Mop wringer

From DDL Wiki

(→User Studies) |

(→Group Dynamic) |

||

| Line 811: | Line 811: | ||

= Group Dynamic = | = Group Dynamic = | ||

| - | + | Team lead: Brad Edelman | |

| - | Team lead: | + | |

| - | + | DFMA lead: Kyle Young | |

| - | DFMA lead: | + | |

| - | + | FMEA lead: Gabrielle Page | |

| - | FMEA lead: | + | |

| - | + | DFE lead: Danny Benvegnu | |

| - | DFE lead: | + | |

| + | Editing lead: Bryan Good | ||

<span style="color:#FF0000"> | <span style="color:#FF0000"> | ||

Summary of team chemistry | Summary of team chemistry | ||

</span> | </span> | ||

| - | |||

| - | |||

= References = | = References = | ||

Revision as of 01:40, 12 February 2012

Contents |

Executive Summary

Your executive summary is not a table of contents -- it is a summary of major findings and recommendations.

You are to provide the key information an executive would need to make a decision in just a few sentences.

Focus on your findings, conclusions, and recommendations rather than telling a chronological story. Bad example: "We identified custimer needs and then we analyzed the product using DFMA, DFE, and FMEA." Good example: "The competitor product is well-designed for manufacturing and assembly, with a low part count and appropriate choice of materials and processes. However, we recommend consolidating the housing into a single part and replacing fasteners with snap fits to further reduce part count and production cost."

Stakeholder Analysis

In performing a product use study the following stakeholders and their needs were identified and documented. Even though the list contains many eccentric interests, there are many shared values.

| Stakeholder | Needs |

|---|---|

| Manufacturers | Low cost, Able to mass produced, Easy to assemble, Environmentally friendly, Easy to store and package |

| Investors | Low cost, Significant innovation, Aesthetics, Large market |

| Retailers | Easy to store, Accessory options, Universal interface, Compatibility, Low cost, Utility |

| Cleaning Supply Companies | Universal interface, compatibility |

| Commercial Consumers | Low cost, Durability, Light Weight, Quiet, Intuitive operation, Ergonomic design, Easy to stow, Easy to clean |

| Independent Consumers | Low cost, Aesthetically pleasing, easy to clean, Storability, Portability, Intuitive operation, Light weight, Durability |

Usage

Product Use Steps

| Mop and Bucket Combination | Self-Wringing Folding Mop | |||||

|---|---|---|---|---|---|---|

| Step # | Description | Image | Step # | Description | Image | |

| 1 | Make a mess | 1 | Make a mess | |||

| 2 | Fill bucket with water | 2 | Obtain a bucket | |||

| 3 | Add recommended amount

of cleaning solution | 3 | Fill bucket with water | |||

| 4 | Put mop in bucket | 4 | Add recommended amount

of cleaning solution | |||

| 5 | Move mop to wringer | 5 | Put mop in bucket | |||

| 6 | Wring out mop | 6 | Slide wringer towards

end of mop, over the bucket | |||

| 7 | Mop floor (i.e. move back

and forth across desired dirty surface) | 7 | Mop floor (i.e. move back

and forth across desired dirty surface) | |||

| 8 | Repeat steps 4-7 until

desired cleanliness is achieved | N/A | 8 | Repeat steps 5-7 until

desired cleanliness is achieved | N/A | |

| 9 | Empty bucket | 9 | Empty bucket | |||

| 10 | Repeat steps 2-3 as desired | N/A | 10 | Repeat steps 3-4 as desired | N/A |

Mechanism

Bill of Materials

| Sub-assembly | Part | Quantity | Description | Material | Manufacturing Process | Weight (g) | Image |

|---|---|---|---|---|---|---|---|

| Wringer | Upper Wringer Plate | 1 | Translates toward the bottom wringer plate to compress the mop head and squeeze water into bucket | Plastic | Injection Molded | 781 | |

| Bottom Wringer Plate (Wringer Base) | 1 | Provides a rigid surface for the upper wringer plate to compress the mop head against | Plastic | Injection Molded | 1520 | ||

| Linkage Stabilizing Pin | 1 | Creates a uniform starting point for linkages to push off from thereby stabilizing upper wringer plate when being compressed | Aluminum | Extruded, cut | 48 | ||

| Upper Wringer Plate Linkage | 4 | Controls translation of upper wringer plate towards bottom wringer plate to compress mop head | Steel | Stamped | 69 | ||

| Rivet | 2 | Secures wringer lever to linkages | Aluminum | Purchased | 4 | ||

| Wringer Lever | 1 | Controls movement of upper wringer plate and therefore the compression of the mop head | Aluminum | Extruded, cut, bent (purchased) | 937 | ||

| Lever Handle Cover | 1 | Provides friction surface and safety feature for operating lever | Rubber | Molding | 27.8 | ||

| Level Torsional Spring | 1 | Resists compression of upper wringer plate and returns it to its original, open position | Aluminum | Extruded, bent (purchased) | 4.4 |

| Sub-assembly | Part | Quantity | Description | Material | Manufacturing Process | Weight (g) | Image |

|---|---|---|---|---|---|---|---|

| Folding Mop | Sponge | 1 | Soaks up water, cleans floor | Synthetic Sponge | Purchased, cut | 50 | |

| Scrubbing Pad | 1 | Allows scrubbing for hard to clean messes | Plastic | Purchased, cut | <1 | ||

| Folding Plates Spring | 1 | Returns two folding plates to linear position to mop floor | Aluminum | Extruded, cut, bent (purchased) | 4 | ||

| Folding Sponge Plate | 2 | Folds towards opposite plate to squeeze excess water out of sponge | Plastic | Injection Molded | 23 | ||

| Mop End Cover | 1 | Allows for the mop to be hung on a hook/nail, provides aesthetic design | Plastic | Injection Molded | 18 | ||

| Plate Folding Handle | 1 | Slides along mop rod to fold bottom plates together and squeeze out excess water | Plastic | Injection Molded | 38 | ||

| Sponge Mount | 1 | Attaches sponge to mop rod | Plastic | Injection Molded | 47 | ||

| Mop Rod | 1 | Controls movement of the mop head | Aluminum | Extruded, cut | 186 | ||

| Folding Handle Pin | 1 | Secures handle to the folding rod | Aluminum | Purchased | <1 | ||

| Folding Rod | 1 | Translated force from folding handle to folding plate spring and plates | Aluminum | Extruded, cut, bent | 35 | ||

| Folding Plate Compressor | 1 | Pushes the folding plates towards each other to squeeze out excess water | Aluminum | Extruded, cut, bent | 51 | ||

| Folding Plate Compressor Roller | 2 | Rolls along folding plates and pushes them together as the folding handle is pushed toward the mop head | Plastic | Injection Molded | 2 |

Design for Manufacturing Analysis

Are there opportunities to improve manufacturability and make a competing product cheaper? Identify where material and process choices are appropriate or inappropriate for expected production volume.

Failure Mode and Effect Analysis

The analysis of failure modes and the effects it has on the consumer or the product must be taken into consideration when redesigning a product. It is important that the product be designed such that it is safe and reliable for the consumer. The evaluation of the product using FMEA allows for us to address the possible effects of failure early on in the design stage.

Numerical Ratings:

S: Severity of Failure (1: Effect not noticed by consumer - 10: Hazardous, failure occurs without warning; life threatening)

O: Occurrence of Failure (1: Extremely unlikely - 10: Extremely high occurrence)

D: Detection of Failure (1: Certain to detect - 10: No chance of detection; no inspection)

RPN: Risk Priority Number = Severity (S) x Occurrence (O) x Detection (D)

After evaluating the product, the parts that were found to have the highest RPNs were those associated with the wringing process. The wringer plates and accompanying parts had high RPNs because if wringer on the bucket fails then the bucket and wringer system will no longer be usable. This can also be applied to the wringing mechanism on the mop rod. If the mechanism fails then the mop will no longer be usable. During the redesign process most of the focus will be on improving the bucket wringing system and the wringing system on the mop.

| Part # | Item | Function | Failure Mode | Effects of Failure | S | Causes of Failure | O | Design Controls | D | RPN | Recommended Action |

|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | Bucket | Holds water and cleaning solution, collects water drained from mop | Breaks/cracks | Can no longer hold water; unusable bucket | 2 | Dropping/hitting | 3 | Durable/hitting | 2 | 12 | Replace bucket or seal crack |

| 2 | Bucket handle | Allows user to pick up bucket (e.g. move up/down stairs, into car) | Detaches from bucket | Can no longer transport bucket | 5 | Overuse - general wear | 4 | Permanently attach handle to bucket, make a more durable connection | 2 | 40 | None |

| 3 | Upper Wringer Plate | Translates towards the bottom wringer plate to compress the mop head and squeeze water into bucket | Breaks/cracks | Can no longer wring mop | 5 | Overuse, dropping/hitting | 4 | Durable plastic | 2 | 40 | Replace bucket or seal crack |

| 4 | Bottom wringer plate (wringer base) | Provides a rigid surface for the upper wringer plate to compress the mop head against | Breaks/cracks | Can no longer wring mop | 5 | Overuse, dropping/hitting | 4 | Durable plastic | 2 | 40 | Replace bucket or seal crack |

| 5 | Linkage Stabilizing Pin | Creates a uniform starting point for linkages to push off from, thereby stabilizing upper wringer plate when being compressed | Loosening | Can no longer wring mop; wringer falls apart while in use | 5 | General wear, user tampering | 6 | Improve on the connection of the pin to the bucket | 2 | 60 | Replace pin |

| 6 | Upper wringer plate linkage | Controls translation of upper wringer plate towards bottom wringer plate to compress mop head | Loosening | Can no longer wring mop; wringer falls apart while in use | 5 | General wear, user tampering | 6 | Improve on the connection of the linkages to pin | 2 | 60 | Replace bucket |

| 7 | Rivet | Secures wringer lever to linkages | Loosening | Can no longer wring mop; wringer falls apart while in use | 5 | General wear; user tampering | 6 | Improve on the connection of the pin to the lever | 2 | 60 | Replace rivet |

| 8 | Wringer lever | Controls movement of upper wringer plate and therefore the compression of the mop head | Detaches from wringer | Can no longer wring mop with lever; wringer falls apart during use | 5 | Overuse - general wear | 4 | Permanently attach lever to bucket, make a more durable connection | 2 | 40 | None |

| 9 | Lever torsional Spring | Resists compression of upper wringer plate and returns it to its original, open position | Loosens, detaches | Can no longer wring mop with lever; wringer falls apart while in use | 7 | Overuse - general wear, user tampering | 3 | Secure to lever | 2 | 42 | Replace spring |

| 10 | Wheel bolt | Secures wheel inside wheel mount | Loosening | Bucket falls of fails while in use | 2 | General wear, user tampering | 4 | Use screw that requires specialized tool to unscrew | 1 | 8 | Screw the bolt back on |

| 11 | Wheel nut | Secures wheel inside wheel mount | Wheel falling off of the mount | Bucket falls or fails while in use | 2 | General wear, user tampering | 2 | Permanently attach wheel to mount | 1 | 4 | Replace nut |

| 12 | Wheel mount | Provides interface to connect wheels to bottom of bucket | Breaks/cracks | Wheels fall off of bucket, bucket fails | 2 | General wear, user tampering, dropping/hitting against rigid object | 3 | Permanently attach wheel to mount | 1 | 4 | Replace mount, replace bucket |

| 13 | Wheel mount pin | Connects the bucket interface to wheel bolt lock | Loosening | Wheels fall off bucket, bucket fails | 5 | General wear, user tampering | 6 | Improve on the connection of the pin to the mount | 2 | 60 | Replace pin |

| 14 | Sponge | Soaks up water, cleans floor | Tear, wear out | Can no longer soak up water | 5 | General wear, user tampering | 6 | None | 2 | 60 | Replace sponge |

| 15 | Scrubbing pad | Allows scrubbing for hard-to-clean messes | Tear, wear out | Can no longer scrub/clean floor | 5 | General wear, user tampering | 6 | None | 2 | 60 | Replace scrubbing pad |

| 16 | Folding plates spring | Returns two folding plates to linear position to mop floor | Loosens, detaches | Can no longer wring out sponge | 5 | Overuse - general wear, user tampering | 3 | Secure to lever | 2 | 30 | Replace spring |

| 17 | Folding sponge plate | Folds towards opposite plate to squeeze excess water out of sponge | Breaks/cracks | Can no longer wring mop | 5 | Overuse, dropping/hitting | 4 | Make out of durable plastic | 2 | 40 | Replace mop |

| 18 | Plate folding handle | Slides along mop rod to fold bottom plates together and squeeze out excess water | Detaches from mop | Can no longer wring sponge with lever, wringer falls apart while in use | 5 | Overuse - general wear, breaking/hitting against rigid object | 4 | Permanently attach lever to bucket, make a more durable connection | 2 | 40 | None |

| 19 | Sponge mount | Attache sponge to mop rod | Loosens, breaks/cracks | Sponge can no longer be connected to mop rod, no longer have usage mop | 5 | Breaking/hitting against rigid object | 4 | Make out of durable plastic | 4 | 80 | Replace mop |

| 20 | Mop rod | Controls movement of the mop head | Breaks/cracks | No longer have a usable mop | 5 | Breaking/hitting against rigid object | 2 | None | 2 | 20 | Replace mop rod |

| 21 | Folding handle pin | Secures handle to the folding rod | Loosening | Can no longer wring sponge, wringer falls apart while in use | 5 | General wear, user tampering | 6 | Improve on the connection of the pin to the handle | 2 | 60 | Replace pin |

| 22 | Folding rod | Translated force from folding handle to folding plate spring and plates | Detaches from mop | Can no longer wring sponge; wringer falls apart while in use | 5 | Overuse - general wear | 4 | None | 2 | 40 | None |

| 23 | Folding plate compressor | Pushes the folding plates towards each other to squeeze out excess water | Breaks, detaches | Can no longer compress the plates | 5 | Overuse - general wear | 4 | None | 2 | 40 | None |

| 24 | Folding plate compressor roller | Rolls along plates and pushes them together as the folding handle is pushed toward the mop head | Breaks, detaches | Can no longer compress the plates | 5 | Overuse - general wear, falling/breaking | 4 | Design a new way to compress the plates besides the rolling system | 2 | 40 | None |

Design for the Environment

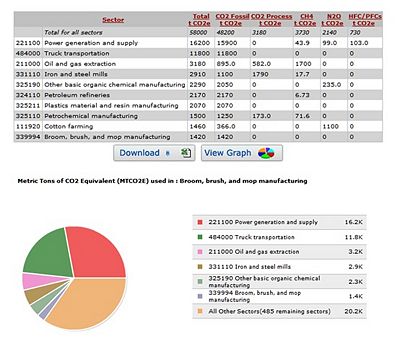

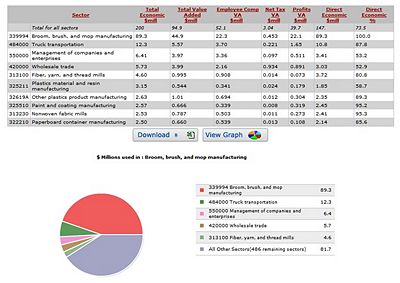

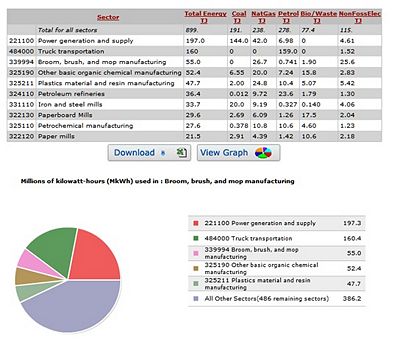

Design for Environment (DFE) is very important because of its ability to shape the design of a product before it is even manufactured. In order to assess the environmental impact of our product we used a tool known as Economic Input-Output Life Cycle Assessment (EIO-LCA). This tool estimates the materials and energy resources required for, and the environmental emissions resulting from, activities in the economy. We will use this tool specifically to find the yearly greenhouse gas emissions, economic impact, and the energy use of the product during the entire product’s life cycle. It is important to note that the product has no major impact on any sector while in the use stage. Also depending on the mode of disposal, there exists the potential for the product to be recycled which will have little to no impact on any sector while the product is at the end of its lifecycle. As a result, we will neglect to conduct an EIO-LCA analysis for the use and end stages.

The charts above show that competitors did a good job at following guidelines which resulted in relatively good greenhouse gas emission numbers although there was room for improvement in the power and generation and the transportation sectors. These two sectors accounted for almost half of the CO2 emissions during the lifecycle of the product making them the major sources of CO2 in the products lifecycle as shown in figure 4. This leads us to believe that if a tax on CO2 were to be passed, there would be no large economic impact resulting from it. If any impact were to be felt, it would most likely occur in the manufacturing of the product as shown in figure 5.

Group Dynamic

Team lead: Brad Edelman

DFMA lead: Kyle Young

FMEA lead: Gabrielle Page

DFE lead: Danny Benvegnu

Editing lead: Bryan Good

Summary of team chemistry

References

Keep Reference Materials

= References =