Toaster

From DDL Wiki

Contents |

Executive Summary

Product

Our product to dissect and analyze was a toaster. For this part of the project, we purchased a $9.99 Chefmate toaster to dissect. We also purchased a $29.99 Hamilton Beach toaster that we hope to compare with our first toaster at a later date.

Function

The purpose of a toaster is to assist in the making of food. Specifically, if the user wants toasted bread or bagels, warmed up waffles, etc. The toaster provides these functions.

To pictorially explain how a toaster is used, pictures from our usability study were taken to show customer product interaction. Following from that, we will delve into how a toaster actually works. From the outside, one might not think a toaster is a complex piece of equipment, but its internals are actually quite intricate. The inputs to the toaster are:

- 800 Watts of power

- food into the slot

- a toast setting

- a force to activate the latching and heating mechanisms.

With these inputs provided, the activating handle is depressed, which completes two separate circuits:

- First, a circuit is completed which provides power to an electromagnet and the timing circuit, holding the toastee inside the toaster where it can be heated.

- The second circuit that is completed is the heating circuit. A current is run through high resistance Nichrome wire, creating heat.

The timing system works as such:

- The variable resistor (regulator knob) controls current to a capacitor, regulating its charge rate. As soon as the capacitor reaches its maximum voltage, it discharges and breaks the power to the electromagnet.

- A spring then pulls the bread holder and toastee back up to where it can be safely removed from the toaster.

- As the spring pulls up the bread tray, the mechanism breaks the heating circuit.

Thus, the outputs of the toaster are heat and warmed food.

Stakeholders

There are at least four major stakeholders in the production and distribution of a toaster:

- Customer

- Company

- Distributors

- Engineers

The customer is only interested in a product if it fulfills their specific needs. In this case, the users need to be able to toast their bread easily and quickly. This is why they are going to purchase a toaster. Although the toaster does fulfill their basic needs, the customers also have minor needs that go along with using the toaster. If these types of needs can be met (ie. containment of crumbs, easy to use, easy retrieval of bread, cool-touch exterior), the toaster would be in much higher demand. In order to fully understand the customer's interactions with the product a usability study was conducted, which helped us further identify the customer's specific needs and opinions of the product.

The company needs are mostly limited to marketing and finance. They main interest and need is to make a profit. This requires finding customers, low manufacturing costs, and low material costs. This requires the company to decipher customer needs and apply them to their product. It also requires the company to work with the engineers and suppliers to ensure a low-cost product that can easily be sold to stores, or distributors, and thus bought by customers.

The distributors have similar needs to the company, they are looking to make a profit. Thus their need is to purchase products from various companies that fulfill needs of their customers. So they depend on the company to have come up with the lowest cost product possible.

The engineers are critical stakeholders, since every other stakeholder's needs has to be met by the engineer's design. The engineers needs are to decrease the amount and cost of material used in the toaster design. It is also the engineers job to design the product using cost and time efficient methods of manufacturing and assembly. Another need of the engineer is to balance cost and design of the product with the environmental impacts caused by the products production/use.

Assembly

Product Analysis

For our product evaluation, we looked at four different types of analysis. Design for Manufacture and Assembly (DFMA), Failure Mode Evaluation and Analysis (FMEA), Design for Environment (DFE), and a quantitative mechanical analysis.

DFMA Analysis

FMEA Analysis

| Part # | Name | Function | Failure Mode | Effects of Failure | S | Causes of Failure | O | Design Controls | D | RPN | Recommended Actions | Responsibility |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 001 | Plastic Casing | Enclose and protect internal components | Warped | Improper fit, Unintended contact with heating element | 10 | Repeated heating and cooling, Improper Manufacturing | 1 | Material Selection, Mold Design | 1 | 10 | HALT for Temperature Variations | Reliability |

| Fractured | Exposure of internal components | 8 | Improper handling | 3 | Material Selection, Poor Packaging | 2 | 48 | Drop Test with and without packaging | Reliability | |||

| # | Name | Function | Failure | Effects | S | Causes | O | Controls | D | RPN | Recommended | Responsibility |

| # | Name | Function | Failure | Effects | S | Causes | O | Controls | D | RPN | Recommended | Responsibility |

| # | Name | Function | Failure | Effects | S | Causes | O | Controls | D | RPN | Recommended | Responsibility |

| # | Name | Function | Failure | Effects | S | Causes | O | Controls | D | RPN | Recommended | Responsibility |

| # | Name | Function | Failure | Effects | S | Causes | O | Controls | D | RPN | Recommended | Responsibility |

| # | Name | Function | Failure | Effects | S | Causes | O | Controls | D | RPN | Recommended | Responsibility |

| # | Name | Function | Failure | Effects | S | Causes | O | Controls | D | RPN | Recommended | Responsibility |

| # | Name | Function | Failure | Effects | S | Causes | O | Controls | D | RPN | Recommended | Responsibility |

| # | Name | Function | Failure | Effects | S | Causes | O | Controls | D | RPN | Recommended | Responsibility |

| # | Name | Function | Failure | Effects | S | Causes | O | Controls | D | RPN | Recommended | Responsibility |

| # | Name | Function | Failure | Effects | S | Causes | O | Controls | D | RPN | Recommended | Responsibility |

| # | Name | Function | Failure | Effects | S | Causes | O | Controls | D | RPN | Recommended | Responsibility |

| # | Name | Function | Failure | Effects | S | Causes | O | Controls | D | RPN | Recommended | Responsibility |

| # | Name | Function | Failure | Effects | S | Causes | O | Controls | D | RPN | Recommended | Responsibility |

| # | Name | Function | Failure | Effects | S | Causes | O | Controls | D | RPN | Recommended | Responsibility |

| # | Name | Function | Failure | Effects | S | Causes | O | Controls | D | RPN | Recommended | Responsibility |

| # | Name | Function | Failure | Effects | S | Causes | O | Controls | D | RPN | Recommended | Responsibility |

| # | Name | Function | Failure | Effects | S | Causes | O | Controls | D | RPN | Recommended | Responsibility |

| # | Name | Function | Failure | Effects | S | Causes | O | Controls | D | RPN | Recommended | Responsibility |

DFE Analysis

Putting a slice of bread in the toaster, one does not often think about the environmental implications this act may have: “What steps were taken to enable this toaster to arrive on my countertop, how much power is it using while toasting, and what will happen to it after it I throw it away?” Delving into the life cycle of a toaster, we see that there is much room for improvement.

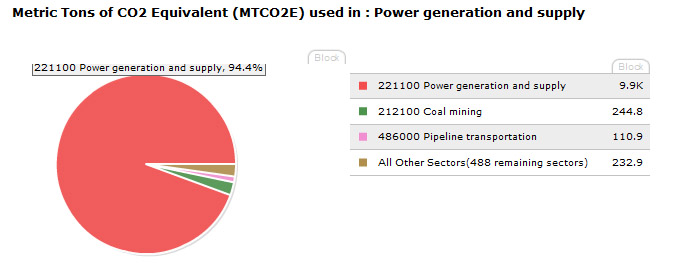

The key element in the life cycle of this appliance is energy. Being made of nearly completely recyclable materials, we are not focusing on the post-use phase. In both the production and use phases of a toaster, power generation and supply is the overwhelming contributor of greenhouse gas emissions. This seems fairly straightforward for the use end – in use, toasters produce little more than heat, from electrical power, and (hopefully) golden brown toast – but this may come as a surprise for the manufacturing end. Indeed, power generation and supply produces nearly four times as much CO2-equivalent than the nearest sectors, truck transportation and steel mills, during the manufacturing of such appliances.

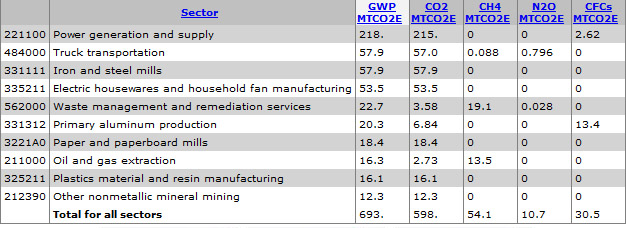

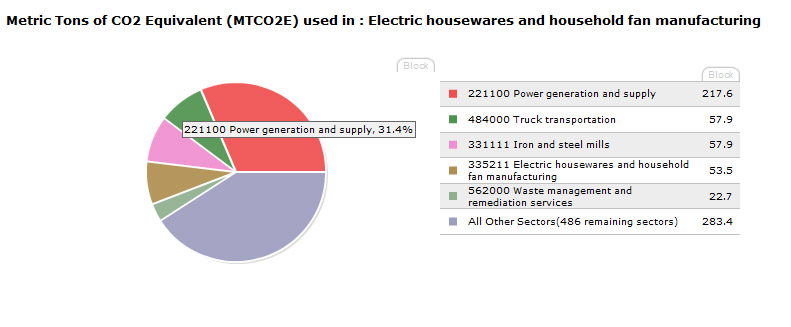

Using the EIO-LCA software from Carnegie Mellon University’s Green Design Institute (results pictured below), we see that every $1,000,000 of production in the ‘Electric housewares and household fans’ sector produces 693 MTCO2E. Given our $10 toaster, this shows us that approximately 0.007 MTCO2E caused by the manufacturing of one toaster. To compare that to the use end, a simple calculation is done:

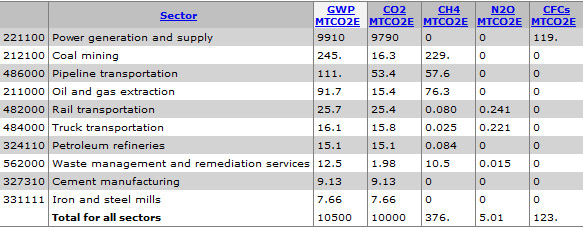

From the EIO-LCA, we see that for every $1,000,000 of production in the ‘Power generation and supply’ sector, 9910 MTCO2E are emitted.

Assuming: $0.10/kWh electricity cost, power consumption is 800W, usage is 6 min (0.1hr) per day, used 300 days out of the year, over the course of a 4 year use-life.

We see that it would cost approximately $9.60 to run this toaster over the course of its life. Given this information, it is seen that the use phase of a toaster’s life emits approximately 0.095 MTCO2E. This is an entire order of magnitude higher than the emissions production phase. Clearly, one of our assumptions, above, needs to be modified. The only option which may not impact the functionality and longevity of the toaster is the power consumption. Furthermore, looking at other toasters, we see that this 800W usage is on the low end of the spectrum. All residential toasters use the same heating method – running current through a filament, which generates heat.

The results for conventional air pollutants, such as SO2, NOx, and CO, show the same result: power generation, both for the creation and use of a toaster, is the largest contributor to harmful emissions.

The numerical results of GHG emissions, above, come with a good level of confidence. Though there are many sub-sectors of the ‘Electric housewares and household fans’ segment, the ‘Small electric household cooking appliances’ sub-sector represents nearly 1/3 of the overall sector.

From our analysis, it appears the best way to approach the DFE is to reduce the power consumption of a toaster. Perhaps an alternative heating method should be considered. A more realistic and attainable possibility is to better insulate the toasting area, as to reduce the amount of heat lost during the toasting process.

| EIO-LCA GHG Results for Electric Housewares and Household Fans |

|

|

| EIO-LCA GHG Results for Power Generation and Supply |

|

|

Mechanical Analysis

References

Degentesh, Drew. "Metal Processing." 24-443: Design for Manufacture. Carnegie Mellon University. 11 Sept. 2008.

Degentesh, Drew. "Injection Molding." 24-443: Design for Manufacture. Carnegie Mellon University. 4 Sept. 2008.

Degentesh, Drew. "Plastics Processing." 24-443: Design for Manufacture. Carnegie Mellon University. 2 Sept. 2008.

Thompson, Rob. Manufacturing Processes for Design Professionals. London: Thames & Hudson, 2007.

Carnegie Mellon University Green Design Institute. (2008) Economic Input-Output Life Cycle Assessment (EIO-LCA) model

Team Members

Future plans:

- Dissect second toaster to continue analysis

- Brainstorm Innovations and Improvements