Blow molding

From DDL Wiki

(→Definition) |

|||

| Line 71: | Line 71: | ||

http://en.wikipedia.org/wiki/Blow_molding | http://en.wikipedia.org/wiki/Blow_molding | ||

| + | |||

| + | [[category:manufacturing]] | ||

Revision as of 01:51, 14 February 2007

Contents |

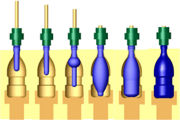

Definition

Blow molding is used to manufacture hollow plastic parts, and can be performed via extrusion, injection or stretch processes. All process use some type of extruded preform called a parison, compressed air and a mold shaping the final container. The final product is a any type of strong container or bottle-like vessel.

Process

Extrusion blow molding (EBM)

1) Plastic is extruded into a hollow tube (called a parison).

2) Melted plastic accumulates at end of barrel around which tube is extruded, closing the form.

3) The parison is captured in a metal mold.

4) Air is blown into the cavity, stretching the parison into the desired shape.

5) The part is removed from the mold after sufficient cooling.

EMB can be continuous or intermittent. If it is continuous, blow molds may either rotate or shuttle with respect to a fixed extrusion head. In intermittent processes, the molds are stationary and the parisons are dropped into them.

Injection blow molding (IBM)

1) Molten plastic is injected into a hollow mold around a core rod.

2) The outer mold is removed.

3) The remaining core rod and initial form are clamped into a cooled blow mold.

4) The rod is removed and pressurized air creates the final shape.

This is the least common type of blow molding, for use with small bottles or one time only applications.

Stretch blow molding (SBM)

1) Forming of parison.

2) Parison placed into neck of bottle (final mold).

3) Core rod stretches parison into bottle, with an initial air pressure of 70 to 350 psi.

4) When stretch rod reaches the bottom of mold, pressure is increased to 580 psi creating the final form.

This type is most preferable because it offers optimal structural and cosmetic advantages, especially in the case of withstanding forces of carbonated beverages. Also, there is no resulting flash, but only a line where the mold halves meet.

Application

Materials

Size

Shape

Precision