Cartridge guitar bridge

From DDL Wiki

(→Prototype 2) |

(→Prototype 2) |

||

| Line 129: | Line 129: | ||

[[Image:guitar_ma_fig7.png|thumb|700px|left|Figure 7: The Prototype 2 Saddle in the Correct Position (left), and at the Worst Case Rotation (right)]] | [[Image:guitar_ma_fig7.png|thumb|700px|left|Figure 7: The Prototype 2 Saddle in the Correct Position (left), and at the Worst Case Rotation (right)]] | ||

| - | |||

Revision as of 00:22, 5 December 2008

Contents |

Executive Summary

Final Design

Features

Comparison to Other Designs

Differences from Final Design

CAD

Market Research

When examining the market potential for our product, it’s most important to see how similar products are faring currently. The most similar product currently on the market is the Floyd Rose Speedloader, which uses special strings to make stringing the Floyd Rose bridge easier. The ‘genuine’ Floyd Rose bridge listed online was priced at roughly 250 dollars. In comparison, a standard Fender bridge is priced at around 70 dollars. Additionally, the Speedloader strings are priced at between 9 and 12 dollars for 6 strings. In comparison, standard guitar strings sell for between 4 and 6 dollars for a pack of six, though the prices for both can vary if the strings are bought in bulk.

The market for our product would most likely exist in between the price points of the two bridges. It would most likely be to our advantage to price the product towards the end of the Fender bridge. The high end market is most likely already taken by the Floyd Rose and existing products, and is also less likely to invest in another technology if they see no reason to. Additionally, our product is mechanically simpler than the Floyd Rose, and the smaller number of parts makes it easier to produce less expensively.

Another solid reason to aim toward the low cost end of the market is that the main mechanical feature of our bridge is its ease of restringing. This is not a feature of the standard Floyd Rose, and therefore less experienced guitar players are less likely to know about the Speedloader feature’s availability. Advertising ease of restringing along with the ability to keep tune will help sell the product to novice guitar players.

The availability of the Floyd Rose Speedloader is important to acknowledge because it shows that a product can sell even if it requires specialized strings. The strings for our bridge will most likely sell in the same price range as the Speedloader strings, though it’s probably possible to sell them for a bit less. The fact that strings are a repeat purchase makes it very important to price correctly, as the strings may very well make more money than the bridges themselves. The difference in price between our strings and the Speedloader strings will probably be determined by manufacturing cost rather than a different profit margin.

Ultimately, the product is unlikely to fare well in a market that is fairly saturated without the backing of a guitar manufacturer. Floyd Rose gained a lot of notoriety on behalf of his product when Eddie Van Halen started using it. This advertising got Floyd Rose offers to license his bridge technology, and this is what really got the design its exposure. In our case, it’s doubtful celebrity advertisers will fall into our laps, but going and seeking a guitar company interested in our design may be the best way to approach the issue of marketing. A company like Fender may be interested in our design, as their two primary competitors already have products available aimed towards maintaining tunability: Gibson with their Robot guitar, and Ibanez with their licensed Floyd Rose bridges.

Floyd Rose’s design is successful, though its market share is still relatively low. Most likely, for our bridge design to succeed, backing of a major guitar company will be necessary. From earlier investigations, there are many patents for different bridge and string attachment mechanisms for guitars. Despite this, the majority of them are not seen in the market. For our design to succeed, the interest of an established company is likely the only way to gain the necessary exposure for the design to pay off. Given the right presentation and the right backer, our design has the right combination of better performance and simpler design to earn a place in the guitar market.

QFD

User Data

Prototype Design

Prototype 1

Pictures

Prototype 2

Changes from Prototype 1

CAD

Pictures

Prototype 3

Changes from Prototype 2

CAD

Pictures

Mechanical Analysis

Jeremy

Tuning Stability

In this design memo, we chose to examine the effect of the design flaws of the Fender bridge on the tuning of a guitar string. We then compared these effects to the simulated behavior of our Prototype 2 design. We found that the Fender Bridge offers very poor tuning stability, while our Prototype 2 design exhibits excellent tuning stability.

Saddle Slippage

One major design flaw in the Fender bridge is that each string saddle is anchored only by a long screw, and the friction between the base-plate and saddle caused by string tension pushing the saddle down. This allows the saddle a great deal of freedom of movement and rotation, especially when the string is slack. On a guitar with no tremolo, this would not be a problem. However, on a guitar with a tremolo bridge, the strings can easily become slack if the user pushes the tremolo by an appreciable amount (by our first quantitative analysis, the G string will be completely slack at a 6.1 degree tremolo angle, and all strings except the high E string are flat by 10 degrees). The saddle is able to translate horizontally, describing an arc with the center at the point where the screw meets the bridge. The saddle can move forward and backwards, since the screw hole is not threaded on the bridge. Finally, the saddle can rotate around the screw. Of these movements, the most likely, is the horizontal translation. We simulated this phenomena using MATLAB.

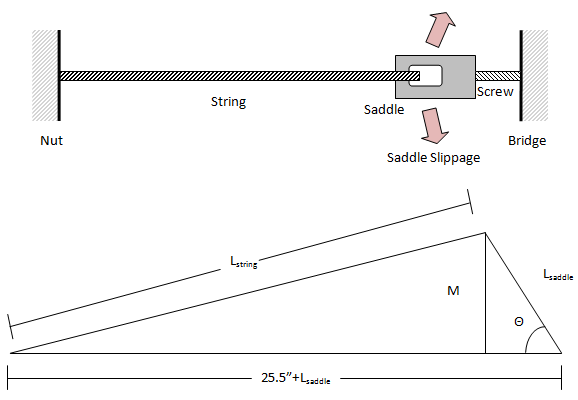

The guitar can be simply modeled as follows:

The angle Θ is the angle of the saddle with respect to its angle when it is correctly lined up. Theta will in general be very small, and difficult to measure. For this reason, we also define M as M= L_saddle sin(θ) . M is the horizontal translation of the saddle. This is easier to measure on a real guitar. Lsaddle is equal to 1”, so M is very small. For the purposes of our test, we chose to examine M in the range of 0 to 2mm, which corresponds to a range of Θ equal to 0 to 3 degrees. The 25.5” measurement is the length of the strings when they are in the neutral, correct position. The Lstring variable represents the length of the strings when the saddle is in the incorrect position. The relation between Lstring and M, or Θ is a simple matter of geometry.

The strings can be modeled as springs. The two ends of the string are fixed, so any change in length of the string while the guitar is being played means that the tension is also going up. In order to stretch the string from 25.5” to Lstring, the string tension goes up by:

Where T0 is the original, in-tune tension of the string. The frequency of a vibrating string is dependent on the tension, length, and linear mass of the string. All of these are known. For reference for the numbers we used, please see our first design report’s quantitative analysis. The strings are standard “light” guitar strings, which are the most common electric guitar strings sold.

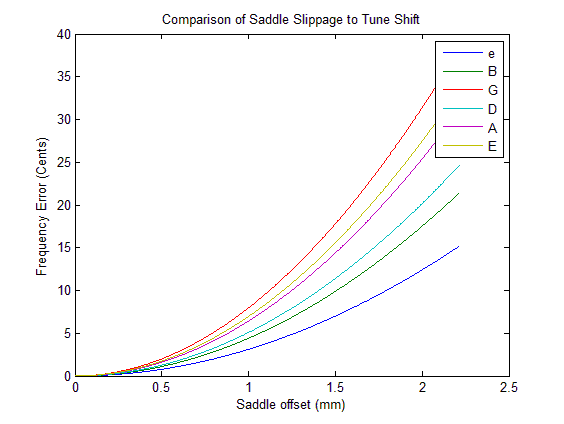

Armed with these equations, we found the frequency change for each string. In order to display the data in a more intuitive format, we graphed the tune of the strings in units of cents. Cents are a logarithmic scale, with 100 cents between each musical note in the scale, or 1200 cents in an octave. A note that is 100 cents out of tune is has moved one piano key from its original tune. The average layman can hear a musical note that is 25 cents or more out of tune. A musician can hear a wrong tuning in the range of 5-6 cents.

The saddle slippage causes a relatively large amount of error that would be obvious even to untrained musicians.

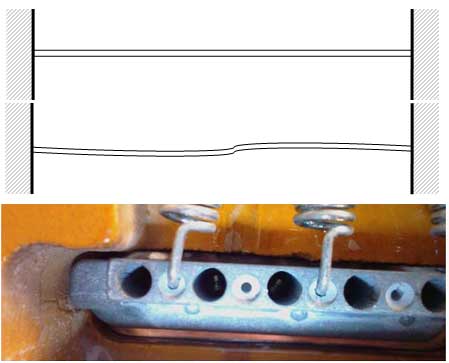

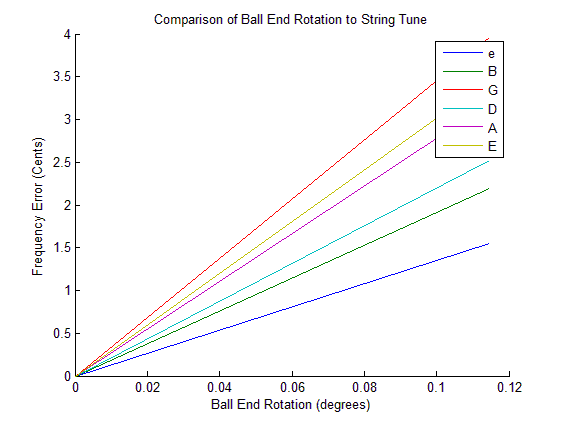

Ball End Rotation

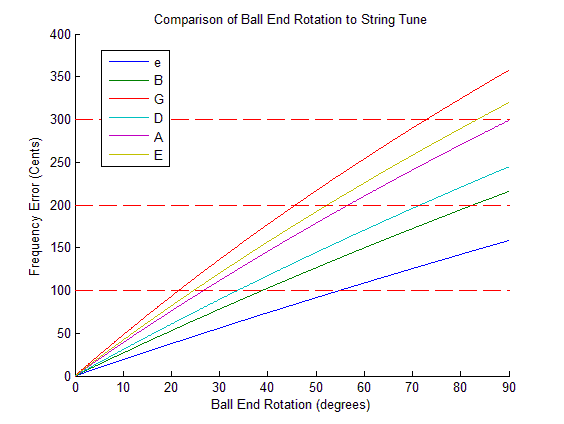

We also considered the tuning error caused by the ball end of the string rotating. In the Fender bridge, the ball end is held secure only by string tension. When the tremolo is used, and the strings are slack, the ball ends can rotate before being pulled taunt again. This rotation adds twist to the strings, which causes it to take a very slight helix shape. We approximated this by saying that the string takes on a helical shape with a diameter the same as the string diameter, and the number of turns equal to φ/360, where φ is the angle of rotation of the ball end. This change in length again changes stretches the string, changing the tension. However, the vibrating length of the string remains the same. Using our frequency equations from above, we graphed the change in pitch from a rotated ball end.

The results of the graph were surprising. The strings very quickly went out of tune, even for a very small rotation of the ball end. The red dotted lines represent how musical notes out of tune the guitar is. For instance, at 70 degrees of rotation, the G string has gone from a G note (196.00 Hz) to a Bb (233.08 Hz). A rotation of 25 or 30 degrees would not be at all unusual, and an enthusiastic guitarist might easily have the ball ends rotate more than that.

.

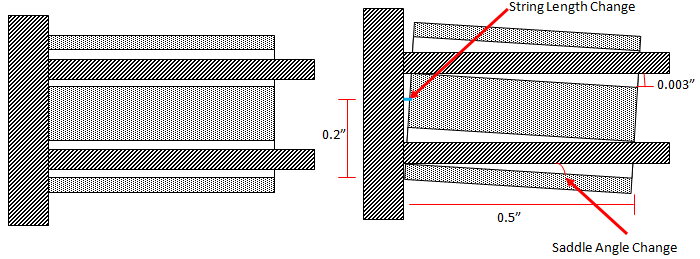

Prototype 2

Our Prototype 2 Bridge design has neither of the previously addressed tuning issues. The string does not have a ball end, and is secured by epoxy inside the saddle cartridge. The saddle cartridge is secured to the bridge plate by two strong “rails” instead of one flimsy screw. Since the sliding fit we used on our saddles has a gap of only 3 thousands of an inch, the saddle can rotate very little, orders of magnitudes less than the Fender bridge. We used MATLAB to see how the little freedom of movement left to the saddle would affect the tune.

According to MATLAB, our maximum change in string length is 0.0012 inches, or 0.0305 mm. We plugged this into our frequency equations.

We only evaluated the Prototype 2 design at two angles, the “correct” neutral angle, and at the worst case scenario. It is unrealistic that the bridge would be at any angle besides these two, because the design is not held in place by friction, like on the Fender Bridge, but by normal forces from the rails and the front bridge stop. We can immediately see that our bridge design has excellent tuning stability. At the worst case, the G string is about 4 cents out of tune, which is inaudible even to a trained musician. This is 10x lower than even a well behaved Fender bridge. It is worth noting that the Floyd Rose bridge offers similar tuning stability to our own bridge. However, the Floyd Rose bridge caters to the upscale guitar market, while we intend our bridge for the lower end market, where the Fender Bridge is prevalent.

Conclusion and Comparison to Experimental Data We ran experiments to test the tuning instability of a Fender Bridge, by tuning a guitar with a tremolo bridge, then depressing the tremolo, and checking the tune of the guitar. This was repeated 5 times. We graphed the tuning data. It is clear that the results we got are in the bounds predicted by our mathematical model. The E string suffers a serious rotation of the ball end, resulting in a 300 cent jump in pitch. All the other strings remain within a 50% error rate, indicating that the errors were caused by either small ball end rotations, or shifting saddle positions. From our mathematical evaluation, we concluded that the Fender bridge has several inherent design flaws that prevent it from maintaining tune while in use. Our own bridge design eliminates the two causes of tuning instability we identified in the Fender, and so should maintain excellent tune, at a similar price.

Musicality

Jeremy

Conclusions

Jeremy