: Hemingway's Bartender

Personal Interview: Fuel and Fuddle Bartender

Product Reviews and Online Research

Should I Get a Soda Gun: http://www.hometheaterforum.com/topic/295421-should-i-get-a-soda-gun/

Home Soda Fountain: http://www.city-data.com/forum/house/579747-home-soda-fountain.html

Soda Stream Carbonator: http://www.sodastreamusa.com/carbonators.aspx

Concession Stand Soda Fountain: http://www.roadfood.com/Forums/Coke-Dispensing-Machine-m551245.aspx

Problems with Soda for the Home Consumers: http://www.homebrewtalk.com/f51/soda-gun-anyone-used-one-these-35702/

How the System Works: http://www.markpowers-and-company.com/Wunder-Bar%20Setup.htm

Soda Gun Help: http://www.avsforum.com/t/1171817/soda-gun-help

PUR Flavor Options: http://www.amazon.com/PUR-Flavor-Options-Faucet-FM-5050B/dp/B000QIYIA4

Everpure Exubera Chiller/Carbonator: http://www.freshwatersystems.com/c-630-everpure-exubera-chillercarbonator.aspx

Patents

Please see links in the Patents section of the wiki