Inkjet Printer Notes Spring 2007

From DDL Wiki

Notes/Others

This section serves as our preliminary analysis information data base as of 02/12/07.Parts:

1.

Printer

2.

Lid/Paper Tray 1/ Paper Tray 2/ Input Buttons

Lid: prevents dust, allows ink replacement & paper adjustment

Paper Tray 1: holds pre-printed paper in straight position

Paper Tray 2: holds printed paper

Input Buttons: lets users input basic commands

Design Potential: *none

3.

Rear Cover(w/ 6 rollers)

Rear Cover: The 6 rollers located on it assist the paper movement inside of the printer

Design Potential: It might be one of the potential location for our rear slot (for CD or other hard materials).

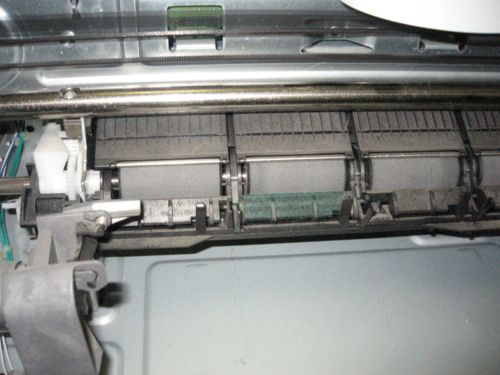

4.

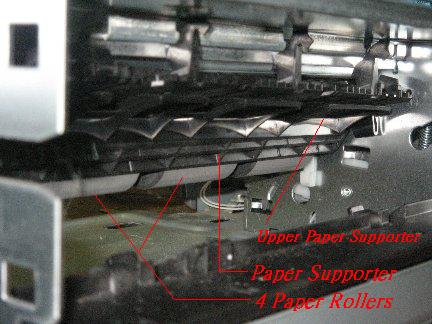

Upper Paper Supporter/Paper Supporter/Paper Rollers

Upper Paper Supporter: holds the printing paper in the y-direction

Paper Supporter: supports the printing paper upward

Paper Rollers: are the main rollers for paper movement

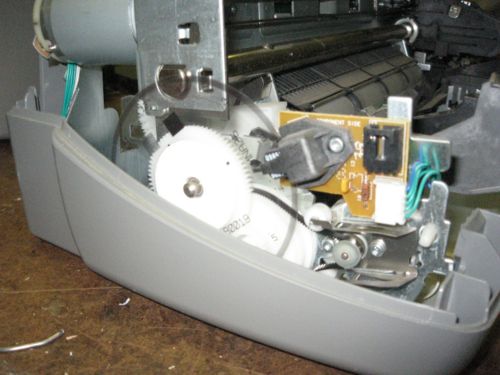

Design Potential: The two supporters need to be repositioned to create enough vertical space for the insertion of materials like CD.

5.

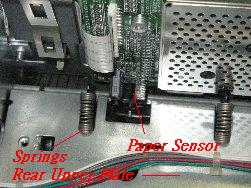

Springs/ Rear Upper Plate/ Paper Feed Sensor

Springs: acts as an simple shock absorber for the interior supporters

Rear Upper Plate: serves as the provider of opposite force on the Springs against the interior paper supporter; wirings attached on top

Paper Feed Sensor: senses the paper right before being printed

Design Potential: All three components will be repositioned to generate space for rear slot.

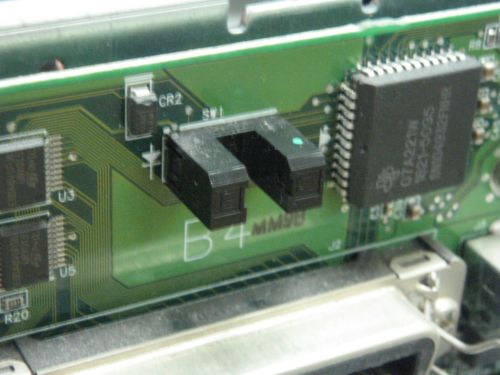

6.

Rear Paper Roller

Rear Paper Roller: rolls the paper into the actual printing process

Design Potential: It might be another target for repositioning to create vertical space; it might have to be adjusted to work with materials that are much thicker than paper.

7.

Lid Sensor

Lid Sensor: senses the opening and closing of the lid to trigger the movement of other interior components such as the cartridge

Design Potential: *none

8.

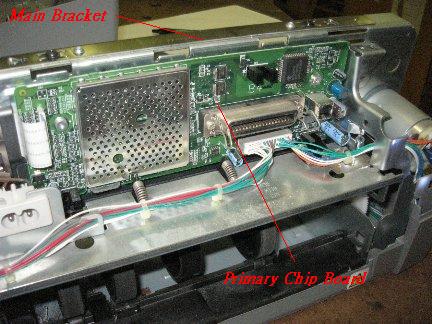

Main Bracket/ Primary Chip Board

Main Bracket: holds all the other major components in place, including the brackets for holding the motor and rear supporters

Primary Chip Board: responsible for input/output/power signals; connects to the main bracket

Design Potential: It will be relocated for the parts under it to be lifted up for additional vertical space

9.

AC Power Supply Input

AC Power Supply Input Takes in 120V AC and supplies it to the power supply of the printer to be converted into DC for the circuit board to use

Design Potential: None

10.

Power Supply

Power Supply: Converts the voltage supplied by the Power Supply Input from AC to DC

Design Potential: None

11.

Inkjet Cleaner Unit

Inkjet Cleaner Unit: Responsible for keeping the head of the inkjet cartridge clean in between operations to prevent the hardening of ink and jamming of the cartridge

Design Potential: None

12.

4 Paper Rollers

4 Paper Rollers: Responsible for moving the paper during the printing process

Design Potential: May need relocation to adapt to different page thicknesses

13.

Inkjet Cartridge Craddle

Inkjet Cartridge Craddle: Holds the Inkjet Cartridge and transports it during the printing process

Design Potential: None, it will operate in the same fashion after redesign

14.

Paper Roller Encoder Gear

Paper Roller Encoder Gear: Sends information to an encoder (not visible) so that the printer knows how far the paper has traveled inside the printer

Design Potential: Physically the part will remain the same, but will need correction in the printing software to accommodate longer sheets of paper

15.

Paper Roller Motor

Paper Roller Motor: Supplies the mechanical energy to the paper rollers so that they can move

Design Potential: We intend to leave this part the same but we may need to replace with a higher torque motor in order to move heavier sheets of paper

16.

Inkjet Cartridge Craddle Motor

Inkjet Cartridge Motor: Supplies mechanical energy to the Inkjet Cartridge Craddle so that it can move

Inkjet Cartridge Encoder Strip: Allows the Inkjet Cartridge Craddle encoder to determine its position laterally across the paper.

Design Potential: None

17.

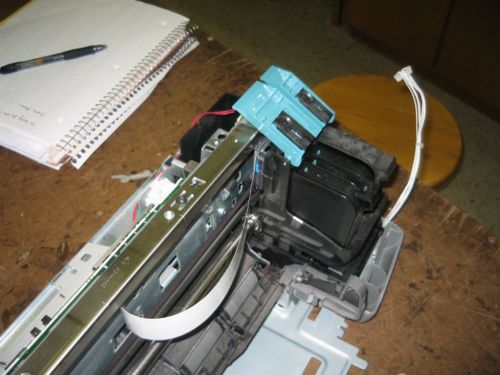

Print Cartridges

Print Cartridges: These cartridges hold the ink and the jets which place the ink on the paper.

Print Cartridge Slots: The slots which hold the cartridges can be seen in this view. The aqua-colored tabs at the top flip down to secure the cartridges in the slots.

Main Vertical Support: The main vertical support can be seen in this picture. It is a metal plate that is secured between two other supports which are in-turn stamped into the base plate. The support is the metal bar that comes up from the bottom left.

User Input Wires: The white bundle of wires at the right of the picture is the connection to the buttons on the top cover of the printer.

Design Potential: *none

18.

Inside of Top Cover

Print Cartridge Slots: The tabs which hold the print cartridges in can be seen in the locked position here.

User Input Wires: The white bundle of wires which was unplugged in the previous picture can be seen here plugged into the circuit board containing the user interface buttons.

Design Potential: *none

19.

Paper Tray

Paper Tray: This tray holds the paper before and after it has been printed. The lower section holds blank paper ready to be printed, the upper tray holds the paper after it has gone through the rollers and been printed on.

Letter Feed: The slot in the top tray can be used to feed envelopes and other irregularly sized paper into the rollers.

Paper Placement Tabs: The two aqua tabs are used to keep the paper stacked neatly and in place for the rollers. These tabs can be moved in or out depending on what size paper is put into the tray.

Design Potential: *none

20.

User Input Buttons

Cancel Button: The left-most button is the "Cancel" button. It cancels the current print job.

Paper Feed Button: The middle button is the "Paper Feed" button. This button feeds through any paper that has stopped part way in the rollers. It also must be pressed to reset a print job if there was a paper jam in the middle.

Power Button: The right-most button is the "Power" button. It does just what it says, it turns the power on or off. It is not a "hard" switch though (i.e. it won't turn the printer off without feeding any paper through the rollers first or returning the print cartridges to their docking position).

Design Potential: Possibly make the buttons more functional and less obscure.

21.

Print Cartridges in Docking Position

This is a picture of the print cartridges and slots in their docking position. When the printer is off or not in use they move to a protected position under the user buttons. The cartridges become locked in this position so that they are not damaged while the printer is not in use. The ribbon cable connecting the cartridges to the main processing circuit board can also be seen in this picture.

Design Potential: *none

22.

Roller Gears and Motor

In this picture one of gears which turns the rollers can be seen as well as the plastic disk which has the radial lines used by the encoder to determine the roller movement. The motor which controls the rollers can also be seen as well as the circuit board with the encoder and motor controller. The guide rail and linear encoder ribbon can be seen coming from the bottom right. The ribbon is used by an encoder on the print cartridge mechanism to determine its left-to-right position along the paper.

Design Potential: *none