From DDL Wiki

(Difference between revisions)

m |

m |

| Line 188: |

Line 188: |

| | | [[Image:Team1-FBD-Hook.JPG|300px]] || '''Bending'''<br /> | | | [[Image:Team1-FBD-Hook.JPG|300px]] || '''Bending'''<br /> |

| | Cross sectional area: 42.9 mm<sup>2</sup> (for one hook)<br /> | | Cross sectional area: 42.9 mm<sup>2</sup> (for one hook)<br /> |

| - | Cross sectional area: 85.8 mm<sup>2</sup> (P/2 is for hook assembly - 2) | + | Cross sectional area: 85.8 mm<sup>2</sup> (P/2 is for hook assembly - 2)<br /> |

| | Second moment of area about centroidal axis: 124.5 mm<sup>4</sup><br /> | | Second moment of area about centroidal axis: 124.5 mm<sup>4</sup><br /> |

| | Maximum bending moment: 1780 N*mm<sup>2</sup><br /> | | Maximum bending moment: 1780 N*mm<sup>2</sup><br /> |

Revision as of 03:19, 8 March 2007

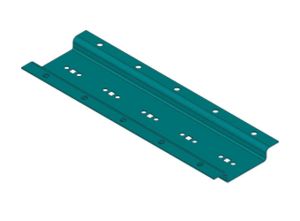

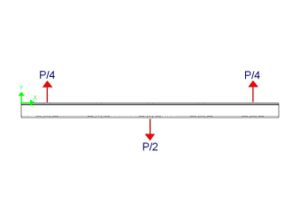

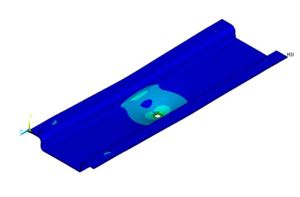

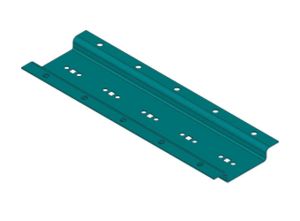

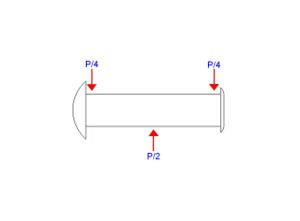

Part # 001: Ceiling Bracket

| Images | Calculations |

|

| Material: Carbon steel

E = 202,700 N/mm2

Yield strength = 220 Mpa

Sheet thickness = 1.22 mm

Loads

P/2 = 111.2 N

P/4 = 55.6 N

(P = 50 lbs)

|

| Bending along X-axis

Distance between support forces: 200 mm

Vertical centroid: -7.57 mm (measure from top surface)

Second moment of area about centroidal axis: 3510 mm4

Maximum bending moment: 5,560 N*mm2

Maximum x-bending stress: 9.47 N/mm2 = 9.47 Mpa

|

| Bending along Z-axis

Distance between support forces: 70 mm

Vertical centroid: -.66 mm (measure from top surface)

Second moment of area about centroidal axis: 37.8 mm4

Maximum bending moment: 1,946 N*mm2

Maximum z-bending stress: 3.4 N/mm2 = 3.4 Mpa

Maximum net bending stress: 10.1 Mpa

|

Stress Concentration Factor

h = 1.22 mm (sheet thickness)

w = 50 mm (section width)

d = 6 mm (hole size)

d/w = .12 d/h = 5

K = 1.7 - From table A-15-12 of (Shigley, Mechanical Engineering Design)

Actual Maximum Stress = 17.1 Mpa

Safety Factor = 12.9 Mpa

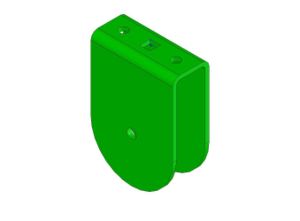

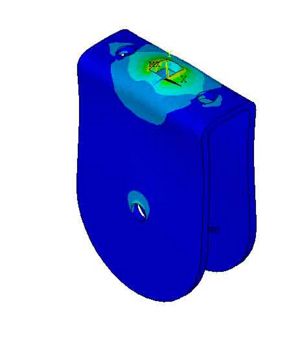

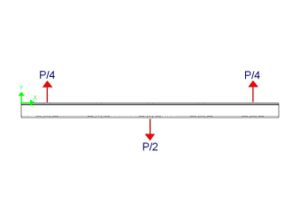

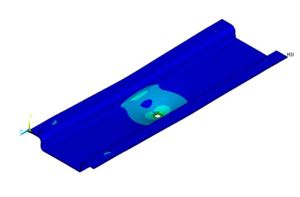

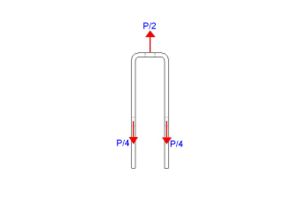

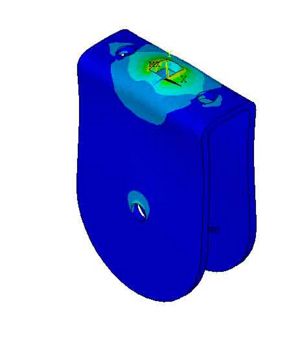

Part # 002: U-Pulley Mount

| Images | Calculations |

|

| Material: Carbon steel

E = 202,700 N/mm2

Yield strength = 220 Mpa

Sheet thickness = 2.29 mm

Loads

P/2 = 111.2 N

P/4 = 55.6 N

(P = 50 lbs)

|

| Bending along X-axis

Distance between support forces: 20 mm

Vertical centroid: -1.15 mm (measure from top surface)

Second moment of area about centroidal axis: 20.0 mm4

Maximum bending moment: 400 N*mm2

Maximum x-bending stress: 23.0 N/mm2 = 23.0 Mpa

|

| Stress Concentration Factor

h = 2.29 mm (sheet thickness)

w = 48 mm (section width)

d = 6 mm (hole size)

d/w = .13 d/h = 2.6

K = 1.7 - From table A-15-12 of (Shigley, Mechanical Engineering Design)

Actual Maximum Stress = 39.1 Mpa

Safety Factor = 5.6 Mpa

|

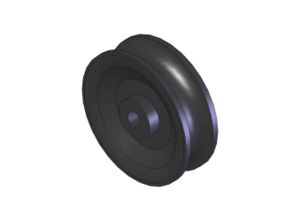

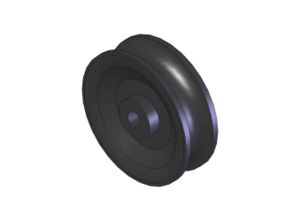

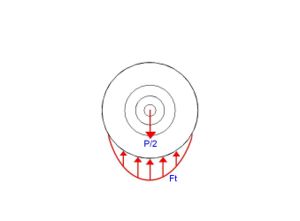

Part # 003: Pulley Wheel

| Images | Calculations |

|

| Material: Injection molded plastic

E = 3,500 N/mm2

v = .4

Yield strength = 103 Mpa

Loads

P/2 = 111.2 N

Ft = force resulting from tension in rope

(P = 50 lbs)

|

| Contact Stress

Diameter 1: 5.3 mm

Diameter 2: 4.9 mm

Contact length = 13.5mm

Half-width of contact surface = 2 mm

Maximum Compressive Stress = 4.2 Mpa

Safety Factor = 24.5

|

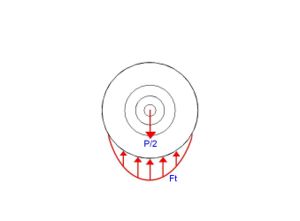

Part # 004: Pulley Rivet

| Images | Calculations |

|

| Material: Aluminum

E = 69,000 N/mm2

Yield strength = 95 Mpa

Loads

P/2 = 111.2 N

P/4 = 55.6 N

(P = 50 lbs)

|

| Shear Stress

Diameter: 4.9 mm

Length = 20 mm

Maximum shear force = 55.6 N

Shear area = 18.9 mm2

Maximum Compressive Stress = 2.9 Mpa

Safety Factor = 32.3

|

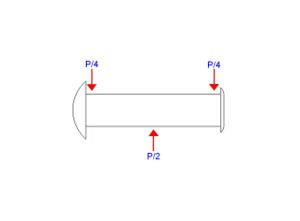

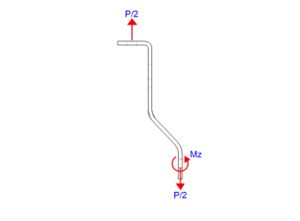

Part # 012: V-Bracket

| Images | Calculations |

|

| Material: Carbon steel

E = 202,700 N/mm2

Yield strength = 220 Mpa

Sheet thickness = 2.29 mm

Loads

P/2 = 111.2 N

Mz = 1780 N*mm

(P = 50 lbs)

|

| Bending at Neck

Distance from support force: 10 mm

Cross sectional area: 36.6 mm2

Second moment of area about centroidal axis: 16.0 mm4

Maximum bending moment: 556 N*mm2

Maximum bending stress: 15.2 N/mm2 = 15.2 Mpa

|

| | Stress Concentration

r: 2 mm

d: 16 mm

D: 18 mm</sup>

D/d = 1.1

r/d = .13

K = 1.6 - From table A-15-5 of (Shigley, Mechanical Engineering Design)

Actual Maximum Stress = 24.3 Mpa

Safety Factor = 9.1 Mpa

|

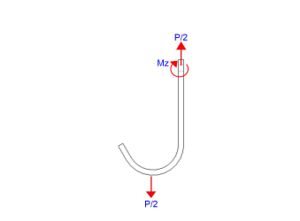

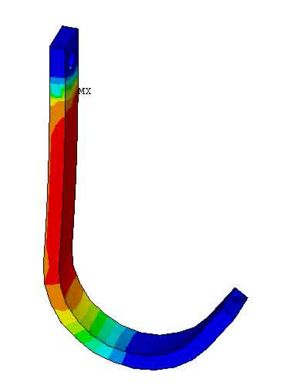

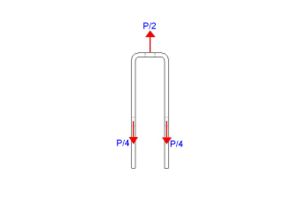

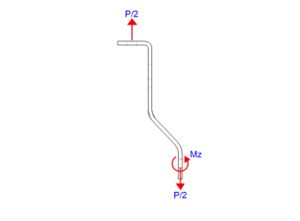

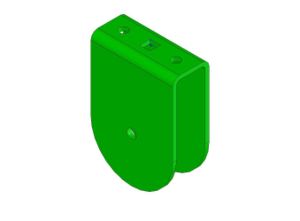

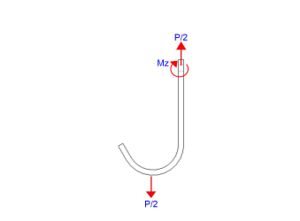

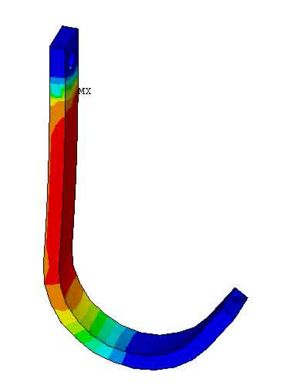

Part # 013: Hook

| Images | Calculations |

|

| Material: Carbon steel

E = 202,700 N/mm2

Yield strength = 220 Mpa

Sheet thickness = 4.17 mm

Loads

P/2 = 111.2 N

Mz = 1780 N*mm

(P = 50 lbs)

|

| Bending

Cross sectional area: 42.9 mm2 (for one hook)

Cross sectional area: 85.8 mm2 (P/2 is for hook assembly - 2)

Second moment of area about centroidal axis: 124.5 mm4

Maximum bending moment: 1780 N*mm2

Maximum bending stress: 29.8 N/mm2 = 29.8 Mpa

|

| Actual Maximum Stress = 29.8 Mpa

Safety Factor = 7.4 Mpa

|