Water filtration pump

From DDL Wiki

Contents |

Primary Stakeholders and Product Needs

Consumers:

Target Consumers: Backpackers, people without access to clean water (3rd world countries)

- Pumps water

- Drinkability – Purifies well

- Portable (light)

- Pump water quickly

- Cheap

- Durable

- Product lifetime/filter lifetime

- Sustainable

- Easy to sterilize/clean

- Safe

- Non-toxic

- Works with existing products (Nalgene, CamelBaks)

Retailers:

Target Retailers: Outdoor equipment stores/sport stores (REI, Dicks), Internet

- Cheap

- Sustainable

- Attractive

- Profitable

- Safe

Manufacturers:

- Cheap

- Simple design (few parts)

- Compatible with large scale manufacturing processes (Injection molding)

- Easy to assemble

- Standardized/interchangeable parts

- Safe

Shipping/Transport:

- Sturdy

- Light weight

- Compact

- Stackable

Product Function and Evaluation

Usage

Find the cleanest possible source of water. The intake hose is unwound, and then the intake hose is inserted into the water source. Attach the pump to the water container. Pump water at a steady rate, until container is full. Pull the intake hose out of the water, and pump to clear pump of any additional water.

Mechanical Function

The product contains a lever that is attached to a pump with two check valves. On the intake stroke, the intake check valve allows water through the water source into the piston. On the compression stroke, the intake check valve is closed and the bottom check valve allows water to be forced through the filter chamber. The filtered water is then sent out of the pump.

List of Parts

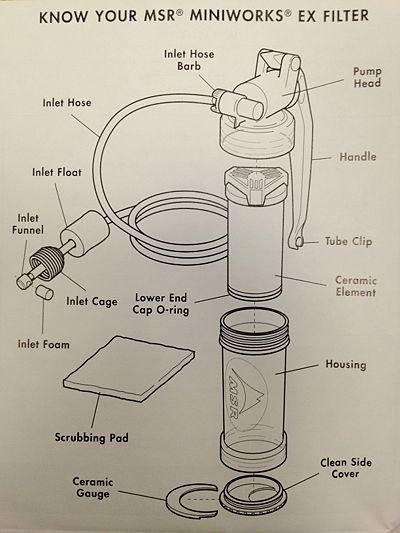

The following details the list of parts of a MSR MiniWorks EX Microfilter.

| Part Number | Name | Quantity | Mass (g) | Subassembly | Function | Material | Manufacturing Process | Image |

|---|---|---|---|---|---|---|---|---|

| 101 | Divert Cap | 1 | 0.5 | Hose Barb | Plastic | Pending Image | ||

| 102 | Washer | 1 | <1 | Hose Barb | Steel | Pending Image | ||

| 103 | Spring | 1 | 2 | Hose Barb | Steel | Pending Image | ||

| 104 | Hose Barb O-Ring | 1 | 0.5 | Hose Barb | Rubber | Pending Image | ||

| 105 | Hose Barb | 1 | 3 | Hose Barb | Plastic | Pending Image | ||

| 201 | Hose | 1 | 44 | Inlet Hose | Rubber | Pending Image | ||

| 202 | Buoy | 1 | <1 | Inlet Hose | Foam | Pending Image | ||

| 203 | Debris Cage | 1 | 11 | Inlet Hose | Steel | Pending Image | ||

| 204 | Intake | 1 | 1 | Inlet Hose | Plastic | Pending Image | ||

| 205 | Foam Filter | 1 | <1 | Inlet Hose | Foam | Pending Image | ||

| 301 | Piston Cap | 1 | 56 | Piston | Plastic | Pending Image | ||

| 302 | Piston | 1 | 9 | Piston | Plastic | Pending Image | ||

| 303 | Piston O-Ring | 1 | 2 | Piston | Rubber | Pending Image | ||

| 304 | Piston Pivot Sleeve | 1 | 1 | Piston | Plastic | Pending Image | ||

| 305 | Piston Pivot Pin | 1 | <1 | Piston | Plastic | Pending Image | ||

| 306 | Handle Pivot Sleeve | 1 | 2 | Piston | Plastic | Pending Image | ||

| 307 | Handle Pivot Pin | 1 | 1 | Piston | Plastic | Pending Image | ||

| 308 | Handle | 1 | 49 | Piston | Plastic | Pending Image | ||

| 309 | Piston Umbrella Valve | 1 | <1 | Piston | Rubber | Pending Image | ||

| 401 | Top Cap | 1 | 18 | Filter | Plastic | Pending Image | ||

| 402 | Outlet Cap | 1 | 10 | Filter | Plastic | Pending Image | ||

| 403 | Ceramic Filter | 1 | 42 | Filter | Ceramic | Pending Image | ||

| 404 | Carbon Filter | 1 | 34 | Filter | Carbon | Pending Image | ||

| 405 | Filter O-Ring | 1 | 4 | Filter | Rubber | Pending Image | ||

| 501 | Filter Body | 1 | 97 | Body | Plastic | Pending Image | ||

| 502 | Clean Cap | 1 | 18 | Body | Plastic | Pending Image | ||

| 503 | Filter Gauge | 1 | 5 | Body | Plastic | Pending Image |

References

Cascade Designs, Inc. MSR MiniWorks EX Water Filter. 24 Jan. 2012. Instruction Manual. Seattle, WA.