Retractable extension cord

From DDL Wiki

m |

(→Product User Study) |

||

| Line 51: | Line 51: | ||

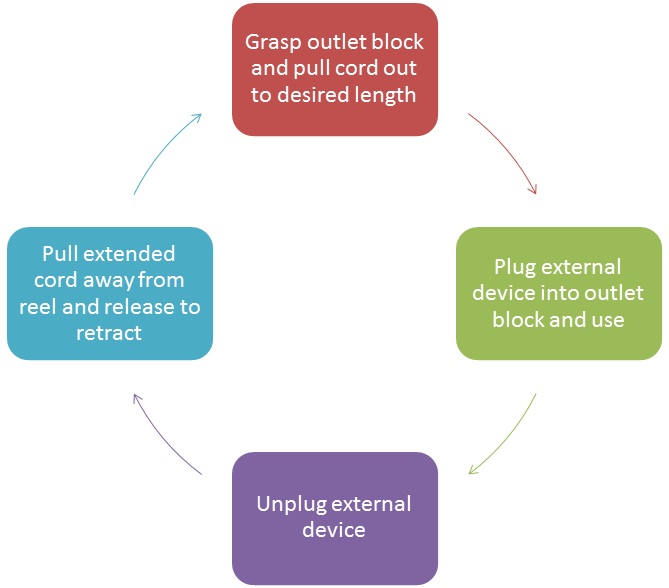

[[Image:Step_6.jpg|600px|thumb|right|6. Plug external device into outlet block and use.]] | [[Image:Step_6.jpg|600px|thumb|right|6. Plug external device into outlet block and use.]] | ||

[[Image:Step_7.jpg|600px|thumb|center|7. After external device is unplugged, grasp extended cord and pull away from reel to release ratcheting mechanism. Internal spring retracts cord back into reel]] | [[Image:Step_7.jpg|600px|thumb|center|7. After external device is unplugged, grasp extended cord and pull away from reel to release ratcheting mechanism. Internal spring retracts cord back into reel]] | ||

| - | |||

| - | |||

| - | |||

| - | |||

| - | |||

| - | |||

| - | |||

'''Mechanical Function'''<br /> | '''Mechanical Function'''<br /> | ||

Revision as of 19:42, 9 September 2012

Contents |

Major Stakeholder Analysis

Listed below are the major stakeholders for the retractable light, which include the manufacturer, customer, retailer, and distributor. The manufacturer generally would strive for low cost to mass produce the product for profit. The customer generally would need the product to be low cost, durable, and safe to use since they desire the product quality they pay for. The retailer would strive for low bulk pricing so that they can purchase the product in large quantity to sell to the customer. The distributor generally would need the product packaging to be durable and able to protect the product during the shipping process.

Manufacturer

- Low material costs

- Limited number of parts

- Ease to assemble

- Ability to be mass produced

- Environmentally friendly manufacturing processes

- Easy to package and ship

Customer

- Easy to use and install

- Multiple mounting options

- Low cost

- Durability

- Portable or light weight

- Ergonomic design

- Good aesthetics

- Multiple length adjustment positions

- Waterproof

- Safe to use

- Ability to customize cord length and reel cover color

- Easy to repair or disassemble

Retailer

- Good aesthetics

- Small packaging size

- Good performance

- Low bulk pricing

Distributor

- Low weight

- Durable product packaging

- Space optimized packaging

- Packaging protects product

Product User Study

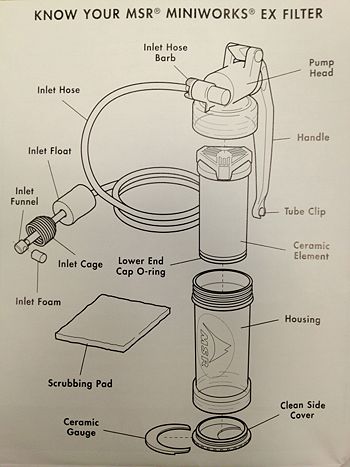

The MSR MiniWorks Pump operates via an oscillating piston with two one-way valves. A duck valve is inline with the pump head and housing to prevent excessive pressure buildup in the housing. The entire product can be completely dismantled in-field, and can be maintained with little prior knowledge. The design seems very simple yet efficient in its purpose.

Usage

Find the cleanest possible source of water. The intake hose is unwound, and then the intake hose is inserted into the water source. Attach the pump to the water container. Pump water at a steady rate, until container is full. Pull the intake hose out of the water, and pump to clear pump of any additional water.

Mechanical Function

The product contains a lever that is attached to an oscillating piston with two check valves. On the intake stroke, the intake check valve allows water to travel through the water source into the piston. On the compression stroke, the intake check valve is closed and the bottom check valve allows water to be forced through the filter chamber. The filtered water is then sent out of the pump. A duck valve lies between the pump head and housing to prevent a buildup of pressure. If the input flow is greater than the outlet flow, then the spring on the duck valve will compress and pressure will be released.

Preliminary User Study

Our group conducted a preliminary user study and determined that the product was self explanatory for either experienced hikers or anyone with moderate technical know-how (i.e. CMU engineering majors). Our group was able to completely dismantle the product without the use of any tools and easily discern the purpose of each part. This product would only need to be purchased by someone with a lot of experience in hiking and the outdoors, as someone without this experience should not be taking trips during which they won't have access to drinkable water. Therefore, nobody should be using it without any prior knowledge.

There are many well-thought-out features which exhibit themselves through simple use. First off, the outlet of the pump is threaded the same size as a Nalgene bottle, so that the pump can sit directly on the bottle and there is no risk of contamination. The included cap for the outlet of the pump also serves to reduce contamination when not in use. The rubber hosing wraps around the pump housing and is secured by a small c clamp in the handle. This serves to not only hold the handle down when when not in use (and prevent incidental breaking), but the c-clamp is properly sized so that it squeezes the hosing closed to prevent excess contamination. Finally the handle is contoured to fit well with the averaged sized in a comfortable pumping position.

Not many issues arise when using the MSR water pump. The most notable problem lies in the fact that the pumping action is cramped and requires several minutes to fill a hiking-sized water bottle. If there were a way to reduce the pumping effort required while keeping the small footprint of the product, it would probably be very beneficial. The only other foreseeable issues are broken parts or a clogged filter, which we didn't encounter and couldn't simulate during this study.

Parts List

| Item Number | Description | Quantity | Mass (g) | Function | Material | Manufacturing Process | Image |

|---|---|---|---|---|---|---|---|

| 101 | Duckbill Valve | 1 | 0.5 | Acts as a check valve, so that water can be pumped in through the hose, but not out | Plastic | Injection Molding | |

| 102 | Hose Barb Washer | 1 | <1 | Sits between the duckbill valve and the spring | Steel | Purchased | |

| 103 | Hose Barb Spring | 1 | 2 | Acts as the pressure relief in the check valve | Steel | Purchased | |

| 104 | Hose Barb O-Ring | 1 | 0.5 | Prevents water leaking from the hose barb | Rubber | Purchased | |

| 105 | Hose Barb | 1 | 3 | Connects to the hose | Plastic | Injection Molding | |

| 201 | Hose | 1 | 44 | Serves as the inlet hose of the contaminated water | Rubber | Purchased | |

| 202 | Buoy | 1 | <1 | Prevents the hose from sinking to the bottom of the water source | Foam | Foam Molding | |

| 203 | Debris Cage | 1 | 11 | Acts as a pre-filter and as a weight so that the hose stays below water | Steel | Purchased | |

| 204 | Intake | 1 | 1 | Water inlet, and also holds the foam filter | Plastic | Injection Molding | |

| 205 | Foam Filter | 1 | <1 | Acts as a pre-filter for large particles | Foam | Foam Molding | |

| 301 | Pump Housing | 1 | 56 | Contains piston and hose barb assemblies, and connects to filter | Plastic | Injection Molding | |

| 302 | Piston | 1 | 9 | Acts as the pump by drawing in and pushing out water | Plastic | Injection Molding | |

| 303 | Piston O-Ring | 1 | 2 | Prevents water from getting past the piston | Rubber | Purhcased | |

| 304 | Piston Pivot Sleeve | 1 | 1 | Connects piston to the handle | Plastic | Injection Molding | |

| 305 | Piston Pivot Pin | 1 | <1 | Connects piston to the handle | Plastic | Injection Molding |