Keg tap

From DDL Wiki

(→Mechanical Analysis) |

(→Mechanical Analysis) |

||

| Line 854: | Line 854: | ||

Dimensions: | Dimensions: | ||

| - | [[Image:Dimensions 2 Keg Tap.jpeg]]< | + | [[Image:Dimensions 2 Keg Tap.jpeg]]<ref>1</ref> |

Revision as of 19:06, 20 September 2009

Contents |

Executive Summary

- Describes key findings and recommendations

Major Stakeholders and Product Needs

- Identify major post-production stakeholders and list major product needs for each

Usage

- Document in detail how the product is used, step by step, and summarize findings from your user studies.

Bill of Materials

- Also identify standard purchase parts.

Keg Tap Components

Assembly Diagrams

- Include pictures of the assembly with all components labeled

Mechanical Function

- Document how the system functions mechanically

Design for Manufacturing and Assembly (DFMA)

- Highlight findings and opportunities for improvement, identifying where our competitor has followed guidelines and made good choices.

- In particular, are there opportunities to improve manufacturability and make a competing product cheaper? Identify where material and process choices are appropriate or inappropriate for expected production volume.

This particular keg tap consists of 26 distinct parts. The majority of the metal pieces are made from stainless steel, with the exception of three interior components that are made from brass. The reasons for making a few pieces brass are unclear; one possible improvement to the keg tap could be standardizing materials and using stainless steel for all the metal components.

The non-metal components are made from plastic and rubber. There are four o-rings in the keg tap, all of which are different sizes. This is a potential problem for consumers. The tap is manufactured so the user can take it apart, and it would not work correctly if the o-rings were mixed up and placed in the wrong locations when reassembled. Also, o-ring fatigue is one of the most likely causes of failure; if users are replacing o-rings somewhat regularly, it would be convenient to only need to order one standard size.

All of the metal components are shaped using a deformation process except for the base and lever, which are cast. Casting is a logical manufacturing choice for the base because of its relatively complex shape. The other main metal parts are extruded, then machined. Machining includes removing material with a lathe or milling machine, drilling holes, cutting threads, and grinding down sharp edges. The amount of machining involved in the manufacturing process is acceptable for this product because it is intended for medium volume production. If the target market increased in size or changed demographics, the current manufacturing processes would have to be reevaluated. An increase in market size would make machining individual parts infeasible. This problem could be solved by either redesigning the tap to have less components, or switching to a process more suitable to high volume production, such as metal injection molding. A change in market demographics, such as a shift in sales from middle-aged beer connoisseurs to college students, would call for a change in the price of the keg tap. This could be achieved by switching to a casting process for more parts; the overall aesthetics might not be as pleasing, but machining costs would go down.

All parts are joined by threads or snapped on (o-rings). This saves machine cost in manufacturing, but may add labor cost. The current joining methods are good for the consumer because you can take the tap apart to clean it and replace parts if need be. A common failure mode may be o-ring fatigue; these parts could easily be replaced instead of buying a whole new tap.

DFM minimize part count standardize components standardize design features keep design simple multifunctional parts ease of fabrication avoid tight tolerances minimize secondary & finishing operations

DFA minimize part count minimize assembly surfaces mistake-proof minimize fasteners

Failure Modes and Effects Analysis (FMEA)

- Highlight findings and opportunities for improvement, indentifying where our competitor has followed guidelines and made good choices.

- In particular, are there important failure modes that should be considered in a redesign or a new design? Focus on use phase, rather than manufacturing.

| Part # | Item | Function | Failure Mode | Effects of Failure | S | Cause of Failure | O | Design Controls | D | RPN | Recommended Actions |

|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | Black Ball | Grip for Pumping | Could be Unscrewed and Lost | Uncomfortable Pumping | 4 | Unaware Users | 1 | Make sure the ball is screwed on tightly | 1 | 4 | Apply Loctite |

| 2 | Plunger | Forces Air into Keg | This part is very robust. Cannot foresee any failure modes. | --- | - | --- | - | --- | - | - | --- |

| 3 | Plunger Disc | Air Tight | This part is very robust. Cannot foresee any failure modes. | --- | - | --- | - | --- | - | - | --- |

| 3.1 | O-Ring | Seal | O-ring becomes hardened | Loss of air tight seal for pressurizing keg | 3 | Repeated use and time | 5 | Oil the o-ring | 5 | 75 | Sell spare parts |

| 4 | Cylindrical Plunger Casing | Supply Keg with Pressure | Dent in the casing, burs, scratches, rust on the inside of the casing | Plunger cannot be moved inside the case, o-ring gets torn up | 7 | Misuse, Dropping the tap | 1 | All these pieces are robust enough | 1 | 7 | None |

| 5 | Cylindrical Top | Encloses Plunger in Casing | Top comes unscrewed | Cannot pressurize keg | 1 | Human tampering | 4 | Check that it is screwed on tightly | 2 | 8 | None, gluing these threads makes disassembly harder |

| 6 | Plunger Spring | Prevents Plunger from Getting Stuck | Breaks | Plunger, though unlikely, may get stuck at top of casing | 7 | Misuse or fatigue | 1 | Make sure spring can handle forces | 1 | 7 | Sell spare parts |

| 7 | Center Cylinder | Separates Air Input from Beer Output | 1)Leaks beer at the connection point with hose

2)Creates turbulence in beer flow | 1)Loss of beer

2)Foamy beer | 5 | 1)Sealant on threads is old

2)Manufacturing | 4 | 1)Check that their are no leaks

2)Their Design | 1 | 20 | 1)None

2)Look into some other way to transition into tubing |

| 7.1 | O-Ring | Seal | O-ring becomes hardened | Loss of air tight seal for pressurizing keg | 3 | Repeated use and time | 5 | Oil the o-ring | 5 | 75 | Sell spare parts |

| 8 | Lever | Attaches Tap and Keg allowing the flow of beer | This part is very robust. Cannot foresee any failure modes. | --- | - | --- | - | --- | - | - | --- |

| 8.1 | Lever Casing | Grip for user | Breaks | Unable to attach tap to keg | 7 | Ridiculous Misuse | 2 | Make sure the part is strong enough | 1 | 14 | None |

| 8.2 | White Cap | Aesthetics | Could break or get lost | None | 1 | Misuse or overuse | 2 | Check this fit | 1 | 2 | None |

| 8.3 | Lever Spring | Helps lock tap in two certain positions | Impact fatigue | Unable to lock tap into open position on keg | 7 | User misuse | 2 | Make sure spring can handle forces | 3 | 42 | Brainstorm new ways to lock tap |

| 8.4 | Center Rod | Helps hold handle together | This part is very robust. Cannot foresee any failure modes. | --- | - | --- | - | --- | - | - | --- |

| 8.5 | Nut | Helps hold handle together | Could come unscrewed | Unable to use tap | Repeated use | Make sure it is screwed on the whole way | None | ||||

| 8.6 | Washer | Helps hold handle together | Cannot foresee any failure modes | ||||||||

| 9 | Lever Pin | Attaches the lever to the base and acts as a pivot point for the lever | No foreseen failure modes. | ||||||||

| 10 | Base | Attaches to Keg | Threads become crooked | Unable to connect tap to keg | Terrible misuse | Threads are very robust | Sell spare parts | ||||

| 10.1 | O-Ring | Seal | O-ring becomes hardened | Loss of air tight seal for pressurizing keg | Repeated use and time | Oil the o-ring | Sell spare parts | ||||

| 11 | Hose | Transfers Beer from Tap to Cup | 1)Hole

2)Kink | 1)Beer is lost

2)Beer cannot reach its destination | 1)Not taking care of tap

2)Jokes | Make sure the tubing is the right kind | None | ||||

| 12 | Nozzle | Releases Beer from Hose | No foreseen failure mode | ||||||||

| 12.1 | Handle | Allows the user to start and stop the flow of beer | Deform/Break | Beer would not be allowed to come out the nozzle | Pushing the handle past where it should be | Use thick enough plastic | Sell spare parts | ||||

| 12.2 | White Plastic Center | Connects nozzle handle to cap seal | Connection point to nozzle handle breaks | Beer can not come out of nozzle | Pushing the handle past where it should be | Test to make sure it operates the way it should | Sell spare parts, look for a possible redesign | ||||

| 12.3 | Spring | Apply extra force to keep the pressurized beer from coming out of the keg | No foreseen failure modes | ||||||||

| 12.4 | Cap Seal | Blocks the flow from leaving the hose | Surface fatigue wear | Beer would leak through and leave the nozzle | Repeated use | Make sure the rubber used can withstand many cycles | Sell spare parts | ||||

| 12.5 | Hard Plastic Cap | Connects the Handle to the nozzle | Fracture | Nozzle/Handle would not be able to function | Over tightening the cap onto the nozzle | Tighten cap enough so users do not have to | Sell spare parts

|

Design for Environment (DFE)

- Highlight findings and opportunities for improvement, indentifying where our competitor has followed guidelines and made good choices.

- In particular, if Congress were to pass a tax on CO2, would this have a significant impact on the cost of production or use of the product?

Manufacturing

- Greenhouse Gas Emissions

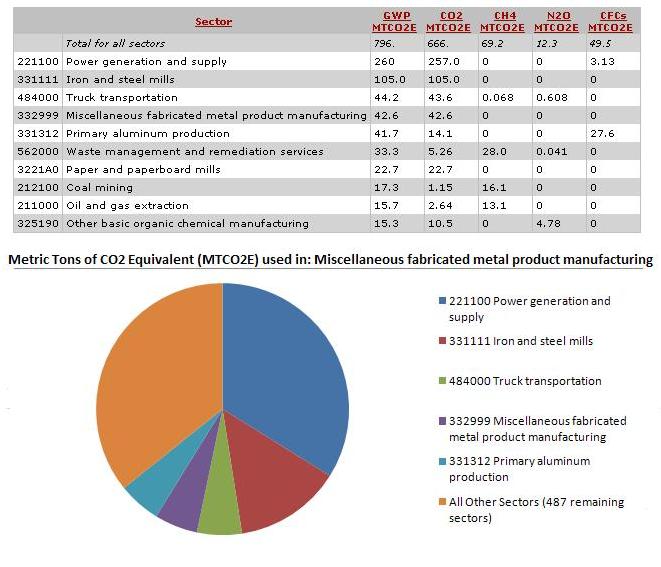

When an additional $1 million dollars is spent in the Miscellaneous fabricated metal product manufacturing sector, greenhouse gas emissions rise by approximately 796 metric tons of CO2 Equivalent (MTCO2E). The data shows that the majority of the gases are produced by power generation and supply, iron and steel mills, and transportation. The actual sector that produces the tap only produces 42.6 MTCO2E, which is small considering the amount released in other sectors.

- Toxic Releases

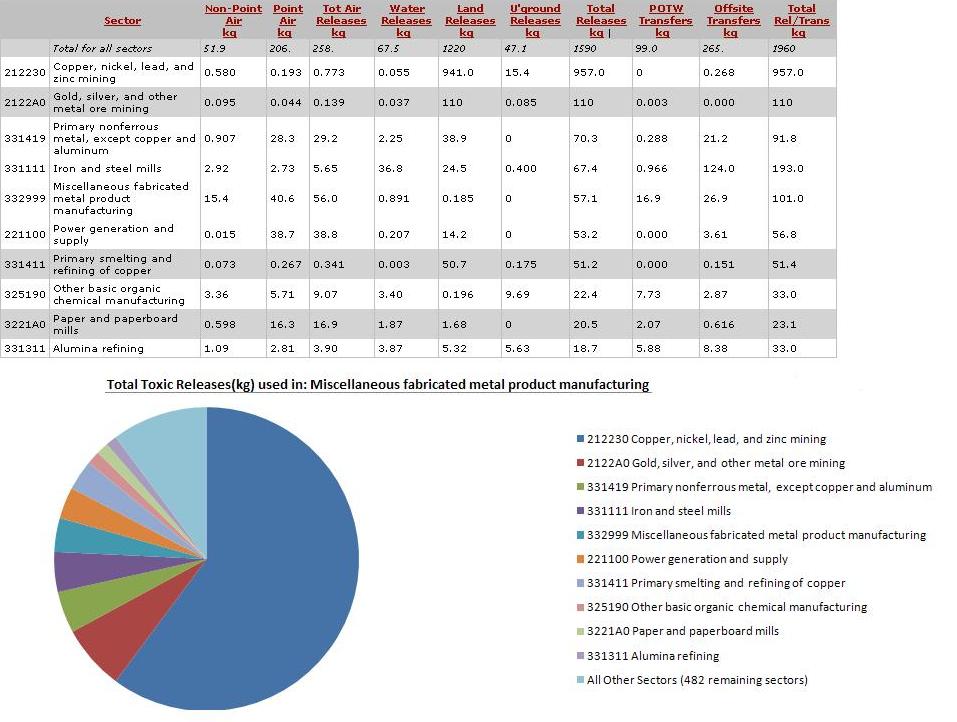

An additional $1 million dollars spent in the sector for keg taps results in a rise in total toxic releases of 1590kg. The primary contributors to these releases are mining of: copper, nickel, lead, and zinc gold, silver, and other metal ore mining. The Miscellaneous fabricated metal product manufacturing sector only amounts to a 57.1 kg increase in toxic releases.

Use

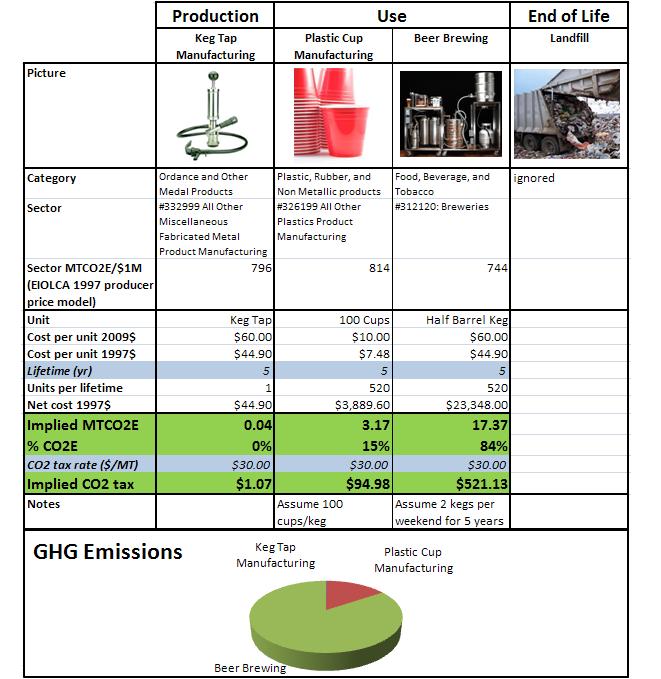

Using the template of Professor Michalek's "EIO-LCA example: coffeemaker" we did a comparison of the emissions associated with the use of the product versus the manufacturing of it. Since the keg tap itself is manually operated the power input is not applicable, but there are other products that are used with the keg tap. Foremost, is beer from a keg and we assumed that this product would be used to the extremes, like a fraternity would use it. We decided this too see what the maximum impact would be of using 520 kegs over a 5 year lifetime window. Secondly, solo cups are a necessity so we included them as well, assuming 100 cups used per keg.

Based on the data above, it is clear that the manufacturing of our tap has next to no environmental impact compared to the manufacturing of plastic cups and especially to the brewing process.

End of life

Our product is composed of only metal and plastic, both of which can be recycled. So once our product can no longer perform as intended it can be recycled in a few ways. Some parts are almost impossible to break and can be used again as is and just reassembled with parts that needed to be replaced. The pieces that break can be melted down and reused in some way, whether they are plastic or metal.

DFE Conclusions

Based on the numbers provided in figure ## it would be wise for our group to emphasize on trying to reduce wasting beer because it is the largest component of greenhouse gas emissions associated with our product. A large amount of foam is produced in transport and distribution of the beer in a keg and it is normally thrown away. If we could reduce the foam created we could in turn reduce the environmental impact that our product is associated with.

Mechanical Analysis

There are 2 different mechanical analysis’ that we did on the keg + tap system. The first is how much pressure per pump increases in the keg, which in turn would increase the pressure in the hose. Second, since our system is composed of fluid flowing through tubes we can determine if it is flowing in a laminar or turbulent fashion.

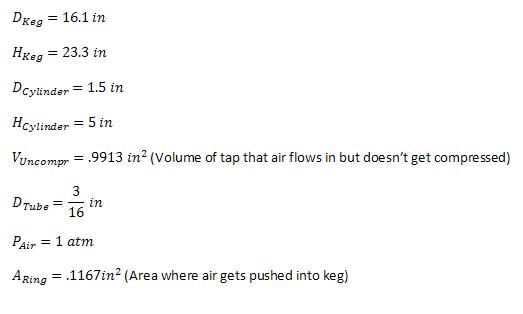

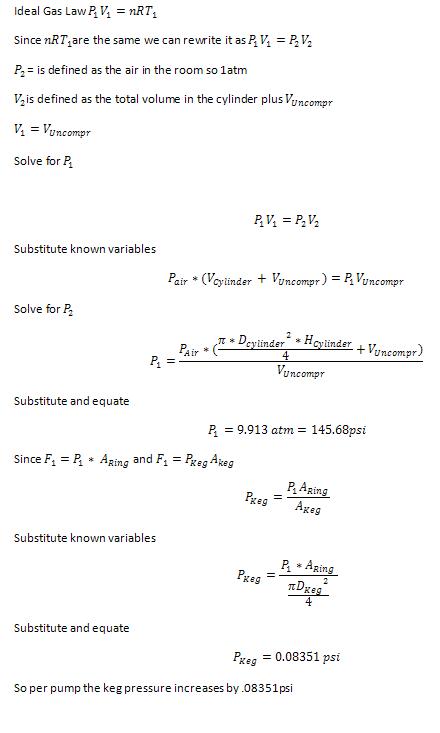

Problem 1: Find the change in pressure per pump

Assume:

- No pressure is lost in the system at all

Free Body Diagram:

Dimensions:

Solution:

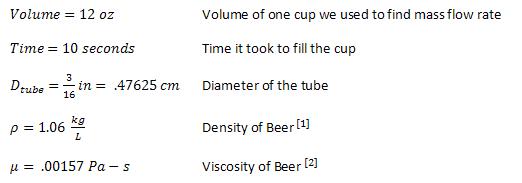

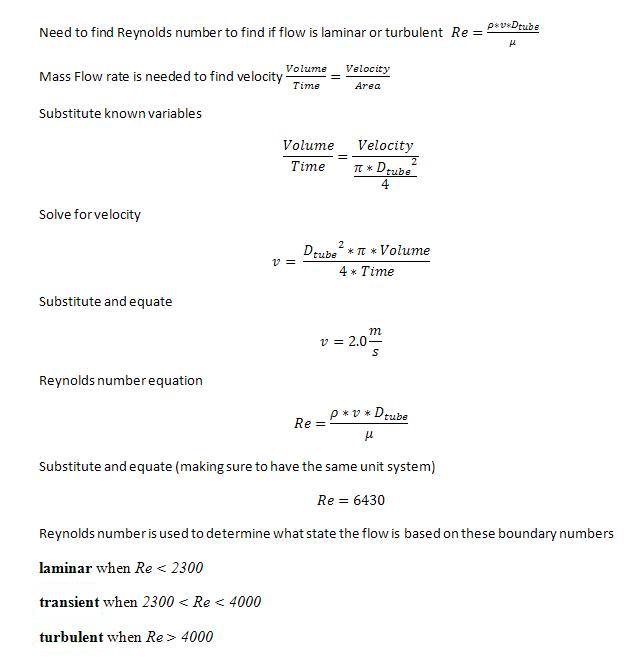

Problem 2: Find out if the fluid flow in the tube is laminar or turbulent

Assume:

- Steady State

- Steady Flow

- Constant Density

- The Reynolds number in the tube is representative of the whole tap’s beer flow

Free Body Diagram:

Dimensions:

Solution:

Team Member Roles

- Identify team member roles during this phase and summarize your process. Submit individual peer evaluations to Prof.