Blender redesign

From DDL Wiki

Contents |

Executive Summary

Through numerous testing observation we have decided that the main user problems are the loud noise level of the blender, inconsistent mixing due to ice and liquid separating and the use of excessive manual effort. Due to our own testing we found that the major problems of the blender we used was dripping and leakage, difficulty in mixing all ingredients, cleaning and again the use of too much manual effort. Combining these ideas we have decided that the main problems to change are to lessen the user effort, make a clean and drip free spout/nozzle as well as try to mix all the ingredients efficiently.

Our top 3 ideas to improve the overall blender are the pitcher/base interface, the pitcher/shape insulation and the cover shape addition.

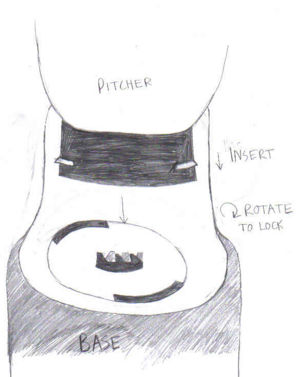

The pitcher base interface allows the blender pitcher to fit securely into the base decreasing manual force and reducing spilling by creating a twisting lock for the pitcher into the base.

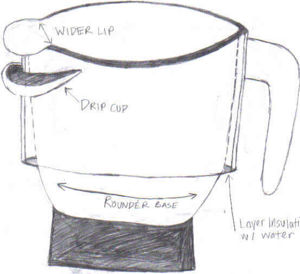

The pitcher/shape insulation allows for the contents of the pitcher to stay cool using a thermal insulator inside the walls of the pitcher.

The cover shape addition allows for better mixing due to a force that can be exerted on the mixture allowing contents to mix more efficiently with the use of a plate with holes that allows liquid to flow upwards but keeps bigger chunks and ice closer to the blades to become blended.

Next we developed a Pugh Chart on the last three concepts and the current blender specifications. Even though the chart showed that the pitcher/base connection had the most positive aspects a more innovative and helpful design would be the cover shape addition.

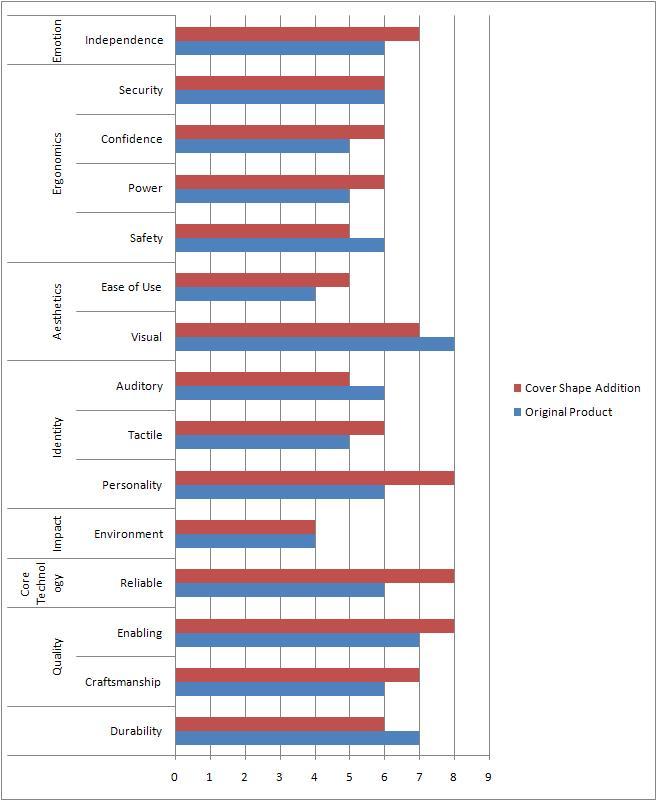

The Value Opportunity Analysis (VOA) chart was used to compare our top design with the current product. Most of the values were relatively close to one another between the two models which made it difficult to decide if our top design is worth pursuing. Because no drastic changes will be made the new designed blender will have a similar appeal as the original.

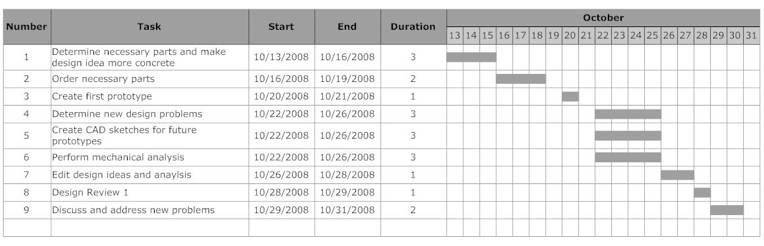

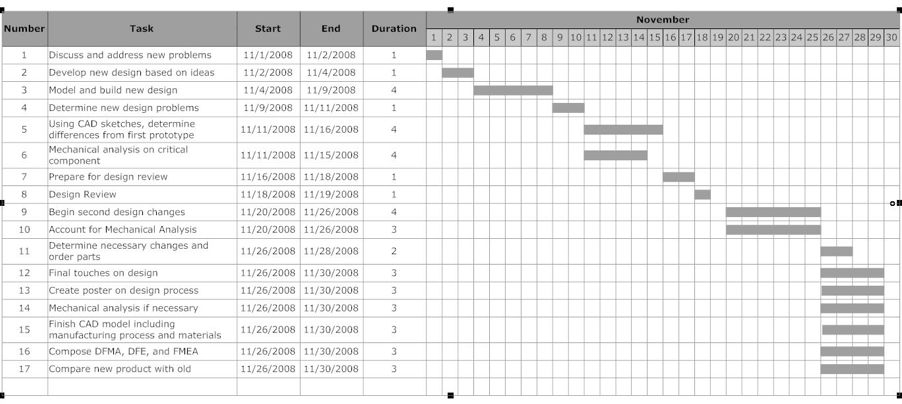

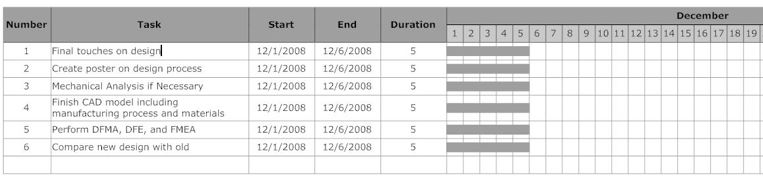

Lastly, we developed a Gantt chart to map out our time effectively and keep our team members informed of design review dates and important deadlines. Also it outlines when the final 2nd prototype will be done.

User Testing

Blender Research and Observations

Our group performed various types of user testing in order to investigate problems associated with the use of a blender. After analyzing the observations we collected, we then identified the major insights and opportunities we have while creating and comparing ideas for possible redesigns of the blender.

To obtain a wide variety of observations, we visited several coffee shops and a restaurant to observe and interview employees that use blenders on a regular basis. We also hosted various user testing events where we made a number of different recipes in the blender, while making observations. To organize this information I have listed each user testing event by date. Under it is the location, the type of user testing, the comments we wrote down, and a list of the major problems found.

User Testing Observations

Monday, Oct. 1

Location: Starbucks – Craig Street

Type of User Testing: Observations and short interviews with employees.

Comments:

- The employees would use large blender pourers for each blended ice coffee.

- They complained of the loud noise of the blender.

- Sometimes the liquid would stay on the top and just the ice would get crushed on the bottom. Another tool was needed to move around the liquid and ice.

- If the ice was too big it was impossible for the blender to break it up.

- An employee described her home experience with a blender saying that sometimes the blender would overflow over the top of the pitcher.

Major Problems Found:

- Noise too loud.

- Pitcher too small for all contents, lead to overflow.

- Not all of ice was blended, larger chunks weren’t broken up.

Tuesday, Oct. 2

Location: Starbucks – Waterfront

Type of User Testing: Observations and short interview with employees.

Comments:

- Biggest complaint was trying to get the drinks out of the blender. Sometimes we had to use a spatula or knock the side of the

pitcher because it would get stuck.

- Very noisy and hard to hear customers when they are talking.

- Noticed that they had to sometimes hold the blender down because it would move around (maybe not a good connection between

the pitcher and base).

- They would jiggle the blender in hopes of getting the ice to go down further down.

Major Problems Found:

- Pouring contents out of blender difficult.

- Very noisy.

- Pitcher/Base connection problems.

- Ice would not go to bottom and not blended.

Wednesday, Oct. 3

Location: Orient Express

Type of User Testing: Observations and short interview with employees.

Comments:

- When inserting the smoothie onto the motor the user had a difficult time lining up the pitcher with the slot. After lining it

up I didn’t hear a click or any noise that would ensure the pitcher was definitely connected.

- Blender had cover with stirring rod on top. Stirring rod was a good feature but it required a lot more work and more hands.

If the stirring rod was electric that would enable user to do other things while blender is on.

- After blending the smoothie, the person emptied the smoothie using a long spatula. The spatula didn’t come with the smoothie

so one would wonder how the blender designer would have expected to empty the pitcher without the spatula. The product should come with all necessary part that will assist the user, including a tool that will ease the emptying process.

- Overall, the user had to his hands too much and the blender was hardly self-operating. It required constant attention to set

up the blender and during the blending process. The user took over 5 minutes to prepare the smoothie, proving the

inefficiency of this product.

Major Problems Found: '

- Pitcher motor connection slot

- Mixing contents so it is easily blended

- Emptying the pitcher

- Required too many hands

Friday, Oct. 5

Location: Janelle’s House

Type of user testing: Blender party; made various recipes, wrote down observations.

Documentation: Blender Party

Comments:

Guacamole Recipe

- Main problems were getting the avacado to the bottom of the blender.

- Had to open it several times and force the pieces down.

- Even after running for several minutes, huge pieces of the parts were still found (quarter of an onion never got

blended...?).

- Very hard to press the buttons when you had to hold the lid down.

- Thought that it would stay well because it was kind of a suction but didn't work.

- Didn't use nozzle, placed cap on it but because there was still the 'chute,' large chunks of food got stuck there.

- Was able to pour easily but stuff would spill down the side (picture 8).

- Difficult to get the final bit at the bottom but wasn't using a spatula, just a spoon (picture 10).

- Cleaning was not hard but not easy either - lots of part to take apart.

- Leaked out the bottom but not a lot, just a little.

Strawberry and Banana Smoothie

- Can see in the pictures that the way the blades worked, pulled down the fluid from the top (picture 21).

- Did very well with the frozen strawberries.

- The nozzle leaked a lot before it was opened

- Poured very slowly - can't make a lot flow out at once (picture 23).

- Much more liquidy than the guacamole and ended up spilling out the bottom.

- Nozzle dripped after it had been opened .

Major Problems Found:

- Hard to get contents to bottom of blender

- Requires too many hands

- Nozzle leakage

- Leaking and spilling from bottom and top of pitcher

- Had to take apart many parts to clean

Summary and Analysis

After compiling the major problems from each user testing event these are the top three problems:

- Pitcher/Motor connection is loose. Fixing this will also help with having to use too many hands.

- Leaking/spilling while blending and pouring.

- Getting a well mixed product. Getting ice and all contents down to blade.

Insights and Opportunities

We believe a well-mixed product is essential to the user. The purpose of the blender is to mix all ingredients thoroughly and provide a consistent end product. In order to get a well-mixed product we need make a design that can push all the contents down closer to the blender. To make this design better for the user we should also design it so it does not require any extra hands to operate.

When the pitcher is loose from the base this creates many problems for the user. They must hold it while blending, keeping them occupied while they could be completing other tasks. Also, it could lead to spilling if the pitcher falls off and at the worst safety issues if it falls and hits something. The vibrations from a loose connection may also be contributing to noise problems. This opportunity for redesigning this part of the blender is simple. We should redesign the pitcher to connect to the base with some sort of locking mechanism. This design should make it easy for the user to insert and take off the pitcher from the base without any safety issues.

The leaking and spilling problems we believe are part of the blending process and cannot be fully eliminated. However, we, as engineers, should find ways to reduce spilling and leaking to make the blending process better for the user. The spilling out the bottom of the pitcher could be due the many components needed for attaching the blade. The spilling while pouring may be due to overflowing from a using a small pitcher and a small lip on the pitcher while pouring. Increasing the size of the pitcher and the lip on the pitcher is an opportunity we will look into more.

Top Design Concepts

After doing our user research and observations, we identified several problem areas. We decided on the following three main design upgrades that would improve a user's blender experience.

| Pitcher/Base Interface | Pitcher Shape/Insulation | Cover/Shape Addition |

|---|---|---|

|  |

|

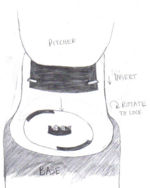

Pitcher/Base Interface

A major difficulty while using a blender was keeping the pitcher and base well attached. Even with the existing trend of a high lip on the base to keep the pitcher from coming out, the interface was poor. Several blenders we looked at failed to show where the pitcher and base had to line up to have a good connection. We propose that a locking mechanism be used whereby the user would insert the blender at certain markings and would twist the blender in to place. The pitcher would only be able to connect to the base with one orientation and would be difficult to topple over when in use.

Pitcher Shape/Insulation

This design focuses on the shape of the blender and increasing the ease of cleaning while decreasin the amount of spilling. The shape of the blender greatly affects the ability of the user to clean the pitcher thoroughly. A more rounded, larger blender would be help solve this problem. While discussing pitcher redesigns, we thought up the concept of possibly insulating the pitcher with a material similar to that used in heat/cool packs. This would decrease the heat transfer through the pitcher greatly. It would be a disadvantage to decrease the surface area so logically, increasing the heat transfer coefficient by using an insulating material would benefit our design.

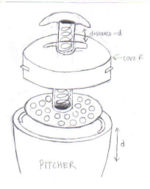

Cover/Shape Addition

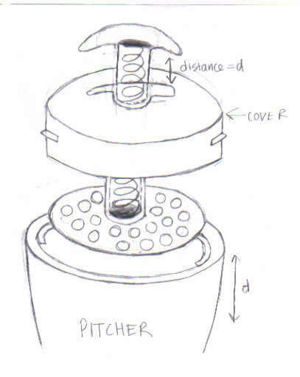

A consumer frustration seen across the board was the effectiveness of the blender at pulling large piece of material down to the blades. One of the blenders that we looked at had blades designed to create a wave motion that would pull the contents continuously. This was an improvement over the other ones that we looked at however the user still had to stop blending and use a spoon to push the unblended materials down. Our design would feature a circular metal plate with holes in it that could be pushed down from the top that allows liquid to pass through but forces larger pieces towards the blades. This design tackles the user complaints of getting a well mixed product.

Pugh Chart

The Pugh chart helped us focus our attention on which design might be best. From this, it appears to be the pitcher/base connection however from user testing, we found the biggest complaint to be getting a well mixed product. This concern outweighs the other problems that would be faced such as an increase in cleaning. Between having a well mixed product and having to clean another part, we feel that users would choose to clean another part. The negative score in manufacturing is due to another part being made however our design could be snap fit together and fixed to the current lid (which has a hole at the top for a possible stir stick). We feel like the lid attachment would be the design that best achieves an improvement in the user's experience.

Value Opportunity Analysis (VOA)

| Blender VOA Chart |

|---|

Emotion

The emotion involved with using a blender is the general security or homeliness of being able to make a dessert or meal from a known starting product. There is no greyness as to what ingredients are in their blended food. Using the blender includes the satisfaction that includes how one feels after they have successfully made their own end product. Finishing a final blended product is a feeling of overcoming and successfully completing the task of preparing a meal. Using a blender to make a meal is not particularly difficult as compared to cooking a meal but it increases the confidence of the user’s food making skills.

Ergonomics

The new product is easier to use because of its ability to blend the mix in a more efficient fashion. This increases the safety because the user does not need to worry about putting extra objects in the pitcher in order to aid in the blending of the contents.

Aesthetics

The new design may contain a bigger scoop to catch the liquid from dripping down the side but the extra lip may look awkward to some consumers. Also the interior ice spring loaded part may look bulky and odd in such a small device. The new design may look more technical and may sway non-technical sided consumers away from buying the product.

Identity

The identity of the new product may give a user a more intelligent identity for using the product because of its interesting advancements. The user may feel more in control and confident in their new product.

Impact

The new design will impact the user based upon its better ability to blend and mix ingredients in the container. When the user is better able to blend their contents, their capabilities increase dramatically and they are not limited in the ability of their mixed contents. The time to blend to a certain consistency is also dramatically decreased as the mixing mechanism is made more efficient. The added lip will aid in cleaning time due to the lessening of spillage over the pitcher.

Core Technology

The technology in our new design is an improvement in the current product and incorporates the current needs of the consumer. The new design will be more versatile in its mixing technique and will prevent unnecessary cleaning due to its new shape.

Quality

Our production capabilities may vary depending upon the availability to properly make the correct moldings and fittings. However, since this will be an innovative addition it will be difficult to manufacture a strong and dependable spring system and this may cause the quality of our product to be less than that of the original product.