| Dough Dispenser Cup Assembly

|

| Part Number | Name | QTY | Weight (g) | Function | Material | Manufacturing Process | Image

|

| 001 | Dispenser spring | 1 | 1 | Keeps dispenser closed when not in use | Steel | |

|

| 002 | Dispenser support | 1 | 19 | Guides the plunger for straight release | Plastic | |

|

| 003 | Dispenser plunger | 1 | 9 | Pushes the dough from the cup into the machine | Plastic | |

|

| 004 | Dispenser funnel | 1 | 27 | Guides the dough to the hole in the cup | Plastic | |

|

| 005 | Dispenser stop | 1 | 4 | Stops the dough from leaving dispenser and gives the doughnut its \"hole\" | Plastic | |

|

| 006 | Dispenser cup | 1 | 122 | Holds the dough for dispensing | Plastic | |

|

| Dispenser Motor Assembly

|

| Part Number | Name | QTY | Weight (g) | Function | Material | Manufacturing Process | Image

|

| 032 | Switch cover | 1 | 23 | Covers and protects the two switch connected to the housing | Plastic | |

|

| 032 | Dispenser motor | 1 | 204 | Drives the dispenser assembly | N/A | |

|

| 010 | Motor rotational output | 1 | 4 | Connects to the motor and rotates with it | Plastic | |

|

| 008 | Dispenser motor guide | 1 | 11 | Guides the motor\'s movement. Stationary | Plastic | |

|

| 032 | Dispenser motor housing | 1 | 113 | Houses and protects the dispenser motor assembly | Plastic | |

|

| 032 | Dispenser motor switch 1 | 1 | 5 | Alerts for dough release | N/A | |

|

| 032 | Dispenser motor switch 2 | 1 | 5 | Halts the dispensing process | N/A | |

|

| 032 | Dispenser switch housing | 1 | 4 | Positions switch to alert for dough release | Plastic | |

|

| 032 | Capacitor | 2 | 5 | Stores electrical charge | N/A | |

|

| 007 | Doughnut dispenser motor cover | 1 | 52 | Gives access to and protects the motor | Plastic | |

|

| 009 | Dispenser motor latch | 1 | 4 | Secures and aligns the motor dispenser assembly | Plastic | |

|

| 032 | Conveyor belt motor | 1 | 219 | Drives the conveyor belt assembly | N/A | |

|

| 023 | Drive gear 2 | 1 | 4 | Moved by the motor and translates motion to conveyor gear | Plastic | |

|

| 032 | Conveyor motor switch 1 | 2 | 23 | Connects and controls dials | N/A | |

|

| 032 | Motor switch holder | 1 | 10 | Holds the switch and cradles the motor | Plastic | |

|

| 024 | Wire guide | 1 | 0.5 | Secures wires to housing | Steel | |

|

| 032 | Power jack | 1 | 15 | Connects to power cord | N/A | |

|

| 032 | Power jack housing | 1 | 5 | Covers and protects the power jack | Plastic | |

|

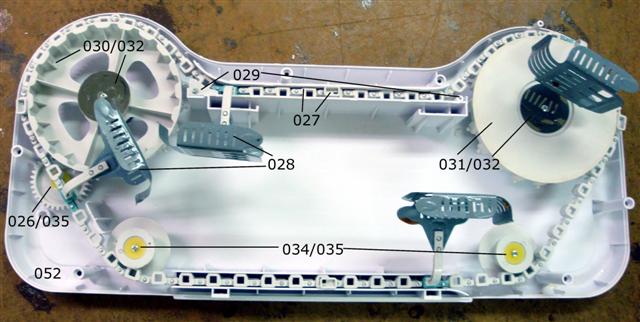

| Conveyor Belt Assembly

|

| Part Number | Name | QTY | Weight (g) | Function | Material | Manufacturing Process | Image

|

| 011 | Back housing | 1 | 772 | Protects delicate machinery from the surroundings | Plastic | |

|

| 012 | Conveyer belt holder | 2 | 0.5 | Guides and supports the conveyor system in its cycle | Plastic | |

|

| 013 | Doughnut carriage | 4 | 27 | Used to carry doughnuts through the system during operation | Plastic and aluminum alloy | |

|

| 014 | Thick Belt gear washers | 2 | 5 | Holds belt gears in place | Steel | |

|

| 015 | Conveyor belt gear (doughnut side) | 1 | 85 | Rotates and moves conveyor belt system | Plastic | |

|

| 016 | Conveyor belt gear (dough side) | 1 | 109 | Rotates and moves conveyor belt system | Plastic | |

|

| 017 | Conveyor belt | 1 | 123 | Driven by the motor to move doughnuts through system | Plastic | |

|

| 018 | Release link | 4 | 1 | Alerts the motor to release the dough | Plastic | |

|

| 019 | Belt guides | 2 | 14 | Guides the belt on lower portion of the cycle | Plastic | |

|

| 020 | Yellow Washer, belt guide | 3 | 0.25 | Separates the belt guide from housing | Plastic | |

|

| 021 | Thin Washer, belt gear | 2 | 2 | Separates the belt gear from back housing | Steel | |

|

| 022 | Belt motor gear | 1 | 14 | Translates motion from motor to conveyor belt | Plastic | |

|

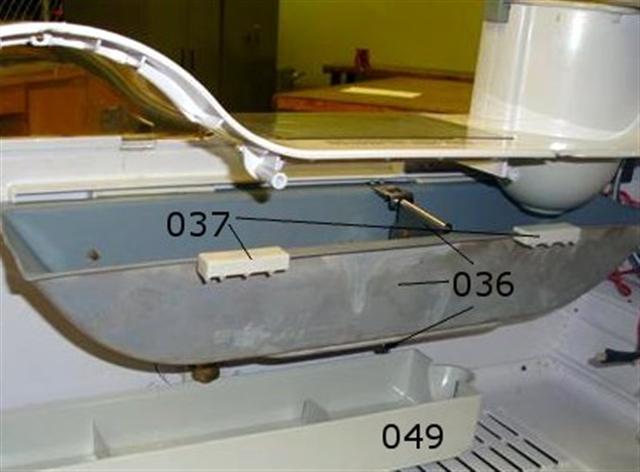

| Oil System Assembly

|

| Part Number | Name | QTY | Weight (g) | Function | Material | Manufacturing Process | Image

|

| 025 | Doughnut flipper | 1 | 10 | Flips donuts to opposite side | Steel | |

|

| Oil bath tub | 1 | 313 | Fills with oil and becomes very hot. | Aluminum Alloy | |

|

| Oil bath heating unit | 1 | | Causes the oil bath tub to become hot. | N/A | |

|

| 026 | Oil bath supports | 4 | 6 | Holds the oil bath in place | | |

|

| 027 | Temperature controller bracket | 1 | 13 | Connects heating element to the oil bath | Steel | Stamping |

|

| 027 | ???? | 1 | ?? | ???? | N/A | N/A |

|

| 032 | Knob housing | 1 | 32 | Protects oil drain components and user | Plastic | |

|

| 029 | Drain switch cover | 1 | 12 | Protects from accidentally enabling the drain switch | Plastic | |

|

| 032 | Adjustment Knob | 1 | 6 | Used to open and close the oil drain. | Plastic | |

|

| 032 | Dial connector | 1 | 3 | Translates knob movement through the housing | Plastic | |

|

| 032 | Drain lever | 1 | 6 | Used for securing switch in both positions | Plastic | |

|

| 032 | Oil drain valve mount | 1 | 4 | Mounts the drain in appropriate location | Plastic | |

|

| 032 | Oil drain valve | 1 | 33 | Controls the flow of the oil | Brass | |

|

| 032 | Oil drain tube | 1 | 2 | Channels the flow of the oil | Rubber/Plastic | |

|

| 032 | Oil drain tube clamp | 2 | .5 | Secures the tube onto the valve and drain | Steel | |

|

| 028 | Oil collection tray | 1 | 237 | Collects the oil that drains after use | Plastic | |

|

| 028 | Oil collection tray guide | 1 | ??? | Guides the oil collection tray into place. | Plastic | |

|

| Exterior Panel Assembly

|

| Part Number | Name | QTY | Weight (g) | Function | Material | Manufacturing Process | Image

|

| 032 | Front panel | 1 | 1160 | Protects the inside machinery from the outside | Plastic | |

|

| 032 | Back panel | 1 | 1160 | Protects the inside machinery from the outside | Plastic | |

|

| 030 | Top window 1 | 1 | 55 | Allows heat to escape when opened during production | Plastic | |

|

| 031 | Top window 2 | 1 | 123 | Cannot be opened. Allows user to view doughnut production | Plastic | |

|

| Miscellaneous Components

|

| Part Number | Name | QTY | Weight (g) | Function | Material | Manufacturing Process | Image

|

| 032 | Power cord | 1 | 107 | Connects to the outlet and supplies power to the machine | N/A | |

|

| 033 | Measuring cup | 1 | 27 | Used to measure out correct amount of ingredients | Plastic | |

|

| 034 | Doughnut slide | 1 | 36 | Removes doughnut from machine and into the doughnut bin | Plastic | |

|

| 035 | Doughnut bin with oil drain | 1 | 100 | Collects doughnuts after production and drains oil off doughnuts after production | Plastic | |

|

| 036 | Doughnut cover feet | 4 | 3 | Contacts surface | Plastic | |

|