Water gun

From DDL Wiki

(Difference between revisions)

(→How It's Used) |

(→How It's Used) |

||

| Line 87: | Line 87: | ||

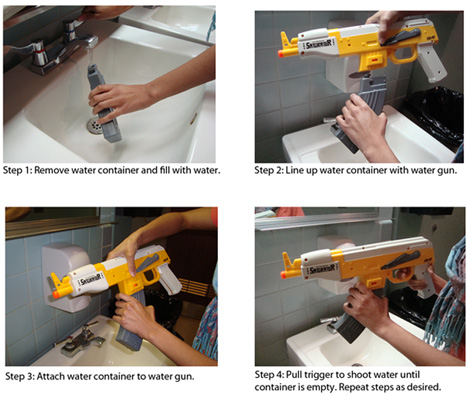

===How It's Used=== | ===How It's Used=== | ||

| - | [[Image:How to Use the Saturator.jpg]] | + | [[Image:Group 7 How to Use the Saturator.jpg]] |

===User Studies=== | ===User Studies=== | ||

Revision as of 15:03, 5 February 2011

Contents |