Folding chair

From DDL Wiki

(→How to Use) |

(→Failure Mode and Effect Analysis) |

||

| Line 348: | Line 348: | ||

| 2 | | 2 | ||

| 48 | | 48 | ||

| + | |- | ||

| + | | rowspan="7" | Leg Endcap - prevent scratching and injury due to sharp metal | ||

| + | | rowspan="3" | falling off | ||

| + | | floor will be scratched | ||

| + | | 3 | ||

| + | | wasn't secured properly | ||

| + | | 8 | ||

| + | | none | ||

| + | | 10 | ||

| + | | 240 | ||

| + | |- | ||

| + | | possible injury | ||

| + | | 4 | ||

| + | | wasn't secured properly | ||

| + | | 8 | ||

| + | | none | ||

| + | | 10 | ||

| + | | 320 | ||

| + | |- | ||

| + | | rocking | ||

| + | | 3 | ||

| + | | wasn't secured properly | ||

| + | | 8 | ||

| + | | none | ||

| + | | 10 | ||

| + | | 240 | ||

| + | |- | ||

| + | | rowspan="3" | wear | ||

| + | | floor will be scratched | ||

| + | | 3 | ||

| + | | longtime use | ||

| + | | 3 | ||

| + | | none | ||

| + | | 10 | ||

| + | | 90 | ||

| + | |- | ||

| + | | possible injury | ||

| + | | 4 | ||

| + | | longtime use | ||

| + | | 3 | ||

| + | | none | ||

| + | | 10 | ||

| + | | 120 | ||

| + | |- | ||

| + | | rocking | ||

| + | | 3 | ||

| + | | longtime use | ||

| + | | 3 | ||

| + | | none | ||

| + | | 10 | ||

| + | | 90 | ||

|} | |} | ||

Revision as of 16:38, 12 February 2012

Contents |

Executive Summary

At this point in our re-design process we have dissected and analyzed a competitors folding chair. Our analysis included a use study, a design for manufacturing study, a design for the environment study, a failure mode analysis study, a design for assembly study and a dissection of a chair; each study gave new insights into folding chairs. We based our analysis on two types of consumers: a consumer who buys a small number of chairs for personal use and a high quantity consumer who would utilize the chairs for events. Through disassembling the product we found the chair had few parts that were made through simple manufacturing processes. However, we also found the chair difficult to take apart, meaning it would be difficult to replace broken parts. In the design for environment study we concluded the best way to minimize the impact of a chair on the environment is to maximize the first life of the chair. In the failure mode analysis we found little safety issues with the chair. Through the following report we discuss these results in detail.

Group Member Information

Joe Wynant - DFMA

Tammy Dvir - DFE

Sarah Kunka - FMEA

Mark Sandusky - Stakeholders Liaison

Will Maher - Team Leader

Stakeholder Wants and Needs

Consumer

Their are many different consumers who require a folding chair. For our study we are focusing on two main groups. First the consumer who buys a chair for his own use, i.e. for special events, dorm rooms or for outdoor seating. The second consumer is one who uses it for business needs i.e. renting out chairs, restaurants or large event facilities. We believe that both consumers have similar wants, these wants are shown below.

- Comfort

- Portability

- Weight

- Nesting

- Cost

- Storage

- Ergonomics

- Safety

- Stability

- Durability

- Ease of use

- Adjustable

- Aesthetics

- Style

- Features

- Cup holders, armrests, etc.

Retailer

Retailers are looking for a chair that can be sold quickly and take up minimal floor space while at their store.

- Marketability

- Unique product that makes it easy to sell

- Storage/”stack-ability”

- Weight

- Durability

- Returns a profit

Manufacturers

Manufactures want a chair that is cheap and easy to produce.

- Materials

- Easy to manufacture, cheap, or eco-friendly

- Cost efficient processes

- Design that is easy to manufacture

- Simple parts, low number of parts, easy to assemble

Shipping/Transport

Transports companies will also want certain qualities of the chair and its packaging.

- Weight

- Packaging

- Space efficiency, smart packaging

- Durability of packaging and product

Use Study

The folding chair product is quite simple to use and store. Four different models of the folding chair were observed and analyzed for the use study. Operation of each of these models is extremely similar and for the most part exactly the same. However, the team documented the good and bad aspects with each of the models as well as how certain features present in each model compared with one another.

Chair 1

This product was relatively simple to use; the folding mechanism was easy to operate. The chair unfolds easily without much internal resistance from friction for the sliding mechanism. There were no major complaints on using this chair other than the fact that it is a little awkward to carry around. One interesting to note about this chair is that it features a lokcing mechanism that is activeated when the chair is fully unfolded. This mechanism insures that the chair does not accidentally fold again; however it it easy to unlock making it a worthwhile feature.

Chair 2

This use of this product is extremely similar to Chair 1. It is mainly the same product with noticeable aesthetic differences as it is priced higher. This chair does not feature the locking mechanism discussed for Chair 1, however. The chair does get stuck every once in a while folding and unfolding which is a hassle for the user.

Chair 3

The use of this product is similar to the other, however one interesting thing to note is the manner in which this chair folds. Due to certain features in the folding mechanism, the chair folds from the back seat. This chair was the easiest to fold of the four, as the user simply has to grab the back seat and apply a small upward force in order to fold it. All other chairs required two hands to fold while this only needed one. Carrying around this chair was fairly awkward.

Chair 4

This chair was the most different in terms of design and operation. This chair was clearly designed for comfort first and foremost. This is shown by the comfortable material as well as the arm-rests and cup holders. While the most comfortable, the chair was also the most difficult to use. Unfolding the chair is simple and easy to do. Folding the chair back up is a little more difficult to do as it is a little tough to ‘scrunch’ the chair back to its original folded position due to internal friction in the folding mechanism and the fact that is requires two hands to do. Another negative aspect about this chair involved how it is stored. Because the chair is unconventionally shaped, it must be stored in a bag. Placing the chair into the bag proved to be quite frustrating and difficult due to how small the opening in the bag was.

Outside User Survey

Individuals outside of the team were observed using the various models of folding chairs. Differences between how outside users operated the chairs and how the team members operated the chairs were minimal. This is because the operation of folding chairs is a relatively simple and straightforward process. Folding chairs are common objects in everyday life so it can be inferred that the general population is able to use a folding chair without much trouble.

One of the group members has prior experience with the storage and transportation of a large number of folding chairs so a case study about this is provided.

How to Use

- Product is in Folded Position

- One Hand is Placed on Either Front Seat or Arms While Other Hand is Placed on Back Rest. A Force is Applied by Either or Both Hands in Order to Unfold the Chair

- Product is Sat Upon

- When Seating is no Longer Needed Product is Folded Up and Stored

Mechanical Function and Parts

Mechanical Function

The fabric camping chair (Chair 4) uses fixed pins and a scissoring geometry to expand and contract radially. It stops unfolding when the fabric is pulled taught. When folded, the fabric crumples up to save space, which is unique to this chair.

The black folding chair (Chair 2) folds in two dimensions, using a system of fixed pins and hinges. The user’s weight keeps it open, as well as plastic stops on the top of the back legs to set the angle it opens to.

The green folding chair (Chair 1) folds in two dimensions, using a sliding joint and pins. A pin stops the slider from moving any further when the chair folds flat. This chair is able to fold much flatter than the others due to its sliding feature.

The restaurant chair (Chair 3) has the façade of a real chair, while folding in two dimensions. It uses much more complicated pin dynamics to fold up. Where the other 3 chairs fold using triangles and crossing, the restaurant chair folds in a square fashion where nothing crosses.

Bill of Materials

Design for Manufacturing and Assembly

Failure Mode and Effect Analysis

The FMEA (failure modes and effects analysis) is an activity that allows us to rank the relative importance of various possible failure modes based on the severity of the failure in terms of effect on or injury to the user (S), the probability that the failure mode will actually occur (O), and the likelihood of detecting the cause of failure using current design control methods (D). The values assigned to S, O, and D are then multiplied together to obtain a risk priority number (RPN). Items with a higher RPN are a higher risk to the consumer, and so should be given a higher priority in the design review. A full analysis of our results follows the table.

| Item & Function | Failure Mode | Effects of Failure | S | Causes of Failure | O | Design Controls | D | RPN |

|---|---|---|---|---|---|---|---|---|

| Seat, Front Rivet - connect front leg to seat | shear | seat will drop | 8 | excessive weight | 3 | sticker warning against excessive weight | 2 | 48 |

| individual testing in plant | 1 | 24 | ||||||

| fatigue | 3 | 1/100,000 chairs fatigue tested | 4 | 48 | ||||

| improper insertion of rivet | 2 | employee training | 2 | 32 | ||||

| visual inspection | 4 | 64 | ||||||

| material flaw in rivet | 2 | visual inspection | 6 | 96 | ||||

| misuse | 4 | warning stickers | 2 | 64 | ||||

| Seat, Back Rivet - connect back leg to seat | shear | seat will drop | 8 | excessive weight | 2 | sticker warning against excessive weight | 2 | 32 |

| individual testing in plant | 1 | 16 | ||||||

| fatigue | 2 | 1/100,000 chairs fatigue tested | 4 | 64 | ||||

| improper insertion of rivet | 2 | employee training | 2 | 32 | ||||

| visual inspection | 4 | 64 | ||||||

| material flaw in rivet | 2 | visual inspection | 6 | 96 | ||||

| misuse | 3 | warning stickers | 2 | 48 | ||||

| Bracket Rivet - connect bracket to legs | shear | folding the chair will be more difficult | 4 | fatigue | 1 | 1/100,000 chairs fatigue tested | 4 | 16 |

| improper insertion of rivet | 1 | employee training | 2 | 8 | ||||

| visual inspection | 4 | 16 | ||||||

| material flaw in rivet | 1 | visual inspection | 6 | 24 | ||||

| operator error | 2 | warning stickers | 2 | 16 | ||||

| Seat Back Screws - hold seat back to front leg | stripping | screw will fall out | 2 | misuse | 1 | none | 10 | 20 |

| Legs - support the seat | bending | rocking | 4 | improper storage | 6 | directions that come with chair | 2 | 48 |

| intuitive storage | 1 | 24 | ||||||

| misuse | 5 | directions that come with chair | 2 | 40 | ||||

| chair falls down | 8 | improper storage | 4 | directions that come with chair | 2 | 64 | ||

| intuitive storage | 1 | 32 | ||||||

| misuse | 3 | directions that come with chair | 2 | 48 | ||||

| Leg Endcap - prevent scratching and injury due to sharp metal | falling off | floor will be scratched | 3 | wasn't secured properly | 8 | none | 10 | 240 |

| possible injury | 4 | wasn't secured properly | 8 | none | 10 | 320 | ||

| rocking | 3 | wasn't secured properly | 8 | none | 10 | 240 | ||

| wear | floor will be scratched | 3 | longtime use | 3 | none | 10 | 90 | |

| possible injury | 4 | longtime use | 3 | none | 10 | 120 | ||

| rocking | 3 | longtime use | 3 | none | 10 | 90 |

When evaluating the results of the FMEA table, we first looked for items with a relatively high RPN. The highest RPN numbers were all related to failures involving the leg endcap. While these failures are not particularly severe in terms of the effect on the user, the rate of occurrence and the low probability of detection for all failure causes lead to the high risk priority numbers. After noting the items with higher RPNs, we then looked for other failure modes that might have a lower RPN but a more severe impact on the user. The possible failure of the rivets on the seat of the chair meet these criteria; the possible impact on the user is much more severe, but the RPN is low compared to failures involving the leg endcap due to a low probability of occurrence and high detection rates.

Based on our analysis of the possible failure modes, we can conclude that the product does not have any serious safety issues that should be considered in the redesign. The two possible failure modes that can result in injury to the consumer have a low probability of occurring with the current design, and are easily detectable if they do occur. Overall, the failure modes with the highest RPN are not severe safety concerns, but rather annoyances that do not have an effective method of detection. These items should be considered in the redesign in order to reduce nuisance to the consumer.

Design for the Environment

DFE is an analysis of the environmental impact of a product throughout its life-cycle, from material extraction, through manufacturing and assembly, to use and end-of-life analysis.

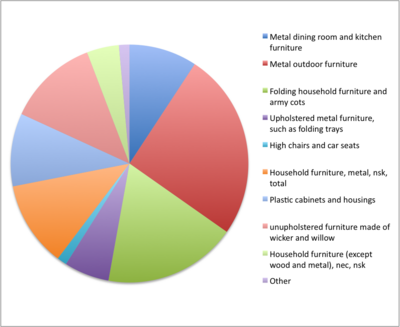

We conducted two types of environmental analyses on the current competitor’s folding chair. First, we conducted a basic economic input-output life cycle assessment. Because we had the retail price of the chair, the analysis opted for the purchaser price model and the price was adjusted to the 2002 GDP. The sector selected, metal and other upholstered furniture, is broken down in the figure below. The sector is very fitting, as the specific chair analyzed could fall into several categories including metal dining room and kitchen furniture, folding household furniture, as well as upholstered metal furniture, all of which make up a significant portion of the sector.

The results of the EIO-LCA analysis, which can be seen in the table below, clearly show that with a CO2 tax of just sixty cents per chair, a cost equivalent to less than 2% of the cost of the chair, not much can be done to improve the environmental impact of the competing product’s production and manufacturing.

| Production | |

|---|---|

| Chair | |

| Sector | 33712A Metal and other household unupholstered furniture |

| MTCO2E per $1M | 613 |

| Unit | chair |

| Unit per lifetime | 1 |

| Cost per unit | $32.38 |

| Lifetime | $32.38 |

| Implied MTCO2E | 0.01984894 |

| CO2 tax @$30/mt | $0.60 |

The second type of analysis we conducted is more subjective and involves analyzing the competitor’s use of good design for environment practices. The data compiled can be seen in the table below. In this analysis we found that while, again, there is little room for improvement in production and manufacturing of current on-the-market products, improvement can be made to maximize the first life and improve the end of life of the product.

| DFE Guidelines | Good Aspects of Competitor | Room for Improvement |

|---|---|---|

| New Concept Development | Plastic backing in lieu of steel backing to decrease weight, thinner pipe walls decrease materials | Consider environmental impact of foam, increase use of recycled and recyclable materials |

| Low Impact Materials | Replace steel with recycled aluminum, find a replacement for foam insert | |

| Reduce Material | Thin plastic backing, thin pipe-walls | Consider cutouts for seat back, possibly thinning walls and decreasing pipe diameter further |

| Eco-Manufacturing | Appears that there is minimal waste material | Consider bending the bottoms of legs instead of welding a crossbeam |

| Optimize Distribution | The product nests well and has minimal packaging | Further research can be done on component manufacturing and transportation |

| Maximize First Life | The product is made of strong and durable materials | Foam usually breaks down first and it is not easy to repair |

| End of Life | Could redesign for modularity and disassembly, also use more recyclable materials |