Paper towel dispenser innovation

From DDL Wiki

Contents |

Executive Summary

Market Analysis

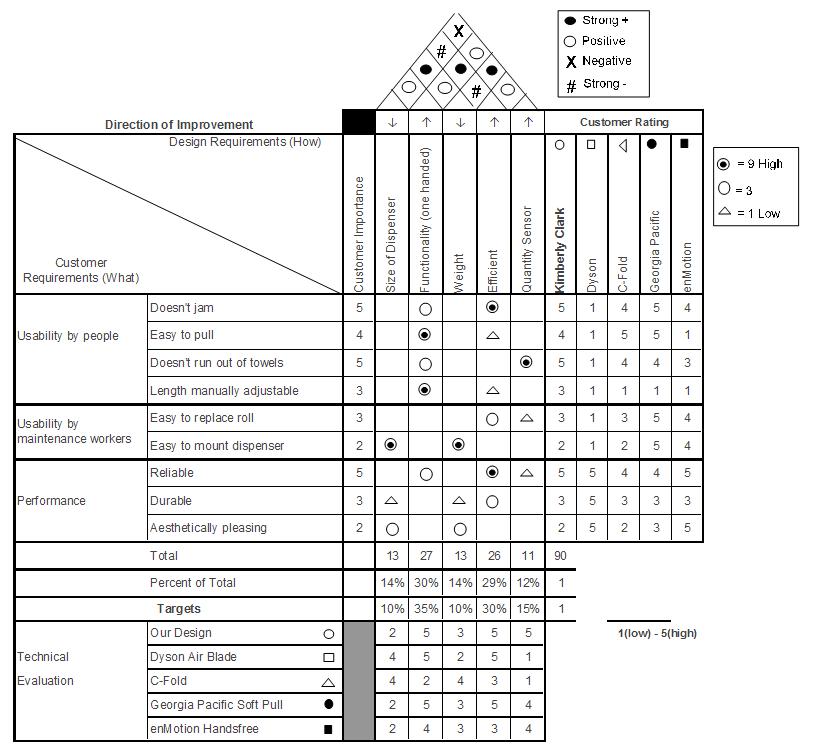

The paper towel dispenser is a common product used every day by millions of people from around the world. Therefore, it is very important that this product functions very well without requiring too much maintenance. However, this is not the case with the current paper towel dispensers in the market. There are many different types of papers towels in the market and we have analyzed the major ones below.

Current Major Models and Designs

Kimberly-Clark In-Sight Sanitouch Roll Towel Dispenser

Kimberly-Clark EZ Load Lev-R-Matic Restroom Paper Towel Dispenser

Georgia Pacific enMotion Automated Touchless Towel Dispenser

User Studies

First Study – Personal Testing

Second Study – Observation in Public Restrooms

Consultation with Maintenance Workers

Design Documentation

House of Quality

Design Analysis

DFMA

The parts that need to be manufactured include the ratchet, pawl, sensor arm, and the circuit board. The design of the ratchet, pawl, and sensor arm are relatively simple and should not be difficult. We tried to figure out a way to integrate this into the current design to reduce parts, but we feel that it would be easier to assemble as separate pieces and would not cause much delay in the assembly process. The circuit board would have to be assembled separately and installed with the sensor arm.

FMEA

Failure mode and effects analysis (FMEA) identifies potential problems of every component in the machinery, lists their effects on the system, and finally provides recommended actions to prevent such failures. The methodology for problem identification depends on ratings of Severity of a failure (S), Occurrence of Failure (O), and Detection of Failure (D). These scales are between 1 and 10 and they are rated in a way that less number of ratings indicates less significant problem and conversely higher rating means more serious failure or effect. The results of a FMEA Analysis (RPN) are calculated by multiplying S, O and D to signify seriousness of the problem.

Conclusion

Our FMEA is very similar to the previous one, with the addition of our parts, which include the ratchet assembly and sensor assembly. These parts are noted in the bottom of the list and are parts that have low potential for failure.

Since our machine is a simple and easy mechanism, it does not require a significant amount of force to operate. Thus, it does not involve any component that undergoes serious stress or force, and under proper usage the mechanism is rigid enough: most parts have low Occurrence of Failure rating. Moreover, it is found that severity of failure of most components is low, but in cases of components with a high severity of failure, the detections are made easy (low Detection of Failure rating), keeping RPN rating to a small number. In conclusion our FMEA analysis, not many parts with high RPN, indicates the mechanism overall is reliable and we found only a few issues.

One issue we did find was the if the cutter was not perforating the paper. We found the culprit to be Part 10, the uneven springs. In the case we find, these springs were missing, which did not allow the paper towel guide (Part 09) to push down on the paper. This, in turn, did not provide enough force to keep the paper towel taught, and ultimately to perforate the paper.

Another issue we found, was a case where one of the Spring 11 were missing. In fact, the paper towel dispenser worked fine even with only one spring, meaning that the second spring may provide more force on a different part of the rotation of the spindle, but the single spring provides enough force to make it complete its rotation. Another consideration is if the spring is stretched quickly (i.e. a user pulls to fast) it often occurs that the next sheet of paper recedes back into the machine. We figured this is why the knob is needed on the side, which is a reliable solution to that problem. Also, pulling at different angles does not affect the way the paper leaves the spindle or gets cut. This is because the thin paper guide is there to make sure the paper is coming straight down off the spindle and not at an angle.

One issue was that the Locking Spring (Part 14) would not prevent the spindle from spinning back into the paper towel dispenser. Although it seems that this may not be its primary function, but rather to prevent the user from turning the spindle using the red knob. Our new design uses a ratchet and pawl to prevent the spindle from turning back into the paper towel dispenser.

The other addition to the assembly is the paper towel sensor to detect the amount of paper left on the roll. This has a possiblity of failure if a wire becomes loose or if the person replacing the paper towel damages it.

We found these occurrences to be very low in our observations of campus paper towel dispensers. Also, the detections are relatively high for the failure of Part 10.

| Part No. | Name | Function | Failure Mode | Effects of Failure | S | Causes of Failure | O | Design Controls | D | RPN | Recommended Actions | Responsibility |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 01 | Front Housing | Protects device from exterior | Fractures, Warped |

| 7 |

| 4 |

| 2 | 56 |

| Reliability

|

| 02 | Front Housing Clip | Holds housings together | Bends |

| 4 |

| 2 |

| 6 | 48 |

| Assembly and Reliablity

|

| 03 | Front Housing Tab | Secures housing clip | Strips |

| 2 |

| 2 |

| 8 | 32 |

| Assembly

|

| 04 | Rear Housing | Holds mechanical components | Fractures |

| 7 |

| 4 |

| 1 | 28 |

| Reliability |

| 05 | Paper Towel Holding Arm | Holds paper towel roll | Bends |

| 6 |

| 3 |

| 2 | 36 |

| Assembly and Manufacturing |

| 08 | Screw Anchor | Holds screw in wall | Fractures |

| 7 |

| 2 |

| 4 | 56 |

| Reliablity |

| 09 | Paper Guide Tube | Guides paper towel to cutting cylinder | Failed |

| 4 |

| 3 |

| 2 | 24 |

| Manufacturing |

| 10 | Spring (uneven hooks) | Holds 09 in place | Deformed |

| 8 |

| 2 |

| 5 | 80 |

| Assembly and Reliablity |

| 11 | Spring (even hooks) | Holds lever to spindle housing | Deformed |

| 5 |

| 5 |

| 4 | 100 |

| Assembly and Reliablity |

| 14 | Locking Spring | Hides screw in turning wheel | Deformed |

| 3 |

| 2 |

| 4 | 24 |

| Assembly and Reliablity |

| 16 | Guide clips for 09 | Guides paper on 09 | Break |

| 4 |

| 3 |

| 2 | 24 |

| Assembly and Manufacturing |

| 18 | Lever Arm | Connects spring to spindle | Breaks |

| 5 |

| 2 |

| 2 | 20 |

| Manufacturing and Reliablity |

| 19 | Spring Connector | Connects two springs to lever arm | Breaks |

| 5 |

| 2 |

| 3 | 30 |

| Assembly and Reliablity |

| 20 | Rounded Spring Guide | Angles spring to desired measurement | Breaks |

| 2 |

| 2 |

| 7 | 28 |

| Manufacturing |

| 21 | Thin Paper Guide | Guides paper out of device | Breaks |

| 4 |

| 3 |

| 1 | 12 |

| Manufacturing |

| 22 | Front Spindle Housing | Final housing before paper leaves device | Fractures |

| 3 |

| 2 |

| 6 | 36 |

| Assembly and Manufacturing |

| 23 | Spindle Housing Back | Back of spindle housing | Fractures |

| 3 |

| 2 |

| 6 | 36 |

| Assembly and Manufacturing |

| 24,25 | Spindle Housing (L,R) | Sides of spindle housing | Breaks |

| 5 |

| 2 |

| 6 | 60 |

| Assembly and Manufacturing |

| 29 | White Teeth Guide/Arm | Guides cutting teeth in spindle | Breaks |

| 3 |

| 3 |

| 6 | 36 |

| Assembly and Manufacturing |

| 30 | Cutting Teeth | Cuts paper towel | Wears,Bends |

| 4 |

| 2 |

| 2 | 16 |

| Manufacturing |

| 31,32 | Spindle | Back of spindle housing | Warps,Breaks |

| 5 |

| 1 |

| 3 | 15 |

| Assembly and Manufacturing |

| 33 | Ratchet | Prevents spindle from turning backwards | Wears,Breaks |

| 2 |

| 2 |

| 2 | 8 |

| Manufacturing |

| 34 | Pawl | Works with ratchet | Wears,Breaks |

| 4 |

| 2 |

| 2 | 16 |

| Manufacturing |

| 35 | Pawl Spring | Pushes pawl into ratchet | Wears,Bends |

| 4 |

| 4 |

| 2 | 32 |

| Manufacturing |

| 36 | Lever Arm | Back of spindle housing | Wears,Bends |

| 4 |

| 4 |

| 2 | 32 |

| Manufacturing |

| 37 | Sensor Assembly | Sends Wi-Fi signal info of towel roll size | Wears,Burns out |

| 4 |

| 3 |

| 2 | 24 |

| Manufacturing |

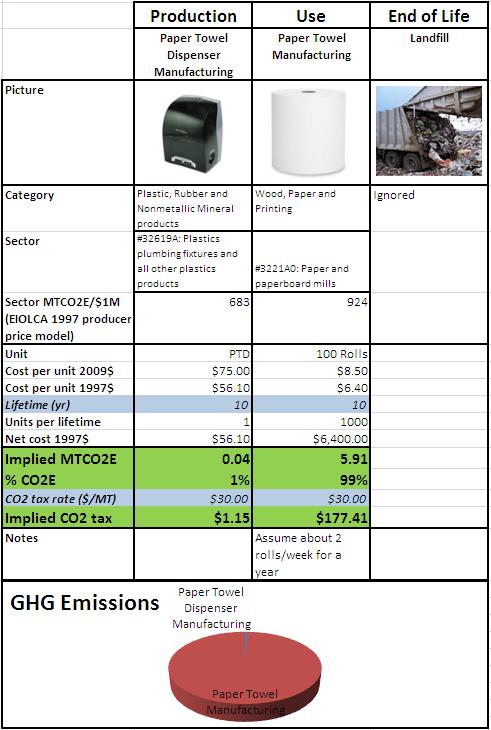

DFE

In our Design for Environment, we feel that the improvements we have made will not have that strong of an effect on the environment. We are essentially making a new part for the ratchet out of injection molded plastic. The sensor assembly will be electrically powered, but we feel that this is an insignificant amount of power use.

In comparison to our competitors, they are similar in paper towel use or electricity use. For the air-powered hand dryers, they are solely electrically powered and use more energy than their paper counterparts. We feel that we will use a similar amount of energy and paper towel as some of the dispensers that use infrared sensors to advance the paper.

Please see Appendix for EIO-LCA.

Mechanical Analysis

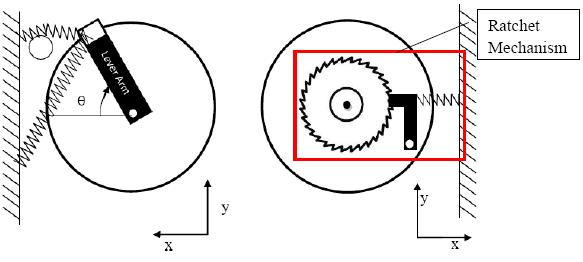

In our new paper towel dispenser, we incorporated a ratchet mechanism to prevent spindle from turning more than needed due to its inertia and causing paper towel to be rolled back in. For engineering analysis, we calculated and investigated to compare the effect of the additional inertia of the ratchet as well as the new resistance moment it will provide. First, we varied rotation angle of spindle and performed static analysis to measure force required for users to pull a paper towel with the original paper towel dispenser and with our new design. Then we assumed the average time it takes for a person to pull a paper towel to be 1 sec, and performed dynamic analysis of systems to find out required pulling force with and without ratchet mechanism.

Left view (left) and right view of spindle(right) with ratchet mechanism indicated by red box

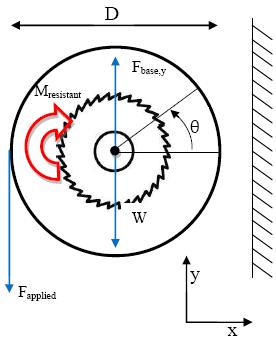

Free Body Diagram

Simplied Free body diagram

Where:

D = diameter of spindle = 0.1m

Θ = angle displacement of spindle from initial state

W = weight of the spindle and ratchet gear

Fbase,y = force applied by axle of the base to the spindle in y-axis

Fapplied = force applied by user by pulling paper towel

Mresistant = Mspring + Mratchet

Mspring = moment from lever arm springs on the left side of spindle(varies with θ, angle of rotation of spindle)

Mratchet = moment from ratchet mechanism (moment due to friction force between ratchet gear and pawl, normal force being ratchet spring force and reaction force from axle of the base)

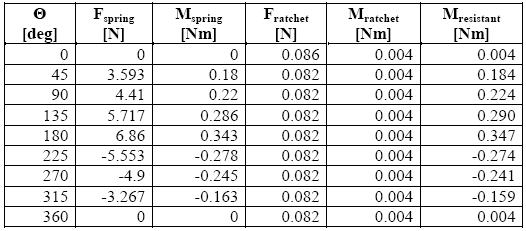

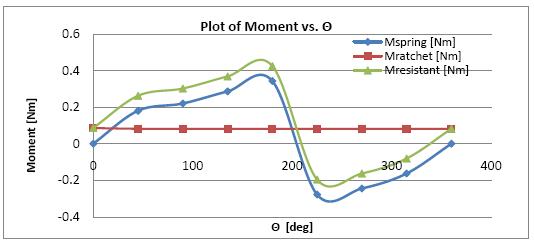

Determination of Mspring and Mratchet

Our group realized that determining Mspring and Mratchet from calculations of actual spring forces, dimensions, and friction forces is inefficient, and also inaccurate. Thus, we tested the actual model at different angles, incremented theta by 45 degrees, and reported forces to obtain Mspring and Mratchet values. To find force, we attached a reference spring to the end of sheet of paper towel and pulled until it reaches certain angle and stays at equilibrium. Then we measure the stretch of spring to find out the force. We applied the same method is used for both of Mspring and Mratchet, but we isolated the two values from each other and tested them separately.

Calculation of Mspring and Mratchet

References spring constant, k = 163.3 N/m

Initial length of reference spring constant, Linitial = 0.023 m

Fspring, i = k ∆xi = (163.33)∆xi N where ∆ xi = Lengthspring,i - Linitial = (Lengthspring,i - 0.023) m

Mspring, i = (D/2) Fspring, i = 0.05 Fspring, i Nm , where i = 0, 45°, 90°, …315°, 360 ° (eq.1)

Summary of results

The difference between Mspring and Mratchet is that unlike Mspring, Mratchet does not depend on angle of rotation. We found that Mratceht is relatively small compared to Mspring (approx. 8% of Mspring). Therefore we believe that adding ratchet mechanism would not cause a huge difference.

Table of resistant forces, moments at different angles of rotation

Resistant moments at different angles of rotation

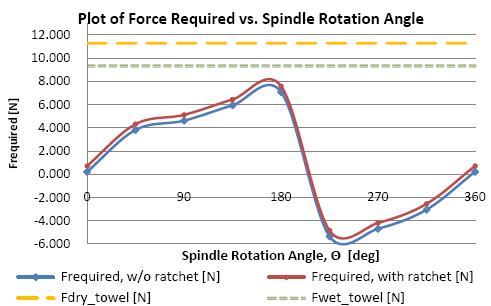

Determination of dry and wet paper towel tensile capacity

Again, we perforemd experiment to find dry and wet paper towel tensile capacity. First we taped one end of paper towel to fix towel and taped weights to the other end. We incremented amount of weights until the paper towel breaks and measured weights to find the capacity. From this we found forces needed to break paper towel when it is dry to be 11.27N (Fdry_towel) and wet to be 9.31N (Fwet_towel). We will use this as an indicators to test validity of our mechanical design.

Static Analysis

In order for the system to be static, sum of forces in all directions and sum of all moments should equal to zero.

Solving Force Applied without Ratchet

∑Fy = 0 => Fbase,y = W + Fapplied

∑Fx = 0: The thin paper towel guide (part 21) cancels forces in x-direction, no matter in what angle user pulls the paper towel.

∑M = 0 at the center of the spindle,

- Mspring + Fapplied(D/2) = 0 => Fapplied = (2/D)(Mspring) (eq.2)

Solving Force Applied with Ratchet

Simlarly, ∑M = 0 at the center of the spindle,

-Mratchet - Mspring + Fapplied(D/2) = 0 => Fapplied = (2/D)(Mratchet + Mspring) (eq.3)

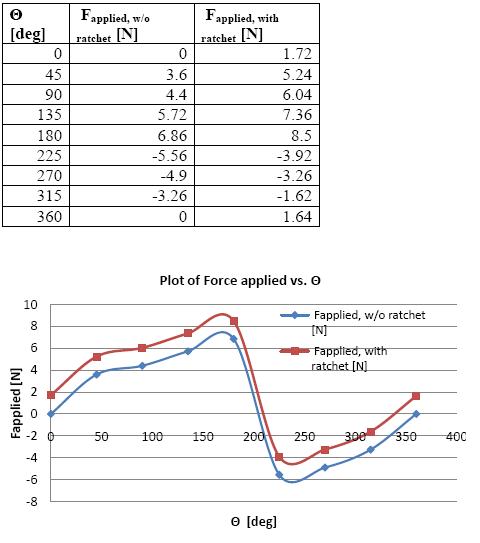

Summary of results

Using eq.2 and eq.3 we calculated F applied with and without ratchet mechanism. As expected, although system with ratchet mechanism requires more force to be applied, it is not significant enough.

Table of Force applied at different angles of rotation at static state

Force applied at different angles of rotation at static state

Dynamic Analysis

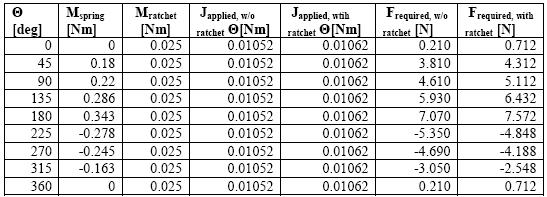

In our dynamic system, sum of forces will equal to zero but the sum of moments would not equal to zero since the spindle will rotate at some angular velocity. In order to analyze this system, we need to figure out inertia of spindle and angular acceleration.

Solving Moment of Inertia

We calculated both the moment of inertia of the spindle and the spindle with the ratchet, assuming spindle as a hollow tube with radius of 5cm, and mass of 0.335 kg and ratchet gear as a disk with radius of 3cm and mass of 0.067 kg,

Jspindle = mspindlerspindle2 = (0.335 kg)(0.10 m/2)2 = 0.0008375 kg-m2

Jspindle, with ratchet = mspindlerspindle2 +1/2 mratchet rratchet2 = (0.335 )(0.05)2 + 1/2(0.067) (0.05)2 = 0.00084504 kg-m2

Solving Angular Acceleration

We first assumed time it takes for user to pull a paper towel is 0.5 s and the angular acceleration of spindle to be some constant value since it

Assume constant θ ̈=a and tpull = 0.5 s

Integrating θ ̈ with respect to t, ∫θ̈dt=∫a dt => θ=at+c1 (c1=0, since θ=0 at t=0) => θ̇=at

Integrating θ ̇ with respect to t, ∫θ̇dt=∫at dt => θ=(at2)/2+ c2 (c2=0, since θ=0 at t=0) => θ=(at2)/2

Since a pull cycle(2π) takes 0.5 s, θ=2π=(a(0.5s)2)/2 => a= (2π×2)/(0.5s)2 => a=50.27 rad/s2

Solving Force Applied without Ratchet for this angular acceleration

∑M=-Jθ̈= Mspring,i - Fapplied,i D/2

=> Fapplied,i = 2/D ( Mspring,i+ J θ ̈ ) (eq.4)

Solving Force Applied with Ratchet for this angular acceleration

∑M=-Jθ ̈= Mratchet,i + Mspring,i + - Fapplied,i D/2

=> Fapplied,i= 2/D (Mratchet,i + Mspring,i + J θ ̈ ) (eq.5)

Summary of result

Using eq.4 and eq.5 we calculated F applied with and without ratchet mechanism. As expected, although system with ratchet mechanism requires more force to be applied, it is not significant enough.

Table of Force applied at different angles of rotation at dynamic state

Force applied at different angles of rotation at dynamic state

Conclusion

Adding ratchet mechanism increases moment of inertia, and force required for user to pull the paper towel in both static and dynamic state. However, this increase is insignificant because average human pulling force with two hands for male ranges from 310-370N and for female ranges from 70-180N. In addition, the required force in the new model does not exceed the amount of forces to break paper dry and wet towels. In both designs, the required forces maximized at when spindle is half way (180 degrees from initial position) of whole turn, and the values were found out to be 7.070N for regular design and 7.572N for our design. With our model, users need to pull dry paper towel less than in 0.219 sec and wet paper less than in 0.294 sec in order to get paper tower get ripped. But we consider these to be extreme cases because we expect average user pulling time to be > 0.5 sec from obeservations and experimentation using paper towel dispenser ourselves. Therefore we believe our design is practical for normal uses.

Prototype Documentation

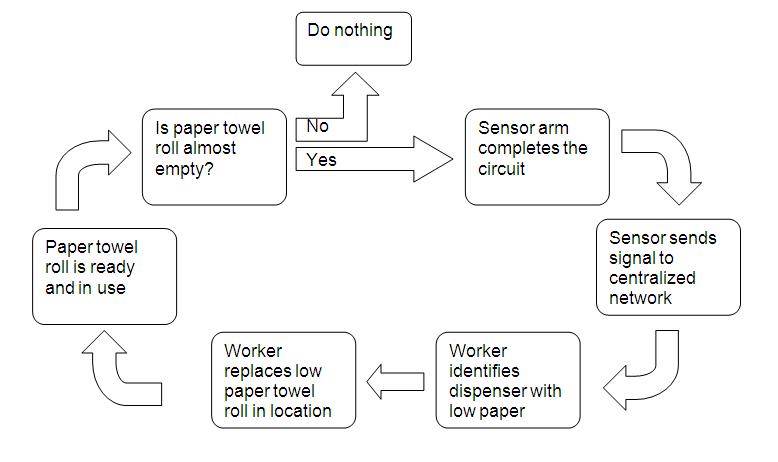

The flowchart below depicts the steps it takes for a paper towel to be replaced. The sensor detects if there is a smaller diameter and sends a signal to a centralized location. A maintenance worker will see which paper towel dispenser needs to be replaced and in which location. The worker replaces the paper towel dispenser and the sensor is reset.

Design Process

Team Member Roles

Chang Keun Jung - Mechanical Analysis

Nishan Kulatilaka -

James Li-Yang Lee -

Eric Totong - Design Analysis, Flowchart

Appendix

References

1. W. Karwowski, International encyclopedia of ergonomics and human factors, volume 1, NW: CRC Press, 2006, page 500.

<references/>