Ratcheting Screwdriver Redesign

From DDL Wiki

(→Market Research) |

(→Final Design) |

||

| Line 74: | Line 74: | ||

The first feature being redesigned is the handle. The existing design, while tried and true, has several flaws. Gripping the handle requires an unatural hand position and quickly leads to fatigue after repeated use. The new design is much more ergonomic. The pistol grip is a much more natural postion and since the device is not operated by a twisting motion the probability of fatigue is greatly reduced. The new handle design also promotes the use of downward pressure and will therefore reduce the number of stripped screw heads. | The first feature being redesigned is the handle. The existing design, while tried and true, has several flaws. Gripping the handle requires an unatural hand position and quickly leads to fatigue after repeated use. The new design is much more ergonomic. The pistol grip is a much more natural postion and since the device is not operated by a twisting motion the probability of fatigue is greatly reduced. The new handle design also promotes the use of downward pressure and will therefore reduce the number of stripped screw heads. | ||

| - | Included with this new handle design is a new operating mechanism. | + | Included with this new handle design is a new operating mechanism. Previosly the screwdriver has been operated by turning the handle with the operator's hand and wrist. The new design is operated by a hand trigger. A simple squeeze of ones hand is all that it takes to operate. This should increase the time before fatigue sets in compared to the old design for a ratcheting screwdriver. It it also an improvement over the power drill in several areas. First off there is no battery to worry about. The new design is always ready to be used. The new design is also variable speed based on the quickness of the operators squeeze, unlike the comparable power drill which only has one speed. |

| + | |||

| + | It was also found the the switch is an area in need of improvement. The switch mechanism for the ratchet can be confusing to use and needs two hands for operation. The new design has a clearly illustrated switch so that the operator can quickly recognize what setting the screwdriver is on. It is also easily operated with only the thumb of the hand holding onto the pistol grip. | ||

| - | |||

| - | |||

| - | |||

| - | |||

| - | |||

loose screw | loose screw | ||

storage for bits | storage for bits | ||

Revision as of 14:23, 12 October 2007

Contents |

Market Research

We asked a number of people to use a ratcheting and non-ratcheting screwdriver on a variety of normal household items. The items tested included a CD player, a towel holder, chairs, a fan, a bedframe, a vaccum cleaner, and an airsoft gun. The idea was to provide a wide array of objects and a large sample size in order to gain a new perspective on how people use the tools and the problems they often encounter.

The users were given one of the two screwdrivers and an object to unscrew, with no other instructions. After carefully observing each of the users and interviewing them about their experiences afterwards, the most common problems experienced were:

- Applying ample pressure

- Screwing from an angle

- Determining which way the screwdriver is set up to ratchet

- Screwdriver being too long to access a screw

- Screwdriver being too short to access a screw

- Bit connection is unstable

- Bit connection point is too thick to access a screw

- Stripping screws

- Lighting issues

- Difficulties with nut/bolts

- Engaging the ratcheting mechanism

It is fairly obvious from our observations that a majority of the problems that arise are a result of complications from the size of the screwdriver. Whether it is too long or short to access a screw, or the screw is simply in an awkward space, it results in having to screw from an angle, which all users had difficulty with. We observed a number of users grow very frustrated in trying to turn these screws, and the problems with the bit connection only furthered the frustration. Bit connection is difficult and ineffective: the bit often falls off and it is not obvious when the bit is secure.

In addition, the ratcheting mechanism does not work well on loose screws. Since the user has to turn the entire screwdriver back in order to ratchet, a loose screw will simply turn along with it. This means the ratcheting mechanism is effectively useless in these situations. The main advantage of our design is that the trigger is where the ratcheting takes place. This defeats the entire problem of loose screws.

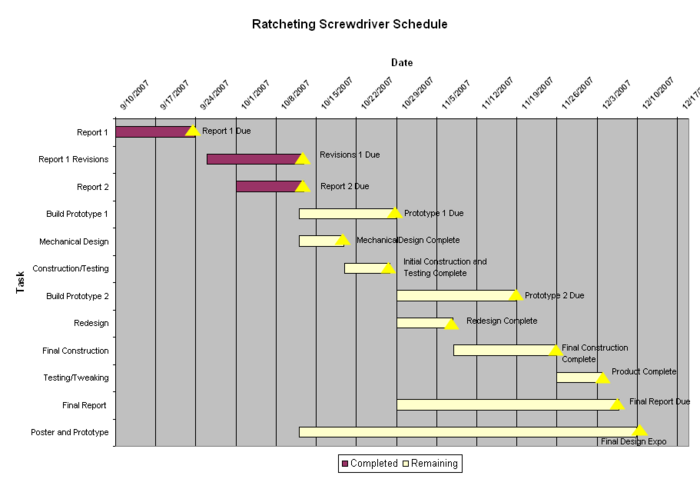

Project Schedule

The schedule for the remaining part of the project is layed out in the Gantt chart below. The milestones' occurences are denoted by a yellow triangle and have a breif description next to them. The big milestones will be the completion of Prototype 1 and Prototype 2, the Final Report, and the Design Expo. The chart is in one week increments with the red parts of the bar denoting the parts of teach task that have been completed and the cream-colored yellow represents the time remaining to complete the task. All tasks will initially be completed as a group, and will be divided up as seen fit when we are doing tasks.

Gantt Chart

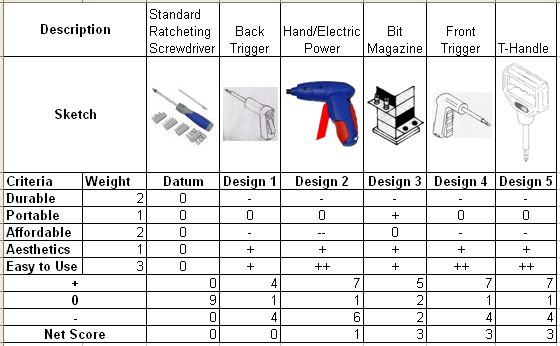

Design Analysis

Pugh Chart

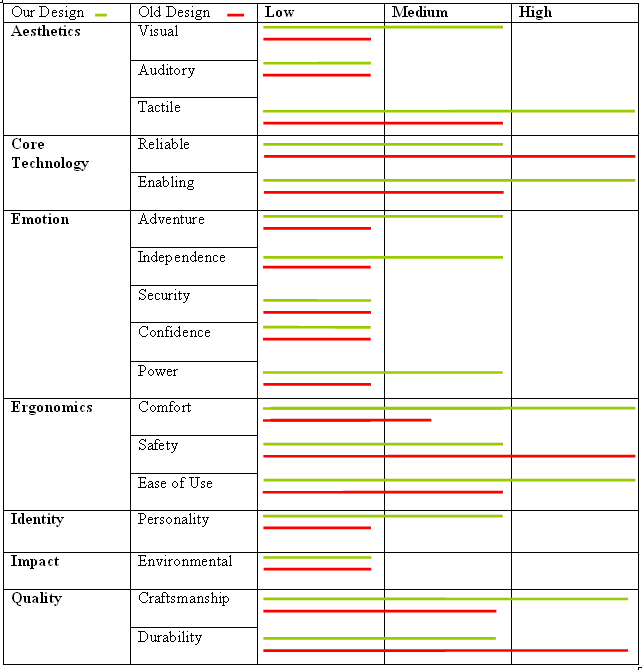

Value Opportunity Analysis

Aesthetics

Core Technology

Emotion

Ergonomics

Identity

Impact

Quality

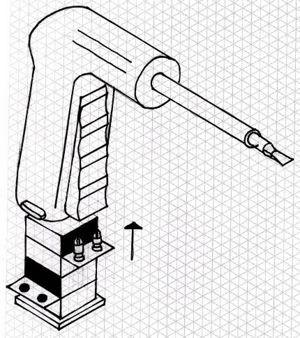

Final Design

Market research has shown some issues with the current design of a ratcheting screwdriver. Our proposed choice of redesigns consists of several key features meant to improve upon the original design. The new design will be easier to use, the controls will be more intuitive, and more versatile than the previous design.

The first feature being redesigned is the handle. The existing design, while tried and true, has several flaws. Gripping the handle requires an unatural hand position and quickly leads to fatigue after repeated use. The new design is much more ergonomic. The pistol grip is a much more natural postion and since the device is not operated by a twisting motion the probability of fatigue is greatly reduced. The new handle design also promotes the use of downward pressure and will therefore reduce the number of stripped screw heads.

Included with this new handle design is a new operating mechanism. Previosly the screwdriver has been operated by turning the handle with the operator's hand and wrist. The new design is operated by a hand trigger. A simple squeeze of ones hand is all that it takes to operate. This should increase the time before fatigue sets in compared to the old design for a ratcheting screwdriver. It it also an improvement over the power drill in several areas. First off there is no battery to worry about. The new design is always ready to be used. The new design is also variable speed based on the quickness of the operators squeeze, unlike the comparable power drill which only has one speed.

It was also found the the switch is an area in need of improvement. The switch mechanism for the ratchet can be confusing to use and needs two hands for operation. The new design has a clearly illustrated switch so that the operator can quickly recognize what setting the screwdriver is on. It is also easily operated with only the thumb of the hand holding onto the pistol grip.

loose screw

storage for bits