Blender 2

From DDL Wiki

(→Bill of Materials) |

|||

| Line 144: | Line 144: | ||

The blending material is blended by moving liquid around and creating a vortex. The liquid around the vortex moves the unblended material around and it falls into the open space created by the vortex. This vortex leads straight to the blade, which chops up the material and pushes it away. The material keeps circulating in this way until it is stopped. | The blending material is blended by moving liquid around and creating a vortex. The liquid around the vortex moves the unblended material around and it falls into the open space created by the vortex. This vortex leads straight to the blade, which chops up the material and pushes it away. The material keeps circulating in this way until it is stopped. | ||

| + | |||

| + | ==Design for Manufacturing== | ||

| + | Oster makes several different kinds of blenders, offering a variety of speed settings, shapes, and sizes. The designers did a good job creating versatile parts that could be used for multiple types of blenders. For instance, the speed controlling system could easily work for any of their push-button 8, 10, 12, or 16 speed models. The motor assemblies are most likely almost identical in all 19 of their current products. Also, the few screws that were found int he blender, are almost definitely standard parts that could be used for any of their appliances. Having standardized parts not only helps the assembly line workers by having less clutter and fewer choices at each station, but also helps from a material flow and supply chain standpoint. | ||

| + | |||

| + | In addition to creating standardized parts, the designers at Oster also eliminated most superfluous connector pieces. This is both good and bad. The designers made used a few screws, but also made use of rivets and tabs. These definitely help keep the part count down, but at the same time requires each line worker to be familiar with several different fastening techniques. | ||

Revision as of 13:04, 26 January 2011

Contents |

Executive Summary

Bill of Materials

List of Components

| Part Number | Name | Quantity | Mass (g) | Function | Material | Manufacturing Process | Image |

|---|---|---|---|---|---|---|---|

| 1 | Bottom Cover Screws | 2 | <1 | Join bottom and top covers | Steel | Cold forming, Thread rolling | -- |

| 2 | Fan Bracket Screws | 2 | <1 | Join fan bracket to bottom cover | Steel | Cold forming, Thread rolling | -- |

| 3 | Spring | 2 | <1 | Push motor brushes into rotor | Metal | Extrusion, coiled | -- |

| 4 | Motor Brush | 2 | <1 | Conduct electricity to rotor | Graphite | Forming, Sintering | -- |

| 5 | Fan Blade | 1 | 31 | Cool motor coils | Steel | Stamping | -- |

| 6 | Fan Washer | 1 | <1 | Distribute load to motor shaft | Steel | Stamped | -- |

| 7 | Fan Nut | 1 | <1 | Secure Fan Blade and Fan Washer to motor shaft | Steel | Cold forming, Threaded | -- |

| 8 | Bottom Cover | 1 | 158 | House motor and electronics | Plastic | Injection Molding | -- |

| 9 | Electrical Cord | 1 | 50 | Provide power to blender from electrical socket | Steel | Cold forming, Thread rolling | -- |

Stakeholders

Buyer (for restaurant/smoothie bar use):

- Inexpensive

- Reliable/long product lifespan

- Safe

- Energy efficient

User (restaurant/smoothie bar employee):

- Safe

- Blades should lock into place safely and should not spin when at risk of cutting the user.

- User should not be at risk of electric shock.

- Easy to clean

- Lightweight

- Blends quickly and to the desired consistency without need to shake or manually stir contents

- Different speed functions for different uses

- Crushes ice quickly and effectively

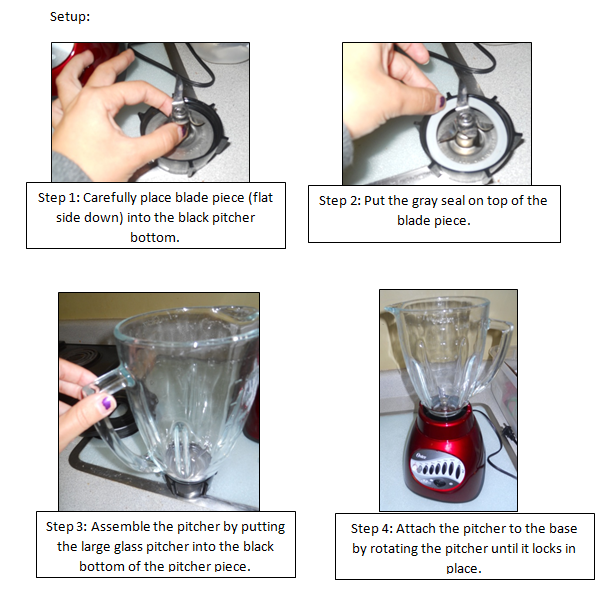

- Simple operation and assembly

- Pours without making a mess

- Contents do not spill out of top during use

- Quiet operation

- Easy to assemble

- Stable, difficult to accidentally knock down

- Sturdy, won’t break if dropped

Home user (Same needs as restaurant user and buyer with the following additional needs):

- Visually appealing

- Child-safe

Manufacturer:

- Minimum number of parts

- Easily manufactured parts

- Easy to assemble

Shipper:

- Lightweight

- Compact

How the Product is Used

How the System Functions Mechanically

The blender works by spinning a blade in a glass container to chop up and liquefy fruits, vegetables, etc. An electric AC motor is used to spin this blade. It uses an AC motor because it is plugged into an outlet and transforming AC to DC adds extra space and cost to the product. An AC motor works by switching the polarities of the electromagnets in the stator making the rotor, which has a constant polarity, rotate where the north pole of the rotor “follows” the switching south pole of the stator and vice-versa for the south pole of the rotor. This motor is likely geared to reduce speed and increase the torque of the blade.

The buttons on the front panel change the speed of the blade. This is likely accomplished by having the switches activate more or less coils in the AC motor. If there are more coils activated in the motor, the speed is reduced but the torque is increased.

The blending material is blended by moving liquid around and creating a vortex. The liquid around the vortex moves the unblended material around and it falls into the open space created by the vortex. This vortex leads straight to the blade, which chops up the material and pushes it away. The material keeps circulating in this way until it is stopped.

Design for Manufacturing

Oster makes several different kinds of blenders, offering a variety of speed settings, shapes, and sizes. The designers did a good job creating versatile parts that could be used for multiple types of blenders. For instance, the speed controlling system could easily work for any of their push-button 8, 10, 12, or 16 speed models. The motor assemblies are most likely almost identical in all 19 of their current products. Also, the few screws that were found int he blender, are almost definitely standard parts that could be used for any of their appliances. Having standardized parts not only helps the assembly line workers by having less clutter and fewer choices at each station, but also helps from a material flow and supply chain standpoint.

In addition to creating standardized parts, the designers at Oster also eliminated most superfluous connector pieces. This is both good and bad. The designers made used a few screws, but also made use of rivets and tabs. These definitely help keep the part count down, but at the same time requires each line worker to be familiar with several different fastening techniques.