Blender

From DDL Wiki

(→Product Dissasembly) |

|||

| Line 153: | Line 153: | ||

|- | |- | ||

! 039 | ! 039 | ||

| - | | Button || 3/<1 || For user to select type of blending. || Plastic || asdf || [[Image: | + | | Button || 3/<1 || For user to select type of blending. || Plastic || asdf || [[Image: newbutton.JPG]] |

|- | |- | ||

! 040 | ! 040 | ||

Revision as of 10:18, 24 September 2007

Contents |

Executive Summary

Major Customer Needs

When examining a blender, it becomes quite obvious that the purpose of the blender is to mix things into a liquid. Often times liquids and solids will be mixed together, for example a milkshake involves mixing milk and ice cream. The way this goal is accomplished is by spinning several blades, at high enough speeds to both grind up solids, and to spin fluids quick enough to create an even mix. Generally a blender will provide several speed settings. These settings are to provide for the different kinds of things you may be mixing.

We have determined that the average customer will use a blender mainly for creating frozen drinks, such as milkshakes, daquiries, pina coladas, etc. It should also be noted that customers will often use it as a mixer for food items like eggs, cake mix, etc. For smoothe, well mixed drinks, it becomes necessary that the blender will spin at high enough speeds to evenly mix all of the ingredients within. It is known to be a hassle when some of the final product comes out as intended, and the rest is still chunky and uneven. This requires a second term of mixing. Another concern for an average user is to have a variety of speeds. This is important because for some drinks, one may want a thicker finish, while in others one may want it to be very smooth. Without speeds settings, it is more necessary that the user decide when it is the way they want it, and this provides for greater user error. A third customer need, is that the blender be easily stored. It is not very common that one would use a blender on a very regular basis, so it would be beneficial that it could be stored away in a drawer or cabinet. As is the case for most products, it is also recommended that the blender be durable and able to last a long time, even when mistakes occur, such as dropping it and mixing hard items. Other design considerations would include but are not limited to user safety and convenience.

The design of a blender should allow for the product to be beneficial over similar products. While there are many tools that exist that can spin to mix foods, a blender should allow for a similar task while holding its contents into some provided volume container. The blender should have a variety of speeds, and be able to exert enough torque to blend a variety of food and drink items of different compositions. In order to make these abilities useful to an ordinary customer, markings and labels should be available to determine the appropriate setting. In a similar fashion, the container should be labeled so as to ensure the appropriate volume of food/fluid items. These are some of the design considerations that are important to customers for use.

Product Use

After purchasing the blender, it was removed from the cardboard box. It did not contain any packaging materials and was fully assembled. After taking the power cord and plugging it in to the wall, place the contents to be blended inside the pitcher. First, remove the white cap. There are measurements along the side of the pitcher to help determine what has been placed inside. Next, replace the cap so that it is closed well. There are three different options when using the blender: smooth, mix, and pulse. Smooth would be used if something needed to be pureed, as it is the fastest. Mix is slightly slower and pulse is used to turn the blade on and off without varying the speed. While using the pulse button, it is not necessary to turn it off.

When using the blender for materials that are particularly chunky, it is best to make sure it is pushed to the bottom so that it is reaching the blade. To use the nozzle featured at the bottom of the blender, move the switch up slightly or push it until it stands up, and keeps the nozzle in the open position.

To store the blender, unplug it and clean thoroughly. The base of the blender screws off to allow for better access to the blades. Make sure to fasten it together well otherwise it may leak. The nozzle also screws off and it is a good idea to pass water through to rinse it. The blender can be stored on the counter or on a shelf.

How System Functions

The system begins with the power of the motor. The motor works as all other motors whereas it converts electrical energy to mechanical energy. It fits snug under the base of the blender and is close to the blades of the blender. The idea of the motor relies on magnetism where one of the two main parts, the rotor, rotates due to a torque caused by the wires and magnetic field configuration. A voltage is applied to the lead battery wires originating from the AC plug that takes power from the wall socket. Along the shaft is the armature which is a set of electromagnets. This set up of magnets is constantly in rotation due to the opposite attraction of the magnetic field from the larger magnet and the wires around the armature. Electron flow changes constantly to allow for the constant rotation and magnetic flow. This axis is then attached through the motor box up until the opening of the blender. This rotation becomes transferred into the shaft of the blender axis. This same axis is connected to the two blades which are the tools necessary for the blending action.

http://electronics.howstuffworks.com/motor.htm

Product Dissasembly

Design for Manufacture and Assembly

The current product is composed of 4 major components. The first being the pitcher, the next being the motor, the base and lastly the operator control. The pitcher is plastic and the mold is not a very difficult design to put through an assembly. It is this first piece of plastic that makes up the pitcher. There is then the additional blade assembly that is placed at the base of the plastic pitcher. This piece is also plastic and is a simple product to be modeled and made into plastic however the intricate part includes forming an area for an addition of a screw that fits the blade assembly. The production of the blades in the blade assembly is most likely taken from a slab of oddly shaped metal where slices of equivalent sizes can be taken in order to produce mass amounts of blades at one time. This is a helpful design decision that aides in the efficiency and productivity of the mechanical process. The blender blade setup uses two identical blades 90 degrees to each other that sit on top of one another. Simple washers and a long screw are straightforward pieces necessary for the overall assembly of the blade placed in the pitcher. There are small gradations on the side indicating liquid volume and these markings can also easily be etched into the plastic container. Taking into consideration the size of the machine used to etch these markings should be accounted for in the decided size of these markings as well as customer readability. The container handle size should be developed with the production process in mind making sure that the production of the handle design is within a reasonable capability of the productions team.

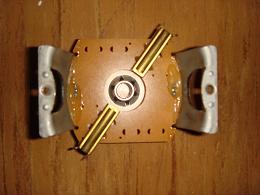

The second major component is the motor which is hidden inside the base and directly under the pitcher. This is usually an in stock purchase from another company that specializes in motors. However many more questions arise when adding an out of house product to an in house development. The problem of heat transfer must be thoroughly examined making sure that the heat produced from the motor and its components will not simply melt the parts nearby. This is not necessarily a design for manufacturing but rather an inquisition into the design specifications and capabilities. The placement of the motor is an important decision in the design because it is based upon its ability to be sufficiently mounted. The mounting clips must be under the blender base and they must be able to withstand the heat from the motor as well as slight movement associated with the vibrations from the motor. The mounting clips for the motor are an extension of the base and not an added addition which add to their stability but the manufacturer must make sure to place mounting clips at points that are available to be machined easily. Sometimes it is hard to extrude extra plastic pieces to form mounts in certain areas especially in a base similar to the design of this blender.

The third main component is the base itself. It is made of plastic and the decision on its form must be considered with the design aspect in mind as well. A plastic model is most likely mass produced but the thickness placement of its interior walls must be able to be made without construction errors or problems. Sometimes if the side walls or mounting walls of the base are too thin this could lead to ineffective design production. There is a limit to how thin a plastic piece can be made in the manufacturing process. These type of specifications must be readily available to the designers of the base in order to make sure to design around these manufacturing flaws. The best way to add to the ease of this manufacture is to create as little parts for the base as possible while maintaining a realistic manufacturing design. However the manufacturing aspect can be eased if numerous plastic base pieces that are easily manufactured can be arrested into the base rather than one intricate base piece. These pieces would most effectively allow for greater stability of the motor and overall blender than compared to a one piece base setup.

The last component is the operator control that allows the user to choose between two different blender speeds as well as an option to stop the blending. This set up is important because it harnesses the electrical wiring component of the blender. Wiring placement is important when dealing with such a product because the ability for wet liquids to dispel around or near the harness could lead to extreme danger or malfunction. The wiring must be designed far from any liquid aspect of the blender as well as far from the heat produced by the motor, however the wiring can be also sealed to maintain a cooler operating temperature as well as keeping the wires dry. Most importantly the wiring of the controller must circumvent the surrounding area of the base piece without getting in the way of the motor and must be able to be wrapped in a safe fashion. The wiring must have ample bend to be navigated inside the base but must also be thick enough to hold the power necessary from the motor.

Design for the Environment

With the research that we’ve done so far, we have found five strategies that if improved, could decrease the impact our product has on the environment. The major concerns include, but are not limited to, new concept development, low impact materials, manufacturing, maximizing first life, and end of life.

New Concept Development - By integrating several other functions in to the blender, it could reduce the need for other appliances within the kitchen. It’s current design featuring the nozzle at the base of the blender allows users to use the blender as both a blender and a pitcher.

Low Impact Materials – The majority of the parts of the blender are plastic which has an awful impact on the environment. It is difficult to recycle and even the process of recycling can emit harmful fumes. The packaging used, cardboard, could be changed to recycled cardboard.

Manufacturing – Further research should be done in to the manufacturing processes and perhaps there could be a reduction in the amount of waste materials.

Maximizing First Life – Clearer instructions on disassembly and cleaning could help decrease the possibility of breaking the blender while trying to do either. Breaking could lead the need to replace multiple parts and damaging the environment further.

End of Life – The motor of the blender could be recycled but the majority of the materials can not. The pressed plastic was made specifically for the blender thus it wouldn’t be reused for anything else, and is very difficult to recycle.

Failure Mode Effects and Analysis

| Item & Function | Failure Mode | Effects of Failure | S | Causes of Failure | O | Design Controls | D | RPN | Recommended Actions | Responsibility & Deadline | Actions Taken | S* | O* | D* | RPN* |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Motor

| Motor overheating | Motor will not be able to turn the blades and would make blender useless. | 8 | Motor could overheat if left on too long when trying to blend foods of a harder consistency | 6 | Testing fan output that assists in cooling motor, as well as testing motor at max speeds with a variety of loads. | 8 | 384 | |||||||

Blade

| Blade edge dulls | It will take longer

| 8 | The increased friction in between the separate gears can cause the gears to strip | 2 | Testing the durability of the gears | 4 | 48 | Test different materials to find the most cost-effective solution | Gear Manufacturer | N/A | 8 | 2 | 4 | 48 |

Mixing Arm

| Mixing arm breaks/fails | Contents of the bowl will not be properly mixed to form a consistent product. | 6 | The increased viscosity of the product may cause the mixing arm to break. | 3 | Test to see the breaking point of the mixing arm. | 1 | 18 | Test different materials to find the most cost-effective solution | Manufacturer | N/A | 6 | 3 | 1 | 18 |

Wiring

| Current does not get transferred from the power outlet to the motor | Motor will not rotate the bowl, so contents of bowl will not get mixed. | 8 | The increased viscosity of the product may cause the mixing arm to break. | 2 | Before final assembly of the product, test connection points to see if all wiring points are valid | 3 | 48 | Install a station in the assembly process to make sure that all wiring connections are good | Assemblerer | N/A | 8 | 2 | 3 | 48

|

Switch

| Switch does not allow current to pass through | Motor will not rotate the bowl, so contents of bowl will not get mixed. | 8 | The switch connection may not contact the part that is used to close the circuit | 2 | Test to see if connection points are durable after many clicks (turn on and off many times) | 3 | 48 | Test a switch for 1,000 times to see if the switch operates properly each time | Assemblerer | N/A | 8 | 2 | 3 | 48 |

Mechanical Analysis

Calculating the change in temperature of the frozen additions into the blender: Assumptions:

1.Objects added to blender are at 0 degrees Farenheit

2. Final temperature is unknown

3. Mass and specific heat of contents is equal to that of H20

4. Motor is not producing peak powers (80%)

5. Contents are 1000mL

Calculations:

Q – W = ΔE

mCpΔT –W = ΔE

ρH20 (ice) = .92g/mL

m = 1000mL *.92g/mL = 9200 g ice

Cp H20 = 2111.4J/(kg*K)

W = .8(500W) = 400J/sec

ω = 20000rpm *(min/60sec) *(2π rad/rot) = 2094.4rad/sec

r = .027m

m = .058kg

ΔE = 1/2mv^2/r = 1/2mrω^2 = ½*.058kg * .027m * (2094.4rad/sec)^2

ΔE = 1.63991J

Solving for Tfinal:

(Tf – Ti) = (ΔE + W)/mCp

Tf = Ti + (ΔE + W)/mCp

Tf = 0°C + (1.63991J + 400J)/(.058kg * 2111.4J/(kg*K))

Tf = 3.28°C