Drink Cooler Innovation

From DDL Wiki

Contents |

Executive Summary

Market Analysis

Market Research

Survey 1

To understand if there was a market for our product and in which direction to take the improvements we created a survey. The purpose of the survey was essentially to determine how cold people like their drinks, how they normally cool them, how they cool them in an emergency and at a social event how long they are willing to wait for their drinks to be cold. We distributed the survey at a social gathering and online and got over 45 useful responses.

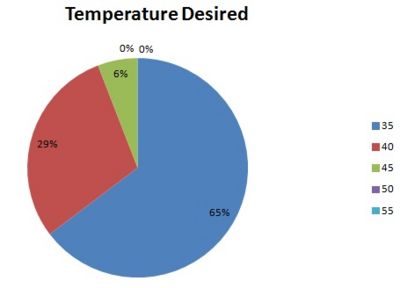

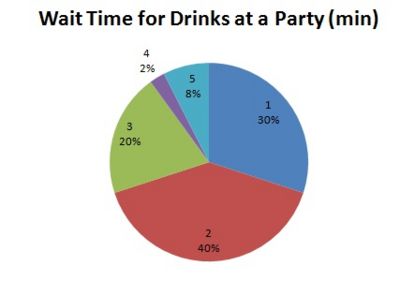

We found that people like their drinks really cold and as seen in the graph above over 94% of the sample would like their drink to be under 40 Fahrenheit. We also found using a separate question that only 10% would wait more than 3 minutes for their drink to be cooled and only 30% would wait more than 2 minutes as seen below in the graph. This definitely showed us there is a market for ice cold drinks that need to be cooled quickly.

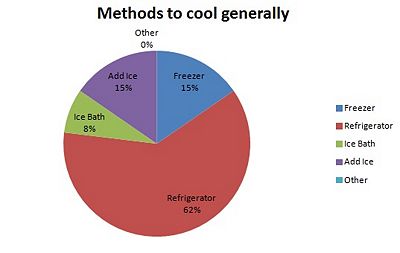

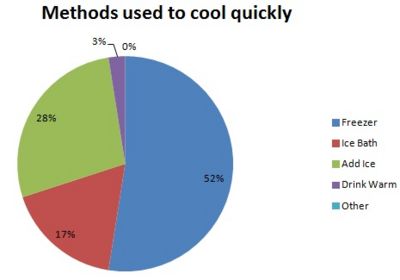

To see what we are dealing with currently we asked people how they cool their drinks given they have time and do not need to do it in a rush. We found that interestingly a majority of 62% would use a refrigerator however given an emergency where drinks need to be cooled quickly we found that over 50% now prefer a freezer. Hence clearly there is a need for a product that has to beat a freezer at quick and efficient cooling.

Having seen in the survey that there is a demand for cooling drinks quickly, we decided to study the difficulties people faced with current quick cooling methods.

Anthropological Observation

In this study, one of the group members turned up for a small party with a case of 24 room-temperature canned drinks. Since the guests at the party wanted to have some of the canned drinks, the host brought out a small bucket of water and emptied two trays of ice into it. He left some of the cans to cool inside the bucket. After a handful of drinks were cooled using this method, the ice had completely melted and the water come up to room temperature. Once the ice had melted, the host tried looking for ice at his neighbors’ place but did not manage to get hold of any. The unopened drinks that were not cooled were just tucked into the freezer. This study, allowed us to observe the use of the ice bath. The use of the ice bath was messy and the cooling process took a long time. Above all, it was inconvenient as it required a large amount of ice that users may usually not have. We thus realized that there would be strong demand for ice-less cooling techniques and decided to take a step further to see how our competitor’s product fared with respect to the more crude techniques of cooling drinks.

User Study for the Competitor’s Product

We conducted two user studies for our competitor’s product, the Blitz Chiller. The first study, the host was having an impromptu gathering on a weekend night with 5-6 guests. Unfortunately, the host did not have space in the refrigerator to keep drinks cool at all time and only had access to room temperature beer. They thus used the Blitz Chiller to chill the drinks. The second scenario observed was slightly different. A couple users had just returned from the store having bought beverages on a weekend evening. They wanted to drink a beer each, but it was all at room temperature. They used the drink cooler to cool two beverages for themselves. In both cases, the users took about five minutes to figure out how to operate the machine. Once, they figured out how to operate the machine, they started cooling their drinks. However, there were a few problems we observed during the usage of the Blitz Chiller. The most important problem we noticed was that the Blitz Chiller cooled about 4 canned drinks with two trays of ice to a consumable temperature. The ice bath study showed us the ice bath too could cool about 4 drinks with two trays of ice to a consumable temperature. The Blitz Chiller thus had an ice consumption seemed similar to the ice bath. Thus soon after the users used up the two trays of ice available in their fridge, they had to go searching for ice. In addition to the need for a large amount of ice, the Blitz Chiller had a few other drawbacks. First, it was a very loud machine. People were forced to speak louder than usual and the television volume was had to be turned up. This is obviously not an ideal scenario. Second, the lid did not function well. On some occasions it would pop open while the device was running. Other times, it would take several tries to open. Third, the water proofing on the lid was weak as water dripped out constantly. Finally, changing the water was a hassle. This task is hard to do with just one person. The lid does not open fully, forcing the user to tilt the device at awkward angles to get the ice out. Pouring in new water is also a hassle for the same reason.

User Interviews for the Competitor’s Product

We followed up the user studies with user interviews. Users were interviewed to get a better understanding of their opinions on the product. The general consensus was that requirement of ice was a significant constraint to the usability of the product. Loading and changing ice into the device was time-consuming and clumsy. Also, a larger cooling capacity (multiple drinks at once) was desired. With the current one drink limit, this cooling method was not much more efficient than the alternative of an ice-water bath, which could be used to cool multiple drinks at once. The one drink limit also meant that somebody always has to constantly be operating the device in order to cool enough drinks. The noise generated by the device was also a problem. It made holding conversations in the same room as the device uncomfortable. In summary, the users felt that the current product had limited use. The requirement of ice and low capacity made it marginally better at cooling beverages than an ice bath yet more of a hassle. The noise didn't help. This made the device only practical for cooling 1-2 drinks at a time. One user suggested developing a product that doesn't need ice and marketing the product for a situation where users would not have access to a refrigerator.

From our survey, anthropological study, user studies and user interviews, it seems clear that there is demand for a quick cooling mechanism that does not use ice. We were thus convinced that our product would have a strong market. We thus proceeded to develop our product, an ice-free, convenient way to cool drinks. After developing the product, we carried out another survey to gauge how much people value our product.

Survey 2

Product Development Economics

Data of the sales of our competitor’s product was unavailable. In addition, similar innovative cooling mechanisms by smaller companies did not have sales figures either. We thus looked at the production level of the most commonly available cooling device, the refrigerator. About 8 million refrigerators are sold every year in the USA (Reference). Assuming refrigerators are uniformly distributed among the various economic classes, about 2 million refrigerators are being used by the top 25% in the economic spectrum. We can thus look at these 2 million households, who feel the need for a cooling device, as our potential market. Assuming we can reach between 1-10% of this market, we are looking at a total production volume of between 2000 and 200000 over the lifetime of our product. Using this estimate on the production volume of our product, we developed a ballpark estimate for the cost of manufacturing our product by focusing on the most costly components involved in making our product.