Retractable extension cord

From DDL Wiki

(→References) |

(→References) |

||

| Line 890: | Line 890: | ||

= References = | = References = | ||

| - | Jiang, Jess. "The Price Of Electricity In Your State." ''NPR'' | + | Jiang, Jess. "The Price Of Electricity In Your State." ''NPR'', 28 Oct. 2011. Web. 20 Sept. 2012. |

<http://www.npr.org/blogs/money/2011/10/27/141766341/the-price-of-electricity-in-your-state> | <http://www.npr.org/blogs/money/2011/10/27/141766341/the-price-of-electricity-in-your-state> | ||

| + | |||

| + | Economic Input Output Life Cycle Assessment (EIO-LCA). US 2002 Industry Benchmark model. ''Carnegie Mellon University Green Design Institute'', 2008. Web. 20 Sept. 2012. <http://www.eiolca.net/> | ||

Revision as of 14:46, 20 September 2012

Contents |

Executive Summary

Retractable cords are essential and practical for household purposes because their adjustable length allows users to use electrical appliances in any place they desire. For our extensive user study we chose to purchase a Bayco 30’ retractable cord reel. During our user study, we have identified the major stakeholders to be the manufacturer, customer, retailer, and distributor. Each of these major stakeholders have different needs and requirements from the product. Through examining the product review page we have found that customers generally use this product in garages for using power tools and other electrical hardware. Most of the product reviews we consulted show that most users feel satisfied with the length of the cord and its relatively cheap pricing. The negative reviews that we found reveal some reliability and durability issues with the product.

Upon disassembling the product, we were able to analyze the mechanical and electrical components of the product. We found that the dispensing process of the cord from the circular casing to be a bit rough as we needed to put a little bit of force into pulling on the cord at times. We were also able to examine the main ratcheting mechanism that holds the cord in place as well as the spring coil that retracts the cord back into its casing. We will conduct further analysis on each components of the product to find possible areas for design improvements.

Major Stakeholder Analysis

Listed below are the major stakeholders for the retractable light, which include the manufacturer, customer, retailer, and distributor. The manufacturer generally would strive for low cost to mass produce the product for profit. The customer generally would need the product to be low cost, durable, and safe to use since they desire the product quality they pay for. The retailer would strive for low bulk pricing so that they can purchase the product in large quantity to sell to the customer. The distributor generally would need the product packaging to be durable and able to protect the product during the shipping process.

Manufacturer

- Low material costs

- Limited number of parts

- Ease to assemble

- Ability to be mass produced

- Environmentally friendly manufacturing processes

- Easy to package and ship

Customer

- Easy to use and install

- Multiple mounting options

- Low cost

- Durability

- Portable or light weight

- Ergonomic design

- Good aesthetics

- Multiple length adjustment positions

- Waterproof

- Safe to use

- Ability to customize cord length and reel cover color

- Easy to repair or disassemble

Retailer

- Good aesthetics

- Small packaging size

- Good performance

- Low bulk pricing

Distributor

- Low weight

- Durable product packaging

- Space optimized packaging

- Packaging protects product

Product User Study

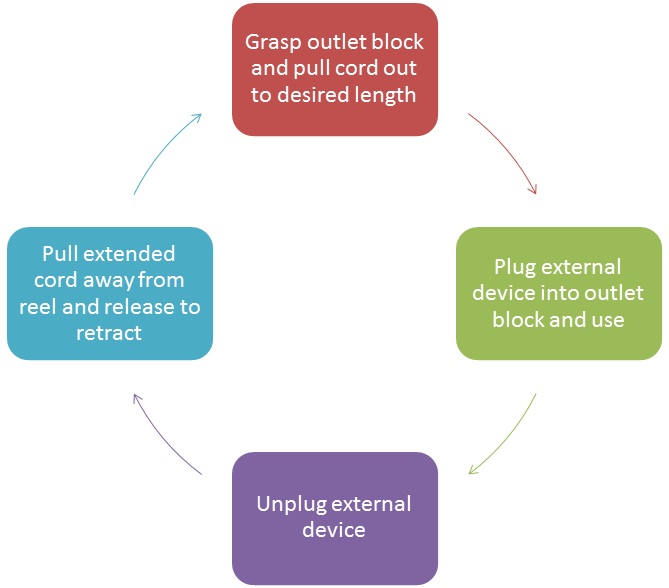

The Bayco Retractable Cord Reel utilizes a spring-loaded, rotational, ratcheting mechanism to provide the user with the functionality of a normal extension cord but with the added benefit of being able to easily retract and store the full length of the cord.

Installation and Daily Use

The user should mount the provided bracket to the ceiling or wall using the included hardware. Once mounted use the locking pin and ring to secure the cord reel to the bracket. After plugging the cord reel into a grounded 3-prong outlet the LED power indicator on the outlet block will light up, indicating the reel is ready for use. An included spherical rubber stopper on the extendable cord can be moved by the user to change the length of cord which is not retracted into the reel. The user should continuously pull on the outlet block to the desired length. The user can then plug in their electrical devices into the outlet block. When use is complete the user should unplug their external devices and pull firmly on the outlet block until they feel the reel release and the cord is retracted.

Mechanical Function

The cord reel contains a steel torsional spring which provides the force to retract the cord. A ratcheting mechanism allows the spool on which the cord is wrapped to lock in different rotational configurations. The ractheting mechanism consists of a spring-loaded pawl and gear. The gear is fabricated with teeth covering approximately two thirds of the circumference. The remaining one third of the circumference has no teeth and a small radius; this results in the pawl slipping on the teeth in only one direction, but when it is in the toothless region it has the ability to switch directions, i.e. allowing the cord to retract freely.

User Study

We determined the retractable cord reel to be ideal for the at home handyman. We have seen use of the retractable cord reel in an automotive garage as well as a machine shop. Users of the retractable cord reel should exhibit caution when mounting the product, particularly at high locations. Precautionary measures should be taken when operating in wet environments as the cord reel does not appear to be waterproof and utilizes electricity in its functionality.

We found it appealing that the installation and use of the cord reel was fairly straightforward. The cord reel appears to be fairly sturdy and the metal external housing was one thing that made us choose this particular reel over other brands. Dissection of the product was not simple but was achievable with a flat head screwdriver, a Philips head screwdriver, hammer, pliers and drill.

Some parts of the cord reel that we felt could be improved were the ratcheting mechanism, the opening of the casing through which the cord retracts, a more ergonomic outlet block, and the size of the cord reel. The current ratcheting mechanism has very specific positions at which the cord will actually retract. We felt that adding bristles to the cord retraction opening on the casing would be useful for keeping the inside of the casing clean from dirt that may become attached to the cord during use. A more ergonomic cord block would be beneficial for pulling the cord effectively during use. Finally we thought the size of the cord reel could potentially be reduced slightly.

Parts List

| Item Number | Description | Quantity | Mass (g) | Function | Material | Manufacturing Process | Image |

|---|---|---|---|---|---|---|---|

| ### | Mounting Bracket | 1 | 105 | Allows retractable cord to be permanently mounted to a ceiling or wall for easier use | Steel | Sheet stamped & bent | |

| ### | Coil Reel | 1 | 161 | Reel for extension cord to wrap around | Plastic | Injection Molded | |

| ### | Mounting Bracket Pin | 1 | 16 | Acts as the pressure relief in the check valve | Steel | Purchased | |

| ### | Pin Locking Ring | 1 | 1 | Holds mounting bracket pin in place | Steel | Purchased | |

| ### | Hardware for Clamp (External) | 1 | 4 | Connects to the hose | Plastic | Injection Molding | |

| ### | External Clamp | 1 | 173 | Serves as the inlet hose of the contaminated water | Rubber | Purchased | |

| ### | Side Casing with Plug | 1 | 255 | Prevents the hose from sinking to the bottom of the water source | Foam | Foam Molding | |

| ### | Side Casing | 1 | 253 | Acts as a pre-filter and as a weight so that the hose stays below water | Steel | Purchased | |

| ### | External Plastic Casing | 1 | 135 | Water inlet, and also holds the foam filter | Plastic | Injection Molding | |

| ### | Spring Position Retainer | 1 | 11 | Acts as a pre-filter for large particles | Foam | Foam Molding | |

| ### | Ratchet Gear | 1 | 7 | Contains piston and hose barb assemblies, and connects to filter | Plastic | Injection Molding | |

| ### | Spring Mounting Rod | 1 | 50 | Acts as the pump by drawing in and pushing out water | Plastic | Injection Molding | |

| ### | Plastic for Circular Elec. Contact | 1 | 11 | Prevents water from getting past the piston | Rubber | Purhcased | |

| ### | Large Circular Contact | 1 | 3 | Connects piston to the handle | Plastic | Injection Molding | |

| ### | Small Circular Contact | 1 | 2 | Connects piston to the handle | Plastic | Injection Molding | |

| ### | Fixed Plastic for Elec. Contact | 1 | 6 | Connects piston to the handle | Plastic | Injection Molding | |

| ### | Insulating Sheet | 1 | 1 | Connects piston to the handle | Plastic | Injection Molding | |

| ### | Fixed Electrical Contacts | 1 | 0.5 | Connects piston to the handle | Plastic | Injection Molding | |

| ### | Rivets for Electrical Contacts | 1 | <1 | Connects piston to the handle | Plastic | Injection Molding | |

| ### | Pawl | 1 | 2 | Connects piston to the handle | Plastic | Injection Molding | |

| ### | Pawl Rivet (Alum) | 1 | <1 | Connects piston to the handle | Plastic | Injection Molding | |

| ### | Metal Coil Casing | 1 | 220 | Connects piston to the handle | Plastic | Injection Molding | |

| ### | Pawl Spring | 1 | <1 | Connects piston to the handle | Plastic | Injection Molding | |

| ### | Lock for Spring Mounting Rod | 1 | <1 | Connects piston to the handle | Plastic | Injection Molding | |

| ### | Screw for Spring Mounting Rod | 1 | <1 | Connects piston to the handle | Plastic | Injection Molding | |

| ### | Electrical Wire Casing | 1 | <1 | Connects piston to the handle | Plastic | Injection Molding | |

| ### | Plastic Ball | 1 | 19 | Connects piston to the handle | Plastic | Injection Molding | |

| ### | Insert for Plastic Ball | 1 | 1 | Connects piston to the handle | Plastic | Injection Molding | |

| ### | Wall Plug | 1 | 85 | Connects piston to the handle | Plastic | Injection Molding | |

| ### | Extension Cord | 1 | 1084 | Connects piston to the handle | Plastic | Injection Molding | |

| ### | Spring Coil | 1 | 516 | Connects piston to the handle | Plastic | Injection Molding | |

| ### | Spring Reinforcement Plate | 1 | 10 | Connects piston to the handle | Plastic | Injection Molding | |

| ### | Spring Coil Rivet | 1 | 2 | Connects piston to the handle | Plastic | Injection Molding | |

| ### | Spring Electrical Contact | 1 | 1 | Connects piston to the handle | Plastic | Injection Molding | |

| ### | Spring Electrical Contact Rivet | 1 | 1 | Connects piston to the handle | Plastic | Injection Molding | |

| ### | Spring Electrical Contact Washer | 1 | 1 | Connects piston to the handle | Plastic | Injection Molding |

Design For Environment

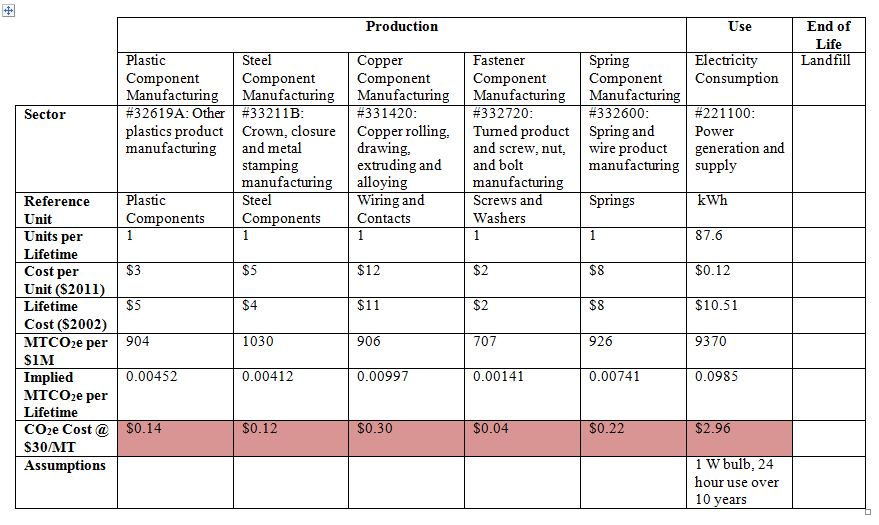

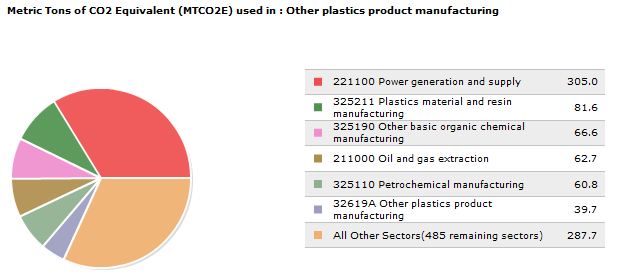

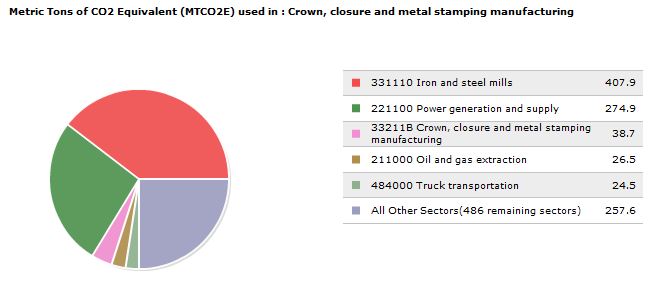

When examining a product, it is important to consider Design for Environment (DFE). The use of the product, manufacture of the product, and extraction of raw materials needed to make the product all produce greenhouse gases such as carbon dioxide (CO2). The CO2 production associated with each component of a product life cycle can be analyzed in order to determine the component that produces the most CO2. Then, the product can be redesigned in order to reduce the CO2 production associated with that particular life cycle component. This will result in a more environmentally product that produces less greenhouse gases over its lifetime. Reduction of greenhouse gases will become particularly important if Congress passes a law that fines companies $30 for each metric ton of CO2 that it produces.

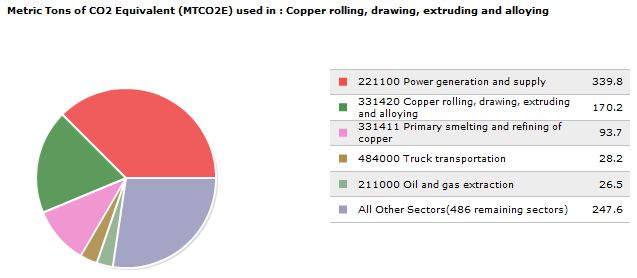

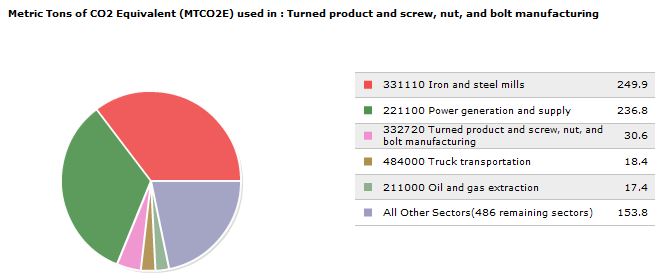

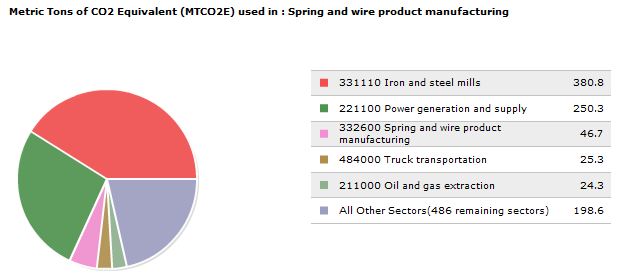

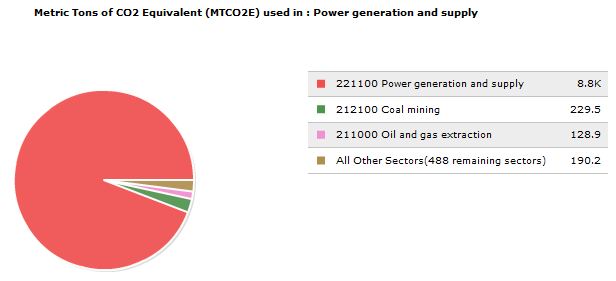

Below is an analysis of the CO2 produced during the lifetime of the Bayco Retractable Cord Reel. This analysis was created primarily through the use of the Economic Input-Output Life Cycle Assessment (EIO-LCA)tool. Included in this analysis are pie charts that break down the the CO2 production associated with each life cycle component into the responsible areas. The production aspect of the product life cycle was divided into 5 distinct areas--plastic production, copper drawing, steel stamping, spring manufacture, and fastener production. Almost all of the product's parts fall under one of these 5 categories. The total cost of the product ($30) was divided amongst these 5 material categories based on the amount of each material contained in the product. The only CO2 producing component of use associated with this product is the power indicator light. This light remains on as long as the cord reel is plugged into an outlet. The assumption has been made that the reel, once installed, will remain plugged in until the product is discarded. So, the light will be on continuously during the product's lifetime. The electricity cost comes from the National Public Radio (NPR) website and is the average US electricity cost for 2011.

As can be observed in the above table, the greatest sources of CO2 production during this product's life cycle are due to electricity use and copper wire production. So, the elimination of the power indicator light and a reduction in the amount of copper wiring used represent two ways CO2 production could be reduced or eliminated during this product's life. However, both of these options would potentially result in a product that is less attractive to the consumer. The table below summarizes aspects of the product that are already environmentally friendly and identifies ways the product could be changed to render it more environmentally friendly.

| DFE Guideline | Good Aspects of Competitor Product | Ideas for Improvement |

|---|---|---|

New Concept Development

|

|

|

Select Low Impact Materials

|

|

|

Reduce Material Amount

|

|

|

Eco-Manufacturing

|

|

|

Optimize Distribution

|

|

|

Reduce Use-Phase Impact

|

|

|

Maximize the First Life

|

|

|

End of Life

|

|

|

Design For Manufacturing and Assembly (DFMA)

In general some goals for designing for manufacturing and assembly are: ease of manufacturing and assembly, lower production cost with maintenance of high quality products. These goals can be attained among other ways by making informed decisions in design of part features and in choosing particular classes of manufacturing process, i.e. casting and molding, deformation, subtractive, and joining.

The table below lists some specific guidelines that should be followed in manufacturing and assembly as well as how we saw them implemented in the competitor's product and areas that we felt could use improvement.

| DFMA Guideline | Good Aspects of Competitor Product | Ideas for Improvement |

|---|---|---|

Minimize Part Count

|

|

|

Standardize Components

|

|

|

Commonize Product Line

|

|

|

Standardize Design Features

|

|

|

Keep Designs Simple

|

|

|

| Multifunctional Parts |

|

Indicator light has button to check if cord plugged in rater than always on |

Ease of Fabrication

|

| |

Avoid Tight Tolerances

|

| |

Minimize Secondary & Finishing Operations

|

|

|

| Take Advantage of Special Process Properties |

|

|

Minimize Assembly Surfaces

|

|

|

Use Subassemblies

|

|

|

Mistake-Proof

|

|

|

Minimize Fasteners

|

|

|

Minimize Handling

|

|

|

Minimize Assembly Direction

|

|

|

Provide Unobstructed Access

|

|

|

Maximize Assembly Compliance

|

|

|

Other

|

|

|

References

Jiang, Jess. "The Price Of Electricity In Your State." NPR, 28 Oct. 2011. Web. 20 Sept. 2012. <http://www.npr.org/blogs/money/2011/10/27/141766341/the-price-of-electricity-in-your-state>

Economic Input Output Life Cycle Assessment (EIO-LCA). US 2002 Industry Benchmark model. Carnegie Mellon University Green Design Institute, 2008. Web. 20 Sept. 2012. <http://www.eiolca.net/>