Reaming

From DDL Wiki

Reaming is the process of enlarging a hole or a bore to an exact diameter. Reaming can also be used to smooth out a drilled surface. The tool used for reaming is called a reamer. Reamers are fluted (grooved), edge cutting tools. They come in two flavors -- chucking reamers and hand reamers. Chucking reamers can be used on lathes, drill presses, and screw machines. Hand reamers have a square drive and can be turned with a wrench.

Generally, reaming is done after the machinist drills the hole at a slightly smaller size. The difference between the reamer's diameter and the drill's diameter is called the allowance. Modern drills are relatively precise, but with a reamer, the machinist is able produce a near perfect hole.

Reamers consist of either a set of parallel straight cutting edges or helical cutting edges along the length of the cylindrical body. Reamers must utilize hardness in its cutting edges for long life and toughness to prevent failure under normal stresses of use. Spiral edges may be be oriented clockwise or counter-clockwise depending on the desired usage. A tapered reamer with a clockwise spiral will tend to self feed, which can possible lead to wedging and breakage, whereas a counter-clockwise spiral spinning in a clockwise direction would be less prone to this.

Contents |

Materials That Reamers Can Be Used On

Reamers should not be used to drastically enlarge a hole. If the size of the hole needs to be increased more than 5 percent, it is recommended that a larger drill bit be used. Reamers are mainly used for metals. Choosing a reamer for a specific job depends on the workpiece. The hardness, the number of holes, the tolerance, the finish, and the costs are all factors in choosing the correct reamer. Please consult a professional machinist when selecting a reamer.

Composition

Reamers are typically made from high speed steel and solid carbide, or from a steel alloy body with a carbide tip. Combination reamers are made out of carbide, or cobalt. Reamers may also be surrounded by a thermal coating. This coating protects the reamer from heat, pressure, coolant, and the workpiece. Typical coatings are titanium nitride and titanium carbonitride. Reamers with titanium nitride coatings have a gold tint and should be used on shallow holes. Reamers with titanium carbonitride coatings have a blue-gray tint and may be used on all abrasive materials.

Drill Bit vs. Reamer Tolerances

| Diametrical Tolerances | Drill Bits | Reamers |

|---|---|---|

| Average | .002" | .0002" - .0003" |

| Best | .001" | .0008" |

Drill bits are limited in their tolerancing capabilities. When higher tolerances are needed, as may be required in certain engineering applications, reamers are used.

Variations of Reamers

Straight Reamer - used to make minor enlargements to a hole

Rose Reamer - used as roughing reamers

Shell Reamer - used for reaming bearings

Tapered Reamer (precision) - used to make tapered holes to later receive a tepered pin

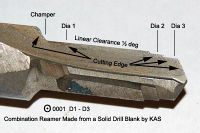

Combination Reamer - used to reduce the number of turret operations in parts with multiple internal diameters

Tapered Reamers (non-precision) - used for cleaning burrs from a drilled hole or to enlarge a hole

The Final Product

The finish in the reamed hole is determined by several things:

1. Sharpness and quality of the grind finish of the tool.

2. The type of material being reamed.

3. The skill of the operator

4. The setup.

5. The coolant. (if used)

6. Cutting speed and feed

References

- Wikipedia Article on Reamers

- American Machinist

- McMaster Chucking and Hand Reamers

- eBay Review of Reaming Practices

Authors

- Terry Chau

- Luke Miller

- Charles Yee