Water gun

From DDL Wiki

(→User Studies) |

(→Bill of Materials) |

||

| Line 4: | Line 4: | ||

== Bill of Materials == | == Bill of Materials == | ||

| + | |||

| + | {| class="wikitable" border="1" cellspacing="0" align="center" style="text-align:center" | ||

| + | ! colspan="9" style="background:#efefef;" | External Gun Assembly | ||

| + | |- | ||

| + | !Part Number !! Sub-Assembly !! Name !! QTY !! Weight (g) !! Function !! Material !! Manufacturing Process !! Image | ||

| + | |- | ||

| + | | 001||Shell||side A||1||110.5||Cases the assembly together||Plastic||Injection molding||[[Image:1.jpg | 100x100px]] | ||

| + | |- | ||

| + | | 002||Shell||side B||1||110.9||Holds sub-assemblies together||Plastic||Injection molding||[[Image:002_1.jpg | 100x100px]] | ||

| + | |- | ||

| + | | 003||Shell||nozzle ring||1||1.2||Cases the nozzle assembly and the assembly shell together||Plastic||Injection molding||[[Image:003.jpg | 100x100px]] | ||

| + | |- | ||

| + | | 004||Reservoir Release||switch||1||0.5||Releases the reservoir from the body||Plastic||Compression molding||[[Image:004_1.jpg | 100x100px]] | ||

| + | |- | ||

| + | | 005||Reservoir Release||slider||1||0.4||Guides the path of the release switch||Plastic||Injection molding||[[Image:006.jpg | 100x100px]] | ||

| + | |- | ||

| + | | 006||Reservoir Release||spring||1||0.3||Creates elastic movement of the release switch ||Plastic||Injection molding||[[Image:005.jpg | 100x100px]] | ||

| + | |- | ||

| + | | 007||Reservoir Release||retaining plate||1||0.2||Glued to the shell side A to hold the reservoir release sub-assembly together||Plastic||Compression molding | ||

| + | |- | ||

| + | | 008||Battery cover||spring||2||0.1||Makes contact with the battery||Steel||Bending|| | ||

| + | |- | ||

| + | | 009||Battery cover||latch||1||0.1||Holds the plastic casing and the two shell sides together||Steel||Cutting|| | ||

| + | |- | ||

| + | | 010||Battery cover||spring bracket||1||2.4||Makes contact with the battery||Aluminum||Blanking|| | ||

| + | |- | ||

| + | | 011||Battery cover||plastic casing||1||6.1||Seals the battery entrance||Plastic||Injection molding|| | ||

| + | |- | ||

| + | | 012||Reservoir||body||1||37||Stores water||Plastic||Blow molding|| | ||

| + | |- | ||

| + | | 013||Reservoir||plug||1||1.2||Seals the reservoir's water entrance||Rubber||Injection molding|| | ||

| + | |- | ||

| + | | 014||Reservoir||Tubing||1||2.1||Used to pump water from the reservoir||Vinyl||Injection molding|| | ||

| + | |- | ||

| + | | 015||Reservoir||Top plug||1||0.2||Tighly seals the space between the tube and the reservoir||Rubber||Injection molding|| | ||

| + | |- | ||

| + | | 016||Reservoir||Bottom plug(bigger than top)||1||0.4||Used to pump water from the reservoir||Plastic||Injection molding|| | ||

| + | |- | ||

| + | ! colspan="8" style="background:#efefef;" | Internal Gun Assembly | ||

| + | |- | ||

| + | !Part Number !! Sub-Assembly !! Name !! QTY !! Weight (g) !! Function !! Material !! Manufacturing Process !! Image | ||

| + | |- | ||

| + | | 017||Motor||Motor||1||44.1||Drives the gears to pump water from the reservoir||Electronic||Standard purchase part|| | ||

| + | |- | ||

| + | | 018||Motor||Capacitor||3||0.3||Used for the motor|| ||Standard purchase part|| | ||

| + | |- | ||

| + | | 019||Motor||Resistor||2||0.3||Used for the motor|| ||Standard purchase part|| | ||

| + | |- | ||

| + | | 020||Battery contact terminals||Spring||2||0.1||Makes contact with batteries||Steel||Bending|| | ||

| + | |- | ||

| + | | 021||Battery contact terminals||Terminal holder||1||1.2||Holds the battery contact terminals together||Plastic||Injection molding|| | ||

| + | |- | ||

| + | | 022||Battery contact terminals||Retaining pads||2||0.05||Prevents the battery contact terminals from sliding up and down||Plastic||Injection molding|| | ||

| + | |- | ||

| + | | 023||Battery contact terminals||Trigger contact bracket||1||0.7||Closes the circuit when the trigger is pulled||Aluminum||Blanking|| | ||

| + | |- | ||

| + | | 024||Battery contact terminals||Trigger||1||2.1||Shoots water(closes the circuit for the motor to run)||Plastic||Injection molding|| | ||

| + | |- | ||

| + | | 025||Battery contact terminals||Spring||1||0.1||Creates elastic movement of the trigger||Steel||Bending|| | ||

| + | |- | ||

| + | | 026||Gear train||Crown gear||1||2||Drives the motion of the motor to the gear system||Plastic||Gear cutting|| | ||

| + | |- | ||

| + | | 027||Gear train||Gear retainer||1||0.6||Holds the gear assembly together||Plastic||Injection molding|| | ||

| + | |- | ||

| + | | 028||Gear train||Small spur gear||1||0.5||Drives the motion of the spur gear to the large gear||Plastic||Gear cutting|| | ||

| + | |- | ||

| + | | 029||Gear train||Large spur gear with half gear||1||4.1||Drive the motion of the small gear to the rack gear||Plastic||Gear cutting|| | ||

| + | |- | ||

| + | | 030||Gear train||Ratchet retainer||1||0.3||Holds the ratchet||Plastic||Injection molding|| | ||

| + | |- | ||

| + | | 031||Gear train||Ratchet||1||0.4||Controls the movement of the large gear||Plastic||Injection molding|| | ||

| + | |- | ||

| + | | 032||Gear train||Spring||1||3.1||Affects the movement of the large gear; attached to the ratchet||Steel||Bending|| | ||

| + | |- | ||

| + | | 033||Gear train||Small axle||1||0.4||Axle for the small gear||Steel||Cutting|| | ||

| + | |- | ||

| + | | 034||Gear train||Short medium axle||1||0.3||Axle for the crown gear||Steel||Cutting|| | ||

| + | |- | ||

| + | | 035||Gear train||Large axle||1||0.5||Axle for the large gear||Steel||Cutting|| | ||

| + | |- | ||

| + | | 036||Firing||Spring||1||0.5||Create elastic motion of the piston while attached to the pressure plate||Steel||Bending|| | ||

| + | |- | ||

| + | | 037||Firing||Pressure plate||1||0.6||Holds the spring for the piston’s movement||Plastic||Compression molding|| | ||

| + | |- | ||

| + | | 038||Firing||Rack gear||1||4.4||Drives the piston in horizontal motion||Plastic||Lathe turning|| | ||

| + | |- | ||

| + | | 039||Firing||Piston||1||6.1||Creates pressure difference in the piston housing||Plastic||Lathe turning|| | ||

| + | |- | ||

| + | | 040||Firing||Ring||1||0.2||Limits the motion distance of the piston||Rubber||Injection molding|| | ||

| + | |- | ||

| + | | 041||Firing||Gasket||1||2.2||Tightly seals the space between the piston and the housing||Rubber||Injection molding|| | ||

| + | |- | ||

| + | | 042||Firing||Tube||1||0.8||Passageway for the water||Plastic vinyl||Injection molding|| | ||

| + | |- | ||

| + | | 043||Firing||Elbow||1||1.2||Valve to pump the water from the reservoir||Plastic||Sheet transforming|| | ||

| + | |- | ||

| + | | 044||Firing||Piston housing||1||0.4||Pressure difference in this housing pumps water from the reservoir||Plastic||Injection molding|| | ||

| + | |- | ||

| + | | 045||Elbow&Valve housing||Spring||1||0.05||Holds the plunger in the valve||Steel||Bending|| | ||

| + | |- | ||

| + | | 046||Elbow&Valve housing||Plunger||1||0.2||Part of the valve system||Plastic||Machine turning|| | ||

| + | |- | ||

| + | | 047||Elbow&Valving housing||O Ring||1||0.1||Part of the valve system||Rubber||Injection molding|| | ||

| + | |- | ||

| + | | 048||Nozzle housing||Nozzle||1||0.5||Exit of the water stream||Plastic||Machine turning|| | ||

| + | |- | ||

| + | | 049||Nozzle housing||Inner housing||1||0.8||The nozzle is composed of inner housing, valve, and outer housing; Inner and outer housing holds the valve from both sides||Plastic||Machine turning|| | ||

| + | |- | ||

| + | | 050||Nozzle housing||Outer housing||1||0.4||Holds the valve together with the inner housing||Plastic||Machine turning|| | ||

| + | |- | ||

| + | | 051||Nozzle housing||Spring||1||0.1||Part of the valve that hold the plunger||Steel||Bending|| | ||

| + | |- | ||

| + | | 052||Nozzle housing||Plunger||1||0.2||Part of the valve||Plastic||Machine turning|| | ||

| + | |- | ||

| + | | 053||Nozzle housing||O Ring||1||0.1||Part of the valve||Rubber||Injection molding|| | ||

| + | |- | ||

| + | |} | ||

| + | |||

===Main Components=== | ===Main Components=== | ||

Revision as of 16:33, 5 February 2011

Contents |

Executive Summary

Bill of Materials

Main Components

Additional Parts

Assembly

Stakeholders

The primary stakeholders for the product are the user, the consumer, retailer, manufacturer, and shipping/transportation of the product.

Consumer

With relation to the Saturator water gun, there are two major consumers: adult (i.e parents) and the users -children and young adults. The needs and requirements of these two consumers are drastically different as shown below.

Buyer (Adults): Consumers are adults including young adults but our primary consumers are parents. Parents of the user will monitor the use of the product and their concerns will mainly be with safety. The needs of the adults are listed below:

- Low cost

- Safe

- Easy for child to use & store

- Durable

- Long product lifespan

- Non-threatening

- Non-toxic

User (Children): The users of the product are children and this categorey also include and are not limited to children over the age of 16. For the primary user the product needs are:

- Visually attractive

- Fun to play with

- Long range of shooting

- Quick & easy to refill

- Accurate & precise shooting

- Lightweight

- Easy to operate

Retailer

Retailers: Retailers are also stakeholders of the product. Their needs are as follows:

- Satisfying to customer

- Easy to shelve and store

- Easy to sell

- Durable

Manufacturer

Manufacturers: Manufacturers as stakeholders of the product have needs including but not limited to:

- Few parts & materials

- Minimize manufacturing processes

- Efficient assemble process

- Low cost production

- Standard parts across a range of models

Shipping/Transport

- Easy to stack

- Small & lightweight product

- Durable

Usage

How It's Used

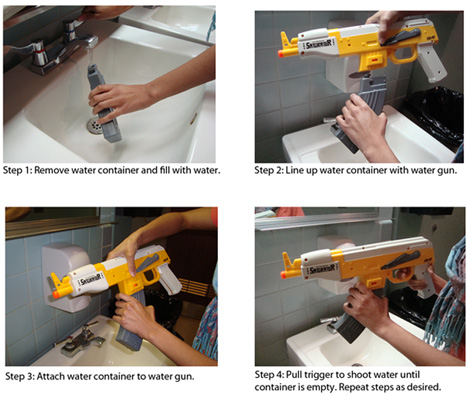

When initially removed from the packaging, the Saturator requires 4 AA batteries for operation (batteries not included). The batteries are inserted through the butt of the water gun. After battery insertion, the Saturator needs to be filled with water before it can be used. This process is described in the image below.

User Studies

Investigative processes include testing of two types of water guns, the Saturator Ak-47 and the Banzai Color Stream Blaster Water Gun. through experimentation we could determine the performance level of both guns.

Saturator Ak-47: Overall, the Saturator AK-47 Water Gun performs at the average standard for toy water guns. While the water container or clip stays in place, the gun needs to be refilled very often during play. Another negative aspect of this product is the range of shooting. Although it is advertised as a gun that can shoot over 25 feet, the stream of water barely makes it a distance of 15 feet.

Banzai Color Stream Blaster: The Banzai Color Stream Blaster is a pressurized gun. In our test we noticed that the product was quite messy.

Comparison: The Saturator is the easiest to use and least messy which was more prefferred in our user study.