Water gun

From DDL Wiki

m (→Bill of Materials) |

m (→Bill of Materials) |

||

| Line 86: | Line 86: | ||

| 035||Large axle||1||0.5||Axle for the large gear||Steel||Cutting|| | | 035||Large axle||1||0.5||Axle for the large gear||Steel||Cutting|| | ||

|- | |- | ||

| - | | 036||Firing||Spring||1||0.5||Create elastic motion of the piston while attached to the pressure plate||Steel||Bending|| | + | | 036||rowspan=9|Firing||Spring||1||0.5||Create elastic motion of the piston while attached to the pressure plate||Steel||Bending|| |

|- | |- | ||

| - | | 037 | + | | 037||Pressure plate||1||0.6||Holds the spring for the piston’s movement||Plastic||Compression molding|| |

|- | |- | ||

| - | | 038 | + | | 038||Rack gear||1||4.4||Drives the piston in horizontal motion||Plastic||Lathe turning|| |

|- | |- | ||

| - | | 039 | + | | 039||Piston||1||6.1||Creates pressure difference in the piston housing||Plastic||Lathe turning|| |

|- | |- | ||

| - | | 040 | + | | 040||Ring||1||0.2||Limits the motion distance of the piston||Rubber||Injection molding|| |

|- | |- | ||

| - | | 041 | + | | 041||Gasket||1||2.2||Tightly seals the space between the piston and the housing||Rubber||Injection molding|| |

|- | |- | ||

| - | | 042 | + | | 042||Tube||1||0.8||Passageway for the water||Plastic vinyl||Injection molding|| |

|- | |- | ||

| - | | 043 | + | | 043||Elbow||1||1.2||Valve to pump the water from the reservoir||Plastic||Sheet transforming|| |

|- | |- | ||

| - | | 044 | + | | 044||Piston housing||1||0.4||Pressure difference in this housing pumps water from the reservoir||Plastic||Injection molding|| |

|- | |- | ||

| - | | 045||Elbow&Valve housing||Spring||1||0.05||Holds the plunger in the valve||Steel||Bending|| | + | | 045||rowspan=3|Elbow&Valve housing||Spring||1||0.05||Holds the plunger in the valve||Steel||Bending|| |

|- | |- | ||

| - | | 046 | + | | 046||Plunger||1||0.2||Part of the valve system||Plastic||Machine turning|| |

|- | |- | ||

| - | | 047 | + | | 047||O Ring||1||0.1||Part of the valve system||Rubber||Injection molding|| |

|- | |- | ||

| - | | 048||Nozzle housing||Nozzle||1||0.5||Exit of the water stream||Plastic||Machine turning|| | + | | 048||rowspan=6|Nozzle housing||Nozzle||1||0.5||Exit of the water stream||Plastic||Machine turning|| |

|- | |- | ||

| - | | 049 | + | | 049||Inner housing||1||0.8||The nozzle is composed of inner housing, valve, and outer housing; Inner and outer housing holds the valve from both sides||Plastic||Machine turning|| |

|- | |- | ||

| - | | 050 | + | | 050||Outer housing||1||0.4||Holds the valve together with the inner housing||Plastic||Machine turning|| |

|- | |- | ||

| - | | 051 | + | | 051||Spring||1||0.1||Part of the valve that hold the plunger||Steel||Bending|| |

|- | |- | ||

| - | | 052 | + | | 052||Plunger||1||0.2||Part of the valve||Plastic||Machine turning|| |

|- | |- | ||

| - | | 053 | + | | 053||O Ring||1||0.1||Part of the valve||Rubber||Injection molding|| |

|- | |- | ||

|} | |} | ||

Revision as of 19:15, 5 February 2011

Contents |

Executive Summary

Summer is great time to be outside and toymakers make ir fun for kids to engage in outdoor activities that allow kids to be active and cooldown simultaneously. Waterguns come in different shapes, sizes and with different firing mechanisms from watergun helmets to the super soaker product line. We were intrigued by the idea of a child friendly version of paintball and did a product comparison of the Banzai Color Stream Blaster and the Saturator Ak-47 which utilizes a motor for power.

Bill of Materials

Main Components

Additional Parts

Assembly

Stakeholders

The primary stakeholders for the product are the user, the consumer, retailer, manufacturer, and shipping/transportation of the product.

Consumer

With relation to the Saturator water gun, there are two major consumers: adult (i.e parents) and the users -children and young adults. The needs and requirements of these two consumers are drastically different as shown below.

Buyer (Adults): Consumers are adults including young adults but our primary consumers are parents. Parents of the user will monitor the use of the product and their concerns will mainly be with safety. The needs of the adults are listed below:

- Low cost

- Safe

- Easy for child to use & store

- Durable

- Long product lifespan

- Non-threatening

- Non-toxic

User (Children): The users of the product are children and this categorey also include and are not limited to children over the age of 16. For the primary user the product needs are:

- Visually attractive

- Fun to play with

- Long range of shooting

- Quick & easy to refill

- Accurate & precise shooting

- Lightweight

- Easy to operate

Retailer

Retailers: Retailers are also stakeholders of the product. Their needs are as follows:

- Satisfying to customer

- Easy to shelve and store

- Easy to sell

- Durable

Manufacturer

Manufacturers: Manufacturers as stakeholders of the product have needs including but not limited to:

- Few parts & materials

- Minimize manufacturing processes

- Efficient assemble process

- Low cost production

- Standard parts across a range of models

Shipping/Transport

- Easy to stack

- Small & lightweight product

- Durable

Usage

How It's Used

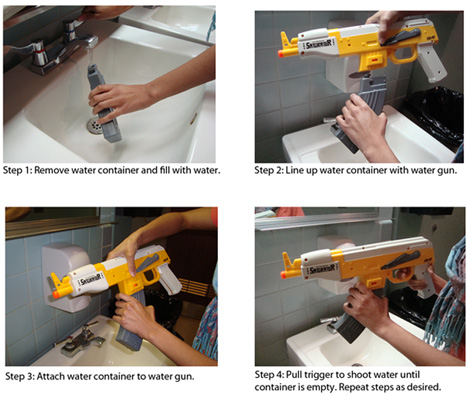

When initially removed from the packaging, the Saturator requires 4 AA batteries for operation (batteries not included). The batteries are inserted through the butt of the water gun. After battery insertion, the Saturator needs to be filled with water before it can be used. This process is described in the image below.

User Studies

Investigative processes include testing of two types of water guns, the Saturator Ak-47 and the Banzai Color Stream Blaster Water Gun. through experimentation we could determine the performance level of both guns.

Saturator Ak-47: Overall, the Saturator AK-47 Water Gun performs at the average standard for toy water guns. While the water container or clip stays in place, the gun needs to be refilled very often during play. Another negative aspect of this product is the range of shooting. Although it is advertised as a gun that can shoot over 25 feet, the stream of water barely makes it a distance of 15 feet.

Banzai Color Stream Blaster: The Banzai Color Stream Blaster is a pressurized gun. In our test we noticed that the product was quite messy. The Color Stream Blast pump system was futile after about 10 pumps, which was necessary for maximum performance. Althought the product manual explains that all that is needed for the water gun to shoot a continuous stream at a maximum distance of 30 feet was 3-4 pumps. In our studies we found that it took 8-10 almost triple the amount documented to get a continuous stream that reached a maximum distance of 20 feet. After testing the gun there was a puddle of water from the container that leaked during the testing. Pumping the water everytime we wanted a shot proved to be tiring.

Comparison: The Saturator is the easiest to use and least messy which was more prefferred in our user study.

Mechanical Function

Batteries are loaded into the compartment by opening the battery hatch, which is held closed by a small captive screw.

Water is loaded by unclipping magazine from bottom, by means of a sliding latch, then opening plug and filling. Magazine slots back into place, reengaging magazine feed tube with pump inlet tube.

Trigger pull acts differently than in other styles of water gun. Rather than opening a valve or directly actuating a pump directly, it, being an electric gun, closes the circuit to activate the motor.

The drive direction of the motor changes axis through a crown gear, and goes through several gear reductions ending in a half-toothed gear. This drives a rack gear which is connected to the plunger of the pump cylinder. As the plunger is retracting, the expanding volume draws water in through the one-way valve connected to the feed tube, which draws water up from the magazine, while closing the valve in the nozzle. The piston is driven against a spring, and when the teeth of the half-gear disengage the spring is released, driving the piston back into the cylinder, closing the feed tube valve and driving the water out through the one-way valve in the nozzle. As the gear continues turning, the teeth reengage, beginning the cycle again.

Design for Manufacture & Assembly (DFMA)

Failure Modes & Effects Analysis (FMEA)

Numerical Ratings:

- S: Severity (1-3: Functionality/efficiency reduced, 4-6: Functionality interrupted, varying levels of repairability, 7-10: Potential danger to user)

- O: Frequency of occurrence (1: Extremely unlikely, 10: Inevitable and frequent)

- D: Detectability (1: Failure immediately apparent, 10: Failure undetectable)

| Item/System | Failure Mode | Effects of Failure | Causes of Failure | Design Changes | User Remedies | S | O | D | RPN |

|---|---|---|---|---|---|---|---|---|---|

| Motor/Circuit | Short Circuit | Inoperation (no motor), overheating, battery damage | Crossed wires/loose contacts | Limit wire movement caused by use, provide positive wire routing fixtures | Depending on damage, fix wiring or dispose of gun | 8 | 2 | 3 | 48 |

| Broken Circuit | Inoperation (no motor) | Broken wire/solder joint | Limit wire movement caused by use | Repair solder | 4 | 3 | 2 | 24 | |

| Trigger | Open Circuit | Inoperation (no motor) | Deformed Contact | Use more robust switch | Bend contact back | 4 | 3 | 2 | 24 |

| Tubing | Puncture | Leak during firing, reduced firing capacity | Damage to tube | None | Patch hole | 2 | 2 | 5 | 20 |

| Leaky connection | Leak during firing, reduced firing capacity | Insufficient seal at joint | Better tubing fixtures: longer hose barbs, locking rings. Sealant on joint. | Add sealant | 2 | 8 | 4 | 64 | |

| Reservoir | Crack | Constant leak | Physical abuse | Thicker material | Cover crack or replace part | 3 | 2 | 1 | 6 |

| Insufficient seal | Leak during firing, reduced firing capacity | Incomplete engagement | Decrease tolerance for tighter engagement | Add sealant, check socket for obstructions | 2 | 2 | 5 | 10 | |

| Gear Train | Jamming | Inoperation, or intermittent operation (motor slowing, no water) | Debris in gun body | None, body well closed/sealed | Open and clear debris | 4 | 2 | 6 | 21 |

| Broken teeth | Reduced firing capacity, possible jamming or complete inoperation | Stress of periodic disengagement/reengagement | Thicker gears, design that doesn't require disengagement | None | 4 | 3 | 8 | 96

| |

| Broken ratchet | Partial cylinder load ejected when firing ends | Stress of engagement | Larger gears/teeth to reduce overall stress | None | 1 | 2 | 8 | 16 | |

| Valves | Stuck open | Inoperation (no water) | Debris, misalignment, broken spring | Stronger spring, aligning features for plunger | None | 6 | 2 | 7 | 84 |

| Stuck closed | Inoperation (no water), possible leak during attempted firing | Debris or misalignment | Aligning features for plunger | None | 6 | 2 | 7 | 84 | |

| Pump Piston | Insufficient seal | Leak during firing, reduced firing capacity | Damage to o-ring, lack of lubricant | Additional redundant o-rings | Relubricate, replace o-ring | 2 | 3 | 6 | 36 |

| Shaft damage/breakage | Reduced firing capacity, possible inoperation | Stress due to misalignment | Alignment features for shaft, thicker cross-section | None | 3 | 1 | 3 | 9 | |

| Reservoir Release | Actuator switch falls off | Cannot remove/refill reservoir | Retention screw loosening | Use integral locking feature instead of screw | Replace screw | 4 | 1 | 1 | 4 |

| Battery Cover | Hinge breaks | Cannot be closed, broken circuit, inoperation (no motor) | Physical abuse | More robust/less protrusive hinge lugs | None | 6 | 1 | 1 | 6 |

| Threaded insert breaks out | Cannot be closed, broken circuit, inoperation (no motor) | Screw overtightening, physical abuse | Thicker plastic around insert | None | 6 | 1 | 2 | 12 | |

| Shell | Cracking | Expose gear train to debris, create sharp edges | Physical abuse | Thicker plastic, though design seems sufficiently robust as-is | None | 7 | 3 | 1 | 21 |

| Halves separate | Lose component alignment, expose gear train to debris | Screws loosening, user tampering | None, plenty of redundant screws already | Retighten/replace screws | 3 | 2 | 2 | 12 |

Design for Environment (DFE)

Team Roles

Santia Valerio- Team Lead

Jonathan Daneman- FMEA Lead

Min Jung Kim- DFMA Lead

Mana Heshmati- DFE Lead