Folding table

From DDL Wiki

(→How it Works) |

|||

| Line 127: | Line 127: | ||

Figure 9 – Pin joint that allows table to fold | Figure 9 – Pin joint that allows table to fold | ||

| - | Additional improvements: | + | ''' |

| + | Additional improvements:''' | ||

| + | |||

• Better/popout handle | • Better/popout handle | ||

| + | |||

• Integrated chair, for when it is folded | • Integrated chair, for when it is folded | ||

| + | |||

• Magnetic closure or magnets to attach utensils and plates | • Magnetic closure or magnets to attach utensils and plates | ||

| + | |||

• Stamps that could fit utensils or plates | • Stamps that could fit utensils or plates | ||

| + | |||

• Transporting it in general, anything that could make it smaller | • Transporting it in general, anything that could make it smaller | ||

| + | |||

| + | |||

| + | |||

| + | {|border=""1" | ||

| + | |- | ||

| + | ! Column 1 heading | ||

| + | ! Column 2 heading | ||

| + | ! Column 3 heading | ||

| + | |- | ||

| + | | Row 1, column 1 | ||

| + | | Row 1, column 2 | ||

| + | | Row 1, column 3 | ||

| + | |- | ||

| + | | Row 2, column 1 | ||

| + | | Row 2, column 2 | ||

| + | | Row 2, column 3 | ||

| + | |} | ||

Revision as of 03:00, 13 February 2012

Executive Summary

The initial documentation we have here is meant to be a resource for our expansion and improvement on the current product line of folding tables. After doing some short analyses on the life cycle and environmental impact of the table, we can then determine the proper areas that can implement innovative qualities. Our product is meant to be a valuable resource for consumers that either have very little space or need transformable affordable furniture or for the consumer that is on the go and needs something more portable than its counterpart. Using materials that are relatively inexpensive to manufacture, but are at the same time sturdy and lightweight the table is a must have for outside use. Similarly the plastic on top is stain proof and relatively scratch proof. Our documentation of the product was conducted after an expansive dissection of the table was done. We then created a catalog of all of the components the table is comprised of. Later we conducted a Design Analysis (DFMA) and a Failure Mode Effects Analysis (FMEA). These were done to determine any improvements that should be done and how we could do improve the products form and function. Our findings of the FMEA showed us that the table could benefit from a bit more simplicity, certain aspects of the unfolding mechanism seemed overly complicated and there were instances where two parts could have been merged into one part, which typically means more simplicity. Additionally, we conducted a EIO-LCA analysis of the table trying to find particular sources of environmental unfriendliness and what could have been improved upon that. Therefore we decided that our primary goal is to reduce product parts and focus on the environmental impact that manufacturing each of these parts has.

Stakeholders and Customer Needs

The importance of having a solidly built table that is easily transportable can be attributed to many situations. Main purposes could include camping, picnics, festivities, and outside events in general. There are various types of folding tables out there so it is hard to tell which would best work into our design. However, the use of each table relies heavily on what type of consumer would be using it. The table should be able to withstand a significant amount of force but does not need to be overly designed as most tables will normally not have a large amount of weight on it. For materials, the top is most likely going to remain some sort of plastic or reinforced composite such as fiberglass or carbon fiber.

Primary Stakeholders and concerns:

• The product must be relatively easy to carry, in a convenient way

• Must be resistant to rust and general wear and tear

• The table must serve its primary function, and support everything evenly

• The design of the table must result in a lightweight frame

• Table must be level and flat

• Since it is a folding design it must be able to fold and close without delay or difficulty

Retailers:

• Because the table can fold for storage it is easy for retailers to carry the item in their store

• The table is also light, therefore, making it possible for customers to carry them and handle them on their own without assistance

• The table will come fully assembled requiring no assembling

• The table will also be aesthetically pleasing as we will have optional lettering on the tables available or a graphic of choice

• Tables could be custom sized or fit

• Custom indented shapes could be fit onto the table (similar to the cup hole in an airplane fold down tray)

Manufacturing:

• The materials used must be cost efficient and sturdy

• Any excess material or waste should be able to be reused/recycled

• The parts of the table should be straightforward for assembly

• Materials and parts should be able to be found locally for ease of transport

Shipping and Transport:

• Table or the shipping box must be durable and sturdy to withstand any careless transportation mistakes.

• Materials must not rust if taken overseas, in case a package is broken or unsealed

How it Works

The folding table improves on a traditional table because, as its name implies, it can be folded up into an envelop of space much smaller than its space envelope when the legs are fully extended. For example our table is 60 in long x 27.5 in wide x 29 in high with the legs extended, but only 30 in long x 27.5 in wide x 3.25 in high with the legs folded in and the table folded in half. As explained earlier this advantage can be exploited all the way down the supply chain from manufacturer, retailer, down to the consumer. The table weighs 24.75 lbs.

Figure 1 – Table with legs fully extended

Figure 2 – Table with legs folded in and table folded in half

To fold the legs in to the center, there are two pin joints shown below in Figure 3. Moving the leg in towards the center will eventually move the middle bar in towards the underside of the table until both are completely flush with the under side of the table. Before this can happen, however, a lock must be removed.

Figure 3 – Illustration of two pin joints

The lock mechanism is a metal ring that slides into a slot at a point in which it wraps around both legs. Thus when one attempts to move the outer leg inward, it can only move so far before being impeded by the ring.

Figure 4 – Legs in the locked position

To unlock the legs, the metal ring must be moved to the right slot where it no longer wraps around the outer leg. Consequently, the outer leg can now be moved in and start the folding process.

Figure 5 – Legs in the unlocked position

Now the legs can be moved in towards the center. As the legs move in, the middle bar moves down towards the underside of the table rotating on a pin joint.

Figure 6 – Legs being folded

With the legs fully folded in, they must now be locked to ensure that they do not flop out again.

Figure 7 – Legs folded

The lock is a flexible piece of plastic that the legs can be snapped into. They will not become unlocked without a pulling force, which would not happen except by someone intentionally pulling them out.

Figure 8- Plastic leg lock

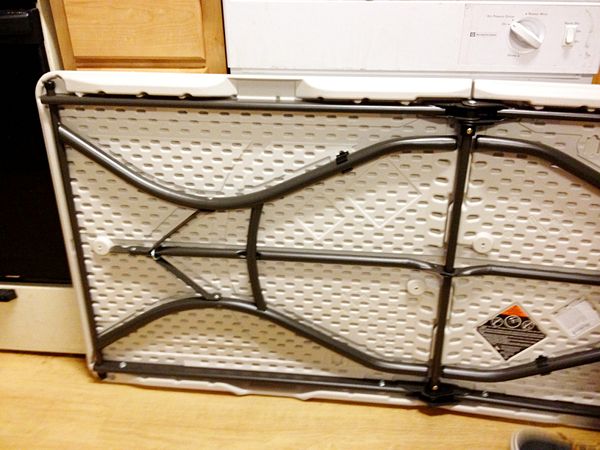

Now that the legs are locked into place, the table can be folded in half through the center pin join that runs through the entire width of the table. Because there is a pole to either side, the pole lies in double shear as shown below.

Figure 9 – Pin joint that allows table to fold

Additional improvements:

• Better/popout handle

• Integrated chair, for when it is folded

• Magnetic closure or magnets to attach utensils and plates

• Stamps that could fit utensils or plates

• Transporting it in general, anything that could make it smaller

| Column 1 heading | Column 2 heading | Column 3 heading |

|---|---|---|

| Row 1, column 1 | Row 1, column 2 | Row 1, column 3 |

| Row 2, column 1 | Row 2, column 2 | Row 2, column 3 |