From DDL Wiki

Executive Summary

Major Post-Production Stakeholders

Customers: The customer has the most at stake and need for any product, in this case a tabletop dishwasher. The primary need customers would have for this product is to effectively clean dirty dishes while being more efficient than hand washing. However, this is not to say that needs satisfied by this dishwasher are also satisfied by all other dishwashers. What sets this unit apart is its small size, non-permanent installation, and easily removed plumbing connections. Satisfying these needs results in a better product and a greater demand to buy it.

Retailers:The needs of a retailer are dependent on those of the customer. In order to make a profit from the sale of this product, retailers need it to be in demand, have the right price point, and be marketed well. If these needs are not satisfied, the product will never find its way to a customer's home.

Transporters: Those who transport the product also have a stake in it. The products packaging must meet both the needs of being shipped from the manufacturer to the retailer and being shipped from the retailer to the customer. In the latter case, portability is again a need. This dishwasher will easily fit in the back seat of a car unlike a conventional dishwasher.

Product Use and User Study

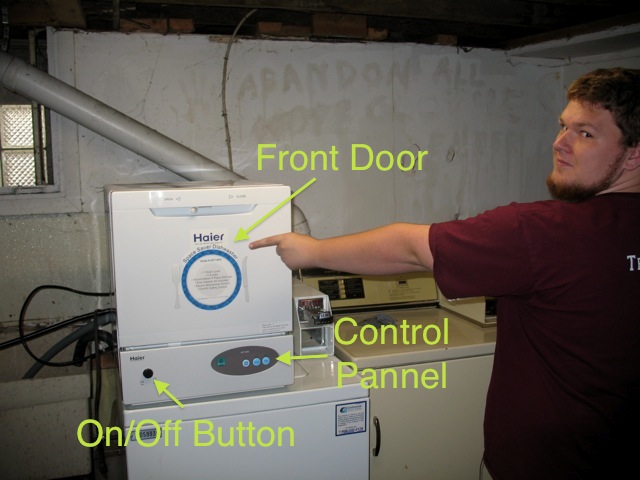

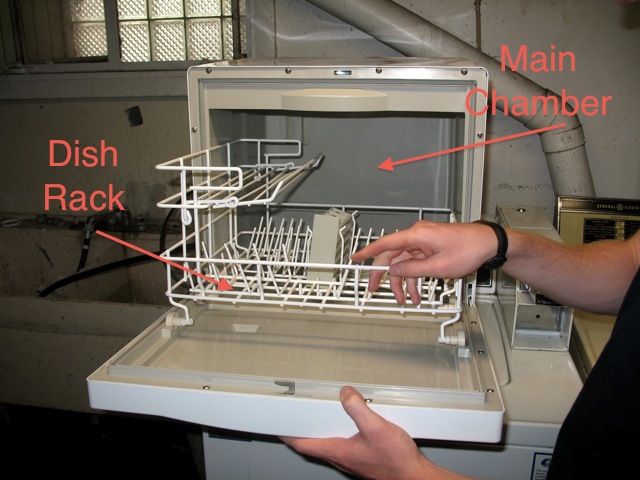

Use of this dishwasher is not that difficult and very straightforward. First, a hose is attached directly to a faucet to act as a water source. Second, another hose is placed in a sink or drain to allow the waste water to be removed. Third, the user loads their dishes into the unit, applies the right amount of detergent, and then selects either a normal or heavy wash cycle. All that remains is for the user to wait until their dishes are clean. The device automatically shuts off when the cycle is complete, and the user removes the dishes from the unit.

Since receiving the unit three weeks ago, it has been tested on both the normal and high cycles by members of our team. Also, a user study was conducted with two students that are not party to this project. Their experience with the device will be summarized below. In this section we will simply share our experience while using the product.

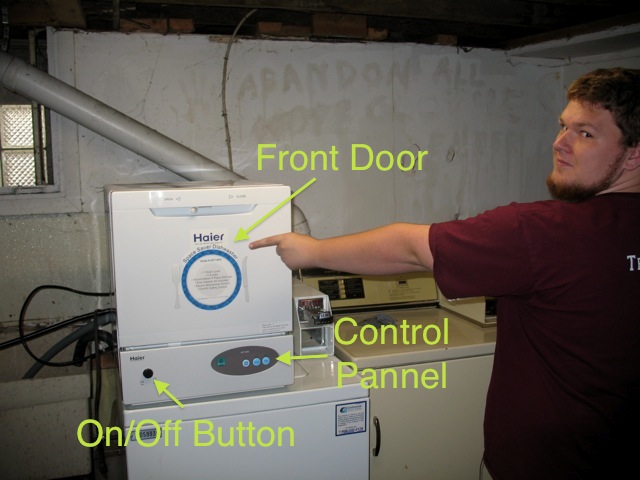

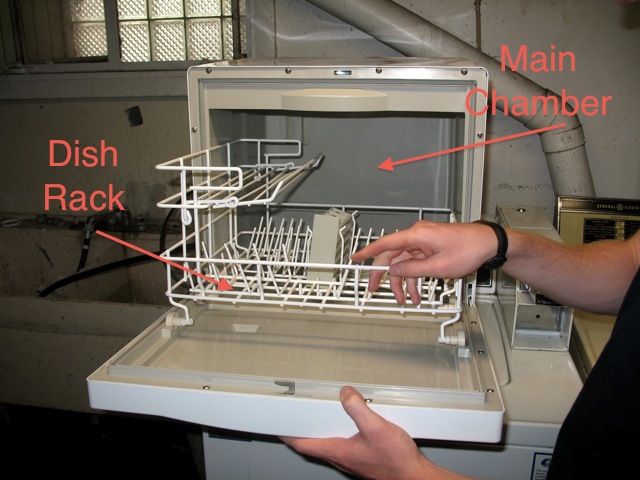

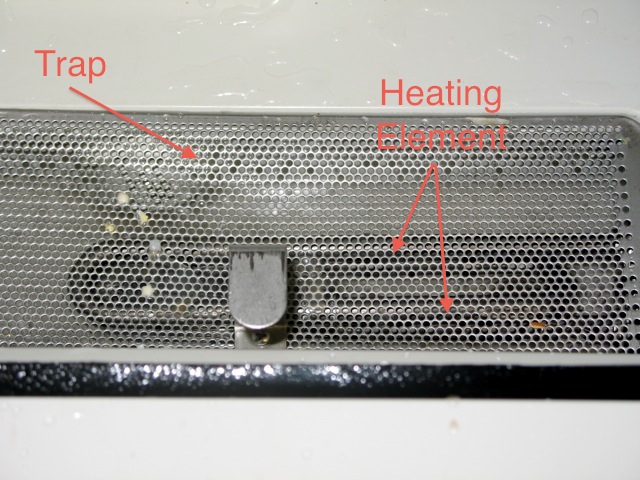

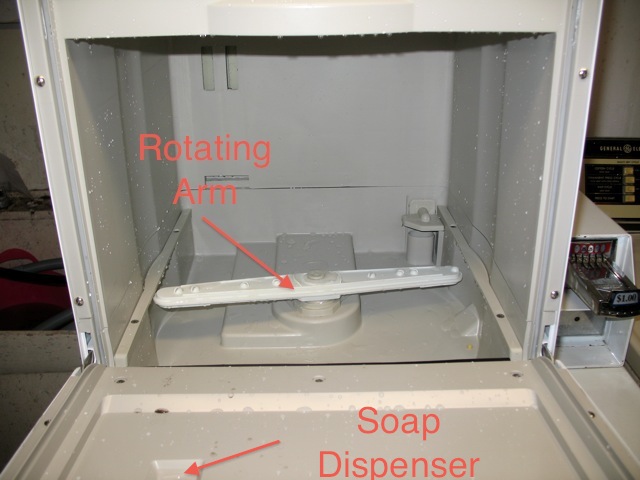

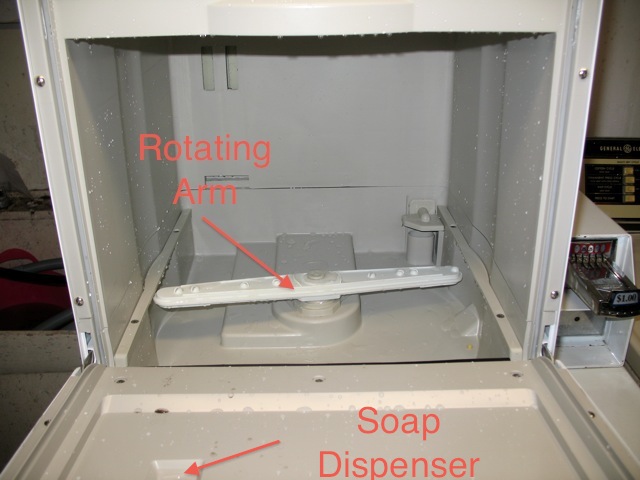

Installing the product was of little difficulty and did not require much time. With the device installed, we then set out to find some of the dirtiest dishes we could. Since testing occurred in a house occupied by five college students, this did not take long. Dishes and cups dirtied with dried on chili, milk, oatmeal, spaghetti, and soup were all used since they were prime candidates for testing. These dishes were then loaded into the device. In order to compensate for any dish being too clean, large amounts of maple syrup were doused on the dishes while in the device. We closed the door, hit the button, and then hopped for the best. There was approximately a minute delay before the product began to function. The operation of the device sounded like that of any other normal dishwasher with the exception of seeing the waste water being removed. Approximately 45 minutes later the dishes were very clean. The following pictures show this process with components of the device labeled as they appeared before product dissection:

In the user study, test users were asked to list the steps taken to operate the device, good and bad qualities about the device, his feelings on the robustness, effectiveness, and ease of use of the product. Finally they were asked to list any potential changes that should be made to the device.

Bill of Materials

The following is a bill of materials containing many individual parts and sub assemblies.

| Part Number | Name/Description | Function | Material | Manufacturing Process | Mass | Quantity | Picture

|

| 1

| Silverware tray | Hold silverware | Plastic | Injection molding | ??? | 1 |

|

| 2

| Dish tray/basket | Hold dishes | Plastic coated | Assembled | ??? | 1 |

|

| 3

| Plastic wheels and axels | Movement of basket | Plastic | Injection molding | ??? | 6 |

|

| 4

| C-clip for sprayer arm | Attachment of sprayer | Plastic | Injection molding | ??? | 1 |

|

| 5

| Washer for sprayer | Allow for rotation of sprayer | Plastic | Injection molding | ??? | 1 |

|

| 6

| O-ring for sprayer | Sealing | Rubber | Molding | ??? | 1 |

|

| 7

| Rotating sprayer arm | Control water spray | Plastic | Injection molding | ??? | 1 |

|

| 8

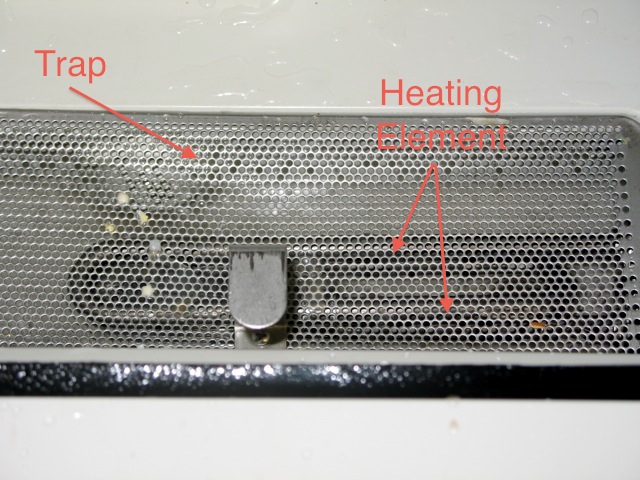

| Mesh trap | Collect food particulate | Metal/Steel | Punched | ??? | 1 |

|

| 9

| Front panel cover | Aesthetic | Plastic | Injection molding | ??? | 1 |

|

| 10

| Panel cover screws (phillips) | Panel attachment | Metal | Molded | ??? | 11 |

|

| 11

| Latch screw and washer | Latch attachment | metal | Punched and molded | ??? | 2 |

|

| 12

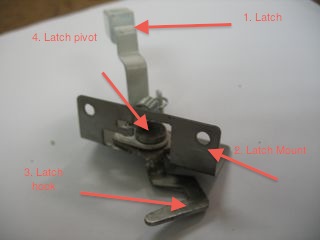

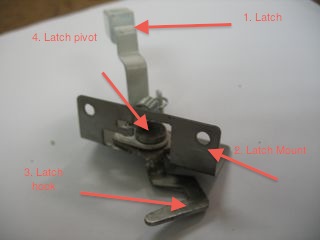

| Latch sub-assembly | Lock door to body | Metal | Assembled | ??? | 1 |

|

| 13

| Latch spring | Provide resistance | Metal | Bent | ??? | 1 |

|

| 14

| Hinges | Fixed rotation of door | Metal | Punched | ??? | 2 |

|

| 15

| Hinge screws (2 metal, 1 plastic) | Fix door to hinge | Metal and plastic | Assembled | ??? | 2 |

|

| 16

| Metal door frame | Rigidity for door | Steel | Pressed | ??? | 1 |

|

| 17

| Rubber seal/spacer | Prevent water leakage | Rubber | Cut | ??? | 1 |

|

| 18

| Inner plastic door cover | Primary seal for water | Plastic | Injection molding | ??? | 1 |

|

| 19

| Inner door cover screws | Attachment of inner door cover | Plastic | Assembled | ??? | 2 |

|

| 20

| Electric panel to frame screws | Attachment | Metal | Assembled | ??? | 2 |

|

| 21

| Back panel of electronics housing | Protect against water damaged | Plastic | Injection molding | ??? | 1 |

|

| 22

| Electric housing connection screws | Attachment | Metal | Assembled | ??? | 6 |

|

| 23

| ON/OFF Button sub-assembly | Activate power to device | Various | Assembled | ??? | 1 |

|

| 24

| ON/OFF Button screws | Button attachment | Metal | Assembled | ??? | 1 |

|

| 25

| Hinge sub-assembly | Attach door to body | Metal | Assembled | ??? | 1 |

|

| 26

| Plastic chamber rails | Connection of main chamber halves | Plastic | Injection molding | ??? | 2 |

|

| 27

| Chamber rail screws | Attachment | Metal | Assembled | ??? | 4 |

|

| 28

| Back panel screws | Attachment | Metal | Assembled | ??? | 10 |

|

| 29

| Cord holder | Cord management | Plastic | Cut | ??? | 1 |

|

| 30

| Back Panel | Protection | Metal | Stamped | ??? | 1 |

|

| 31

| Main Body | Protection | Metal | Bent and cut | ??? | 1 |

|

| 32

| Main Body Screws | Attachment | Metal | Assembled | ??? | 8 |

|

| 33

| Switch Latch Electronic sub-Assembly | Acknowledge door closure | Various | Assembled | ??? | 1 |

|

| 34

| Inlet tube | Provide feed water | Rubber | Cut | ??? | 1 |

|

| 35

| Rubber feet | Stabilization | Plastic | Injection molding | ??? | 4 |

|

| 36

| Inlet valve sub-assembly | Control water flow rate | Various | Assembled | ??? | 1 |

|

| 37

| Solenoid screw | Inlet control | Metal | Assembled | ??? | 1 |

|

| 38

| Rubber door seal | Prevent water leakage | Plastic | Cut | ??? | 1 |

|

| 39

| Inner shell, upper half | Main washing chamber | Plastic | Injection molding | ??? | 1 |

|

| 40

| Inner shell seals | Prevent water leakage | Plastic | Cut | ??? | 1 |

|

| 41

| Hose clamp for outlet tube | Attachment | Metal | Bent | ??? | 1 |

|

| 42

| O-ring for outlet tube | Seal | Rubber | Cut | ??? | 1 |

|

| 43

| Outlet hose | Water discharge | Plastic | Injection molding | ??? | 1 |

|

| 44

| Metal base to lower plastic chamber screws | Attachment | Metal | Assembled | ??? | 6 |

|

| 45

| Main plastic housing screws | Attachment | Metal | Assembled | ??? | 8? |

|

| 46

| Basin to base plates | Reenforcement | Metal | Assembled | ??? | 2 |

|

| 47

| Bottom sub-assembly | Various electrical and mechanical components | Various | Assembled | ??? | 1 |

|

| 48

| Brick | Balance | Ceramic | Molded | ??? | 1 |

|

| 49

| Pump hose | Pump connection | Plastic | Cut | ??? | 1 |

|

| 50

| Pump hose clamp | Sealing | Metal | Bent | ??? | 1 |

|

| 51

| Pump hose screws | Attachment | Metal | Assembled | ??? | 1 |

|

| 52

| Main pump sub-assembly | Water intake | Various | Assembled | ??? | 1 |

|

| 53

| Sprayer mount | Water feeding and rotation | Plastic | Injection Molding | ??? | 1 |

|

| 54

| Pump turbine sub-assembly | Produce water flow | Various | Assembled | ??? | 1 |

|

| 55

| Thermocouple 1 sub-assembly | Temperature measurement | Various | Assembled | ??? | 1 |

|

| 56

| Heating element attachment | Attachment | Metal | Assembled | ??? | 1 |

|

| 57

| Thermocouple 2 sub-assembly | Temperature measurement | Various | Assembled | ??? | 1 |

|

| 58

| Thermocouple 2 housing | Protection | Metal | Stamped | ??? | 1 |

|

| 59

| Trap to outlet house | Water discharge | Rubber | Cut | ??? | 1 |

|

| 60

| Heating element sub-assembly | Heat water | Various | Assembled | ??? | 1 |

|

| 61

| Waste | Water flow for discharge | Various | Assembled | ??? | 1 |

|

| 62

| Waste to outlet hose | Waste water discharge | Rubber | Assembled | ??? | 1 |

|

| 63

| Trap to base hose | Waste water discharge | Rubber | Assembled | ??? | 1 |

|

| 63

| Bob casing | Housing/protection | Plastic | Injection molding | ??? | 1 |

|

| 64

| Bob sub-assembly | Water level control | Various | Assembled | ??? | 1 |

|