Coffeemaker

From DDL Wiki

(→Design For Manufacturing and Assembly (DFMA)) |

(→Failure Modes and Effects Analysis (FMEA)) |

||

| Line 176: | Line 176: | ||

= Failure Modes and Effects Analysis (FMEA) = | = Failure Modes and Effects Analysis (FMEA) = | ||

| + | |||

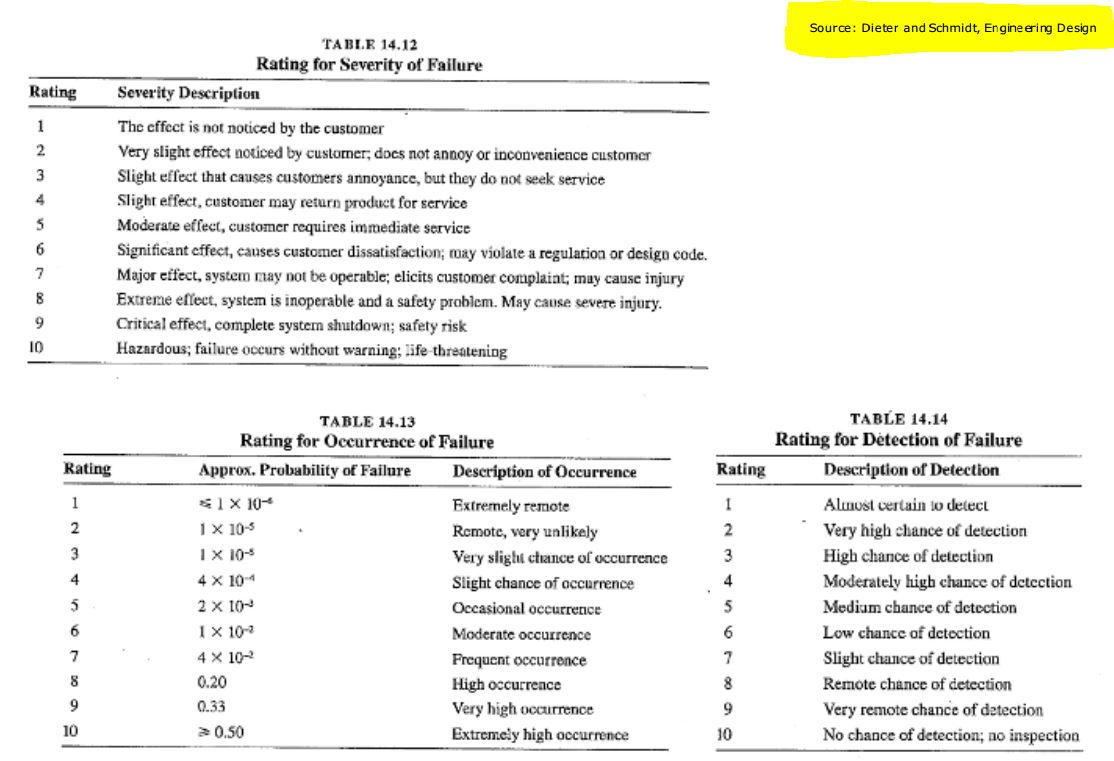

| + | '''Scale for Severity, Occurrence, and Detection of Failure''' | ||

| + | [[Image:coffeemaker_scale_of_failure.jpg]] | ||

{| class="wikitable sortable collapsible" border="1" cellspacing="0" align="center" style="text-align:center" | {| class="wikitable sortable collapsible" border="1" cellspacing="0" align="center" style="text-align:center" | ||

Revision as of 19:12, 30 January 2014

Contents |

Product Introduction

Product: Hamilton Beach 12-Cup Coffee Maker

Executive Summary

Major Product Needs for Major Stakeholders

Customers A customer wants it to be easy to setup, easy to figure out the right proportions, and easy to dispense. Coffee shouldn’t come out burnt, and should be quick and reliable.

Retailer The retailer demands small packaging and arrangeable for stacking and shipping. The current design has large rectangular packaging and fairly light weight.

Product Use Study

What's Easy? Easy to plug in and turn on. Coffee maker shows amount of water labeled and visible.

What’s Non Intuitive? Not easy to tell if its programmable. Also, figuring out if it needs cleaning and how to clean it.

What’s Challenging? Difficult to figure out proportions of water to ground coffee. Figuring out the first steps for draining out the plastic residue as stated on the instruction manual.

Steps for Using Product: 1) Wash the coffee maker following the cleaning instructions on the pamphlet packaged with the product. 2) Plug in the coffee maker to an outlet. Do not turn on. 3) Have a cone shaped coffee filter ready and place it inside the plastic filter basket. 4) For one cup of medium strength coffee, have one tablespoon of ground coffee ready and dumped into the coffee filter. 5) Fill the glass pitcher with one cup of water, then lift the coffee maker lid and dump the water into the back bin of the coffee maker. 6) Place the glass pitcher back inside the coffee maker onto the hot plate. 7) Close the coffee maker lid and turn on the coffee maker.

Mechanical Operations: First observations about the mechanics behind the coffee maker include a pump inside the base to channel hot water through the coffee lid and into the coffee filter, where hot water seeps down into the glass pitcher. The coffee maker lid acts to open up the coffee maker channel of bringing hot water up and into the coffee filter. There is an electric heater to bring the poured water up to very hot temperatures.

Parts List

The following table is a list of all the parts that come out of the coffeemaker. The picture below is an exploded view of our coffeemaker with all the components shown and labeled.

Bill of Materials

The following is a table of individual components, assemblies and certain off the shelf parts that we took apart during our dissection process of the coffeemaker.

| Part Number | Name | QTY | Weight (g) | Function | Material | Manufacturing Process | Image |

|---|---|---|---|---|---|---|---|

| 1 | Cubic Peg for Metal Strip | 1 | 0.79 | Holds the metal strip that goes around the glass container | Plastic | Injection Molding | |

| 2 | Screw for the Glass Container | 1 | 1.30 | Tighten up the metal strip | Aluminum | Standard Purchase Part | |

| 3 | Lid for the Glass Container | 1 | 16.12 | Lid of the Glass Container | Plastic | Injection Molding | |

| 4 | Metal Strip for the Glass Container | 1 | 15.60 | Goes around the glass container | Aluminum | Rolling and Machining | |

| 5 | Handle for the Glass Container | 1 | 39.77 | Handle of the glass container | Plastic | Injection Molding | |

| 6 | Filter Lever | 1 | 1.92 | A spring controlled lever within the filter that allows the boiled coffee to go into the glass container | Plastic | Injection Molding | |

| 7 | Filter Spring | 1 | 0.41 | Attached to the filter lever and controls and coffee flow | Aluminum | Standard Purchase Part | |

| 8 | White Filter Rubber Piece | 1 | 0.24 | Cover of a hole within the filter | Rubber | Injection Molding | |

| 9 | Filter | 1 | 42.27 | Perform as a intermediate container for the boiled water and ground coffee | Plastic | Injection Molding | |

| 10 | Plastic Lid | 1 | 87.43 | Lid for the coffeemaker and carries hot water to coffee | Plastic | Injection Molding | |

| 11 | Cardboard Piece | 1 | 6.72 | Covers the area of thermal paste that applied onto the heater | Cardboard | Standard Purchase Part | |

| 12 | Bottom Screws | 5 | 0.57 | Tighten the bottom lid with the bottom half of the coffeemaker | Aluminum | Standard Purchase Part | |

| 13 | Plastic Bottom Lid | 1 | 89.69 | Cover for base of the coffeemaker | Plastic | Injection Molding | |

| 14 | Plastic Ring | 1 | 37.56 | Holds heating plate | Plastic | Injection Molding | |

| 15 | Insulator Rubber Band | 1 | 12.50 | Insulation for the heater plate | Rubber | Injection Molding | |

| 16 | Heater Plate | 1 | 89.28 | Keeps the glass container heated and in place | Aluminum | Casting | |

| 17 | Heater Plate Screw | 1 | 2.48 | Attach the heater plate to the bottom lid of the coffeemaker | Steel | Standard Purchase Part | |

| 18 | Rectangular Lid Piece | 1 | 1.63 | Supports the coffeemaker lid when it is open | Plastic | Injection Molding | |

| 19 | Rubber Tube Rings | 4 | 0.55 | Tighten and put the tubes in place | Copper | Machining | |

| 20 | Heater Bar | 1 | 20.22 | Holds the heater in place | Aluminum | Extrusion and Machining | |

| 21 | Heater | 1 | 110.86 | Heats both the water and the container | Aluminum | Casting | |

| 22 | Resistor Piece | 1 | 9.47 | Part of the heater circuit | Assembly | Standard Purchase Part | |

| 23 | Little Screw for Plastic Wire Piece | 2 | 0.61 | Holds wire in place | Aluminum | Standard Purchase Part | |

| 24 | Slightly Larger Screw for Heater | 1 | 0.66 | Holds heater in place | Aluminum | Standard Purchase Part | |

| 25 | Nut for Heater Screw | 1 | 1.21 | Holds the heater in position within the coffeemaker | Aluminum | Standard Purchase Part | |

| 26 | Plastic Piece for Wires | 1 | 0.55 | Functions as a connector for the wires that go into the heater | Plastic | Injection Molding | |

| 27 | Smaller Screw | 6 | 0.63 | Attaches heater plate to coffee machine base | Aluminum | Standard Purchase Part | |

| 28 | Washer for Smaller Screw | 6 | 0.50 | provides greater purchase for smaller screws | Aluminum | Standard Purchase Part | |

| 29 | Top-Bottom Connection Screw | 3 | 0.58 | Connect the top and bottom half of the coffeemaker | Aluminum | Standard Purchase Part | |

| 30 | Lid Lever | 1 | 14.13 | Supports the lid | Plastic | Injection Molding | |

| 31 | Plastic Volume Meter | 1 | 38.3 | Meter of the coffeemaker | Plastic | Injection Molding | |

| 32 | Lid Hinge Connected to Tubes | 1 | 12.07 | Connection between the lid and tubes | Plastic | Injection Molding | |

| 33 | Transparent Tube | 1 | 4.2 | carries water to the coffee maker lid | Rubber | Injection molding | |

| 34 | Opaque Tube | 2 | 8.23 | Carries water to and from the heater | Rubber | Injection molding | |

| 35 | Red Ball | 1 | 0.09 | Part of the valve in the opaque tube | Plastic | Injection Molding | |

| 36 | Base of Switch | 1 | 0.85 | Base of the switch | Plastic | Standard Purchase Part | |

| 37 | Switch | 1 | 0.53 | Control on/off of the coffeemaker | Plastic | Injection Molding | |

| 38 | Tiny Spring | 1 | <0.01 | Part of the switch | Aluminum | Standard Purchase Part | |

| 39 | Tiny Piece from the Switch | 1 | 0.26 | Part of the switch | Plastic | Standard Purchase Part | |

| 40 | Red Heating Connection | 2 | 0.10 | Insulates the wire to heater connection | Rubber | Standard Purchase Part | |

| 41 | Wires Coming out from the Heater | 2 | 0.83 | Carries current to heater | Aluminum | Standard Purchase Part | |

| 42 | White Capacitor Screw | 2 | 0.39 | Put the capacitor in place | Aluminum | Standard Purchase Part | |

| 43 | Washer for Capacitor Screw | 2 | 0.11 | Washer for screw | Aluminum | Standard Purchase Part | |

| 44 | N label | 1 | <0.01 | Label negative of the circuit | plastic tape | Standard Purchase Part | |

| 45 | Switch with Three Wires | 1 | 6.11 | Inside part of the switch | Assembly | Standard Purchase Part | |

| 46 | Blue Wire | 1 | 0.85 | Carries current from switch to heater wires | Copper and Fiber | Standard Purchase Part | |

| 47 | White Wire | 1 | 1.14 | Carries current from switch to heater wires | Copper and Fiber | Standard Purchase Part | |

| 48 | Power Cord | 1 | 50.17 | Carries current from outlet to coffee maker | Copper and Rubber | Standard Purchase Part | |

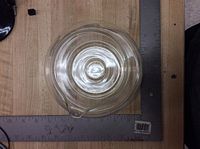

| 49 | Glass Container | 1 | 332 | Coffee Container | Glass | Glass Blowing | |

| 50 | Top Part of Body | 1 | 296 | Top half of the coffeemaker | Plastic | Injection Molding | |

| 51 | Bottom Part of Body | 1 | 196 | Bottom half of the coffeemaker | Plastic | Injection Molding |

Design For Manufacturing and Assembly (DFMA)

| Design for Manufacturing: Strengths and Areas of Improvement | ||

|---|---|---|

| Guideline | Strengths | Areas of Improvement |

| Minimize Part Count:Eliminate fasteners, part consolidation | Many snapping components and hinges. Screws are used to connect only larger components. | Hinge for the lid has too many moving parts to accomplish a simple job |

Failure Modes and Effects Analysis (FMEA)

Scale for Severity, Occurrence, and Detection of Failure

| Item and Function | Failure Mode | Effects of Failure | S | Cause of Failure | O | Design Controls | D | RPN | Recommended Actions |

|---|---|---|---|---|---|---|---|---|---|

| Row 1, column 1 | sadfsdaf | asdfsadf | |||||||

| Row 1, column 2 | |||||||||

| Row 1, column 3 | |||||||||

| Row 2, column 1 |

Design for Environment (DFE)

Analysis Summary

Group 8 Team Members

Lucas Neffa

Andrew Vickory

Nick Ciesielski

Yang Wen

Kaifu Wang

References

1. Dieter, George E., and Linda C. Schmidt. Engineering Design. 5th Edition. New York, NY: McGraw-Hill, 2012. Print.

2. Hamilton Beach 12-Cup Coffee Maker, n.d. photograph, viewed 28 January 2014, <http://www.amazon.com/gp/product/B002EJF8TI/ref=oh_details_o00_s00_i00?ie=UTF8&psc=1>