Automatic can opener redesign

From DDL Wiki

(→Background Information) |

|||

| Line 10: | Line 10: | ||

==Background Information== | ==Background Information== | ||

| - | The original can opener has many quality features that made it hard for us to decide exactly what to change. The safety features were probably the best aspects that we saw on the can opener. Some of the safety features that were on the can opener already included a safety switch and a well covered blade. The safety switch made it so that the user could only turn on the can opener when it was sitting on top of the can. This prevents children from finding the can opener and cutting their fingers. The well covered blade gives a very solid barrier between your fingers and the blade when operating the can opener. Another safety feature was the way that the can opener actually opened the can. It cut on the outer edge of the can just below the lip so that it did not leave any sharp jagged edges behind. One of the problems that we | + | The original can opener has many quality features that made it hard for us to decide exactly what to change. The safety features were probably the best aspects that we saw on the can opener. Some of the safety features that were on the can opener already included a safety switch and a well covered blade. The safety switch made it so that the user could only turn on the can opener when it was sitting on top of the can. This prevents children from finding the can opener and cutting their fingers. The well covered blade gives a very solid barrier between your fingers and the blade when operating the can opener. Another safety feature was the way that the can opener actually opened the can. It cut on the outer edge of the can just below the lip so that it did not leave any sharp jagged edges behind. One of the problems that we saw in the origianl design was the location and design of the manual override. To us it seemed that this aspect of the original can opener took a lot away from the ease of use for the customer. The original can opener’s outer design also appeared to be somewhat bulky to us which took away from the ergonomics of the can opener. |

==Market Research== | ==Market Research== | ||

Revision as of 14:08, 4 May 2007

Executive Summary

The OneTouch Automatic can opener gives users a convenient and simpler way to open cans as compared to the usual manual types of can openers. The purpose of this page is to analyze the current design aspects of the can opener and to see what improvements could possibly be made. Even though we could have our own ideas as to what is important to users when using the can opener, we had to conduct research by way of a survey to see exactly what the user was looking for in regards to an automatic can opener. The two main aspects of the can opener that were most important to the user were safety and ease of use. After analyzing the can opener thoroughly we decided as a team to focus on the ease of use aspect. When looking at the can opener’s safety aspects we thought the original design was very safe and that there really was not much that we could do to increase the safety.

With ease of use as our number one objective in the redesign of the can opener we had to then specify exactly what we could improve to achieve this objective. The first thing that we discussed was the ergonomics of the original can opener. We felt that the original can opener was somewhat bulky and could be designed to fit in the hands of the user better, but the cost of the can opener was very reasonable so we did not want to have to increase that. This led to a few specific design changes that we felt would benefit the user. The specifics of these changes can be read in detail in the text below.

With our new design we feel that the consumer will react very positively to the changes that we have made since they follow exactly what the consumer was looking for in the survey. Below we will discuss in detail the new design aspects and the analysis that was conducted which was the basis of our changes.

Contents |

Background Information

The original can opener has many quality features that made it hard for us to decide exactly what to change. The safety features were probably the best aspects that we saw on the can opener. Some of the safety features that were on the can opener already included a safety switch and a well covered blade. The safety switch made it so that the user could only turn on the can opener when it was sitting on top of the can. This prevents children from finding the can opener and cutting their fingers. The well covered blade gives a very solid barrier between your fingers and the blade when operating the can opener. Another safety feature was the way that the can opener actually opened the can. It cut on the outer edge of the can just below the lip so that it did not leave any sharp jagged edges behind. One of the problems that we saw in the origianl design was the location and design of the manual override. To us it seemed that this aspect of the original can opener took a lot away from the ease of use for the customer. The original can opener’s outer design also appeared to be somewhat bulky to us which took away from the ergonomics of the can opener.

Market Research

Market research is a way to allow us to gain knowledge about the target consumers. Therefore we have completed a survey and obtain a sample size of 107. Three questions were asked in the survey and they are:

- "What is the most significant feature"

- "What is the most problematic"

- "What is the most significant changes that applies to an automatic can opener".

Based on the results of the survey, we generated five ideas that we believe we would pursue on.The ideas are:

- the LED status light,

- Finger grooves to increase comfort,

- Silion casting for water proofing,

- Using triple AAA batteries to diminish size

- an manual override for ease of use.

Survey graphs

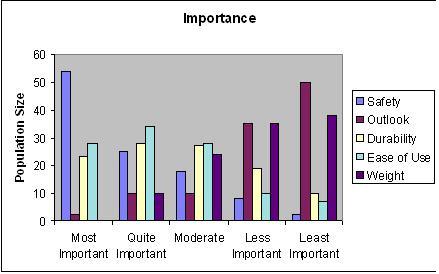

Please rank how important are the following features to you when you buy a can opener?

From this graph, it showed that safety is definitely the most important concern that consumers have. Durability came second, Ease of Use came third, Weight came fourth and the Outook (size, Style of the can opener seemed to be the least significant feature among all.

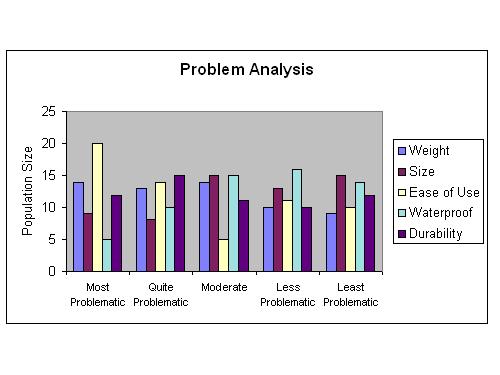

Please rank which aspect you think is the most problematic with can openers?

Apparently, ease of use is the most concerned problem. Then it comes to waterproofing, where it tends to be troublesome for users either when their hands were wet or when the can opener was dropped into water and had malfunctionability. Weight is the next concern, where girl users or higher aged group consumers believe the current designs of can openers are a little too bulky and heavy. Durability came next. Most of the consumers tend to still use original hand driven can openers, and they were concerned about the rusting and how the blades will get dulled. Size is the least concern as most of them believed the current size was ideal.

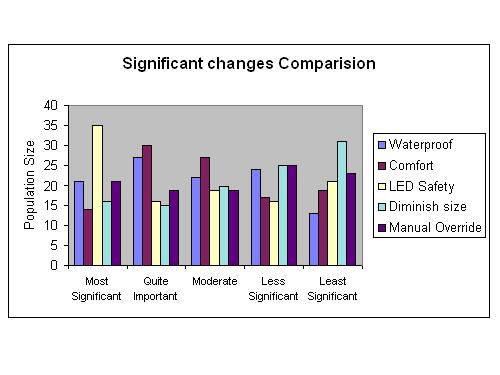

Please rank the following new features that you felt is most significant for an electric can opener?

Not surprising that since safety was the highest importance in the consumers mind, the LED satefy feature was the most significant in consumers' minds. Waterproofing came in second , so it justified that there is a need to improve when the can opener is involved with water. Thirdly, is the option for a manual override. Reason believed is that an automatic can opener would not be able to function properly if it faced a notch dent. Lastly, Comfort and Sizes are good improvements that the consumers believed that would have a significant impact

Market Research conclusions

Due to the nature of our environment, the majority of our sample are college students. since can openers' target consumers have a wide range in age That might not be as reflective as we wished to be, as the can opener's target market ranges from young kids to elderlys. That might influence the fact that weight might not be a big issue for our sample population. But in reality elderlys would prioritize it much higher among the list.

Overall, we can tell that safety is the highest priority, which is also reflected by the high rank of the LED status changes.

Waterproof is also another significant aspect that affects durability and a high concern among the users.

In general, the results from the market research supported our thoughts in what aspects that concerns the users and justifies the need for improvement. With the newly changes that will be made to the automatic can opener will be a much better product itself.

Value Oportunity Analysis

In our VOA we decided to look at the aspects of our automatic can opener that we thought had the most room for improvement. We decided that we would rather have a product that was better in more categories than extraordinary in a couple. This would lead to a better product overall. Our results can be viewed in the Automatic Can Opener VOA chart.

Our new ideas for imrovement help with most aspects of the can opener that we felt were on the low end of the VOA chart. Since our idea for improvement has different components we are able to please more people because of the number of positive changes to the can opener. Our main focus was on the ergonomics of the can opener. Our prospective changes to the product improve every aspect of ergonomics on the chart: comfort, safety and ease of use. A combination of the LED lights, rubber grips, water-proofing and changes in the battery source and manual override are the prospective changes that we are looking at the most. So, compared to the present can opener our new ideas for improvement lead to a better product.

Sketches

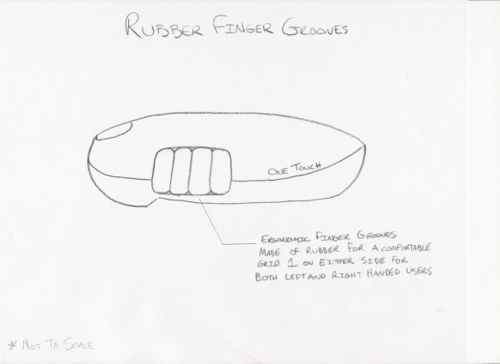

- Current Design:

- No comfortable grip

- Slippery if wet

- New Design:

- Finger Grooves

- No-Slip rubber

The current design involves no comfortable way for the user to grip the can opener. It is bulky and hard for a user with small hands to grip completely. This problem is exacerbated if the users hands or the opener itself is moist. To overcome such problems, our first proposed design entails the addition of finger grooves contoured to an average sized hand which will afford the user the opportunity to completely and comfortably grip the can opener. These grooves would be added to either side of the can opener so as to accommodate both left and right handed users. To attack the problem of "slippery when wet" we intend to add some type of non slip surface. This could either be done by adding a vulcanized rubber or a spray on silicone. It would be added to each half separately so as not to impede the opening of the casing to access the battery terminals.

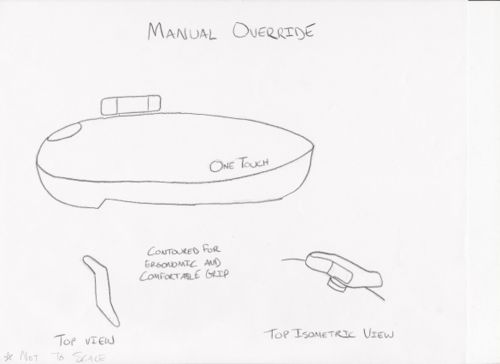

- Current Override:

- Impractical

- Hard To Reach

- New Design:

- Ergonomic

- Easy to Use

The original can opener has a manual override that is located on the underside of the opener near the blade and the cutting wheel. This location is impractical and reach, especially if it is in mid-cycle. A screwdriver is also required to utilized this manual override and often the entire apparatus must be turned upside down unless a perfect position on the edge of a table can be achieved. These inconveniences can be overcome with the addition of a manual override that is similar to an ordinary manual can opener. The new override will also be contoured in such a way that a wide variety of demographics will be able to use it comfortably.

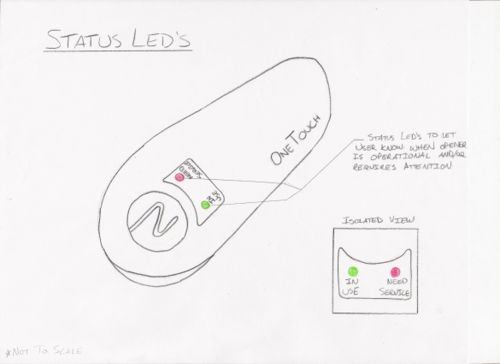

- Current Design:

- Hesitation during Cycle

- Mechanism status is unclear

- New Design:

- Red & Green LED’s to indicate functional status

A problem that has been experienced with the original can opener is hesitation during a cycle or hangups on dents. This can cause confusion for the user as they may not know that there can is not open because a full cycle was not completed. To overcome this we proposed the idea of instating LED Status lights. A green light would indicate that the opener is functioning correctly. A red light would indicate that the opener has not completed its cycle and requires attention from the user.

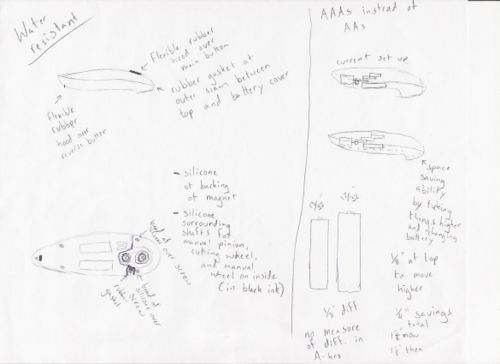

The above image refers to two design concepts: 1. Waterproofing the Can Opener; 2: Switching from AA to AAA Batteries

- Current Design (Waterproofing):

- No seal over blade or battery compartment

- No seal over buttons

- New Design:

- Rubber Gasket

- Rubber Hoods

- Silicone

The design of the current can opener does not include any form of waterproofing to protect the internal components from wetness. If the user were to spill the contents of the can being opened or if they were to drop the opener into the sink, there is a chance that the can opener would be ruined. To tackle this problem we propose to insert a rubber gasket between the upper and lower shells. It would be attached to the shell so that it would not have to be placed properly every time the batteries need changing. A drop of silicone gel would be placed over the screws, magnet, and cutting wheel. Rubber gasket hoods would also be place over the Activation button and the reverse button.

- Current Design (Batteries):

- AA Batteries

- Bulky

- New Design:

- AAA Batteries

- Smaller and Space Saving

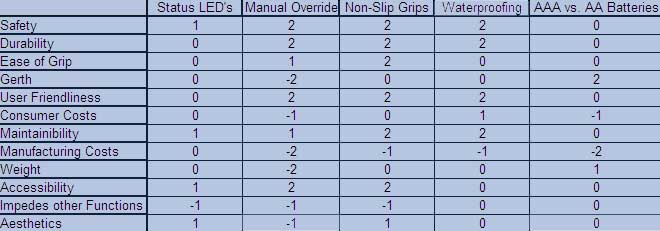

Pugh Chart

- This Pugh Chart is a representation of how each design innovation will effect certain aspects of the overall quality of the Automatic Can Opener. The most important aspect to the consumer is at the top of the left hand column. Each row from the top becomes successively less important to the consumer. The rankings are based in part on formal market research (obtained from our survey) and informal talks with people who used the product.

Detailed Design Description

In regards to the survey results, the ease of use aspect led us to our first few design changes. In regards to the bulkiness we wanted to make the can opener smaller and more streamlined, so we had to think of ways to make space. Our first idea was to try and eliminate one of the gears in the gear train. So in our second prototype we tried this and discovered that this would make the blade move much too quickly and could harm the user, so we decided to stick with the original setup. The next idea we had was to use AAA batteries instead of AA. This proved to work the best and it also saved us some much needed space. In dealing with ergonomics we felt that adding finger grooves and a sticky surface to the exterior of the can opener would help with the comfort of holding the can opener. The original design was very smooth so it would be hard to hold if your hands were not exactly dry. The changes would also help with the safety of the product because the user would be less likely to drop the can opener. Another improvement with the casing that we decided to do is making snap fit pieces so that we could eliminate a lot of fasteners in the assembly of the exterior. This would cut out a lot of time needed to assemble the product and would end up saving the company a lot of money. The next change that we made on the original was the location and design of the manual override. In the original the manual override is very inconveniently placed on the bottom of the can opener and a wrench is needed to use it. With our new design we put the manual override on the top and will have it resembling a normal manual can opener. This will give the user an easier way to manually open the can if the can opener fails. The next aspect involving ease of use was the runtime for one cycle. We wanted to decrease this so that the user did not have to wait as long to open a can. The elimination of gears would also have helped this idea but in our second prototype it proved to go too fast. The next idea we had was installing a new motor with the original gear train. This proved to be the best choice because the new motor cut down cycle time from 33 seconds to 24 seconds, which is not too fast that we have to worry about safety. Even though the safety features of the original design are very solid we still wanted to try and improve some aspect of the safety in our new design. We decided to put something on the can opener that could be used to indicate that something was wrong with the interior. This would make it easier for the user to tell if there was a problem with the can opener as opposed to just dead batteries. We decided to go with an LED that could tell the user if the can opener is operating or not. With these added design features we feel that our can opener is superior to the original, and we can produce this can opener at the same cost or even lower.