Talk:Apple peeler

From DDL Wiki

Client Comments on Report 1

We received your report, and we have some comments and questions. It sounds like you have identified a few opportunities for improvement, including reducing likelihood of being cut, improving flexibility for alternative mounting directions, and improving the suction stability. Please respond point by point to the items below. We are looking forward to seeing your ideas in Report 2.

- Executive Summary: Nice overview of findings. Could be more concise - e.g.: no need to explain FMEA here.

- Executive summary edited. It is now more concise with less trivial explanation.

- Stakeholder Needs: Good initial list. Some needs appear to be missing, such as easy to clean and store, reliable, robustness to working on alternative work surfaces, etc.

- Addressed. More detailed needs have been added.

- Use: Good description and observations. This product as a lot of potential areas for improvement. Is the product intended and/or used for any objects besides apples?

- Potentially yes. The stakeholder needs addresses the robustness in terms of usage with various products.

- Assembly: Clearly labeled.

- Mechanical Function: The report describes the steps the user takes and some observations about use, but there is no section describing how the peeling, slicing and coring actually takes place mechanically. A diagram or labeled picture would help. It is not clear how pressing the vacuum lever creates the suction.

- Diagrams and pictures have been added to explain the process in detail.

- Mechanical Analysis:

- What are the design implications of your analysis question and result?

- The analysis is intended to find out the maximum force user can apply to peel an apple before the device is no longer stable. We have concluded that 40N is enough to peel any apple, and therefore it is unlikely that the user will experience difficulty due to instability.

- How do you know that 40N applied to the handle is sufficient to peel an apple? Do these findings correspond to the experiences of the users?

- By using the Newton meter, we have found out that the maximum force required at any point when peeling an apple is 20N. In most cases, it is much less.

- Please define your notation and be consistent (P versus Pmax, r versus d). Also state where each equation comes from.

- Addressed.

- Your free body diagrams are somewhat confusing as the forces and pivot points seem to move around between the different diagrams. Please explain why they move and justify your assumptions of force and pivot point locations. You may consider simplifying the problem by modeling the suction cup as a pin instead of a cylinder.

- Addressed. Suction cup is simplified to a point.

- Where do your numbers come from, in particular the mass? Is that the measured mass of your product? Does it include the mass of an apple?

- The mass has been quoted from bill of materials. The total mass is calculated by summing the device mass and average mass of an apple which is assumed to be 150g.

- You might need an additional free body diagram to show where you got the suction cup forces from.

- Addressed.

- Your sig figs (111.684N) suggest a level of precision that we are doubtful one could achieve.

- Modified to an appropriate significant figures.

- What are the design implications of your analysis question and result?

- Bill of Materials: Good.

- DFMA: You say that paint is necessary to keep the aluminum parts from rusting? Although aluminum does oxidize, it does not rust like steel. Is there an increased risk because of contact with fruit juices? Please explain. Standardizing fasteners seems like a reasonable goal - are there any other relevant comments about DFA guidelines?

- FMEA: Good list. You only have one failure mode listed for "vacuum", which is simply labeled "failure". Is this due to deformation or use on a rough surface or hardening of the material or some other mode?

- FMEA edited. Several detailed failure modes for the vacuum suction base is now listed in the table - suction base detached from surface, losing suction, and no suction. Different failure causes and RPN numbers are demonstrated.

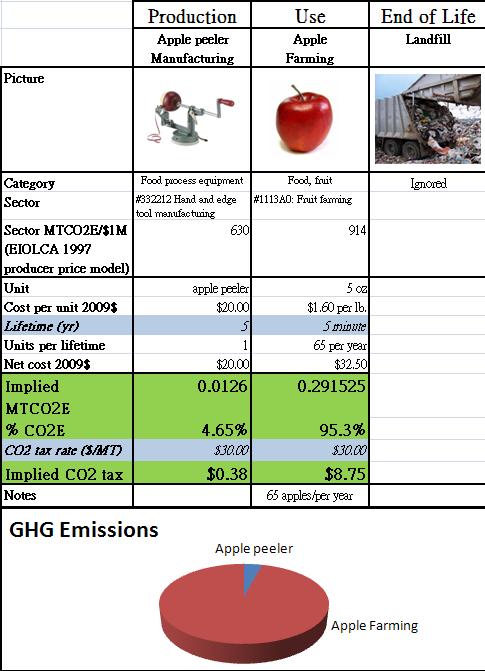

- DFE: Good observations. Do you think the sector you chose is sufficiently representative of the apple peeler? You did not answer our question about a CO2 tax. You say that the product is used by itself. We thought it was used with apples?

- I used the wrong sector,so I went back and change most analysis data in DFE section.

- Do you think the sector you chose is sufficiently representative of the apple peeler?

After researching all the sectors again, we found that #332212 Hand and edge tool manufacturing is a better sector representative of apple peeler than the original sector, #335221: Household cooking appliance manufacturing, because under sector #335221, most activities are such as ovens and stoves manufacturing, and because sector #332212 has a lot similar activities such as Can openers, Axes manufacturing, Forks manufacturing, which some of them are the exact same components on our apple peeler. - You did not answer our question about a CO2 tax. You say that the product is used by itself. We thought it was used with apples?

The C02 taxes shows that the process of manufacturing an apple peeler causes only 0.38/8.75 = 4.3% of the total CO2 produced by growing 65 apples for one year diet.

- If any of your images, figures, or text were taken from another source, please be certain to provide proper attribution.