Ice cream maker redesign

From DDL Wiki

Contents |

Executive Summary

Research and Observations

We have observed the ice cream maker in use and have noticed many processes that can be improved. The process that is currently used in today’s industry is a bit extensive and a consumer may grow tiresome of the long waiting process. In one of the trials, the users had to wait for approximately three hours before deciding to give up and put the mixed product into the freezer.

Our other trials were much more successful. The users were able to add the ingredients into the bowl and create ice cream in the advertised time. However, since there is extensive preparation time, this elongates the process of actually making ice cream. If you need to prepare the ingredients for an hour before placing them in the bowl, then the actual time needed to make ice cream becomes one and a half hours.

When observing the subjects interacting with the ice cream maker, it was evident that there was difficult with the clean up with the mixing arm. Since some of the spots were difficult to reach and the ice cream was sticking onto the arm, the cleaning of the mixing arm became frustrating. Also, since the mixing bowl is not dishwasher safe, this had to be cleaned manually.

Another observation that we observed is that the user has very little interaction with the actual device. Once the ingredients are properly mixed and prepared, then this is placed into the bowl and the user will turn the switch from the “Off” position to the “On” position. For a user to be able to produce all of the desired products (sorbet, sherbet, shushes, frozen drinks), they need the use of other products. The user has more interaction with other products, which include blenders, pots, pans, etc. Without these other products, it is not possible to make these other desserts.

Design Problem and Possible Solutions

The main problem that we would like to address is the excess preparation time. This includes the time it takes to prepare the ingredients to make ice cream along with the time required to leave the mixed ingredients in the mixing bowl. If we are able to significantly shorten this process, then the consumer will be able to enjoy their dessert without all of the waiting.

With the current process, if a consumer would like to enjoy dessert after dinner, they would have to prepare the ingredients before dinner and then make the ice cream while they eat dinner. This may not be optimal because the consumer is already preparing dinner, and adding another process may be confusing or stressful.

Some possible solutions to alleviate this problem are to redesign the bowl, redesign the process to make the ice cream, or to create a multi-functional bowl. The first solution, to redesign the bowl, is aimed to lower the preparation time of the ice cream after the ingredients have been mixed. This is aimed at lowering the half hour of mixing time that the bowl needs to make the ice cream. Since the bowl is freezing the ice cream as it is being made, if we increase the contact surface area, then there will be increased heat transfer between the walls of the bowl and the ice cream. We will have to do further research if the increased surface area significantly decreases the time required to make the ice cream.

The second possible solution is to create a multi-functional device that would incorporate the other processes in one appliance. This would shorten the cleaning up process because the consumer wouldn’t have to use other products such as a mixing bowl or blender. Our proposed solution is to include a dual speed motor with interchangeable whisking and mixing arm attachments that the user could switch based on need. The whisking arm would be in place for the preparation process and the mixing arm would be in place for ice cream making process. One major change from the current design is that the bowl itself would not rotate. Instead, the motor would rotate either the whisking or mixing arm. If we created an all-in-one device, the consumer would not have to clean the other devices after use, since only one container was used in the process.

The third possible solution is to redesign the process of making ice cream. The current process requires a bowl and some arm that is used to mix the ingredients to allow for consistency. A new process that would be able to expedite the process is to extrude the ice cream through a tube. The tube will have a small cross-section, and its wall will be cooled with a cooling mechanism. Then, the ingredients will be pushed through the tube until it forms into ice cream. Some research that needs to be done with this process will be the effectiveness of the tube. What will be the cross-sectional diameter of the tube? Depending on the cross-section, how long will the tube need to be to create the proper consistency of ice cream? Also, a major factor will be the length of time that is needed to make the ice cream. Will this new idea cut down the preparation time significantly? Lastly, cost will be a factor into this equation. Will the cost of this device be more expensive or cheaper? What parts will be used to make this redesign and how much will they cost?

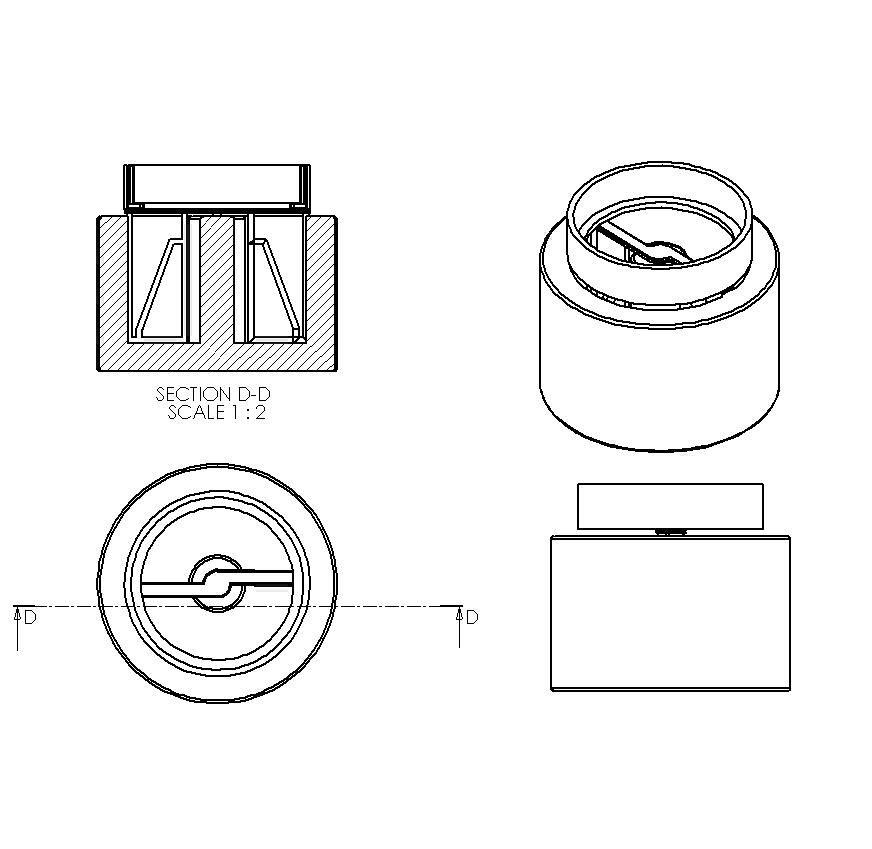

Proposed Design Change 1

Increase Surface Area of the Freezer Bowl: An additional tube of the freezeing fluid that sticks up into the middle of the freezer bowl would expose more of the ice cream to a frozen surface of the bowl. It is obvious that the Ice Cream in the old design freezes unevenly, hardening faster at the edge of the bowl, then at the middle. This design chage requires a redesign of the mixing arm as well.

The design uses a similar geometry to the orginal mixing arm, but slimmed up and doubled. These dual arms are suspended on an added beam and then retained on a ring similar to the orginal. The new freezer bowl sits on the same base as the old one and rotates. The same Easy Lock Lid is used to hold the mixing arms in place. The added beam also has a pin in the center that the mixing arms rotate around.

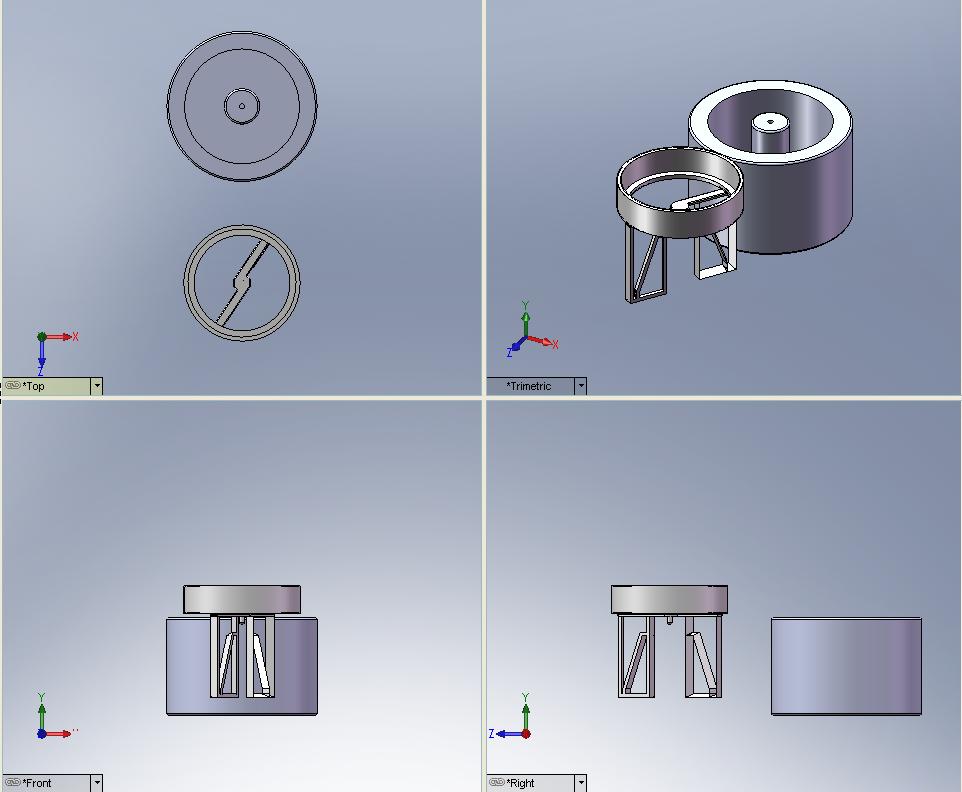

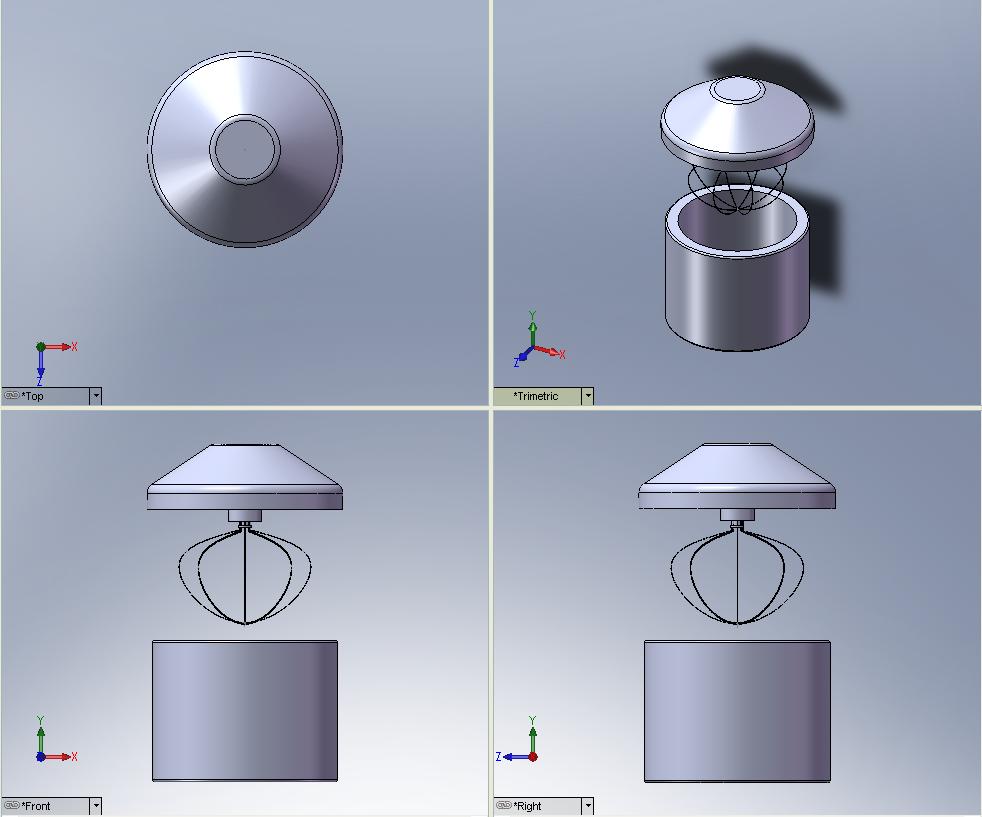

Proposed Design Change 2

Combined Mixer/Ice Cream Maker: This design change requires several changes to the design. The motor must be position on top of the freezer bowl so that it can spin a whisking arm attackment. The whisking attachment clips into the motor with a spring loaded locking mechinism, similar to the one on common houshold electric mixers. The classic mixing arm from the old design is slightly altered to fit on to the locking mechinism as well. By adding a gear shift to the gear train that comes off the motor it can spin at two speeds. A fast speed to whisk the ingredience of the recipe together, and a slow speed to churn the ice cream. This desing also allows for a third blended attachment (not shown) that would blend ingredience as necessary for certian chocolate ice cream recipes.

The added whisking component ensures that additional air is whipped into the raw ice cream mix before it has a chance to freeze. The additional air in the ice cream mixture would add to the fluffy texture of the final ice cream.

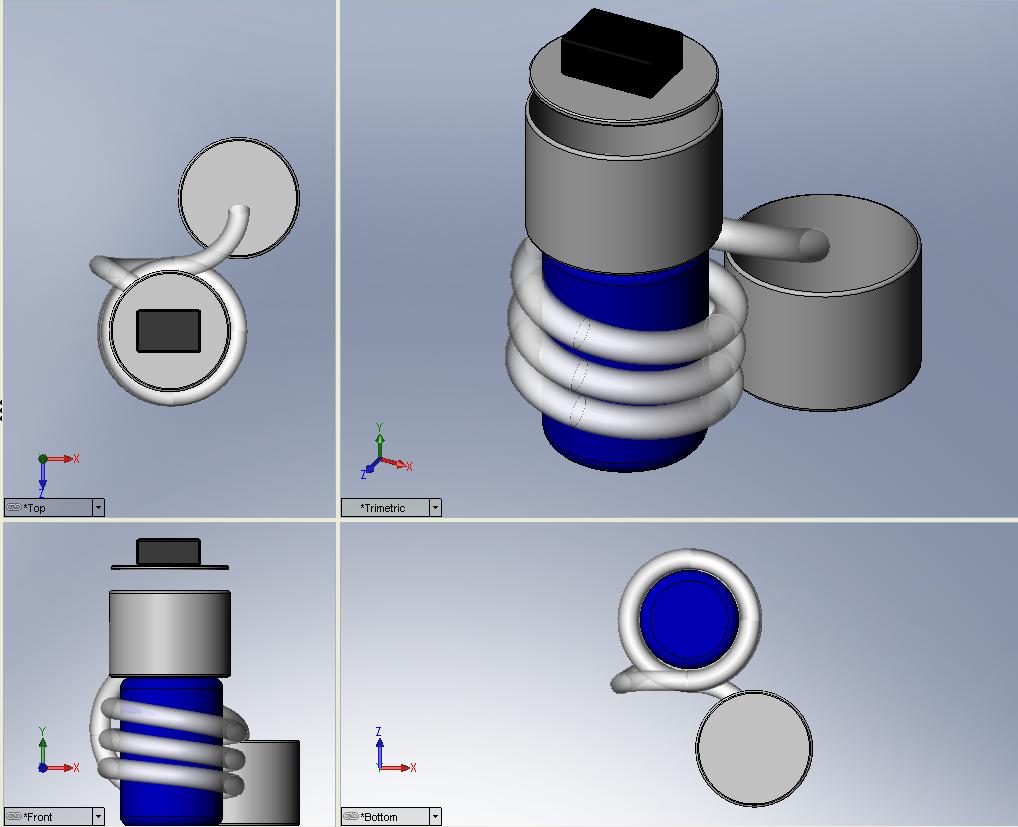

Proposed Design Change 3

Freezing Tube: This design concept revolutionizes how ice cream maker have historically worked. In this concept the surface area of the ice cream exposed to the freezing unit is increased by running the ice cream through a tube that coild around between two freezing units. The outer caseing (not shown) and the inner (blue) cooling cylinder are both filled with either a 23% salt-water concentration, or a suitible cooling chemical that have a freezing point of around -20 degrees F.

The freezing tube device is used by pouring the room temperature ice cream mixture into the containter on the top. The liquid then runs down the device into the freezing tube. At this point a small compressor (about the size of an aquarium air pump) is engaged and starts pumping air into the system. The pumping both airates the ice cream mixtue and pushes it though the freezing tube, as the ice cream hardens. Agitators may be inserted into the freezing tube as well to aid in mixing the cream as it travels up the tube. The ice cream leaves the tube in a semi-hard soft serve state. It then falls into an ending cotainer that can be placed directly into the freezer for additional hardening.

Pugh Chart

A Pugh Chart, or design selection matrix is a useful tool for comparing several design concepts against each other. The key component is to compare several qualities of different concepts against a currently existing design, notated as the datum.

To first explain our Pugh Chart, we will give a description of the different criteria and weighting

- hello

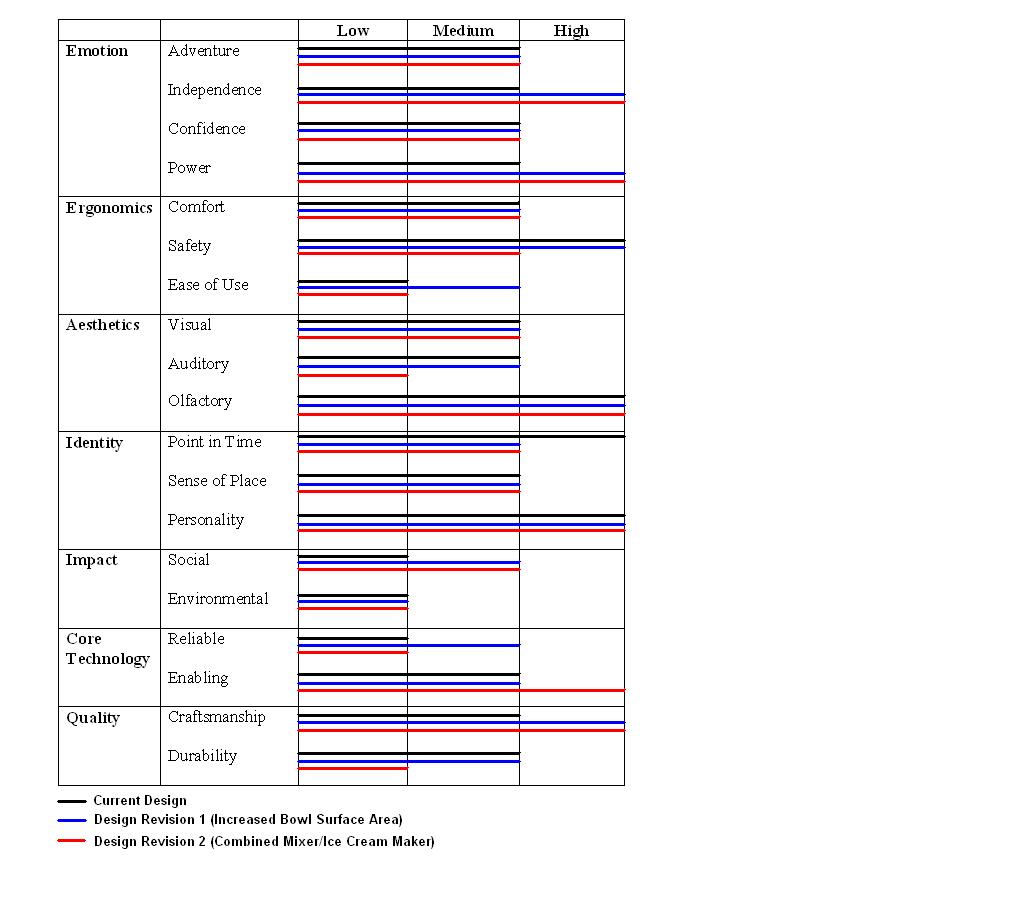

Value Oppurtunity Analysis (VOA)

A value opportunity analysis (VOA) of the ice cream maker designs described above can give valuable insight into what the user hopes to gain from using the product. By looking at the product designs from the user’s point of view, one can compare the worth of a new design compared to the existing base model. A VOA chart is broken down into seven main categories: Emotion, Ergonomics, Aesthetics, Identity, Impact, Core Technology, and Quality.

Each of these categories is further broken down into sub-categories which are rated from low to high for each design. We have limited the scope of our value opportunity analysis to only two of our three design concepts. The third design idea of using a pressure system to extrude ingredients through a chilled tube to make ice cream is not yet concrete enough at this point to proceed with a VOA. Further research needs to be done on this idea. The VOA chart below shows how the first two design concepts rate in comparison with the current base model that is out on the market. A further explanation of each category follows as well.

Emotion

Ice cream is a product that has a variety of flavors but consumers are usually dependent on professional ice cream parlors or restaurant to provide ice cream. Therefore, the biggest emotional impact that users can gain from an ice maker is that it allows them to be creative and independent in making their own ice cream. Both of the re-designs described in the VOA chart essentially allow the user to make ice cream more efficiently by saving time in some phase of the ice cream making process. This gives users more independence in that they don’t have to depend on as many extra components, such as a blender, and that they don’t have to spend as much time. Users also don’t have to depend on professional ice cream parlors for different flavors of ice cream, leading to a high level of independence. For this reason, we also feel that users will feel more empowered. The confidence and feeling of adventure the user will gain will be similar for the current design and both design concepts since the process of making ice cream and the quality of ice cream made will largely remain the same. Security and sensuality are also commonly used sub-categories in a VOA chart; however, they do not really apply to ice cream makers and have been omitted from this analysis.