Toaster redesign

From DDL Wiki

Current revision (23:45, 15 October 2008) (view source) (→Design Problem) |

|||

| (97 intermediate revisions not shown.) | |||

| Line 3: | Line 3: | ||

= Executive Summary = | = Executive Summary = | ||

| - | + | Since our first report, we conducted a thorough user survey, from observing toaster use, to questioning customers at retail stores, to receiving 90 responses to an online survey. From these surveys, we learned many important things about what consumers think of current toaster products, briefly summarized here: | |

| - | + | '''Issues with toaster''' | |

| + | *Inconsistent toasting and inaccurate toast settings | ||

| + | *Food product getting stuck in toaster | ||

| - | + | '''Necessary Attributes''' | |

| + | *Accurate settings | ||

| + | *Wide slots | ||

| + | *Crumb Tray | ||

| - | + | Based on these stakeholder needs, we generated over one hundred concepts for toaster innovation. From those, we narrowed our options down to four concept designs. The designs were: | |

| - | + | *Clear Walled Toaster | |

| + | *Fold Out Wall Toaster | ||

| + | *Front Load Toaster | ||

| + | *Enclosed Toaster | ||

| - | + | A Pugh Chart was made in order to help us decide which concept to recommend for prototyping. We have decided to pursue the Fold Out Toaster design, for the following reasons: | |

| - | + | *Virtually eliminates the problem of having toast stuck in the toaster | |

| + | *Easier to maintain and clean | ||

| + | *Easier to load and start | ||

| + | *Should maintain affordability of the toaster | ||

| - | + | We received feedback from our peers, who were concerned about the safety of this concept. We believe it will be just as safe as a conventional toaster, and will aim to prove this with our prototypes. | |

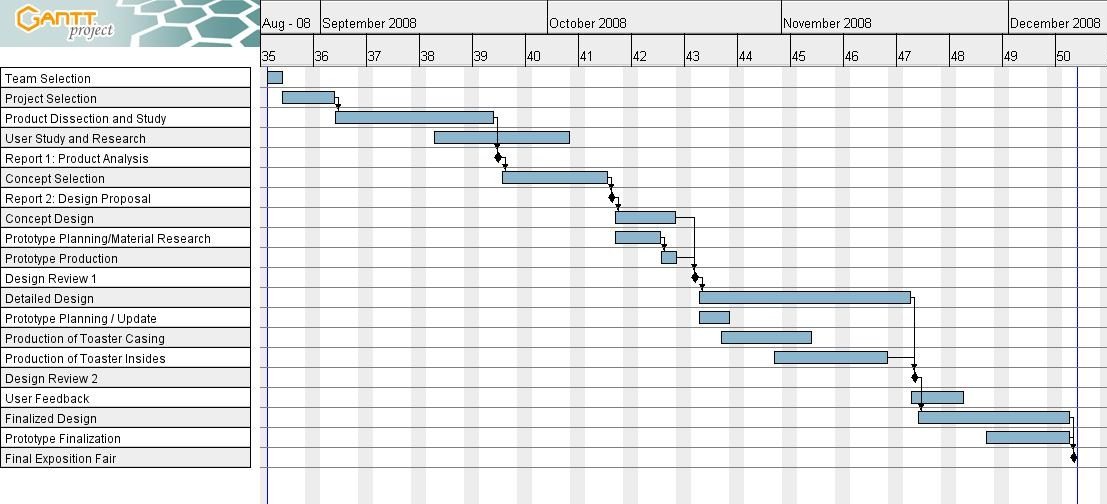

| - | + | For the next milestone, we will create a prototype of the mechanism for the fold out walls. This will be a proof of concept. Following that, we will produce a functional prototype. A detailed schedule can be found in our Gantt Chart, in Section 4. | |

| - | + | = Research and Observations = | |

| - | + | In order to help determine and evaluate potential conceptual designs, our team researched users, stakeholders, design problems, patents, and current products. This research allowed us to determine our design problems as far as toasters go and move forward to narrow down our ideas to four concepts. | |

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | == Users Survey== | |

| - | + | ||

| - | + | ||

| - | [[ | + | We really wanted to know what our users thought about and how they interacted with toasters. This would give us a good idea of what was good and what needed improvements. We created our |

| + | <u>[[toaster survey]]</u> using www.surveymonkey.com and sent it to all our family, friends, organizations on campus, and to Misc Market. We received responses from 90 people. Here are our results: | ||

| - | + | *59% Female | |

| - | * | + | *41% Male |

| - | * | + | |

| - | + | ||

| - | + | ||

| - | + | *Mean Age: 36 | |

| - | == | + | *66% of people would spend between $19.99 and $39.99 on a toaster |

| + | *29% of people would spend $19.99 on a toaster | ||

| + | |||

| + | When asked what was necessary in a toaster, people responded: | ||

| + | *Accurate Toast Settings – 92% | ||

| + | *Crumb Tray – 81% | ||

| + | *Wide Slots – 67% | ||

| + | *Cool Touch Sides – 53% | ||

| + | *Cancel Button – 50% | ||

| + | |||

| + | The biggest problems with toasters were: | ||

| + | *Overcooked/uneven & other issues with timing – 41% | ||

| + | *Toast stuck in toaster – 21% | ||

| + | |||

| + | In the survey, only 8% reported that there was nothing wrong and no improvements on their toaster. | ||

| + | |||

| + | This survey was a good representation of our users, as the mean age was 36. We had people from all ages and all occupations, a real random representative of users. The results of the survey relayed to us that there is a great deal of room for improvement and innovation in a toaster. Not only are there many issues that need to be addressed, but there are also a restraint of keeping the toaster low price. | ||

| + | |||

| + | == Expert Interview: Pamela's in Squirrel Hill == | ||

| + | |||

| + | [[Image:Pamelas.jpg|300px]] | ||

| + | [[Image:Pamelas_hotcake.jpg|300px]] | ||

| + | |||

| + | For getting more information about what users like or dislike about toasters, we decided to ask the people preparing food at Pamela's Restaurant in Squirrel Hill for their expert advice. Information was gathered on the type of toaster in use, and how they felt about it. A conveyor toaster was being used at the restaurant, due to the high volume of bread that needed to be toasted quickly and efficiently. On asked why a pop up toaster was not desired, the employee said that he thought the conveyor toaster worked very well for the needs of the restaurant. A pop up toaster would not be able to cope up with the large demand of toast during breakfast and rush hours, and would need to have many toasting slots in order to keep up. This would be impractical as space was a limiting factor at Pamela's. Another reason that the employee mentioned was the fact that no one had to keep watch to see if a pop up toaster was toasting right or not. The conveyor toaster's slow continuous tread surface also ensures reasonably even toasting, and little supervision. This information was useful to us, as we could understand what markets our toaster could target, and what needs need to be met. We believe that Pamela's is a good example of a business that would use a toaster, and think that the information gathered here would be very similar to other restaurants as well. | ||

| + | |||

| + | == User and Stakeholder Needs == | ||

| + | |||

| + | We focused on three major stakeholders in the production and distribution of a toaster. These stakeholders are very influential to the design process and the decisions made. Each represent a different viewpoint and have various needs that are important to them. | ||

| - | |||

* Customer | * Customer | ||

| - | * | + | ** affordable |

| - | * | + | ** intuitive design and use |

| - | * | + | ** reliability |

| + | ** quick toasting | ||

| + | ** safe | ||

| - | |||

| - | + | * Manufacturing | |

| + | ** low part count | ||

| + | ** affordable | ||

| + | ** least amount of tools necessary | ||

| - | |||

| - | + | * Retail | |

| + | ** low volume | ||

| + | ** easy stacking packaging | ||

| - | == | + | == Existing Toasters and Relevant Patents == |

| - | |||

| - | |||

| - | |||

| - | |||

| - | + | [[Image:dyson-toaster.jpg|300px]] | |

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | *Clear-wall glass toaster, with heating coils between two plates of glass. Only a single slice toaster. | |

| - | |||

| - | |||

| - | |||

| - | + | [[Image:transparent_toaster.jpg|300px]] | |

| - | + | *Glass walled toaster. Glass is heated from the base. Also, only a single slice toaster. Both these clear toasters show the toast as it is cooking, and allow the user better control over the done-ness of their food. | |

| - | |||

| - | |||

| - | |||

| - | |||

| - | [[Image: | + | [[Image:toaster-modern.jpg|300px]] |

| - | + | *Recently patented toaster, with programmable toast settings and memory of up to 3 settings. | |

| - | + | ||

| - | |||

| - | |||

| - | |||

| - | + | [[Image:dropdowntoaster-1.jpg|300px]] | |

| - | + | ||

| - | + | *Toaster which drops food out the bottom when cycle is complete, making it easier to access toast, but is much less space efficient. It seems more suited for commercial applications. | |

| - | |||

| - | |||

| - | + | [[Image:orb-toaster.jpg|300px]] | |

| - | + | *Another drop down toaster, with an artistic twist to it. More of a residential drop down toaster. | |

| - | |||

| - | |||

| - | + | [[Image:conveyor-toaster.jpg|300px]] | |

| - | + | *Commercial conveyor type toaster. Is very effective for toasting large amounts of toast. Thus, it is the choice of many food service establishments. Downsides are space usage and large power consumption. | |

| - | + | == Design Problem == | |

| - | + | '''Modes of Dissatisfaction (MoD)''' | |

| - | + | Here are a few examples of situations which user may not like when using a toaster, and is actually quite common from our user survey data. | |

| - | + | *Bread gets stuck in the toaster, and is hard to get out. | |

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | * | + | |

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | [[Image:toaster_mod1.JPG|300px]] | |

| + | [[Image:toaster_mod2.JPG|300px]] | ||

| + | [[Image:toaster_mod3.JPG|150px]] | ||

| + | [[Image:toaster_mod4.JPG|150px]] | ||

| - | + | *Uneven toasting | |

| - | + | [[Image:toaster_mod5.JPG|300px]] | |

| - | + | ||

| - | + | ||

| - | + | *Extremely Burnt toast | |

| - | + | [[Image:toaster_mod6.JPG|300px]] | |

| - | + | *Toast does not pop up all the way | |

| - | + | [[Image:toaster_mod7.JPG|300px]] | |

| - | + | ||

| - | + | ||

| - | + | *Toast catching on fire | |

| - | + | [[Image:FireFIREfire.gif|300px]] | |

| - | + | = Design Concepts = | |

| - | + | ||

| - | + | From our brainstorming and list of 100 ideas, we have narrowed down our ideas to 4 concepts. These concepts are the ideas that we thought were most tangible and were chosen based on user study research. | |

| - | + | ||

| - | + | == Concept 1: Clear Walled Toaster == | |

| - | + | ||

| - | + | ||

| - | + | ||

| - | + | [[Image:Toaster-ClearWall-Overall.jpg|500px]] | |

| - | | [[Image: | + | |

| - | + | One of the concepts that was considered from the 103 brainstorming ideas was a clear walled toaster. The reasoning behind this was that from the data we gathered from the survey, it was noted that one of the issues that users has with toasters was that they had no idea how toasted the bread was, until it popped out. The concept of a clear walled toaster would alleviate this problem. The user would always know how toasted the bread was at any given instant, and if no more toasting was deemed necessary, the user could terminate the toasting process if he/she wished. This design would require higher maintenance compared to the other conceptual ideas and the stock toaster, as the user would have to continually clean the toaster to keep it looking its best all the time. This cleaning upkeep may not be all a waste of time though. With care and cleaning, the toaster would be a very chic addition to any kitchen, with its shiny glass walls and look of sophistication. | |

| - | + | ||

| - | | | + | The glass walled toaster would have the following interesting features for practical operation: |

| + | |||

| + | *The glass used in the toaster would be tempered so it would be able to withstand the high temperatures of a toaster. | ||

| + | *The heating element would be stuck onto the glass sheets in a similar grid like arrangement like that of a normal toaster. | ||

| + | *Multiple layers of glass would be placed in between the heating glass, and the outside of the toaster (the user side). The layers of air in between the glass sheets would insulate the user from the heat of the heating glass. As glass and air are BOTH insulators, this would allow for safe operation of the toaster. | ||

| + | *A cancel button and toasting selection dial would also be standard. Everything else resembles a classic toaster. | ||

| + | |||

| + | This toaster would clearly be able to address some stakeholder needs, but we think that the cost of of manufacture would be higher than what we would like. The toaster does not address the scenario of what happens when the bread gets stuck in the slot, and it may be difficult to get out. The summary of advantages and disadvantages are listed below. | ||

| + | |||

| + | Advantages: | ||

| + | |||

| + | *Can see toast 'toast' | ||

| + | *Looks cool | ||

| + | |||

| + | Disadvantages: | ||

| + | |||

| + | *May be expensive to manufacture | ||

| + | *Toast may get stuck in slot | ||

| + | *High maintenance | ||

| + | |||

| + | == Concept 2: Fold Out Toaster == | ||

| + | |||

| + | The fold out toaster design is intended to solve several problems users have with toasters as well as major failure modes. The heating sides will use a solid sheet of conductive material to promote more even heating and protect the internal components. These sheets will also protect the user from internal components and make it nearly impossible for the toast to get caught and shred during ejection. Small shelves will run up and down the fold out sides to push the toast up, similar to a conventional toaster. This will allow the user to pick up the toast from the top of the ejected side. | ||

| + | |||

| + | [[Image:toaster-FoldOut-Overall.jpg|300px]][[Image:toaster-FoldOut-Open.jpg|300px]] | ||

| + | |||

| + | This new toaster will begin operation whenever the user pushes the handle down OR closes the fold out sides manually. Pushing together the sides of the toaster is a much easier action than pushing down the small handle on conventional toasters. The inside heating panels will be able to "float", allowing various sizes of bread to be toasted equally. The fold out panel will push the bread flat against the inside panel, such that both sides of the bread are pushed up against the conductive material. | ||

| + | |||

| + | [[Image:Toaster-FoldOut-Mechanism.jpg|300px]] | ||

| + | |||

| + | Fold out sides allow for much easier loading of toasting products as well. Different shape and size products can simply be placed on the diagonal panel and pushed in to toast. Smaller items that would normally be difficult to remove after toasting will be much more accessible. No more sticking a fork in the toaster to remove inadequately ejected food products. | ||

| + | |||

| + | {| | ||

| + | | | ||

| + | Advantages: | ||

| + | * More even, consistent heating | ||

| + | * Easier to load and start | ||

| + | * Accessible for easy cleaning | ||

| + | * More reliable ejection system | ||

| + | | | ||

| + | Disadvantages: | ||

| + | * More parts to assemble | ||

| + | * Difficulty in storing | ||

| + | * Expensive | ||

| + | * Possibly less safe for the user | ||

| + | | | ||

|} | |} | ||

| - | == | + | == Concept 3: Enclosed Toaster == |

| - | + | ||

| - | + | The enclosed toaster concept addresses certain, key stakeholder needs. Specifically, an enclosed design would allow for more uniform heat distribution within the toaster, helping to uniformly toast the food. Another important improvement over the standard toaster is that it would lessen the heat and power needed for each toasting cycle. In current toasters, energy is wasted because of the open toaster slots. Having a capping system would prevent much of this convection to the environment. Thus, the cycle times could be shortened, and less power could be used. | |

| - | + | There are, however, issues with such a design. First, it does not address the issue of the bread, bagel, or pastry becoming stuck in the toaster. In fact, it would likely make removing such a piece of food even more difficult. Also, it brings about more complexity in a toaster. This has two effects on the stakeholders. For the manufacturer, it introduces more steps and parts to be assembled on the toaster, raising production costs. For the user, more complexity often decreases reliability. In this case, it may cause more nuisances with toasters; for example, the lid getting stuck closed. | |

| - | + | The basic mechanism is shown below. Essentially, a thin rod would connect the bread holder to the lid. As the bread holder rises, it pushes up the lid. In this way, the main mechanism of ejecting the toast would not be modified, so it would be a relatively simple addition to the toaster and toaster manufacturing process. | |

| - | + | [[Image:Toaster-Enclosed-Front.jpg|300px]] | |

| + | [[Image:Toaster-Enclosed-Mechanism.jpg|150px]] | ||

| - | + | To summarize: | |

| - | + | '''Advantages''' | |

| + | *More even toasting | ||

| + | *Less power consumption | ||

| - | + | '''Disadvantages''' | |

| + | *Potentially more difficult to remove toast | ||

| + | *Adds complexity | ||

| + | *Reliability issues | ||

| - | + | == Concept 4: Front Loading Toaster == | |

| - | + | [[Image:Toaster-FrontLoad-Overall.jpg|300px]] [[Image:Toaster-FrontLoad-ToastTray.jpg|300px]] | |

| - | + | The front loading toaster concept came about in the attempt to come up with an innovative way of making the toaster more user friendly and help toasting stay uniform and even. The toaster still would have a toaster settings knob that would adjust the level of browning, but the loading and ejection methods would be different. | |

| - | + | The toast is loaded side by side horizontally, which makes the toaster much wider but also a lot shorter. By doing this, the heating coils are not doubled up like the middle section of a traditional toaster. This will keep one side of the toast from being more toasted than others. | |

| - | + | When loading the toast, the toast is placed on a toasting tray. This tray then is brought into the toaster and ejected just like a DVD toaster. This should keep people from using bread that is too big for the toaster, and thus also address the issue of toast being stuck in the toaster. Another thought was that having this front loading toaster made toaster much easier for elderly and children as it was easier to reach and extremely intuitive. (Most people are familiar with DVD players or computer CD drives) | |

| - | + | ||

| + | | | ||

| + | Advantages: | ||

| + | * More even, consistent heating | ||

| + | * Easier to load and use | ||

| + | * Keeps bread from getting stuck in the toaster | ||

| + | * Address young and old users | ||

| + | | | ||

| + | Disadvantages: | ||

| + | * More parts to assemble | ||

| + | * Larger counter footprint | ||

| + | * Expensive Ejection system | ||

| + | |||

| + | == Concept Comparison with Pugh Chart == | ||

| + | |||

| + | {| class="wikitable" border="1" cellspacing="0" align="center" | ||

| + | |||

| + | |- align="center" | ||

| + | ! colspan="2" | Description | ||

| + | | Standard Toaster || Clear Wall Toaster || Fold Out Toaster || Enclosed Toaster || Front Load Toaster | ||

| + | |- align="center" | ||

| + | ! colspan="2" | Sketch || [[Image:toaster.jpg|100px]] || [[Image:Toaster-ClearWall-Overall.jpg|100px]] || [[Image:toaster-FoldOut-Open.jpg|100px]] || [[Image:Toaster-Enclosed-Front.jpg|100px]] || [[Image:Toaster-FrontLoad-Overall.jpg|100px]] | ||

| + | |- align="center" | ||

| + | | style="border-bottom:3px solid grey;" | '''Criteria''' || style="border-bottom:3px solid grey;" |'''Weight''' || style="border-bottom:3px solid grey;" | '''Datum 1''' || style="border-bottom:3px solid grey;" | '''Design 1''' || style="border-bottom:3px solid grey;" | '''Design 2''' || style="border-bottom:3px solid grey;" | '''Design 3''' || style="border-bottom:3px solid grey;" | '''Design 4''' | ||

| + | |- align="center" | ||

| + | ! Manufacture/Assembly | ||

| + | | 2 || 0 || - || - || - || - | ||

| + | |- align="center" | ||

| + | ! Affordable | ||

| + | | 3 || 0 || - || - || 0 || 0 | ||

| + | |- align="center" | ||

| + | ! Toasting Consistency | ||

| + | | 2 || 0 || ++ || 0 || + || 0 | ||

| + | |- align="center" | ||

| + | ! Toast Retrieval/Ejection | ||

| + | | 3 || 0 || 0 || ++ || 0 || ++ | ||

| + | |- align="center" | ||

| + | ! Storage | ||

| + | | 1 || 0 || 0 || - || 0 || -- | ||

| + | |- align="center" | ||

| + | ! Maintenance | ||

| + | | 1 || 0 || - || ++ || 0 || 0 | ||

| + | |- align="center" | ||

| + | ! Safety | ||

| + | | 1 || 0 || - || 0 || - || + | ||

| + | |- align="center" | ||

| + | ! style="border-bottom:3px solid grey;" | Easy to Use | ||

| + | | style="border-bottom:3px solid grey;" | 1 || style="border-bottom:3px solid grey;" | 0 || style="border-bottom:3px solid grey;" | ++ || style="border-bottom:3px solid grey;" | + || style="border-bottom:3px solid grey;" | 0 || style="border-bottom:3px solid grey;" | 0 | ||

| + | |- align="center" style="border-bottom:3px solid grey;" | ||

| + | ! colspan="2" | + | ||

| + | | 0 || 6 || 9 || 2 || 7 | ||

| + | |- align="center" | ||

| + | ! colspan="2" | 0 | ||

| + | | 9 || 2 || 2 || 5 || 4 | ||

| + | |- align="center" | ||

| + | ! colspan="2" | - | ||

| + | | 0 || 7 || 6 || 3 || 2 | ||

| + | |- align="center" | ||

| + | ! colspan="2" style="border-top:3px solid grey;" | Net Score | ||

| + | | style="border-top:3px solid grey;" | 0 || style="border-top:3px solid grey;" | -1 || style="border-top:3px solid grey;" | 3 || style="border-top:3px solid grey;" | -1 || style="border-top:3px solid grey;" | 3 | ||

| + | |} | ||

| + | |||

| + | = Design Schedule = | ||

| + | |||

| + | [[Image:ToasterSchedule.jpg]] | ||

| + | |||

| + | = Recommendation Summary = | ||

| + | |||

| + | [[Image:Toaster-FoldOut-Overall.jpg|300px]][[Image:Toaster-FoldOut-Open.jpg|300px]] | ||

| + | |||

| + | After considering many potential designs and comparing the top concepts, we decided to prototype the fold out toaster design. This design was chosen over the others because it address more problems. We believe this design has the potential to become a breakthrough in toaster technology. Not only does it toast bread, but it ejects it in a way that is easier to retrieve. | ||

| + | |||

| + | The other top concepts attempt to address the even and consistent heating problem while ignoring the problems users encounter with ejection systems. The fold out design provides a potential solution to even heating with its solid conductive plates lining both sides. The inner "floating" plate pushing the bread against these plates helps maximize the even heating potential. | ||

| + | |||

| + | The innovative ejection system makes toastable products of all sizes easier and safer to toast. The enclosed and clear walled toasters use the same ejection mechanism that has failed in the past, while the front loading toaster may be easier for the user to manually pull out, but may have issues ejecting on its own. A fold out toaster would have a much harder time getting stuck closed. In the unlikely event that it does, the user could actually pull it open by force, while the clear walled and enclosed toasters make this impossible to do safely. | ||

| + | |||

| + | The three other toaster designs also are much more difficult to clean properly. The clear walled toaster makes cleaning more necessary, but would be difficult to clean well since it would have to be partially disassembled. A fold out toaster would easily expose all surfaces the user would usually want to keep clean. Overall, the fold out toaster seems to have the most potential to replace the old style toaster. It will perform most the functions users would want in a good, reliable toaster. | ||

=Team Members= | =Team Members= | ||

| Line 724: | Line 336: | ||

|[[Image:Toaster-Jon.JPG|200px]] | |[[Image:Toaster-Jon.JPG|200px]] | ||

|[[Image:ToasterAkshay.JPG|200px]] | |[[Image:ToasterAkshay.JPG|200px]] | ||

| - | |[[Image:Toaster- | + | |[[Image:Toaster-Ian2.JPG|200px]] |

|- | |- | ||

| - | | style="text-align: center;" | | + | | style="text-align: center;" | Front Loading Toaster Concept, User Study, Design Problems |

| - | | style="text-align: center;" | | + | | style="text-align: center;" | Fold Out Toaster Concept, Recommendation Summary |

| - | | style="text-align: center;" | | + | | style="text-align: center;" | Clear Wall Toaster Concept, Expert Interview, Design Problems |

| - | | style="text-align: center;" | | + | | style="text-align: center;" | Enclosed Toaster Concept, Executive Summary, Patent and Market Research |

|- | |- | ||

| - | |} | + | |} |

| - | + | = Appendix = | |

| - | + | == Possible Innovations == | |

| - | + | ||

| - | + | List of 100 ways to innovate a toaster: | |

| + | {| | ||

| + | | | ||

| + | # Pre-Heat button for toaster | ||

| + | # Enclosed toaster (to keep heat inside) | ||

| + | # Open toaster- toaster walls fold down for easy access to done toast | ||

| + | # Illegal toaster. | ||

| + | # NOS toaster + turbo button | ||

| + | # Intercooled Toaster | ||

| + | # Toaster powered by a Honda Civic | ||

| + | # Carbon Fiber Toaster | ||

| + | # Open flame toaster. | ||

| + | # Self Extinguish Toaster | ||

| + | # Turret Toaster (shoots toast at people, motion sensitive, SENTRY toast) | ||

| + | # Toast Launcher | ||

| + | # Optional slot load toaster drive for laptops | ||

| + | # Toaster instead of FlexFan idea. | ||

| + | # Toaster that acts as an electric space heater (built in fan) | ||

| + | # Built in counter top toaster (space saver idea) | ||

| + | # Smore maker addition | ||

| + | # Talking toaster (“You’ll still need a tray. “) | ||

| + | # High Tech Toaster with LCD Display | ||

| + | # Temperature and Time Control | ||

| + | # Bread Clip for self loading toaster. | ||

| + | # Cruton Mode toaster | ||

| + | # Toaster that turns into a portable stove | ||

| + | # Ground effects (Neon Lights on bottom) toaster/ | ||

| + | # One slice USB Toaster | ||

| + | # Solar Slow-Toast Toaster | ||

| + | # HydroPowered Toaster (sink faucet attachment) | ||

| + | # InfraRed heating Toaster | ||

| + | # RollerPress Toaster (two rollers insert and remove toast) | ||

| + | # Battery powered toaster | ||

| + | # Horizontal Eject Toaster | ||

| + | # Toaster which drops toast out of bottom after done. (Top insert) | ||

| + | # Computer controlled Toaster (Toaster Toast Software) | ||

| + | # Military Grade Toaster- Kevlar walls | ||

| + | # Floating Toaster-Put it in your pool! | ||

| + | # Hover Toaster-Give em to your kids! | ||

| + | # Brave little Toaster | ||

| + | # Flamethrower Toaster | ||

| + | # Collapsible toaster | ||

| + | # Dishwasher safe toaster (break apart) | ||

| + | # Team Fortress 2 themed Toaster | ||

| + | # Wireless Extender Toaster | ||

| + | # Voice activated Toaster (for arthritis people) | ||

| + | # Toaster with beeper for blind people. (to let them know where it is) | ||

| + | # Toaster with beeper for not blind people. (just to let you know when its done) | ||

| + | # George Foreman toaster. (Burns the fat away!!) | ||

| + | # Conduction Toaster | ||

| + | # Clear walled toaster | ||

| + | # Build-It-Yourself Toaster | ||

| + | # K’Nex Toaster | ||

| + | # MP3 Toaster | ||

| + | # Spy/Recon/Surveillance Toaster | ||

| + | | | ||

| + | # 5.1 channel Toaster Speaker System (5 Single slice toasters spread around kitchen) | ||

| + | # Butter dispenser toaster (‘Lightly buttered, or HEAVY GREASE…’) | ||

| + | # Crumb compacter, to make crutons. | ||

| + | # Breakfast super combo toaster (Coffee + Toast + Eggs) | ||

| + | # Disposable toaster | ||

| + | # ULET- Ulta Low Emissions Toaster | ||

| + | # Cigar Lighting Cuban Toaster | ||

| + | # Thermo Color change toaster | ||

| + | # Glow in the Dark Toaster | ||

| + | # Nite Light Toaster | ||

| + | # Ironing Toaster | ||

| + | # Front Loading Toaster | ||

| + | # Conveyor-like toaster (front load, come out back) | ||

| + | # Camping Toaster (fire powered) | ||

| + | # Engine Block Toaster | ||

| + | # Warning Toaster (countdown) | ||

| + | # Alternate Fuel Toaster (furnace powered) | ||

| + | # Crank toaster (electricity generating) | ||

| + | # Button/knob for lowering toaster instead of lever | ||

| + | # Window to see toast and determine toasting status | ||

| + | # Customizable toaster (different heating inserts with pictures etc) | ||

| + | # No mica sheet, add heat shield | ||

| + | # clock toaster (classy, alarm clock?) | ||

| + | # Radio Toaster | ||

| + | # Toaster Lamp | ||

| + | # CD player or CD burner that looks like a toaster | ||

| + | # Load internal hard drives into | ||

| + | # Defrost/thawing | ||

| + | # Power Shut off when bread done (toast sensor) | ||

| + | # Launches fireworks | ||

| + | # Drop Down 360 degree rotation | ||

| + | # Open up on side, but drop down normally | ||

| + | # Recycle heat | ||

| + | # VCR toaster | ||

| + | # Enclosed toaster with sliding door | ||

| + | # Laser toaster (scanning) | ||

| + | # Tray drive with eject that brings toast in | ||

| + | # Cooking with light toaster | ||

| + | # Tanning toaster | ||

| + | # Convection heating, add fan | ||

| + | # Flexible toaster (roll up) | ||

| + | # Toaster purse | ||

| + | # Heat wires on glass so you can see it | ||

| + | # Vacuum between glass for cool touch | ||

| + | # Cut toaster for diagonal slices | ||

| + | # Bread crumb maker, shreds toast | ||

| + | # Roller toaster, roll on toasting power | ||

| + | # Expanding width | ||

| + | # Vertical conveyor toaster | ||

| + | # Hot water toaster, attached to house water heater | ||

| + | # Extension cord toaster, allow other things to be plugged into it | ||

| + | |- | ||

| + | |} | ||

Current revision

Contents |

Executive Summary

Since our first report, we conducted a thorough user survey, from observing toaster use, to questioning customers at retail stores, to receiving 90 responses to an online survey. From these surveys, we learned many important things about what consumers think of current toaster products, briefly summarized here:

Issues with toaster

- Inconsistent toasting and inaccurate toast settings

- Food product getting stuck in toaster

Necessary Attributes

- Accurate settings

- Wide slots

- Crumb Tray

Based on these stakeholder needs, we generated over one hundred concepts for toaster innovation. From those, we narrowed our options down to four concept designs. The designs were:

- Clear Walled Toaster

- Fold Out Wall Toaster

- Front Load Toaster

- Enclosed Toaster

A Pugh Chart was made in order to help us decide which concept to recommend for prototyping. We have decided to pursue the Fold Out Toaster design, for the following reasons:

- Virtually eliminates the problem of having toast stuck in the toaster

- Easier to maintain and clean

- Easier to load and start

- Should maintain affordability of the toaster

We received feedback from our peers, who were concerned about the safety of this concept. We believe it will be just as safe as a conventional toaster, and will aim to prove this with our prototypes.

For the next milestone, we will create a prototype of the mechanism for the fold out walls. This will be a proof of concept. Following that, we will produce a functional prototype. A detailed schedule can be found in our Gantt Chart, in Section 4.

Research and Observations

In order to help determine and evaluate potential conceptual designs, our team researched users, stakeholders, design problems, patents, and current products. This research allowed us to determine our design problems as far as toasters go and move forward to narrow down our ideas to four concepts.

Users Survey

We really wanted to know what our users thought about and how they interacted with toasters. This would give us a good idea of what was good and what needed improvements. We created our toaster survey using www.surveymonkey.com and sent it to all our family, friends, organizations on campus, and to Misc Market. We received responses from 90 people. Here are our results:

- 59% Female

- 41% Male

- Mean Age: 36

- 66% of people would spend between $19.99 and $39.99 on a toaster

- 29% of people would spend $19.99 on a toaster

When asked what was necessary in a toaster, people responded:

- Accurate Toast Settings – 92%

- Crumb Tray – 81%

- Wide Slots – 67%

- Cool Touch Sides – 53%

- Cancel Button – 50%

The biggest problems with toasters were:

- Overcooked/uneven & other issues with timing – 41%

- Toast stuck in toaster – 21%

In the survey, only 8% reported that there was nothing wrong and no improvements on their toaster.

This survey was a good representation of our users, as the mean age was 36. We had people from all ages and all occupations, a real random representative of users. The results of the survey relayed to us that there is a great deal of room for improvement and innovation in a toaster. Not only are there many issues that need to be addressed, but there are also a restraint of keeping the toaster low price.

Expert Interview: Pamela's in Squirrel Hill

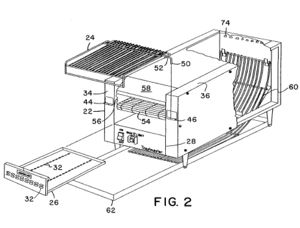

For getting more information about what users like or dislike about toasters, we decided to ask the people preparing food at Pamela's Restaurant in Squirrel Hill for their expert advice. Information was gathered on the type of toaster in use, and how they felt about it. A conveyor toaster was being used at the restaurant, due to the high volume of bread that needed to be toasted quickly and efficiently. On asked why a pop up toaster was not desired, the employee said that he thought the conveyor toaster worked very well for the needs of the restaurant. A pop up toaster would not be able to cope up with the large demand of toast during breakfast and rush hours, and would need to have many toasting slots in order to keep up. This would be impractical as space was a limiting factor at Pamela's. Another reason that the employee mentioned was the fact that no one had to keep watch to see if a pop up toaster was toasting right or not. The conveyor toaster's slow continuous tread surface also ensures reasonably even toasting, and little supervision. This information was useful to us, as we could understand what markets our toaster could target, and what needs need to be met. We believe that Pamela's is a good example of a business that would use a toaster, and think that the information gathered here would be very similar to other restaurants as well.

User and Stakeholder Needs

We focused on three major stakeholders in the production and distribution of a toaster. These stakeholders are very influential to the design process and the decisions made. Each represent a different viewpoint and have various needs that are important to them.

- Customer

- affordable

- intuitive design and use

- reliability

- quick toasting

- safe

- Manufacturing

- low part count

- affordable

- least amount of tools necessary

- Retail

- low volume

- easy stacking packaging

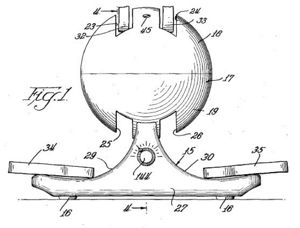

Existing Toasters and Relevant Patents

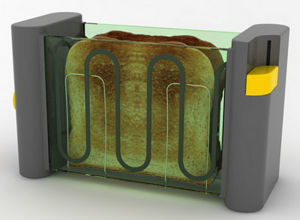

- Clear-wall glass toaster, with heating coils between two plates of glass. Only a single slice toaster.

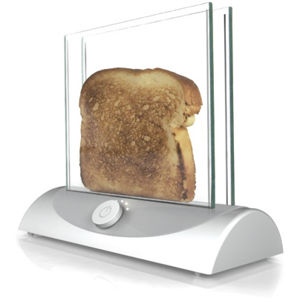

- Glass walled toaster. Glass is heated from the base. Also, only a single slice toaster. Both these clear toasters show the toast as it is cooking, and allow the user better control over the done-ness of their food.

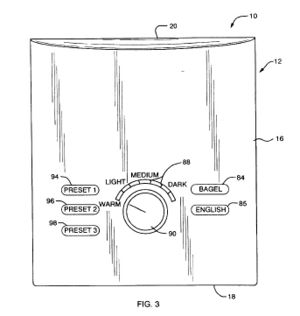

- Recently patented toaster, with programmable toast settings and memory of up to 3 settings.

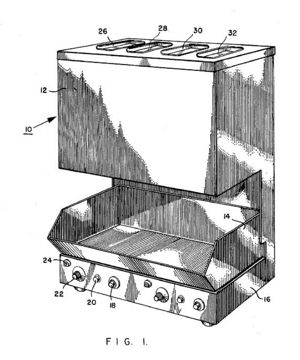

- Toaster which drops food out the bottom when cycle is complete, making it easier to access toast, but is much less space efficient. It seems more suited for commercial applications.

- Another drop down toaster, with an artistic twist to it. More of a residential drop down toaster.

- Commercial conveyor type toaster. Is very effective for toasting large amounts of toast. Thus, it is the choice of many food service establishments. Downsides are space usage and large power consumption.

Design Problem

Modes of Dissatisfaction (MoD)

Here are a few examples of situations which user may not like when using a toaster, and is actually quite common from our user survey data.

- Bread gets stuck in the toaster, and is hard to get out.

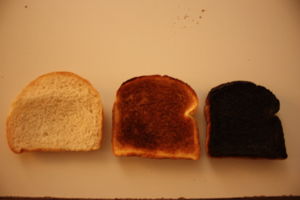

- Uneven toasting

- Extremely Burnt toast

- Toast does not pop up all the way

- Toast catching on fire

Design Concepts

From our brainstorming and list of 100 ideas, we have narrowed down our ideas to 4 concepts. These concepts are the ideas that we thought were most tangible and were chosen based on user study research.

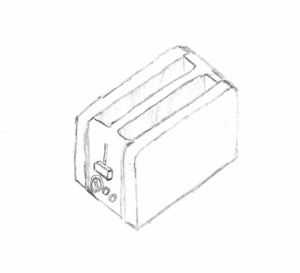

Concept 1: Clear Walled Toaster

One of the concepts that was considered from the 103 brainstorming ideas was a clear walled toaster. The reasoning behind this was that from the data we gathered from the survey, it was noted that one of the issues that users has with toasters was that they had no idea how toasted the bread was, until it popped out. The concept of a clear walled toaster would alleviate this problem. The user would always know how toasted the bread was at any given instant, and if no more toasting was deemed necessary, the user could terminate the toasting process if he/she wished. This design would require higher maintenance compared to the other conceptual ideas and the stock toaster, as the user would have to continually clean the toaster to keep it looking its best all the time. This cleaning upkeep may not be all a waste of time though. With care and cleaning, the toaster would be a very chic addition to any kitchen, with its shiny glass walls and look of sophistication.

The glass walled toaster would have the following interesting features for practical operation:

- The glass used in the toaster would be tempered so it would be able to withstand the high temperatures of a toaster.

- The heating element would be stuck onto the glass sheets in a similar grid like arrangement like that of a normal toaster.

- Multiple layers of glass would be placed in between the heating glass, and the outside of the toaster (the user side). The layers of air in between the glass sheets would insulate the user from the heat of the heating glass. As glass and air are BOTH insulators, this would allow for safe operation of the toaster.

- A cancel button and toasting selection dial would also be standard. Everything else resembles a classic toaster.

This toaster would clearly be able to address some stakeholder needs, but we think that the cost of of manufacture would be higher than what we would like. The toaster does not address the scenario of what happens when the bread gets stuck in the slot, and it may be difficult to get out. The summary of advantages and disadvantages are listed below.

Advantages:

- Can see toast 'toast'

- Looks cool

Disadvantages:

- May be expensive to manufacture

- Toast may get stuck in slot

- High maintenance

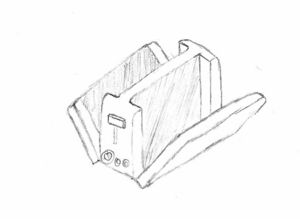

Concept 2: Fold Out Toaster

The fold out toaster design is intended to solve several problems users have with toasters as well as major failure modes. The heating sides will use a solid sheet of conductive material to promote more even heating and protect the internal components. These sheets will also protect the user from internal components and make it nearly impossible for the toast to get caught and shred during ejection. Small shelves will run up and down the fold out sides to push the toast up, similar to a conventional toaster. This will allow the user to pick up the toast from the top of the ejected side.

This new toaster will begin operation whenever the user pushes the handle down OR closes the fold out sides manually. Pushing together the sides of the toaster is a much easier action than pushing down the small handle on conventional toasters. The inside heating panels will be able to "float", allowing various sizes of bread to be toasted equally. The fold out panel will push the bread flat against the inside panel, such that both sides of the bread are pushed up against the conductive material.

Fold out sides allow for much easier loading of toasting products as well. Different shape and size products can simply be placed on the diagonal panel and pushed in to toast. Smaller items that would normally be difficult to remove after toasting will be much more accessible. No more sticking a fork in the toaster to remove inadequately ejected food products.

|

Advantages:

|

Disadvantages:

|

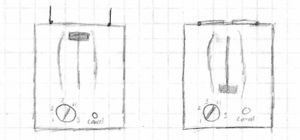

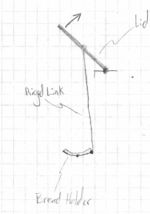

Concept 3: Enclosed Toaster

The enclosed toaster concept addresses certain, key stakeholder needs. Specifically, an enclosed design would allow for more uniform heat distribution within the toaster, helping to uniformly toast the food. Another important improvement over the standard toaster is that it would lessen the heat and power needed for each toasting cycle. In current toasters, energy is wasted because of the open toaster slots. Having a capping system would prevent much of this convection to the environment. Thus, the cycle times could be shortened, and less power could be used.

There are, however, issues with such a design. First, it does not address the issue of the bread, bagel, or pastry becoming stuck in the toaster. In fact, it would likely make removing such a piece of food even more difficult. Also, it brings about more complexity in a toaster. This has two effects on the stakeholders. For the manufacturer, it introduces more steps and parts to be assembled on the toaster, raising production costs. For the user, more complexity often decreases reliability. In this case, it may cause more nuisances with toasters; for example, the lid getting stuck closed.

The basic mechanism is shown below. Essentially, a thin rod would connect the bread holder to the lid. As the bread holder rises, it pushes up the lid. In this way, the main mechanism of ejecting the toast would not be modified, so it would be a relatively simple addition to the toaster and toaster manufacturing process.

To summarize:

Advantages

- More even toasting

- Less power consumption

Disadvantages

- Potentially more difficult to remove toast

- Adds complexity

- Reliability issues

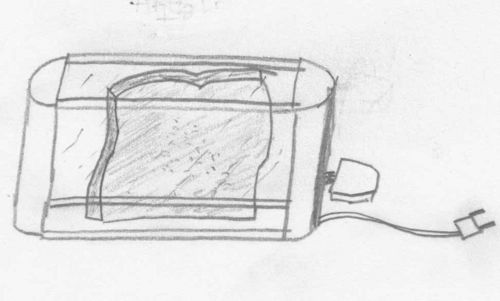

Concept 4: Front Loading Toaster

The front loading toaster concept came about in the attempt to come up with an innovative way of making the toaster more user friendly and help toasting stay uniform and even. The toaster still would have a toaster settings knob that would adjust the level of browning, but the loading and ejection methods would be different.

The toast is loaded side by side horizontally, which makes the toaster much wider but also a lot shorter. By doing this, the heating coils are not doubled up like the middle section of a traditional toaster. This will keep one side of the toast from being more toasted than others.

When loading the toast, the toast is placed on a toasting tray. This tray then is brought into the toaster and ejected just like a DVD toaster. This should keep people from using bread that is too big for the toaster, and thus also address the issue of toast being stuck in the toaster. Another thought was that having this front loading toaster made toaster much easier for elderly and children as it was easier to reach and extremely intuitive. (Most people are familiar with DVD players or computer CD drives)

|

Advantages:

- More even, consistent heating

- Easier to load and use

- Keeps bread from getting stuck in the toaster

- Address young and old users

| Disadvantages:

- More parts to assemble

- Larger counter footprint

- Expensive Ejection system

Concept Comparison with Pugh Chart

Design Schedule

Recommendation Summary

After considering many potential designs and comparing the top concepts, we decided to prototype the fold out toaster design. This design was chosen over the others because it address more problems. We believe this design has the potential to become a breakthrough in toaster technology. Not only does it toast bread, but it ejects it in a way that is easier to retrieve.

The other top concepts attempt to address the even and consistent heating problem while ignoring the problems users encounter with ejection systems. The fold out design provides a potential solution to even heating with its solid conductive plates lining both sides. The inner "floating" plate pushing the bread against these plates helps maximize the even heating potential.

The innovative ejection system makes toastable products of all sizes easier and safer to toast. The enclosed and clear walled toasters use the same ejection mechanism that has failed in the past, while the front loading toaster may be easier for the user to manually pull out, but may have issues ejecting on its own. A fold out toaster would have a much harder time getting stuck closed. In the unlikely event that it does, the user could actually pull it open by force, while the clear walled and enclosed toasters make this impossible to do safely.

The three other toaster designs also are much more difficult to clean properly. The clear walled toaster makes cleaning more necessary, but would be difficult to clean well since it would have to be partially disassembled. A fold out toaster would easily expose all surfaces the user would usually want to keep clean. Overall, the fold out toaster seems to have the most potential to replace the old style toaster. It will perform most the functions users would want in a good, reliable toaster.

Team Members

Appendix

Possible Innovations

List of 100 ways to innovate a toaster:

|

|