Doughnut maker

From DDL Wiki

Contents |

Executive Summary

Bill of Materials

Main Components

Additional Parts

| Screws |

|---|

|

| Nuts and Washers |

|

Assembly Diagrams

| Dough Dispenser Cup Assembly |

|---|

|

| Dispenser Motor and Conveyor Motor Assembly |

|

|

| Dispenser Motor and Conveyor Motor Assembly Schematic |

|

| Conveyor Belt Assembly |

|

| Cooking Oil Assembly |

|

| Exterior Panel Assembly |

|

Major Stakeholders and Needs

Usage and Usability

Mechanical Function

Design for Manufacturing and Assembly (DFMA)

Design for Manufacturing (DFM)

Manufacturing Processes

Injection molding is used for bulk manufacturing of identical plastic products. The cost of the tool itself is very high, but with the sleep of production and the quality, with bulk manufacturing it will save money over other processes. The unit cost is incredibly low, making injection molding the ideal process for manufacturing the plastic pieces of the doughnut maker. Given the use of rivets on the front and back panel, injection molding is the likely process, which allows for both added strength and avenues for molten plastic. Large plastic compoents, such as the exterior panels, and large gear wheels are probably manufacturing in their own mold. However, multiple smaller pieces can be made in one mold to decrease manufacturing time per part.

Metal stamping is used to form shallow sheets and bends from a piece of sheet metal. Similarly to injection molding, the cost of creating the custom tool for each component is expensive, however the per unit cost is relatively low and is ideal for rapid, high volume production with a high quality finish. Stamping is not as aesthetically pleasing as drawing. Drawing is a similar process that uses a punch to force a piece of sheet metal into a die to form a particular shape. Drawing also has a high cost, but unlike stamping, the unit cost is also high. Drawing is more applicable to deeper profiles, while stamping is used for shallow ones. In the doughnut maker, stamping is more likely for the shallow stamps because it is cheaper and when only functional bends are needed stamping is more cost effective. Stamping is also ideal because it allows for high recycle-ability of the scrap metal and reduces waste. Pieces such as the temperature controller (P/N 038), are manufactured uses stamping for this reason. The oil bath (P/N 036) on the other hand appears to be drawn. A rounded, even shape with smooth corners can be achieved with drawing. Despite drawing being more expensive, with more important pieces a more expensive process is acceptable.

A large number of purchased parts are used throughout the assembly for the electrical components. All motors, screws, nuts and other standard parts were most likely purchased and then included in the assembly. Especially for mass produced consumer goods such as this doughnut maker, it is more efficient and cheaper to purchase these parts instead of manufacturing and assembling them individually.

Materials

The majority of components are made of plastic. Plastics are manufactured by heating them up to a given temperature at which they become a fluid, and forming them into shape. Particularly for consumer electronics plastics are ideal because they are often cheap, lightweight and can be easily formed and colored to be more ascetically pleasing. In most cases, plastic is strong enough to service the purpose for a consumer product. In addition, use of the doughnut maker involves significant heat to cook the doughnuts and the thermal conductivity of the plastic means that it doesn't get dangerously hot nearly as fast as other materials. Overall, any component that could be made out of plastic was made out of plastic to reduce cost and increase efficiency in manufacturing.

Metals are more expensive than plastics are, however, in some cases the extra expense is important. In the doughnut maker studied, a portion of the oil bath is heated to heat oil enough to cook the dough. Because of the high temperature of the oil bath, the bath itself and other temperature controlling components must be made from metal for safety. Plastic would likely melt and cause injury. Metal is a more effective conductive surface so it can heat the oil more efficiently as well. When necessary, metal was used at an extra cost.

Design for Assembly (DFA)

Given the huge number of components, this is not a quick and easy process to assembly by hand, but given the complexity and the size of many of the parts hand assembly is likely. While it is intended to be a mass produced item, clearly machining costs to automate this process would be unnecessarily expensive.

There are 59 components of the doughnut maker studied, not including sub-assemblies. Almost every component is distinct and must be manufactured separately, this vastly increases the number of parts to be manufactured and then assembled and increases the complexity of the overall assembly. By reducing the number of parts and simplifying the assembly design, the assembly process can be simplified and more cost efficient. In addition, with a complicated assembly design, such as the doughnut maker, the error in assembly is drastically increased. A more "idiot-proof" design would result in fewer errors in the assembly process.

Standardability of parts is key to good assembly design. At least nine different kinds of screws were used throughout the assembly. A single screw driver is capable of removing all kinds of screws, but there are a variety of lengths and diameters used in all components of the assembly. The same dial is used on all three of the front dials (P/N 022 and P/N 042), so the same mold can be used to make all three dials. However, very few other components of the overall are identical and usable in other areas of the assembly. The design of the assembly requires two different motors and multiple distinct gears. Common parts will reduce the parts to be manufactured and decrease the overall inventory to decrease cost and increase overall quality of the product.

There are five major sub-assemblies that can be assembled separately and then brought together. Particularly, the conveyor belt assembly and the motor assemblies, so each can be assembled independently and then brought together. Many of the components of the conveyor assembly are gears which can only fit in one way on a moon-shapped shaft allowing for little error when putting the gears on the assembly. Any gear that doesn't require exact alignment, or needs to be able to rotate freely.

Failure Modes and Effects Analysis (FMEA)

This product has several glaring failures which must be addressed while performing a necessary redesign. Although most of the analysis is on the component level, the major failures occur as a result of several components interacting and thus they are considered on the assembly level. Although there are many failures exhibited by this system, only the most severe will be discussed in detail.

A dramatic improvement on this product can be made to the dispenser system. The dispenser motor and the rotational output (part 11) both attribute to the failure of the dispenser to emit the correct amount of dough producing small burnt blobs. In a redesign, the motor speed should be reduced or the rotational output should be enlarged to allow for more dough to be released from the dispenser. This will dramatically improve the production of doughnuts and make the product more enjoyable.

In addition, the oil tub has several failures with high RPN's (270). Because the user is unable to clean the oil tub, the machine remains dirty and greasy and therefore has a safety issue involved. In addition, the doughnut flipper is unable to turn the doughnut which results in a poorly cooked product. In order to improve the system, a panel should be introduced to the plastic housing to allow the user access to clean the oil tub. Also, the doughnut flipper should be completely redesigned in order to perform its desired function.

There is also a serious safety failure present in this product, as can be seen in the table below. The top window (part 53) must be opened during use in order to prevent overheating, but this allows oil to escape and possibly burn the user. In addition, the housing heats up during use and can burn the user if touched. Since this product is used by children, these concerns must be addressed in a redesign of the system. By designing the product to allow heat to escape efficiently, both of these failures can be avoided.

The following table outlines the basic Failure Modes and Effects Analysis (FMEA) for the doughnut maker. The severe failures are in bold. The scale used can be found in the Engineering Design textbook by Dieter and Schmidt.

| Part # | Item and Function | Failure Mode | Effects of Failure | S | Causes of Failure | O | Design Controls | D | RPN | Recommended Actions | Responsibility and Deadline | Actions Taken | S | O | D | RPN |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 001 | "Dispenser spring"

| Deformed spring (too long/short) | Unable to fully open/close causing incorrect dough dispensing | 7 | Improper manufacturing | 2 | Inspecting dispenser spring | 2 | 28 | Introduce quality control measures to ascertain accurate spring dimension | Manufacturing and Quality Control | None | 7 | 2 | 2 | 28 |

| 002 | "Dispenser support"

| Warped | Dispenser plunger moving at angle disrupting dough shaping | 6 | Improper manufacturing | 2 | Inspecting dispenser support or dispenser plunger | 2 | 24 | Introduce quality control measures to ascertain dispenser quality | Manufacturing and Quality Control | None | 6 | 2 | 2 | 24 |

| 003 | "Dispenser plunger"

| Cracked | Dough unable to be pushed into system | 8 | Improper manufacturing | 1 | Inspecting dispenser assembly | 1 | 8 | Introduce quality control to ascertain dispenser quality | Manufacturing | None | 8 | 1 | 1 | 8 |

| 005 | "Dispenser stop"

| Leaking or cracked | Dough seeps from dispenser cup to machine | 6 | Improper manufacturing | 3 | Inspect dispenser assembly for leaks | 3 | 54 | Introduce quality control measures to ascertain dispenser quality | Manufacturing and Quality Control | None | 6 | 3 | 3 | 54 |

| 006 | "Dispenser cup"

| Cracked | Dough seeps from dispenser cup to machine | 6 | Improper manufacturing | 3 | Inspect dispenser assembly for leaks | 2 | 36 | Introduce quality control measures to ascertain dispenser quality | Manufacturing and Quality Control | None | 6 | 3 | 2 | 36 |

| 007 | "Switch cover"

| Warped | Misalignment of components | 8 | Improper manufacturing | 1 | Specify process, Material selection | 1 | 8 | None | Manufacturing | None | 8 | 1 | 1 | 8 |

| Fractured | Exposure / Misalignment of components | 8 | Improper handling | 2 | Material Selection, Packaging | 2 | 32 | Drop test with and without packaging | Reliability | None | 8 | 1 | 1 | 8 | ||

| 008-010 | "Dispenser motor assembly"

| Motor operates too fast | Insufficient dough released from dispenser | 6 | Poor design, motor rotates too quickly | 9 | Lab test with various motor rotational outputs | 5 | 270 | Redesign is necessary. Alternative motor speed or alternate motor | Research and development | None | 6 | 9 | 5 | 270 |

| Rotational output (part 11) too small | 6 | Poor design, part too small to release sufficient dough | 9 | Lab test with various sized parts | 5 | 270 | Redesign is necessary. Larger sized rotational output (part 011) | Research and development | None | 6 | 9 | 5 | 270

| |||

| 011 | "Dispenser motor housing"

| Fractured | Motor is moved off position, disrupting dispensing process | 7 | Improper manufacturing | 1 | Material selection, placement | 3 | 21 | Introduce quality control actions to check dispenser motor assembly | Reliability | None | 7 | 1 | 3 | 21 |

| 012 | "Dispenser switch 1"

| Sticking | Plunger stays open, dough pours into oil tub | 8 | Improper manufacturing or assembling | 1 | Inspect control systems | 5 | 40 | Take quality control actions or may redesign for extra clearance | Manufacturing | None | 8 | 1 | 5 | 40 |

| 013 | "Dispenser switch 2"

Halts the dispensing process | Sticking | Plunger does not open, no dough released | 8 | Improper manufacturing or assembling | 1 | Inspect control system | 5 | 40 | Take quality control actions or may redesign for extra clearance | Manufacturing | None | 8 | 1 | 5 | 40 |

| 014 | "Dispenser switch housing"

| Fractured | Plunger stays open/closed | 8 | Improper manufacturing | 1 | Inspect dispenser motor assembly | 2 | 16 | Introduce quality control measures on dispenser motor assembly | Manufacturing | None | 8 | 1 | 2 | 16 |

| 018 | "Conveyor belt motor"

| Conveyor belt assembly moves too slow | Doughnuts take a very long time to move through system | 4 | Motor rotates too slowly | 8 | Lab test with different motor speeds | 5 | 160 | Purchase more powerful motor, redesign for smaller drive gears | Research and development | None | 4 | 8 | 5 | 160 |

| 019 | "Drive gear 2"

| Fracture | Conveyor belt system unable to move | 8 | Improper manufacturing | 1 | Inspect conveyor belt assembly | 1 | 8 | Introduce quality control measures on conveyor assembly | Manufacturing | None | 8 | 1 | 1 | 8 |

| 023 | "Wire guide"

| Dislocating from position | Wires come into contact with oil bath | 9 | Improper handling | 1 | Material selection, packaging | 1 | 9 | Drop test with and without packaging | Reliability | None | 9 | 1 | 1 | 9 |

| 024 | "Power jack"

| Short circuit | Unable to function | 8 | Internal problem | 1 | Choose reliable supplier | 4 | 32 | Test completed units before distribution | Assembly | None | 8 | 1 | 4 | 32 |

| 026 | "Belt motor gear"

| Fractured | Conveyor belt unable to move | 8 | Improper handling | 2 | Material selection, packaging | 2 | 32 | Drop test with and without packaging | Reliability | None | 8 | 2 | 2 | 32 |

| 027 | "Conveyor belt link assembly"

| Fracture | Doughnut unable to move through system, machine unable to perform function | 8 | Improper manufacturing | 1 | Inspect conveyor belt assembly | 4 | 32 | Introduce quality control measures on conveyor assembly | Manufacturing | None | 8 | 1 | 4 | 32 |

| 028 | "Doughnut carriage assembly"

| Bends too easily | Contributes to doughnut being unable to flip | 5 | Poor design, part too flexible | 9 | Lab test different materials with various flexiblities | 4 | 180 | Redesign using a less flexible material | Research and development | None | 5 | 9 | 4 | 180 |

| 030-031 | "Conveyor belt gear"

| Fracture | Conveyor belt system unable to move | 8 | Improper manufacturing | 1 | Inspect conveyor belt assembly | 1 | 8 | Introduce quality control measures on conveyor assembly | Manufacturing | None | 8 | 1 | 1 | 8 |

| 034 | "Belt guides"

| Fracture | Conveyor belt system unable to move | 8 | Improper manufacturing | 1 | Inspect conveyor belt assembly | 1 | 8 | Introduce quality control measures on conveyor assembly | Manufacturing | None | 8 | 1 | 1 | 8 |

| 036 & 039 | "Oil bath assembly"

| Flipper does not turn doughnuts | Doughnut unevenly cooked | 6 | Poor design, doughnut pushes flipper | 9 | Inspect oil bath assembly | 4 | 216 | Redesign the oil flipper by making a more rigid connection | Research and development | None | 6 | 9 | 4 | 216 |

| Oil bath temperature fluctuates too greatly | Doughnut burnt (usually) or undercooked | 5 | Oil bath diminishes too fast, temperature controller too poor | 7 | Inspect oil bath assembly | 4 | 140 | Purchase a better temperature controller | Research and development | None | 5 | 7 | 4 | 140 | ||

| Fractured/Leaking | Release of hot oil into system, possibly onto user | 9 | Improper handling | 1 | Material Selection, Packaging | 3 | 27 | Drop test with and without packaging | Reliability | None | 9 | 1 | 3 | 27 | ||

| Oil tub hard to clean | Oil stays in system and machine gets very dirty/greasy | 6 | Poor design, no access to oil tub | 9 | Inspect oil bath assembly | 5 | 270 | Redesign needed. Make removable panel to access oil tub | Research and development | None | 6 | 9 | 5 | 270 | ||

| 043-045 | "Oil drain knob assembly"

| Fracture | Oil drain system unable to function | 7 | Improper manufacturing | 1 | Inspect oil drain assembly | 1 | 7 | Introduce quality control measures on oil drain assembly | Assembly | None | 7 | 1 | 1 | 7

|

| 046-048 | "Oil drain tube, clamps, and valve"

| Leaking | Hot oil released into machine and possibly onto user | 7 | Improper manufacturing | 2 | Inspect oil drain assembly | 4 | 56 | Introduce quality control measures on oil drain assembly | Assembly | None | 7 | 2 | 4 | 56

|

| 049 | "Oil collection tray"

| Warped/Deformed | Misalignment of components, improper fit | 7 | Improper manufacturing | 1 | Specify process, Material selection | 1 | 7 | None | Manufacturing | None | 7 | 1 | 1 | 7 |

| Fractured/Leaking | Hot oil released from machine, possibly onto user | 9 | Improper handling or manufacturing | 3 | Material Selection, Packaging, Quality control measures | 4 | 108 | Drop test with and without packaging | Reliability | None | 6 | 3 | 4 | 108

| ||

| 051 - 052 | "Front and Back Panels"

| Reaches excessive temperature during use | Burns user if contacted accidentally | 9 | Poor design, material selection, heat transfer | 6 | Material selection, Safety analysis | 4 | 216 | Redesign necessary, choose less conductive material, insulate the housing | Research and Development | None | 9 | 6 | 4 | 216 |

| Fractured | Exposure/Misalignment of components and heat release | 6 | Improper handling | 4 | Material Selection, Packaging | 4 | 96 | Drop test with and without packaging | Reliability | None | 6 | 4 | 4 | 96 | ||

| 053 | "Top Window 1"

| Oil splatters from machine | Hot oil able to get on user | 9 | Poor design, alternative ways to release heat | 6 | Inspect alterative designs for heat transfer | 4 | 216 | Design alternative ways to safely release heat | Research and Development | None | 9 | 6 | 4 | 216 |

| 055 | "Power cord"

| Short circuit | Unit unable to function | 8 | Cord Pinching | 2 | Set assembly process | 4 | 80 | Test completed units before distribution | Assembly | None | 8 | 2 | 4 | 64 |

| Internal cord problem | 1 | Choose reliable supplier | 4 | 32 | Test completed units before distribution | Assembly | None | 8 | 1 | 4 | 32 |

Design for Environment (DFE)

Surface Level Environmental Impact

In considering environmental implications of this appliance, it is important to consider both the direct effects (material flow) and the indirect effects (gaseous emissions) during the complete life cycle. Whereas market research demonstrated the material flow associated with consumer use, the product dissection showed the complex array of individual components and sub-assemblies required for proper function, implying that much of the material and energy consumption will occur during the manufacturing phase. An inexpensive kitchen appliance is designed to have a finite lifespan, where it becomes cheaper to replace the product than to repair it. This conclusion is justified by the excessive difficulty with which the components are removed and replaced, indicating that disposal will be a significant aspect to consider.

The direct, or visible, effects were observed during the market research. From a consumer’s perspective, this includes:

- Large amount of detergent/water/paper towels to clean, as oil gets on nearly every component of appliance

- Waste oil must be disposed of after each use

- Plastic casing gets extremely hot, leading to waste heat energy

- Only one doughnut is pulled through at a time, implying that the conveyor/heater must remain active for a much longer period of time to produce one batch, drawing much more energy

- This consumes an obscenely large amount of electricity per doughnut

- Excess dough is wasted due to the dispensing unit

- Complexity of product ensures that it can never be reasonably recycled by consumer, as it cannot be separated into plastic/metal components

The indirect effects come from further research, and will be highlighted in the following subsection of EIO-LCA.

Material Considerations

The product dissection allows us to further understand the material flow put into the product during manufacturing and assembly.

- Plastic

- Nearly the entire assembly is built of injection-molded plastic and is designed to be disposable. Non-recycled plastic will not degrade in a landfill. These parts cannot be easily disassembled for replacement. Energy is consumed (and consequently pollutants emitted) during the processing of such plastics.

- Metal

- Several crucial parts are built of metal, but they are designed to be removed and will not be recycled by the consumer. Energy is consumed in the extraction and processing of metals.

EIO-LCA Model

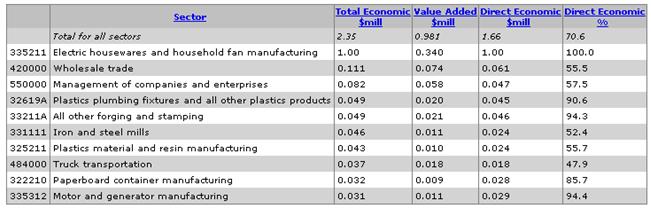

The Economic Input-Output Life Cycle Assessment (EIO-LCA) model allows us to explore the tangential sectors that will contribute to the product’s net environmental implications. An automated doughnut maker can best be described as a novelty kitchen appliance designed for a niche market; it is not expected to be found in every home. However, from an engineering and environmental impact perspective this product follows a similar life cycle to that of a toaster, coffee pot, or waffle iron. It combines injection-molded plastic pieces with a simple heating element and basic mechanical components. Therefore, while it does not explicitly fall under a category, we can make a reasonable assumption that the life cycle of our product is comparable to those found in #335211 Electric Housewares and Household Fan Manufacturing.

Economic Activity

Conventional Air Pollutants

Greenhouse Gases

Energy

Toxic Release

Conclusions

This model simulates environmental response values for $1,000,000 of economic input activity. We see that the majority of emissions come from power generation, which constitutes approximately 31% of all CO2 emissions. This doughnut maker, at $100 per unit, can be produced at 10,000 units per $1,000,000 input. Therefore, if 10,000 units produce 693 metric tons of CO2, this equates to 69.3 kg-CO2 per doughnut maker.

Beyond the effects of electricity generation, other major sources of CO2 emissions come from the production of metals (8%), transportation (8%), and the product’s manufacturing process itself (7%).

Electricity generation associated with this product accounts for more than half of all sulphur dioxide (SO2) emissions, one of the chief chemicals contributing to acid rain. Truck transportation is responsible for the large quantity of Carbon Monoxide (CO) that is released into the atmosphere, a chemical that is characteristic of incomplete combustion.

Given the knowledge that electricity consumption has far more critical implications than the materials involved in creating the product, it seems unreasonable to attempt to change these. There are no particularly elaborate materials used and there are areas of consumer usage that would be ideal for environmental analysis and redesign.

The most significant improvement would come by reducing the electrical consumption per doughnut. This could be achieved by carrying multiple doughnuts through the oil simultaneously (instead of letting each doughnut cycle fully (~1 min) before the next doughnut is dispensed). This has the potential to reduce the time from 2+ hours to a matter of minutes without significantly affecting the production. Maintaining oil temperature and powering the conveyor belt for this duration is extremely energy intense. This time should be kept to a minimum.

Mechanical Analysis

Team Members & Roles

Michael Barako - DFE, Mechanical Analysis

Meng Yee Chuah - Mechanical Function

Katie McManus - Assembly Photos, DFMA

Sam Powers - Bill of Materials, FMEA

Sara Whitby - Executive Summary, Major Stakeholders, Usage and Usability