Water filtration pump

From DDL Wiki

m (→Product Function and Evaluation) |

m (→Product Function and Evaluation) |

||

| Line 43: | Line 43: | ||

Find the cleanest possible source of water. The intake hose is unwound, and then the intake hose is inserted into the water source. Attach the pump to the water container. Pump water at a steady rate, until container is full. Pull the intake hose out of the water, and pump to clear pump of any additional water. | Find the cleanest possible source of water. The intake hose is unwound, and then the intake hose is inserted into the water source. Attach the pump to the water container. Pump water at a steady rate, until container is full. Pull the intake hose out of the water, and pump to clear pump of any additional water. | ||

| - | [[Image:PumpBag.jpg| | + | { |

| - | [[Image:PumpBagContents.jpg| | + | |-[[Image:PumpBag.jpg|300px|thumb|left|Bag]]||[[Image:PumpBagContents.jpg|300px|thumb|center|Bag Contents]]||[[Image:PumpWhole.jpg|300px|thumb|left|Pump Apparatus]]|| |

| - | [[Image:PumpWhole.jpg| | + | } |

| - | + | <br />'''Mechanical Function'''<br /> | |

| - | '''Mechanical Function'''<br /> | + | |

The product contains a lever that is attached to a pump with two check valves. On the intake stroke, the intake check valve allows water through the water source into the piston. On the compression stroke, the intake check valve is closed and the bottom check valve allows water to be forced through the filter chamber. The filtered water is then sent out of the pump. | The product contains a lever that is attached to a pump with two check valves. On the intake stroke, the intake check valve allows water through the water source into the piston. On the compression stroke, the intake check valve is closed and the bottom check valve allows water to be forced through the filter chamber. The filtered water is then sent out of the pump. | ||

Revision as of 21:02, 7 February 2012

Contents |

Primary Stakeholders and Product Needs

The primary stakeholders and their needs for the product are listed below. The stakeholders are parties that have an vested interest in the product. Consumers, retailers, manufacturers, and shipping/transport were identified as the most important stakeholders in the product.

Consumers:

The consumers are the group of people that purchase and use the product, and therefore have a major interest in the product. As the product is a portable water filter, major target consumer groups are backpackers, and people without easy access to clean water.

- One of the most important functions of the water pump is that it pumps water. Without the ability to pump water, it can't push water through the filter, and thus can't filter water.

- Another important aspect is the drinkability of the water. The pump will need to eliminate dangerous pathogens and bacteria, or else the user of the product could get potentially life-threatening diseases. In addition, since the pump is meant to be used as a backpacking filter, medical first aid may not be readily available.

- The portability of the water pump is important as well, as it is meant to be a backpacking water pump. It needs to be carried, and so having a light product that can fit into a backpack is essential to the consumer.

- In order for the product to compete with similar products on the market, it must pump water quickly and efficiently. The pump can't be too hard to operate.

- The pump must also be cheap in order to be competitive with similar products.

- As the pump is meant to be taken backpacking, the pump must be durable. It should be able to sustain loads that could result from being thrown into a backpack. As having a source of water is vital, the pump breaking in the middle of a backpacking trip could not only be inconvenient but dangerous to the consumer.

- Product lifetime and filter lifetime are both important factors in a consumers decision as well. The longer lasting the product and the filter, the less hassle and cost it is for the consumer.

- Using sustainable materials for the water filter is important as well. The target consumers generally spend a lot of time in nature and appreciate the importance of using sustainable materials and processes in creating the product

- Since the water filter could be contaminated and needs to be cleaned regularly, the ease of cleaning and sterilization of the water pump is very important.

- The product must also be safe, as there are moving parts, and could be a potential cause of injury.

- Finally, the product should work with existing products such as Nalgene and CamelBaks, as many backpackers already have these products, and would prefer to choose a product that works with equipment that they already own.

Retailers:

The retailers are another group that has a major interest in the product. The retailers sell the product to the customer, in exchange for profit. The target retailers include outdoor equipment and sports stores such as REI and Dicks, as well as internet vendors such as Amazon.

- The price of the product is very important to retailers, as it affects their profit margin, and the quantity of product they can sell.

- The sustainability is important to many retailers, especially for retailers that have sustainability as part of their brand image.

- An attractive product will stand out to consumers more, and will contribute to sales. This is important especially in comparison to similar products.

- As the bottom line of the retailer is profit, the profitability of the product is very important to the retailer. Even if a product sells well, if the profitability is low, the retailer will not see a lot of profit, and will not want to carry the product.

- Safety is an important factor to the retailer, as the retailer will be partly responsible for any injuries from products it carries.

Manufacturers:

Manufacturing is an important stakeholder, as it is responsible for the creation of the product. The effects of manufacturing can be felt downstream by the retailers and consumers as well.

- The manufacturing of a product represents the majority of the cost of the product. Therefore, keeping manufacturing costs low will in turn have a big effect on the final retail price and profitability as well.

- Having a simple design with few parts will help decrease the assembly complexity and the number of necessary processes, thereby keeping the cost low.

- The design must also be compatible with large scale manufacturing processes such as injection molding. By doing so, the cost for creating a large quantity of the product will go down.

- The ease of assembly of the product will help keep assembly costs low, and also make the product easily maintainable by the consumer as well.

- Using standardized, interchangeable parts will eliminate the need of custom parts, and simplify the manufacturing process as well as lower cost.

- All processes and parts must be safe for the worker to handle, and be in accordance to any government regulations such as OSHA.

Shipping/Transport:

As shipping and transport can constitute a significant cost, it is necessary to be cognizant of shipping and transport needs.

- The product needs to be sturdy, so it won't be easily damaged during shipping. A fragile product needs extra packaging and handling care, which will be an additional cost to the company.

- As the weight of a product has a significant effect on the gas mileage of vehicles, the weight of the product is an important factor.

- A compact product will allow more of the product to be shipped together, thereby lowering the cost of shipping.

Product Function and Evaluation

Usage

Find the cleanest possible source of water. The intake hose is unwound, and then the intake hose is inserted into the water source. Attach the pump to the water container. Pump water at a steady rate, until container is full. Pull the intake hose out of the water, and pump to clear pump of any additional water.

{

|-||||||}

Mechanical Function

The product contains a lever that is attached to a pump with two check valves. On the intake stroke, the intake check valve allows water through the water source into the piston. On the compression stroke, the intake check valve is closed and the bottom check valve allows water to be forced through the filter chamber. The filtered water is then sent out of the pump.

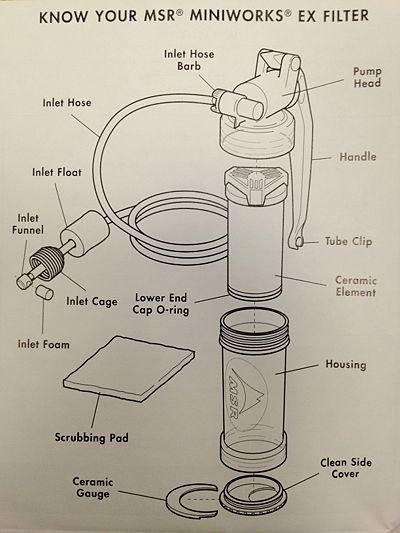

List of Parts

The following details the list of parts of a MSR MiniWorks EX Microfilter.

| Part Number | Name | Quantity | Mass (g) | Subassembly | Function | Material | Manufacturing Process | Image |

|---|---|---|---|---|---|---|---|---|

| 101 | Divert Cap | 1 | 0.5 | Hose Barb | Plastic | Pending Image | ||

| 102 | Washer | 1 | <1 | Hose Barb | Steel | Pending Image | ||

| 103 | Spring | 1 | 2 | Hose Barb | Steel | Pending Image | ||

| 104 | Hose Barb O-Ring | 1 | 0.5 | Hose Barb | Rubber | Pending Image | ||

| 105 | Hose Barb | 1 | 3 | Hose Barb | Plastic | Pending Image | ||

| 201 | Hose | 1 | 44 | Inlet Hose | Rubber | |||

| 202 | Buoy | 1 | <1 | Inlet Hose | Foam | |||

| 203 | Debris Cage | 1 | 11 | Inlet Hose | Steel | |||

| 204 | Intake | 1 | 1 | Inlet Hose | Plastic | |||

| 205 | Foam Filter | 1 | <1 | Inlet Hose | Foam | |||

| 301 | Piston Cap | 1 | 56 | Piston | Plastic | Pending Image | ||

| 302 | Piston | 1 | 9 | Piston | Plastic | Pending Image | ||

| 303 | Piston O-Ring | 1 | 2 | Piston | Rubber | Pending Image | ||

| 304 | Piston Pivot Sleeve | 1 | 1 | Piston | Plastic | Pending Image | ||

| 305 | Piston Pivot Pin | 1 | <1 | Piston | Plastic | Pending Image | ||

| 306 | Handle Pivot Sleeve | 1 | 2 | Piston | Plastic | Pending Image | ||

| 307 | Handle Pivot Pin | 1 | 1 | Piston | Plastic | Pending Image | ||

| 308 | Handle | 1 | 49 | Piston | Plastic | Pending Image | ||

| 309 | Piston Umbrella Valve | 1 | <1 | Piston | Rubber | Pending Image | ||

| 401 | Top Cap | 1 | 18 | Filter | Plastic | |||

| 402 | Outlet Cap | 1 | 10 | Filter | Plastic | |||

| 403 | Ceramic Filter | 1 | 42 | Filter | Ceramic | |||

| 404 | Carbon Filter | 1 | 34 | Filter | Carbon | |||

| 405 | Filter O-Ring | 1 | 4 | Filter | Rubber | Pending Image | ||

| 501 | Filter Body | 1 | 97 | Body | Plastic | |||

| 502 | Clean Cap | 1 | 18 | Body | Plastic | |||

| 503 | Filter Gauge | 1 | 5 | Body | Plastic |

References

Cascade Designs, Inc. MSR MiniWorks EX Water Filter. 24 Jan. 2012. Instruction Manual. Seattle, WA.