Window blinds

From DDL Wiki

Contents |

Executive Summary

Window blinds are a consumer product present in almost every household. They offer a cheap and easy way to enhance privacy, control lighting and even affect temperature of a room. Blinds and shades come in many varieties and their pricing varies accordingly. For our product study we examined a set of $3 venetian blinds purchased at target. We performed a user study, product dissection and various analyses to better understand the product. Despite their ubiquity, blinds still present several functional problems including problems with tilting and uneven rising.

During our user study we found that the quality of blinds greatly impacts their rate of failure and tolerance for user input. We found that blinds of higher quality were nearly impossible to ruin, even when trying to do so. Cheaper blinds on the other hand often resulted in unevenness and sporadic tilting when exposed to vigorous user input.

Product dissection gave us a chance to examine the inner working of the blinds and showed us some interesting features indicating a communication link between the design and the manufacturing processes. The lock housing pin shape double to hold the locking gear while holding the entire lock housing in place and required no special tool for insertion.

During our study, we performed DFMA, FMEA well as DFE analysis in order to learn more about our product. We found that many of the components for the blinds were manufactured with very basic processes such as injection molding and bending. The blinds we examined had only 3 mechanical fasteners which indicate that assembling the blinds requires few tools. From our FMEA we saw that the failure mode with the highest RPN score of 160 was due to the main string being a potential choking hazard for small children. This failure mode having the highest RPN score was reflected in the warning labels that appear in three different locations on the blinds.

From our DFE analysis we found that blinds manufacturing represents an extremely small portion CO2 emissions and that they may in fact reduce overall emissions by lowering CO2 emissions form energy used to heat and cool a household. Ultimately the blinds we examined seemed to be an excellent product; easy to manufacture while maintaining low emissions, cheap to purchase, and simple to assemble. The largest problem we found was the rate of failure associated with these inexpensive blinds. Ideally the manufacturing processes would remain mostly unaltered but a design improvement on the blinds seems necessary.

Major Stakeholders

Major Post-production stakeholders include Customers, Users, Installers and Retailers.

Customer: Customers include those individuals or parties who actually purchase the blinds to fulfill a purpose. What they might be looking for in a set of blinds can vary from style and color to functionality and efficiency. Should there be any problems with the original set of blinds, parts should be easily replaceable. For consumers, it is all about an attractive, low-cost, and easy-to-maintain product.

Customer product needs: attractiveness, easily maintained, easily replaceable, good value

User: Users in most cases will not be limited to the customer. Depending on where the blinds are installed, there could be 1 user or 1,000 users. A user will expect the blinds to be effective, sturdy and durable, and easy to use and clean.

User product needs: durability, effectiveness, easily adjustable, easily cleaned, standard design, sturdiness

Installer: The installer could be the customer, but in some cases could also be a professional who is familiar with home product installations. Of utmost importance in this case will be the compatibility of the blinds with standard tools and the minimization of steps for assembly.

Installer product needs: compatibility with standard tools, easily assembled, light-weight

Retailer: For retailers, it is necessary that blinds not only cater to consumer needs, but do so in a way that gives retailers an incentive to sell them. Specifically, there should be sufficient variety in size, color, etc. to capture the needs of most customers, the blinds should fit into packaging that is easy to handle, store and ship, and the wholesale cost should be low enough that the retailer can make a profit.

Retailer product needs: variety (size, color, style), easily handled packaging (for storage and shipping), profitable

Distributor: The distributor will be is responsible for relocating the product from where it is assembled to where it is sold. They require the packaging to use space efficiently and they benefit from a light weight product that would make transportation less costly.

Distributor needs: efficient packaging, light weight product

Product Use

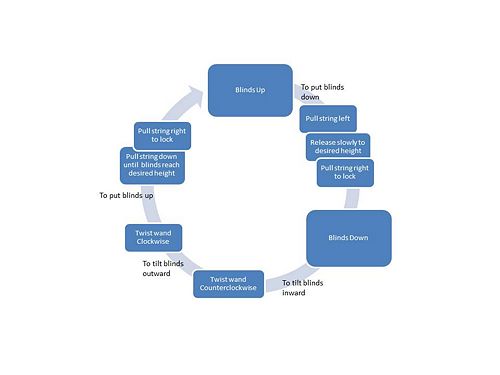

Here is an analysis of how to use the product as well as the different problems encountered during use.

Process of Use

If the blinds are down:

To tilt the blinds, grab the tilt wand and twist it either right or left to tilt in or out, respectively. To pull up, grab and tug the main string straight down until blinds are at the desired height. While keeping tension in the string, tug the string to the right, towards the outer edge of the blinds, to engage the locking mechanism. Then let go of the string.

If the blinds are up:

To let down, grab and tug the string to the left, towards the center of the blinds, to disengage the locking mechanism. Allow the string to retract slowly as the blinds fall. When at the desired height, tug the stright to the right to engage the lock. Let go of the string.

Here is a flow chart to illustrate use.

User Study

The user study involved the observation of two different sets of users operating two separate sets of blinds. Each user was instructed to first pull the blinds up, let the blinds down, and then adjust the tilt of the blinds. After that, we asked a few questions about when and how they used their blinds in general.

The first set of users was a couple of engineers on our design team. We found that as one of them used this set of blinds, which was a different size and material than the set that was dissected, they moved up and down fairly easily, and tilted inward and outward with no problems. The user was able to pull the blinds to different heights to lock them in place, then raise or lower them reasonably quickly with no mechanical malfunctions. Due to the size of the blinds, he noted that it did take a firm pull to unlock them. Also, if adjusted too quickly, individual blinds might tilt themselves or the entire base would become crooked. We also noticed a small bead on the main string that, in normal use, regulated the amount of tension on each of the “breakout strings” such that the blinds could be raised and lowered uniformly.

When asked about typical use of the blinds, the other engineer, in whose apartment the blinds were installed, noted that she rarely adjusts them. Generally the blinds were kept at about half height, and only tilted to adjust the amount of light and visibility in the room.

The second part of the user study involved two users who were not engineers. We observed them in their home with a set of their own blinds. This set of blinds was of similar size and material as the set that was dissected. Both subjects demonstrated that ordinary use of these blinds was normal. When pulled or released too quickly, there was a tendency for the blinds to fall crookedly or blinds to tilt themselves. When this happened, the user was able to correct the issue with no problem, as though she was familiar enough with the blinds to know exactly what to do. We noticed that there was no bead on the main string of this set to regulate the string tension. We believe this to be the cause of the more frequent malfunction.

When asked about typical use of the blinds on a given day, they noted that they would open the blinds to add light to the room or to see outside during the day. At night, they would close the blinds for privacy. When asked about what it meant to “open” the blinds, they noted that about half of the time this meant pulling the blinds up, and the rest of the time it meant to tilt them open. We went on to ask about the users’ expectations of their blinds, they expected that when the blinds were closed, no one could see past them, and when they wanted, that they were easily adjustable.

Our conclusions from this study were based on the active use of the blinds. Both sets of blinds were reasonably easy to use. Even when there were malfunctions, which was certainly an annoyance, fixing them was no problem. It was interesting to compare operation between users as well as the characteristics of different sets of blinds, indicating that the cost and overall quality of blinds varies a great deal. Inexpensive sets of blinds, like those found in the 2nd part of our study, tended to malfunction more often than more costly sets. The quality in the more expensive blinds was found in the heavier, more durable materials used, as well as the small thoughtful and ergonomic attachments that made operation that much easier. Ultimately, blinds are mostly easy to use, regardless of quality.

Product

This is an analysis of the product assembly, the components and the mechanical function of the product.

Assembly

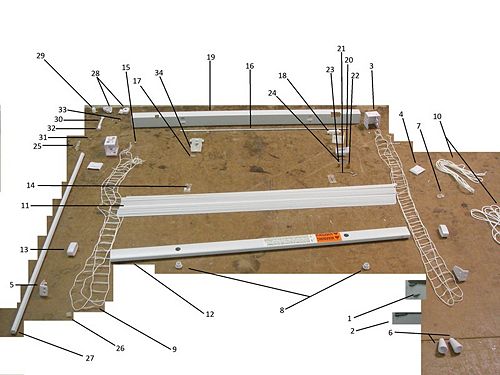

Exploded view of basic Venetian Blinds

Bill of Materials

Basic Venetian blinds had a total of 34 unique parts. Most of the parts are made of extruded plastic and many are shaped in such a way that they snap together. The whole assembly only requires three rivets and no other standard purchase parts. However there also were 14 screws included with the blinds for installation purposes.

How the system functions mechanically

The packaged set of blinds can be split up into two separate phases: installation and use. During the installation phase the customer is supposed to install the wall mounts using the provided screws. Additionally the package provides an optional installation of the hold down mounts these mounts have pins that will hold the blinds in a lowered resting state. The hardware to install these mounts is included in the package. There are two ways for the customer to interact with the blinds after installation is complete.

The first way is to raise and lower the blinds according to preference. On the right side of the blinds

there are two strings that can be pulled to disengage the lock or pulled to the right and released to

reengage the lock. The locking mechanism consists of a gear that catches the string when it is released

and pins it against another surface. The main string runs over a series of rollers in the main body, travel

through the blinds and are tied off in the bottom bar. When the user pulls the string to adjust the

height, the main string pulls or releases the bottom bar thereby raising or lowering the blinds.

The second way the customer can interact with the blinds is by controlling the tilt on the blinds by adjusting the twisting rod. By turning the rod clockwise the blinds rotate so that they are concave towards the customer. Rotating the rod counterclockwise produces an opposite effect. This is achieved through the translation of motion from the tilt rod to the inner rotating rod. When the twisting rod is turned, it turns a worm gear inside of the twisting rod casing. The worm gear turns a worm wheel that the inner rotating rod is attached to. On the rotating rod are two braces that can hold the ends of the ladder string. When the rotating rod turns, it makes one end of the ladder string pull up into the mainframe while releasing the other end. When this occurs, the blinds begin to tilt according to the customers input.

DFMA

DFMA is Design for Manufacturing and Assembly. By maximizing the DFMA we assure that designs can be easily manufactured and assembled. It is important to consider these principles during the design phase of a product; and after dissecting the product we are able to find possible areas of improvement. By examining raw materials, machines and processes, and the assembly of the product, we are able to create a high quality and efficient assembly.

The blinds that we dissected are inexpensive and mass produced. The assembly is relatively complicated with many interdependent working parts. After assessing the manufacturing techniques used to produce the blinds we feel that the efficiency has been maximized. We saw that unnecessary material was removed from certain parts to reduce material usage and to make installation easier. The blinds use a lot of plastic parts and most of the plastic is the same. Most of the parts were injection molded or extruded. Some of the metal components were shaped through bending. None of the parts manufactured seem to require tight tolerances and none require machining. We found that many parts snap together to lessen the need for additional standard purchase parts and to further reduce assembly time.

From what we could tell, the most complicated part of assembly is feeding the individual blinds through the slats in the ladder string. A specialized machine is required for this process. The individual blinds are punched (to create the hole for the main string) and threaded through the ladder string in one process [1]. The only other machine required in assembly is a rivet gun; all other parts are pressure fitted and are put in place by hand. A paper ruler was included in the package so the only additional tool needed for installation is a drill. Because these are inexpensive blinds that design was kept simple and fulfills its most basic purposes. More expensive blinds require more expensive materials (e.g. aluminum or wooden blind slats) and a more labor intensive manufacturing process.

FMEA

A failure modes and effects analysis, or FMEA, is a procedure in product development where we analyze the potential failure modes within a system. Based on past experience with similar products we are able to identify potential failure modes and rate them based on the severity and frequency of their occurrence. The table estimates the severity, S, the probability of occurrence, O, and the detectability, D, of failure. The risk priority numbers, or RPN, Is generated by multiplying, SxOxD.

| Item & Function | Failure Mode | Effects of Failure | S | Causes of Failure | O | Design Controls | D | RPN | Recommended Actions |

|---|---|---|---|---|---|---|---|---|---|

| Cord used to operate blinds – moving up and down | Cord is long and left dangling | Children can choke and it may cause death | 10 | cord string is long and dangling where it may create a loop | 4 | Safety hazard | 4 | 160 | string will automatically reel back up, hook attachment |

| Cord used to operate blinds – moving up and down | Blinds are raised unevenly | Doesn’t cover window properly and aesthetically unpleasing | 3 | string is pulled unevenly | 10 | Visual | 1 | 30 | bead keeps stings even |

| Tilt wand controls blind angle | Snaps off at the top | user may suffer minor injury, can no longer tilt blinds | 6 | twisted at the wrong angle, twisted a lot of times | 3 | Operational | 1 | 18 | make it a single piece, use stronger material |

| Blind keeps out sunlight – privacy | Blinds get bent | aesthetically unpleasing, doesn’t block out sunlight or provide privacy | 3 | person hits them, kids bend them, furniture pushed into them | 5 | Visual | 1 | 15 | create more sturdy blinds, create blinds that can are more fluid/bendable |

| Blind keeps out sunlight – privacy | Flipped the wrong way | aesthetically unpleasing, doesn’t block light as well | 4 | string pulled too quickly | 10 | Visual | 1 | 40 | stopper to prevent blinds from flipping |

| Cord and ladder string which hold individual blinds | Cords get cut/damaged | blinds fall apart and are no longer operational | 6 | misuse | 2 | Operational | 1 | 12 | stronger/ thicker cord to prevent failure |

Overall the product is safe for adult users, the failure modes that we identified are more failures of proper operation as opposed to threatening one’s health. After examining the use phase of the product we have identified important failure modes that should be considered in a redesign or a new design of the blinds. There are a few major failure potentials we identified. The product warns us multiple times about the potential of a child entangling themselves in the dangling cord. This is the most important failure mode for these blinds as it is may jeopardize the health and well-being of a person. The label warns us that the cord may form a loop and become wrapped around a child’s neck resulting in death.

According to The Royal Society for the Prevention of Accidents, children are most susceptible to accidental death by blind cord as toddlers that are able to move around but are still physically underdeveloped [5]. The Consumer Product Safety Commission issued a recall of over 50 million Roman blinds. Since 2001, there have been five deaths and an additional 16 near deaths associated with Roman blinds. A child death is a tragedy and the deaths have gotten a considerable amount of publicity [3]. The blinds we purchased had three warnings of child strangulation and recommended that the user install the blinds away from cribs and furniture that a young child could climb on to. The Window Covering Safety Council recommends that parents should only install cordless blinds if they have young children or use a hook to keep the cord out of a child’s reach [4].

Other failure modes we identified relate to the proper functionality of the blinds as they may be raised unevenly. This will cause the blinds to be less visually appealing, and could potentially be fixed by implementing some mechanism to keep them even. The blinds can get bent out of shape and fail to block out sunlight or provide privacy. This could be fixed by using a different material for the blades. If the tilt wand breaks off then the blinds will not be operational in blocking out or letting in sunlight. Finally, if the ladder-like string which holds the individual blinds was to be cut then the entire set of blinds would fall apart and be non-operational. We think that by making the tilt wand a single piece or by thickening the string it will prevent these types of failures.

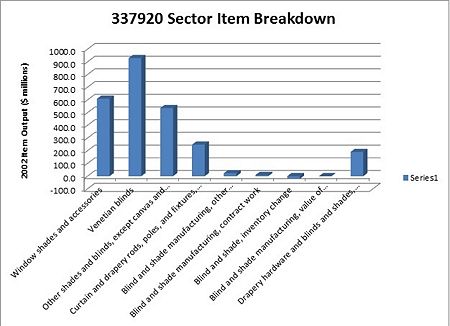

DFE

Below is a graph of the sector breakdown for the year of 2002. It shows how representative our specific product is of the entire blinds and shade manufacturing sector based on dollars in revenue accrued.

From the graph we see that our product makes up the largest single component of the blinds and shade manufacturing sector. However it only accounts for 36.7% of the total 2002 breakdown. Given the data, We would still consider the sector to be a good representation for venetian blinds and we will be using the sectors values for further DFE analysis.

Below is a table summarizing on our findings on the CO2 emissions during the production phase of the blinds. Dollar values have been adjusted for inflation and are based off a one million dollar sector.

| Item Consumed | Venetian Blinds |

| Sector # and Name | Sector #337920: Blind and shade manufacturing |

| Reference Unit | Bali White Mini Blind Vinyl White 27'X64' |

| Units Consumed Per Product Life | 1 |

| Cost Per Unit ($2002) (Retail) | $2.53 |

| Lifetime Cost ($2002) | $0 |

| Sector mtCO2e Per $1M | 548 mtCO2e |

| Implied mtCO2e per Product Life | .00138 mtCO2e |

| CO2 Tax @ $30/mtCO2e | $.0416 |

Below is a table listing the top 5 contributing sectors to blind and shade manufacturing per product along with their relative contributions.

| Sector | mtCO2e per Product | % of product mtCO2e |

|---|---|---|

| 221100: Power Generation and Supply | .000471 | 34.1 |

| 484000: Truck Transportation | .000213 | 15.4 |

| 331110: Iron and Steel Mills | .0000718 | 5.2 |

| 33131A: Alumina refining and Primary Aluminum Production | .0000704 | 5.1 |

| 211000: Oil and Gas Extraction | .0000635 | 4.6 |

Given that our product produces no GHG’s during use, it is clear that the main impact from the window blinds on the environment comes during the production phase. Based on the data provided from the software we see that manufacturing GHG’s costs are mostly due to power generation and supply and truck transportation. In order to reduce the overall impact the product has, we would need to look into cleaner sources of energy or more efficient packaging.

Among the top five contributing sectors we see that the sectors related to obtaining raw materials represents a small portion of the GHG emissions of manufacturing. This may be the result of effective resource gathering processes or simply that the blinds use very small amounts of material. We also see that the energy used in producing accounts for a large portion which makes sense considering the heavy machinery that is used to produce blinds. The second largest sector for GHG emissions is truck transportation; this includes transporting materials as well as finished products. These sectors are very intuitive when considering the entire manufacturing process of blinds.

From our first table, we see that the overall price increase per unit would be only four cents if a CO2 tax was enacted. We believe this is a small enough impact that would not deter customers from purchasing the product. Additional analysis was done to see if blinds offered any amount of CO2 savings by reducing the amount of air conditioning energy that a household would consume. The United States Environment Protection Agency (EPA) estimates the individual CO2 emissions as a by-product of air heating and cooling to be 1021 lbs.[2]; this translates to 0.463 mtCO2/ year per person. The average provided by the EPA does not discriminate however between blinded households and unblinded households. However when comparing the relative magnitude of the impact of blinds and air conditioning, we can see that blinds would only need to reduce the energy consumption by 1.49% given that there is roughly 5 windows per person. Although we cannot say with certainty that window blinds have a net negative effect on CO2 emissions, the numbers seem to suggest that over the product lifetime blinds probably reduce GHG emissions.

Team Member Roles

Min-Qiang Chan-Manufacturing and Assembly

Laura Gurwitz-Team Leader

Kory McDonald-Safety

Francisco Santiago-Environment

References

[1] Hoss, Gabriel, dir. "How It's Made Window Blinds." How It's Made. Science Channel. YouTube - Broadcast Yourself. Web. 04 Feb. 2011. <http://www.youtube.com/watch?v=cfapphn-4hQ>.

[2] "Individual Emissions - Household Emissions Calculator | Climate Change - Greenhouse Gas Emissions | U.S. EPA." US Environmental Protection Agency. Web. 04 Feb. 2011. <http://www.epa.gov/climatechange/emissions/ind_calculator2.html#c=transportation&p=reduceOnTheRoad&m=calc_currentEmissions>.

[3] "Window Covering Safety Council Recalls to Repair All Roman and Roll-Up Blinds Due to Risk of Strangulation." CPSC Home Page | Cpsc.gov. 15 Dec. 2009. Web. 04 Feb. 2011. <http://www.cpsc.gov/cpscpub/prerel/prhtml10/10073.html>.

[4] Window Covering Safety Council - Safety Information and Free Cord-Repair Kits. Web. 04 Feb. 2011. <http://www.windowcoverings.org/>.

[5] "Accidents to Children | Child Safety | Advice & Information | Home Safety | RoSPA." Health and Safety Training Courses, Accident Prevention Advice & Information from RoSPA. Web. 04 Feb. 2011. <http://www.rospa.com/homesafety/adviceandinformation/childsafety/accidents-to-children.aspx#strangulation>.