Low-foam keg tap

From DDL Wiki

(→Market Analysis) |

(→Mechanical Analysis) |

||

| Line 795: | Line 795: | ||

==Mechanical Analysis== | ==Mechanical Analysis== | ||

| - | Clearly state the purpose of the analysis, methods and assumptions. Define all symbols, and provide a free body diagram, if applicable. Summarize conclusions and implications for you design, and explain how the analysis serves to justify your design choices. | + | Clearly state the purpose of the analysis, methods and assumptions. Define all symbols, and provide a free body diagram, if applicable. Summarize conclusions and implications for you design, and explain how the analysis serves to justify your design choices. |

| + | |||

| + | The purpose of this analysis is to determine whether the bend in the center cylinder causes the pressure to drop below than the vapor pressure. This is a plausible conjecture, due to the fact that centrifugal acceleration of the fluid creates a pressure drop across the streamline. This means that the pressure on the inside of the bend should be much higher than the outside corner. If pressure on the outside is indeed lower than the vapor pressure of the beer, cavitation will occur, creating bubbles in the fluid and ultimately proving to be a large source of foam creation. | ||

| + | |||

| + | By first applying the Bernoulli equation, we can get an approximate value for the pressure at the center streamline of the bend. Assuming steady, incompressible flow, the Bernoulli equation <ref>1<\ref> is as follows: | ||

| + | |||

| + | [[Image:Example.jpg]] | ||

==Prototype Documentation== | ==Prototype Documentation== | ||

Revision as of 22:44, 6 December 2009

Contents |

Executive Summary

Provide a brief executive summary summarizing your findings and conclusions. In particular, summarize

- Findings from market research justifying need for the new product: Survey distributed; found that users desire a lower foam output, easier pumping mechanism, and more intuitive tap design

- The product's main features, advantages over competitors, and target market: center cylinder redesigned to eliminate 90 degree bend in liquid output (straight tube means less foam), final product will include pressure gauge to prevent overpumping; competing products create more foam; target market is beer distributors and college students

- The most important findings from your product analyses that justify design choices and support your case for the new product.

Market Analysis

The two markets researched were beer distributors and consumers. We conducted interviews and collected survey responses to gain insight as to what customers look for in a keg tap and gauge market need.

Beer Distributors

To determine the needs of beer distributors, we interviewed the store managers. We found that most distributors own about 50 taps and need to restock every few months. They restock mainly because customers do not return the taps after use. We also found that workers routinely disassemble the taps for cleaning. From these interviews, we learned that beer distributors want keg taps that are:

- Easy to disassemble

- Composed of standard parts to facilitate part replacement

- Simple to clean

- Durable enough to withstand customer abuse

Consumers

For consumers, we distributed a survey to students, young professionals, and adults in order to get responses from a representative sample of all potential keg tap users. The goals of the survey were to identify the target demographic, key complaints, advantages and disadvantages of keg use as opposed to bottles, and other customer needs. From the survey results, we found that consumers mainly desire the following:

- Reduced foam output

- Better pumping mechanism

- Intuitive tap design

- Simple way to keep keg cold

- Faster dispensing method

We found that the greatest complaint was the foam output of the tap. Our product not only reduces foam, but it also has a better pumping mechanism (that is easier on the palm as well as requiring less pumps) and also facilitates all of the requirements that the beer distributors need for their keg taps all while remaining an intuitive tap design. We felt that the market was already flooded with products that can keep the keg cold and/or dispense the beer faster so we did not include those elements into our design.

The price estimates that were done for our product are for low volume production and distribution. The raw cost of the product would be roughly $76, which includes a $41 dollar sub assembly. Marking up 50% for profit and machining costs puts the price at just under $115. While the original tap that we looked at cost about $60, there is a "supreme" tap that is priced at $110+. This shows that there is already a market for more expensive taps and our product would fit right in. We feel that there is a high likelihood that this product could be profitable in low volume output at around $40 profit above raw material cost. If the machining was to be outsourced the profit would be reduced for each tap, but the volume could be increased to compensate.

If the product were to be produced at higher volumes the raw cost of the product would be drastically reduced, the $41 sub assembly could be made in house and the stainless steel that is purchased can be bought en masse. All the machining processes can be programmed into a CNC machine for quick milling and lathing processes. Only assembly would have to be done by a person and it only involves screwing in the threaded parts.

Design Documentation

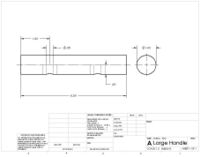

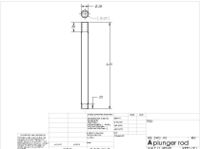

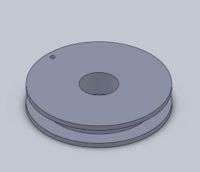

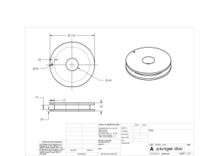

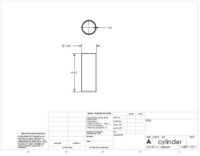

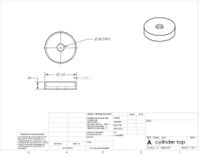

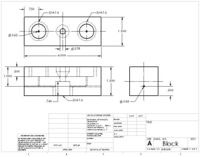

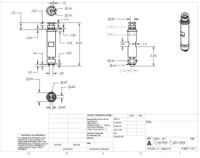

Include assembly drawings with all components labeled as well as a bill of materials defining each component with quantity, material, etc. Include a fully dimensioned CAD drawing for each custom component and a company and part number for each purchased component.

Whether or not the base is cast or bought depends on the production volume. As of now, the assumption is that the number of taps produced will not make it worth it to make the part. Parts 10-19 can be all bought together from Micro Matic for $41. By buying this sub assembly we are eliminating the manufacturing processes that have high initial costs (such as casting). All of the other pieces of our design can be machined which is beneficial for low volume production. If a large company were making our tap the costs of manufacturing all the pieces would not be a problem and high volume production could be achieved.

House of Quality

Provide a complete house of quality table to summarize your design choices, targets, relationships, and benchmarking against the competition. Highlight major findings and conclusions.

In terms of physical testing, we focused our comparison on the standard $60 keg tap, since we modeled our design off of it.

| Error creating thumbnail: convert: unable to open image `/ux0/websites/wiki.ece.cmu.edu/wiki/virtual-hosts/ddl/images/HOQ.JPG': No such file or directory @ error/blob.c/OpenBlob/2882. convert: no images defined `/ux0/websites/wiki.ece.cmu.edu/wiki/virtual-hosts/ddl/images/thumb/HOQ.JPG/400px-HOQ.JPG' @ error/convert.c/ConvertImageCommand/3235. |

Design Analysis

Report on conclusions and recommendations from your DFMA, FMEA, and DFE findings for your product, and benchmark against the competition. Highlight major findings in the report and provide data in the appendix.

DFE

Our DFE conclusions from the tap design in use currently, showed that our group should work to reduce the amount of foam created. The foam was the largest component of greenhouse gas emissions associated with our product. Therefore reducing the foam created would be a great way to reduce the impact our product has on the environment. See the appendix for our DFE.

Due to the number and types of changes we have made to the original tap to create our foam-reducing tap, the DFE for our product would be identical to the original tap, with one major change: the amount of foam created by our product is less. The reduced foam creation in our tap means our product will have a reduced impact on the environment.

FMEA

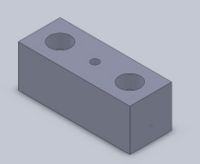

The following FMEA is very identical to the FMEA done on the current tap design due to multiple parts being the same. The key differences that should be highlighted are the changes in the handle, the changes in the center cylinder. and the addition of the main block.

The new handle may cause a few new problems, such as improper taping and binding. The old tap design inadvertently forced the user to tap the keg the proper way by grabbing the plastic handle near the base and twisting. Now that our handle for pumping is larger the user may try taping the keg with that part, which may tighten/loosen some of the threaded parts instead of taping the keg. The other problem of binding was cause for concern before the prototype was actually completed. It was thought that having the double barrel may cause the plungers to bind, no allowing the user to pump the tap easily. After completing the prototype and testing multiple times this does not seem to be a problem.

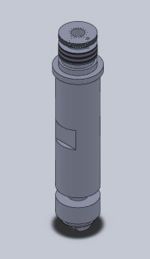

The FMEA done on the original tap led our group to make changes on the center cylinder. It was this part that received the highest RPN (49) the first time around. It received that number due to the flow path it made the beer follow. The testing and mechanical analysis we have done shows that more foam is created when the beer has to go around a 90 degree bend. With that in mind our group decided to redesign this piece so that there were no bends in it, allowing for the least amount of foam to be created in it, ultimately lowering its RPN.

Lastly the main block is a new part added to our re-design. Just as the new handle is a place to tap the keg improperly, the main block could give the user a place to make the same mistake. If tapped by twisting the main block, threaded parts may be tightened or loosened instead of the keg being properly tapped. One way to combat this problem would be to put warning signs on the tap, or to make the handle by the base bigger so the user will want to use that to tap the keg.

| Part # | Item | Function | Failure Mode | Effects of Failure | S | Cause of Failure | O | Design Controls | D | RPN | Recommended Actions |

|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | Handle | Grip for Pumping | Could bind while trying to pump | Rough pumping | 7 | Poor Design | 1 | Design it to function smoothly | 1 | 7 | Had no trouble with this in prototype |

| 2 | Plungers | Force Air into Keg | Could be snapped off while locked into keg | Unusable | 7 | Unaware Users | 1 | Increase diameter | 1 | 7 | Even more less likely now |

| 2.1 | Plunger Disc | Air Tight | This part is very robust. Cannot foresee any failure modes. | --- | - | --- | - | --- | - | - | --- |

| 3 | Plunger O-Ring | Seal | O-ring becomes hardened | Loss of air tight seal for pressurizing keg | 3 | Repeated use and time | 2 | Oil the o-ring | 5 | 30 | Sell spare parts |

| 4 | Cylindrical Plunger Casing | Supply Keg with Pressure | Dent in the casing, burs, scratches, rust on the inside of the casing | Plunger cannot be moved inside the case, o-ring gets torn up | 7 | Misuse, Dropping the tap | 1 | All these pieces are robust enough | 1 | 7 | None |

| 5 | Cylindrical Casing O-Ring | Seal | O-ring becomes hardened | Loss of air tight seal for pressurizing keg | 3 | Repeated use and time | 2 | Oil the o-ring | 5 | 30 | Sell spare parts |

| 6 | Cylindrical Top | Encloses Plunger in Casing | Top comes unscrewed | Cannot pressurize keg | 1 | Human tampering | 4 | Check that it is screwed on tightly | 2 | 8 | None, gluing these threads makes disassembly harder |

| 7 | Plunger Spring | Prevents Plunger from Getting Stuck | Breaks | Plunger, though unlikely, may get stuck at top of casing | 7 | Misuse or fatigue | 1 | Make sure spring can handle forces | 1 | 7 | Sell spare parts |

| 8 | Main Block | Takes air from cylinder and puts it into the center cylinder | 1)Improper Tapping

2) Air leak | 1) Over tightening/loosening of threaded parts

2) Unable to maintain pressure in keg | 1) 2

2) 6 | 1)Improper Use

2) Bad seal | 1) 4

2) 2 | 1) Larger handle near base, warnings

2) o-rings | 1) 2

2) 2 | 1) 16

2) 24 | 1) None

2) None |

| 9 | Faucet | Transfers Beer to Cups | Could Break off | Beer would spray all over the place | 8 | Misuse | 2 | Make sure the faucet is robust enough | 1 | 16 | None |

| 10 | Lever | Attaches Tap and Keg allowing the flow of beer | This part is very robust. Cannot foresee any failure modes. | --- | - | --- | - | --- | - | - | --- |

| 11 | Lever Casing | Grip for user | Breaks | Unable to attach tap to keg | 7 | Ridiculous Misuse | 2 | Make sure the part is strong enough | 1 | 14 | None |

| 12 | White Cap | Aesthetics | Could break or get lost | None | 1 | Misuse or overuse | 2 | Check this fit | 1 | 2 | None |

| 13 | Lever Spring | Helps lock tap in two certain positions | Impact fatigue | Unable to lock tap into open position on keg | 7 | User misuse | 1 | Make sure spring can handle forces | 2 | 14 | Brainstorm new ways to lock tap |

| 14 | Center Rod | Helps hold handle together | This part is very robust. Cannot foresee any failure modes. | --- | - | --- | - | --- | - | - | --- |

| 15 | Nut | Helps hold handle together | Could come unscrewed | Unable to use tap | 7 | Repeated use | 1 | Make sure it is screwed on the whole way | 1 | 7 | None |

| 16 | Washer | Helps hold handle together | Cannot foresee any failure modes | --- | - | --- | - | --- | - | - | --- |

| 17 | Lever Pin | Attaches the lever to the base and acts as a pivot point for the lever | No foreseen failure modes. | --- | - | --- | - | --- | - | - | --- |

| 18 | Base | Attaches to Keg | Threads become crooked | Unable to connect tap to keg | 7 | Terrible misuse | 1 | Threads are very robust | 2 | 14 | Sell spare parts |

| 19 | Base O-Ring | Seal | O-ring becomes hardened | Loss of air tight seal for pressurizing keg | 3 | Repeated use and time | 2 | Oil the o-ring | 5 | 30 | Sell spare parts

|

| 20 | Center Cylinder | Separates Air Input from Beer Output | Creates turbulence in beer flow | Foamy beer | 7 | Manufacturing | 2 | Their Design | 1 | 14 | None |

| 21 | Center Cylindrical O-Ring Bottom | Seal | O-ring becomes hardened | Loss of air tight seal for pressurizing keg | 3 | Repeated use and time | 2 | Oil the o-ring | 5 | 30 | Sell spare parts |

| 22 | Center Cylindrical O-Ring Top-Small | Seal | O-ring becomes hardened | Loss of air tight seal for pressurizing keg | 3 | Repeated use and time | 2 | Oil the o-ring | 5 | 30 | Sell spare parts |

| 23 | Center Cylindrical O-Ring Top-Big | Seal | O-ring becomes hardened | Loss of air tight seal for pressurizing keg | 3 | Repeated use and time | 2 | Oil the o-ring | 5 | 30 | Sell spare parts

|

Looking over the FMEA for the low-foam keg tap, the biggest problem will be o-rings, which we decided in the last FMEA is allowable. O-rings allow for the keg to come in multiple parts, which make it possible to take the tap apart and clean it. Also o-rings are cheap and easy to replace, so an o-ring gone bad is not a terrible occurrence. It does affect the functionality of the tap but it is a quick and easy fix.

DFMA

This particular keg tap is made of 22 parts. The non-metal components are made from plastic and rubber, and for the most part are manufactured via injection molding. One potential improvement for the manufacturing of the non-metal components is the o-rings. There are ten o-rings in the keg tap, and 7 different sizes/types of o-rings. This is a potential problem for consumers. The tap is manufactured so the user can take it apart, and it would not work correctly if the o-rings were mixed up and placed in the wrong locations when reassembled. Also, o-ring fatigue is one of the most likely causes of failure; if users are replacing o-rings somewhat regularly, it would be convenient to only order one standard size that can be placed in any of the locations.

The original keg tap had pieces made from brass and stainless steel, a concept we could not explain. In order to keep everything uniform in our design we chose to make everything stainless steel. This way different types of metals will not need to be ordered in bulk, we can simply get stainless steel.

All of the metal components are shaped using a deformation process except for the base and lever, which are cast. Casting is a logical manufacturing choice for the base because of its relatively complex shape. The other main metal parts are extruded, then machined. Machining includes removing material with a lathe or milling machine, drilling holes, cutting threads, and grinding down sharp edges. The amount of machining involved in the manufacturing process is acceptable for this product because it is intended for low volume production. If the target market increased in size or changed demographics, the current manufacturing processes would have to be reevaluated. An increase in market size would make machining individual parts infeasible. This problem could be solved by either redesigning the tap to have less components, or switching to a process more suitable to high volume production, such as metal injection molding. A change in market demographics, such as a shift in sales from middle-aged beer connoisseurs to college students, would call for a change in the price of the keg tap. This could be achieved by switching to a casting process for more parts; the overall aesthetics might not be as pleasing, but machining costs would go down.

Another way to decrease manufacturing costs is to make more components out of plastic. Plastic injection molding is cheap and fast, at least for high volume production, and produces components lighter than the current metal parts. Injection molding also allows for more freedom in the structure of the tap, since parts are shaped in the mold and not machined. Downsides to increasing the number of plastic components include durability issues and the potential for plastic flavor leeching into the beer.

The keg tap is relatively easy to assemble. All parts are joined by threads or snapped on (o-rings); if given a reference, the average person would be able to put the parts together. This saves machine cost in manufacturing, but increases labor cost. The current joining methods are convenient for the consumer because the tap can be disassembled for cleaning and repair; if an o-ring broke, you could replace it instead of buying a whole new tap.

Overall, the producers of the original keg tap have designed carefully for both manufacturing and assembly, though our switch to all stainless steel will make the purchase of material more efficient.

Mechanical Analysis

Clearly state the purpose of the analysis, methods and assumptions. Define all symbols, and provide a free body diagram, if applicable. Summarize conclusions and implications for you design, and explain how the analysis serves to justify your design choices.

The purpose of this analysis is to determine whether the bend in the center cylinder causes the pressure to drop below than the vapor pressure. This is a plausible conjecture, due to the fact that centrifugal acceleration of the fluid creates a pressure drop across the streamline. This means that the pressure on the inside of the bend should be much higher than the outside corner. If pressure on the outside is indeed lower than the vapor pressure of the beer, cavitation will occur, creating bubbles in the fluid and ultimately proving to be a large source of foam creation.

By first applying the Bernoulli equation, we can get an approximate value for the pressure at the center streamline of the bend. Assuming steady, incompressible flow, the Bernoulli equation <ref>1<\ref> is as follows:

Prototype Documentation

Our final prototype demonstrates all the aspects we have in our final design with minor changes for aesthetics and material reduction. Our final prototype allows the beer to flow straight out of the keg without having to make a harsh 90 degree turn. It also implements a more comfortable handle along with the double barrel design to minimize the number of pumps needed to properly pressurize the keg.

In order to decrease the amount of material needed for our product we decided that the double barrels will be placed much closer to each other in order to decrease the size of the main block. This change will actually allow us to cut the main block in half. Another change from our final prototype will be to the plugs sticking out the sides of the main block. For aesthetics we will place plugs in that will not be noticeable. The plugs will be placed in, the excess plug will be cut off and ground down to be flush to the block, at which point the main block will be finished, and the existence of the plugs will be unnoticeable.

Another change being made to decrease foam production further is the addition of a faucet. The hose allowed for the possibility of forcing the beer through other harsh twists and turns. The faucet will allow us to control the beer's flow path all the way from the keg to the user’s cup. A larger radius will be put into this faucet. This will be done because research has shown that small radiuses cause higher pressure gradients, possibly leading to cavitation, and foam production, which we want to avoid.

In order to get some feedback on our design we invited some friends over to enjoy some beer. Most of the comments were related to how cool the tap looked, or they can't believe we actually got it to work. As further testing took place the comments became even less constructive, though we did notice some aspects that needed to be addresed. The most important aspect being the improper tapping of of the keg. The testers were asked to tap the keg with our product, at which point we noticed they would twist from the main block or pumping handle. Both of these parts were not meant for that. Twisting from there may lead to over tightenign or loosening of the threaded parts, as well as the tap not being all the way in the keg.

Lastly, we did have some users say they would buy a tap if we were to make one for them.

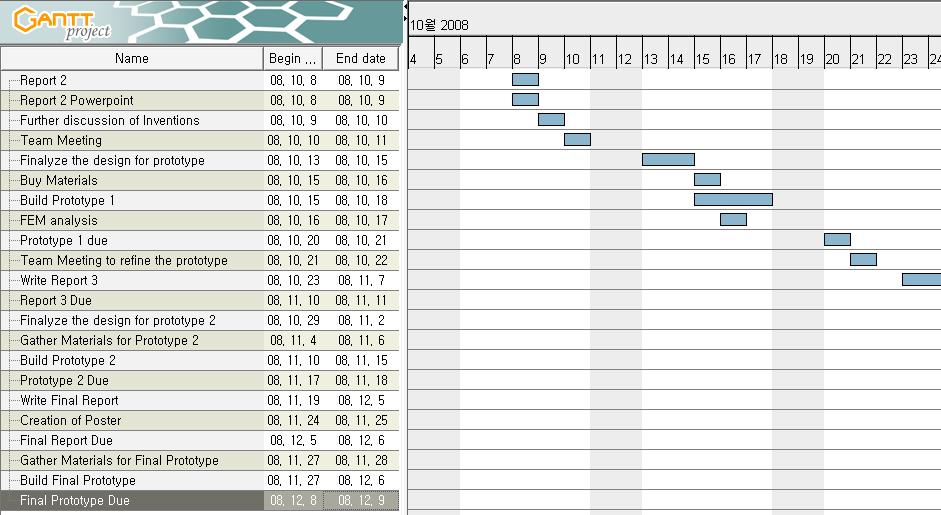

Design Process

Throughout the semester our team has worked well together. We have all been flexible with our time, communicated well, and enjoyed collaborating on our low-foam keg tap. We tried our best to follow the Gannt chart we created in Report 2, though the plan changed slightly here and there. Scheduling times to meet and coordinating with one another was usually done over the phone or with all of us sitting down together in our group talking about what we want to do. Completing tasks usually involved the task being completed by one person or various members of the group working together. When the task was completed it would then be checked and agreed upon by the rest of the group to insure what was done is what the group wants to be handed in. There was never something handed in without the whole groups approval.

Our team member roles had no specific boundaries. One report you could be doing the mechanical analysis and the next report someone else might have taken it over. Most of the time responsibilities were allocated based on preference. We would simply ask each other what the other person wanted to do, and if someone had specific areas they wanted to work on, it was theirs. Each group member made many contributions to our project. For example on Report 1 the split looked like this:

Dan Boljonis: DFE, Mechanical Analysis

Keith Haselhoff: FMEA, Stakeholders

Abby Morrell: BOM and Diagram, FBD of Mechanical Analysis, Usage, Summary, Participant in User Study

Julia Weirman: DFMA, BOM, Mechanical Function, Participant in User Study

For report 2:

Dan Boljonis: Gantt chart, market research

Keith Haselhoff: Competitor research, Pugh chart

Abby Morrell: Design concept sketches and descriptions, findings & recommendations, executive summary

Julia Weirman: Market research, created survey and compiled results, editing

For the most part these sections were completed as a group, though the names by each section were the ones leading that input.

After all our hard work this semester, our product is in a state where it could be manufactured. The Solidworks drawings are complete, the prototype is functional, and a market has been identified. Though the prototype is functional, it is not what the final design will look like. There is also an estimate on cost, and before we would actually start manufacturing these taps and trying to sell them, there needs to be more research done to see if consumers would buy the tap at the price specified. If they would not buy the tap at that price there may be some changes we could make to bring the price down, though this should be figured out before we start manufacturing the taps.

Appendix

References

<references/>