Bicycle light generator

From DDL Wiki

(→Introduction) |

|||

| Line 380: | Line 380: | ||

* Create energy efficient manufacturing process<br /> | * Create energy efficient manufacturing process<br /> | ||

* Create environmentally friendly manufacturing process<br /> | * Create environmentally friendly manufacturing process<br /> | ||

| + | |||

| + | [[category:design studies]] | ||

Revision as of 01:46, 14 February 2007

Contents |

Introduction

The major functions of a bicycle lighting system is seeing and to be seen. It is dangerous riding a bicycle without adequate lighting, especially at night. A bicycle lighting system can illuminate the path in front of the rider, and alert anyone within the lamp’s range.

There are many lighting systems available in the market, and each has their own trade offs. The least expensive bicycle headlights use a tungsten filament lamp, and more expensive models use the brighter alternative halogen lamp. LEDs are sometimes used for its inexpensive and high lumen-per-watt nature, but its limited light output can be a serious disadvantage. Bicycle lighting systems are usually powered by a battery pack or an electrical generator. The battery pack could be disposable or rechargeable. A dynamo lighting system has unlimited duration, but its maximum power output is relatively low.

Product Requirements

1. Able to illuminate a path of certain distance in front of the rider

2. Able to alert other people of the rider’s presence

3. Able to be mounted on a bicycle’s frame easily

4. Able to withstand temperatures extremities and different weather conditions

5. Durable and tough enough to withstand minor impacts and various road conditions

6. Light in weight so it does not add to the rider’s burden

7. Runs on either batteries or an electrical generator

Customer Needs

1. Brightness of the lamp

2. Small size

3. Light weight

4. Durability

5. Long lasting battery

About

Bicycle light generators are used to power battery-less safety lights mounted on bicycles. Safety lights are important to bicycle enthusiasts alike as they provide the necessary lighting to traverse a road as well as inform auto drivers of the bikers presence at night. The generator converts the energy put into the bicycle in the form of a pedaling motion into an electric current through the friction developed by the generator’s contact with the wheel of the bicycle.

The purpose of the bicycle light generator project is to dissect and understand the design processes behind this product. Our goal is to study this product thoroughly in order to engineer a modification that will result in an improvement in its functionality.

In our preliminary observation, we have noticed that current generator powered bicycle light sets do not have a means of storing power. As a result, these generator powered bicycle lights do not operate when the bicyclist is not pedaling and could be hazardous when the stopped at a traffic light.

In an attempt to incorporate a power storing functionality, we will also be studying a hand-crank generator powered flashlight. Using the same principles as a generator powered bicycle lights, these flashlights also have a rechargeable battery pack that is able to store power; thus, allowing the user to operate a light without having to input energy at the same moment.

Use

The installation of the power generation is probably the most difficult part. The user has to first analyze the structure of the bike and choose a location to mount the headlight. Since the light mounting mechanism is not universal, a hole on the front fork is required for mounting with an additional screw. User can also purchase a set of universal mounting device for the installation of the front and rare lights. The generator should be positioned vertically and that the roller connects with the middle part of the tire. The grounding screw on generator bracket must be screwed in completely to make contact with the metal of the bicycle frame. To complete the power generator circuit, connect headlight wire and tail light wire with generator terminal by pressing down the metal connector on the generator and put wires through the metal hole, then release the connector so the metal part of wires get stuck in that hole. It is very important that the generator and the lights are properly grounded to metal parts on the bike. The tail light can be fastened to rear frame stay of bicycle. Finally, press lever on the generator downward so the roller touches the tire. Before riding the bike, be sure that all screws are tight and that the wires and generator are clear of all moving parts. To activate the front and rare lights, user would have to rotate pedals by riding the bike.

1. Choose a location to mount the headlight and rare light.

2. Position generator so that the roller connects with the middle part of the tire.

3. Ground the generator by screwing the bracket to the metal of the bicycle frame.

4. Connect headlight wire and tail light wire with generator terminal.

5. Wind generator cable to avoid getting entangled.

6. Press lever on the generator downward so the roller touches the tire.

7. Rotate the bike pedals to activate the generator.

8. Confirmation the activation of the front and rare lights.

Functions

The rotation of the bicycle tires causes the roller on the power generator to spin due to friction. Since the roller is connected to the shaft, it would transfer the rotational force to the motor. The mechanical force generates magnetic fields in the motor and creates a current that goes through the small metal connector. The metal screws coming out of both lights serve as grounding devices. The wire that connects the small metal connector and the bicycle lights would carry the current through the entire circuit and light up both lights.

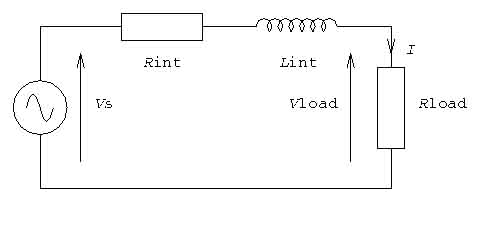

The power generator’s output should vary with the speed of the bicycle. This variation can be limited to prevent blowing bulbs. To predict the output of power generator lights under various conditions we constructed an equivalent circuit of the system. The model below shows a voltage source Vs, an internal resistance Rint, an internal inductance Lint, and a load resistance Rload connected in series.

There are several assumptions that we made to make the analysis simpler.

- The load resistance is constant. In reality, the resistance of the light bulb increases as it warms up

- The voltage source is sinusoidal

- The internal resistance and inductance are constant

As the cycle speed increases, the voltage and frequency also increase governed by the equation Vs = k f. The reaction of the internal inductance is also proportional to frequency: Xint = 2π f Lint. To compute the overall impedance of the circuit we use Pythagoras’ theorem: Z = √((Rint + Rload)2 + (Xint)2). The current would become I = Vs / Z. This is where the notion that bicycle power generators produce a constant current comes from. If Xint is much larger than (Rint + Rload), both Z and Vs are proportional to speed, so I is constant.

Hand-Crank Generator Flashlight Components:

Generator Bicycle Light Set Compenents:

Design for Manufacture and Assembly

The product parts are designed in such a way that they are overall favoring their manufacturing processes and assembly. Most parts are very easy for disassembly because of the maintenance requirement.

Manufacture:

- There are no complex geometries in all plastic parts. They used two parts injection molding to create most parts

- Metal parts are made from stamping. Which is easy to mass produce

Assembly:

- Assembly of plastic parts is simple and efficient. They are built with sockets to reduce the use of screws

- Many parts are used for both electrical and mechanical purpose to reduce the number of parts

- Screws, bolts, nuts and washers are used to secure parts that may require future disassembly/adjustment

- Used bicycle frame to finish circuits for lights. Save material -> reduces cost

- Generator parts were bolted on -> not meant for disassembly

Disassembly:

- Most sub-assemblies are easy to identify and disassemble (besides the generator)

- Disassembly for light parts was intuitive for easy replacement of light bulbs

- Phillips screw driver is sufficient to take apart most parts (besides the generator)

Failure Modes and Effective Analysis

Failure Part – Roller

The roller is assembled onto a threaded shaft using two hex-nuts to provide pressure and holding the roller in place. When the two hex-nuts fail to provide sufficient friction, the roller will slip and unable to power the generator and parallelize the entire system. The roller may fail during wet conditions, and it will fail when its threads are worn out over time.

Improvements:

The roller part can be secure by using a pin to bolt the shaft and the roller together. However, the additional part will induce trade-off for assembly and cost. To ensure the roller provides enough friction in wet condition we will have to conduct further research and testing to find the optimal material.

Failure Part – Bicycle Frame

The light system is made in such a way that it utilizes the bicycle frame to complete the circuit for light. This makes the product only functional in bicycles with conductive frames. The light system may also fail when the bicycle frame is coated with a layer of non-conductive paint. In addition, this product does not provide brackets to mount the lights. Some of the bicycle light mounts may be made from non-conductive materials.

Improvements:

This problem can be fixed by providing additional wires to complete the circuit rather than using the bicycle frame. It will not effect the complication for installation, however, this will increase cost to manufacture.

Failure Part – Mounting Brackets for Installation

Mounting bracket for the generator is not universal for all bicycles. Especially for bicycles with front shock absorbers. In order to provide sufficient contact between the wheel and the roller the generator bracket must be mounted on the lower section of shock absorbers. In most common cases the suspension’s diameter is much larger than this system’s bracket size.

Improvements:

This will require research on all bicycle designs to come up with an universal (or almost universal) brackets for most bicycles.

Design for Environment

This bicycle lighting system is designed to be environmental friendly. It is battery less. However, its manufacturing process may not be as optimal.

Environmental Problems:

- Waste produced during manufacturing process

- Harmful pollutions during manufacturing process

- Harmful materials (Plastics)

Improvements:

- Use recycle or reusable materials

- Create energy efficient manufacturing process

- Create environmentally friendly manufacturing process