Chain drive opportunity

From DDL Wiki

(→User Study) |

(→User Study) |

||

| Line 20: | Line 20: | ||

We designed a study to identify normal issues with the pretension and function of maintenance on the drivetrain of the Carnegeie Mellon Racing Formula SAE car. This vehicle is representative of the set up used both in the FSAE series but also in other low cost racing series. Two mechanically inclined individuals who did not have prior knowledge of the car’s design were asked to loosen the chain completely and re-tighten the driveline. This was done with the car elevated. | We designed a study to identify normal issues with the pretension and function of maintenance on the drivetrain of the Carnegeie Mellon Racing Formula SAE car. This vehicle is representative of the set up used both in the FSAE series but also in other low cost racing series. Two mechanically inclined individuals who did not have prior knowledge of the car’s design were asked to loosen the chain completely and re-tighten the driveline. This was done with the car elevated. | ||

| - | |||

| - | |||

| - | |||

The first thing observed in this study was that access to adjustment turnbuckles was very limited. This was compounded by the fact that tools were not common between the separate locking nuts and the turnbuckles. The lack of access also made finding the position desired for the plates was hard. | The first thing observed in this study was that access to adjustment turnbuckles was very limited. This was compounded by the fact that tools were not common between the separate locking nuts and the turnbuckles. The lack of access also made finding the position desired for the plates was hard. | ||

| - | |||

| - | |||

Towards the end of the study lots of confusion was noticed surrounding determining how tight the chain needed to be and whether the differential housing was indeed aligned properly. This meant a lot of time wasted trying to figure out how to determine these specifications and also how to see if they were close to these. “When are we done here?” was the common phrase used. This shows a key flaw in the system, there is no way to indicate alignment and tension. | Towards the end of the study lots of confusion was noticed surrounding determining how tight the chain needed to be and whether the differential housing was indeed aligned properly. This meant a lot of time wasted trying to figure out how to determine these specifications and also how to see if they were close to these. “When are we done here?” was the common phrase used. This shows a key flaw in the system, there is no way to indicate alignment and tension. | ||

| - | |||

They ended up just pulling on the chain to determine tension (a That looks about right method) and then standing back a bit and closing one eye to gauge alignment. It seemed as though they got a grasp on the whole process fairly well but were confounded by the end goal. There is no specification for chain tension on a project like this (custom race car) and while trying to also align the differential this made determining when they were finished hard. | They ended up just pulling on the chain to determine tension (a That looks about right method) and then standing back a bit and closing one eye to gauge alignment. It seemed as though they got a grasp on the whole process fairly well but were confounded by the end goal. There is no specification for chain tension on a project like this (custom race car) and while trying to also align the differential this made determining when they were finished hard. | ||

| + | |||

| + | {| style="background: transparent; margin: auto;" | ||

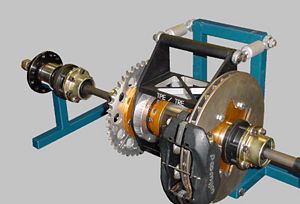

| + | |[[image:Diff1.jpg|300px|thumb|center|Loosening and Pretension the Drivetrain]] | ||

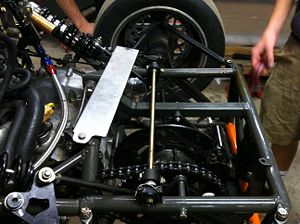

| + | |[[image:Diff2.jpg|300px|thumb|center|Difficult access]] | ||

| + | |[[image:Diff3.jpg|300px|thumb|center|Is it tight?]] | ||

| + | |} | ||

===User Interviews=== | ===User Interviews=== | ||

Revision as of 21:46, 4 October 2012

Contents |

Executive Summary

Market Research

In order to ascertain the market in which this product would exist we looked into the needs of small scale racing teams, such as Formula SAE teams and more widespread amateur racing series. This includes entry level series such as the Radical SR1 cup and other racing cars built to use motorcycle engines. In order to determine stakeholder needs we performed a user study and interview, Interviews with professionals and survey results.

Stakeholder Needs

Competitor Products

Before deciding on a path for the rest of the market research we first came up with a market space and found competitor products.

User Study

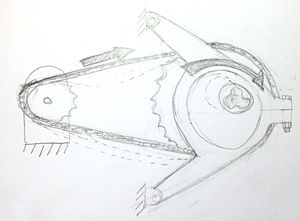

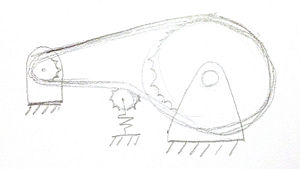

We designed a study to identify normal issues with the pretension and function of maintenance on the drivetrain of the Carnegeie Mellon Racing Formula SAE car. This vehicle is representative of the set up used both in the FSAE series but also in other low cost racing series. Two mechanically inclined individuals who did not have prior knowledge of the car’s design were asked to loosen the chain completely and re-tighten the driveline. This was done with the car elevated.

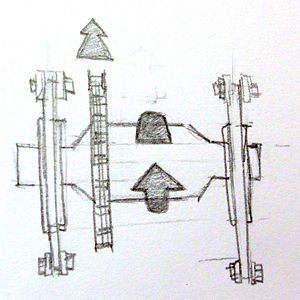

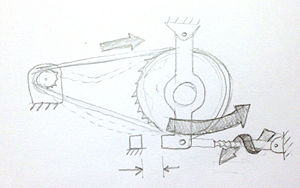

The first thing observed in this study was that access to adjustment turnbuckles was very limited. This was compounded by the fact that tools were not common between the separate locking nuts and the turnbuckles. The lack of access also made finding the position desired for the plates was hard.

Towards the end of the study lots of confusion was noticed surrounding determining how tight the chain needed to be and whether the differential housing was indeed aligned properly. This meant a lot of time wasted trying to figure out how to determine these specifications and also how to see if they were close to these. “When are we done here?” was the common phrase used. This shows a key flaw in the system, there is no way to indicate alignment and tension.

They ended up just pulling on the chain to determine tension (a That looks about right method) and then standing back a bit and closing one eye to gauge alignment. It seemed as though they got a grasp on the whole process fairly well but were confounded by the end goal. There is no specification for chain tension on a project like this (custom race car) and while trying to also align the differential this made determining when they were finished hard.