Automatic apple peeler

From DDL Wiki

(Difference between revisions)

(→Design Documentation) |

(→Design Documentation) |

||

| Line 17: | Line 17: | ||

|- | |- | ||

! 3 | ! 3 | ||

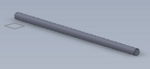

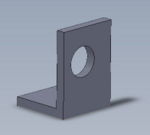

| - | | clear rod length 45cm || 1 || acquired from mechE shop || To stabilize the rolling frame from being overturned|| $10 || [[Image:clear rod.jpg|150px|]] | + | | clear rod<br />length 45cm || 1 || acquired from mechE shop || To stabilize the rolling frame from being overturned|| $10 || [[Image:clear rod.jpg|150px|]] |

|- | |- | ||

! 4 | ! 4 | ||

| Line 23: | Line 23: | ||

|- | |- | ||

! 5 | ! 5 | ||

| - | | threaded rod | + | | threaded rod<br />length 45cm, diameter 0.9cm || 1 || acquired from mechE shop || Spinning threads move forward the rolling frame || $30 || [[Image:threaded rod.jpg|150px|]] |

|- | |- | ||

! 6 | ! 6 | ||

| Line 32: | Line 32: | ||

|- | |- | ||

! 8 | ! 8 | ||

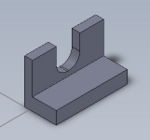

| - | | apple slicer 18cm x 11cm x 3.5cm || 1 || purchased from Chefmate|| To slice apple into 8 pieces || $5 || [[Image:slicer.jpg|150px|]] | + | | apple slicer<br />18cm x 11cm x 3.5cm || 1 || purchased from Chefmate|| To slice apple into 8 pieces || $5 || [[Image:slicer.jpg|150px|]] |

|- | |- | ||

! 9 | ! 9 | ||

| Line 47: | Line 47: | ||

|- | |- | ||

! 13 | ! 13 | ||

| - | | washer<br /> | + | | washer<br /> diameter 1.5cm, hole width 0.8cm || 4 ||purchased || To fix slicer || $1 || [[Image:washer.jpg|150px|]] |

|- | |- | ||

! 14 | ! 14 | ||

| Line 53: | Line 53: | ||

|- | |- | ||

! 15 | ! 15 | ||

| - | | butterfly nut<br /> | + | | butterfly nut<br /> hole width 0.5cm || 2 || purchased || To fix slicer || $1 || [[Image:nut1.jpg|150px|]] |

|- | |- | ||

! 16 | ! 16 | ||

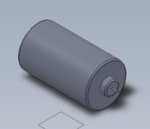

| battery|| 2 || come with power drill purchased<br />from Black$Decker GC9600 || power source for the motors || $1 || [[Image:battery.jpg|150px|]] | | battery|| 2 || come with power drill purchased<br />from Black$Decker GC9600 || power source for the motors || $1 || [[Image:battery.jpg|150px|]] | ||

|} | |} | ||

Revision as of 22:21, 7 December 2009

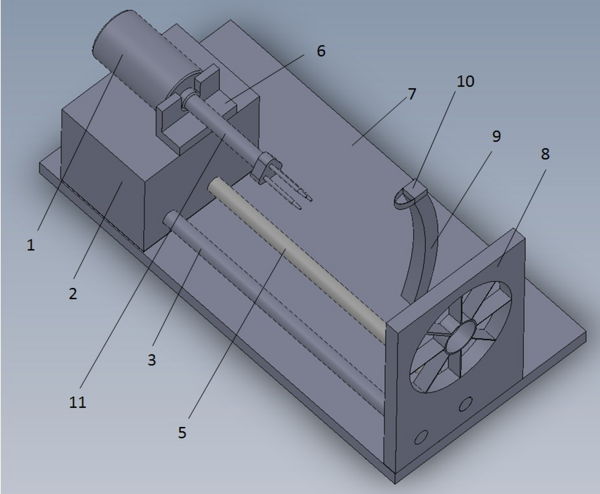

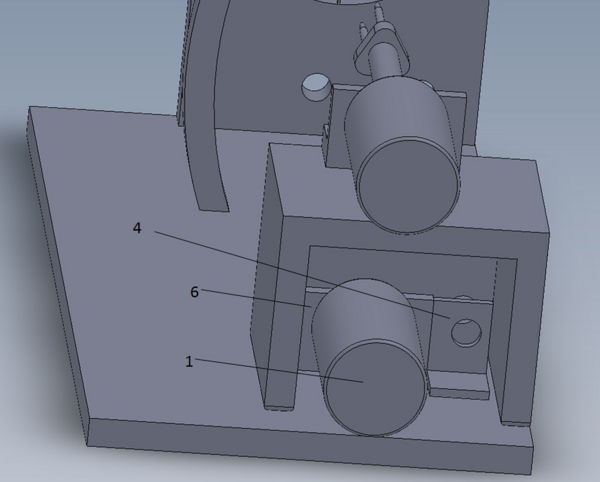

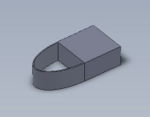

Design Documentation

Following table is the list of materials used for the final prototype.

The case, small screws, washer, and bolts are not shown in the CAD model, but they are included in the list.