Active climbing cam

From DDL Wiki

==Executive Summary ...

Contents |

Product Overview

Customer needs

- reliable in a fall

- light weight

- easy and versatile placement

- low cost for user group

- durable and long lasting, able to withstand use in the mountains

- easy to handle

- diverse functionality

- compatible with sizes of older models

- accomdates variety of hand sizes

- intuitive for new users

- easy to retrieve from rock

- fast placement and removal

User interaction

Inputs

- retraction force from hand

- friction force from rock

- reaction force from rock

Outputs

- force on climbing rope

- force on rock

Function

Spring Loaded Camming Devices

- protect against falls in free or aid climbing

- build removable anchors in rock

- secure a belayer

- mountaineering uses

- mountain rescue

- passive climbing protection

Method of Use

- locate crack

- Identify appropriate size cam unit

- remove cam from harness/chest sling

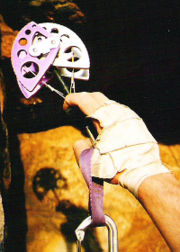

- grip cam securely

- retract the trigger

- insert in crack, pocket or flake

- find secure placement

- orient the cam with expected direction of force

- retract trigger and remove

- removed either on rappel or by 2nd climber

- replace back on harness or chest sling

Issues associated with use

- having proper size for each type of placement

- dropping the device while climbing

- "walking" in cracks (when device gets stuck in a rock and you cannot remove it)

- with many devices the extra weight is evident

Stakeholders

- climber

- rescue workers (mountain rescue)

- insurance companies (health, life & company insurance)

- tourism

- manufacturers

- hospitals

- environment

- retail services

- distributors

Watch a demonstration video on using a climbing cam that we did in the lab

Functionality

On its initial position, the camming device starts with the three lobes aligned horizontally. The trigger is pulled towards the sling using the index and middle finger. This movement slides the trigger down pulling the trigger wires, which are attached to the trigger on one end, and to the lobes on the other end. The tension on the cables causes the lobes to rotate around the axle; the trigger must be pulled until the lobes are completely aligned vertically. During the triggering process, the springs come into action, creating an opposite force that causes the lobes to resist to rotation (and at the same time trying to bring the lobes back to their initial position); the fingers in the trigger must therefore apply resistance to keep the lobes aligned vertically. At this time is when the cam is inserted in the crack. Once the cam is in place, the trigger must be released, causing the lobes to return to their normal position. Now, the springs are in charge of pushing the lobes against the rock walls inside the crack.

Part analysis

Manufacture of parts

The climbing cam is a mechanical device composed of 12 different parts.

Assembly Procedure

The climbing cam seems to have been assembled roughly using the following process. Most of the parts used in this assembly do not have any external fasteners/screws; this reduces the assembly time considerably. Some parts however require welding to be secured which will increase assembly time. Finally there are many very small parts which would produce handling difficulties during orientation and insertion.

A. Initial Base Assembly

1. Taking the thick cable (3) and inserting it into the thick plastic orange tube (5).

2. Bending the thick cable to form a ‘U’ shape.

3. The bent thick cable seems to have been inserted into the finger support (9) and then fused in place.

4. Two thin plastic tubes (4) were then inserted over the open side of the assembly.

B. Trigger Assembly

1. The three trigger wires (11) were connected and fused into the trigger (6).

2. Then the wires attaching the cam lobes (2) to the trigger assembly are joined and fused using the three copper connectors (12).

3. Spring pins (10) are then inserted into the three cam lobes.

C. Final Assembly

1. The initial base assembly is then inserted through the trigger base assembly.

2. Then the cam lobes along with the two springs (1) are aligned on the axle.

3. Axle ends (8) are then fused onto the initial base assembly.

4. Finally the axle is put through the axle ends and welded shut.

* Note: numbers in () correspond to part number

Failure analysis

The climbing cam relies mostly on the correct functionality of the lobes, which are the parts in contact with the rock while the device is in place. The lobes rest on the axle and the springs give them the force keeping them against the rock walls. The camming device's main cable is also crucial, since it is attached to the axle and it is the part holding the weight.

Additionally, during climbing more than one cam is used. In case of any single one cam failing, the remaining cams will support the climber(s) from falling.

DFMA, FMEA and DFE Analysis

| Part number | Parts | DFMA | FMEA | DFE |

|---|---|---|---|---|

| 1 | spring | attaching the spring onto the axle is no problem as there is only one way it can go on, attaching the springs to the pins are complicated due to their very small size | failure of all 3 springs would result in complete failure of the cam in normal usage. cam could still be partially functional with one or two failed springs but should not be used for climbing. cam could still function as passive protection without springs. | spring may be made leaner, metal can be recycled |

| 2 | cam lobes | Due to the partial symmetry of the cam lobes, orientation time during assembly is reduced | failure of one cam lobe by serious deformation would reduce the friction provided by the cam it would also interfere with how the other lobes engaged within the rock. | casting instead of machining to reduce waste metal, recycle metal |

| 3 | main cable | Fully symmetrical and large enough to manipulate it easily with bare hands | a severed cable would result in the cam no longer supporting the weight of a falling climber. excessively worn or severely bent cables should be used with extreme caution. | increase durability to maximize first life, recycle material |

| 4 | thin plastic tubes | Designed for easy alignment as they both have axial symmetry | failure of tubing would accelerate the deterioration of the main cable, thus reducing the lifespan of the product. Failure would also increase force needed to retract trigger. | make plastic tube shorter, recycle plastic |

| 5 | sling; plastic tube (orange) | Similar to the thin plastic tubes this tube has axial symmetry and thus orientation time during assembly is minimized | Failure of tubing would result in faster wearing of main cable and also wearing on nylon slings often looped onto cam and clipped to rope. | less thick plastic, recycle plastic |

| 6 | trigger | The trigger can be inserted both directions i.e. it only has one axis which it must be rotated upon insertion | Failure of trigger would release trigger cables and make placement and retrieval of cam very difficult yet still possible | use less material, recycle material |

| 7 | axle | The axle is made of extremely durable metal and is a simple cylinder construction which is easy to handle. Additionally the parts which have to be inserted on the axle can be done so easily as there is very little resistance to insertion | Failure of axle by complete fracture would result in a complete failure of the cam yielding it unsafe for use in climbing | use material efficiently, casting instead of machining, recycle metal |

| 8 | axle ends | The ends have to be oriented over two axes upon insertion which increased the time of assembly this can be eliminated by making it symmetrical over one face | failure of axle ends would result in a detachment of the axle from the main cable. If both ends were to fail the cam would not support the weight of a falling climber. Failure of one end would result in an unbalanced force on the cam and the lobes would probably be spun free form the rock | use less material to weld, use a lower emission production like join/bend |

| 9 | finger support | Simple part which only requires two forms of alignment on insertion, also it is large enough to handle with the hands easily | Complete fracture of finger support would make retrieval and placement of cam difficult but still safe for climbing | reduce mass, casting instead of machining the holes, recycle material |

| 10 | spring pin | the spring pins are symmetrical over one axis but they are extremely small and insertion into the cam lobes would require extra time | failure of a spring pin would have the same effects as failure of the spring | use less metal, recycle material |

| 11 | trigger wire | The wire is simple and large enough to install without the aid of other tools | failure of all trigger wires would make placement and retrieval of cam extremely difficult, if not impossible in normal climbing situations. Partial failure of wires would make placement and retrieval difficult. | increase durability to maximize first life, recycle material |

| 12 | copper connector | The copper connectors again are extremely small but they are symmetrical over two axes thus orientation is not a problem with them, insertion and securing though will take additional time as it needs to be welded | Failure of the connectors would be very similar to failure of the trigger wires, making it difficult to place and remove the product | use lighter material, recycle less material |