Inkjet printer

From DDL Wiki

(→Design Considerations) |

|||

| Line 396: | Line 396: | ||

<br />In this picture one of gears which turns the rollers can be seen as well as the plastic disk which has the radial lines used by the encoder to determine the roller movement. The motor which controls the rollers can also be seen as well as the circuit board with the encoder and motor controller. The guide rail and linear encoder ribbon can be seen coming from the bottom right. The ribbon is used by an encoder on the print cartridge mechanism to determine its left-to-right position along the paper. | <br />In this picture one of gears which turns the rollers can be seen as well as the plastic disk which has the radial lines used by the encoder to determine the roller movement. The motor which controls the rollers can also be seen as well as the circuit board with the encoder and motor controller. The guide rail and linear encoder ribbon can be seen coming from the bottom right. The ribbon is used by an encoder on the print cartridge mechanism to determine its left-to-right position along the paper. | ||

<br />'''Design Potential:''' *none | <br />'''Design Potential:''' *none | ||

| + | |||

| + | [[category:design studies]] | ||

Revision as of 01:45, 14 February 2007

Contents |

Executive Summary

We are dedicating our effort on improving the functionality of a typical Inkjet Printer in this project, As of Febuary 12th, 2007, we have completed the product analysis (shown below) at a depth that we consider as sufficient to properly enter the actual designing stage. Because of the complexity of the product, the analysis below only involves the components we consider most relevant to our design ideas/goals. For additional/complete information, please check howstuffworks.com or other web sources.

Our initial goal of adding the ability to print on CDs or other hard materials has not altered after the analysis. We have identified some preliminary targets of components for additional design investigation at the next phase of the project.

Product Study

Function

1. To print images in color or black&white or gray-scale on certain sizes of paper

2. To print images on a variety types of paper that have a certain softness level

Inputs/Outputs

Input

1. Paper

2. CPU data

3. Ink

Output

1. Printed paper

Functional Operation

1. Place Printer on a flat surface

2. Plug in Parallel port to CPU

3. Plug in Power Cord to outlet

4. Install Printer Drivers

5. Insert Ink

6. Insert material to be printed

7. Upload Image desired from CPU to Printer

8. Remove Printer Image (End Product)

Different User

1. Someone inexperienced with computers.

2. People who want to print images on special materials that are not bendable.

3. Physically Disabled/Elderly.

Other Stakeholders

1. Printer/Paper/Ink/Others Manufacturer

2. Providers of Raw Materials

3. Retail Stores

4. Transportation workers

Component List

Sub-Assembly Analysis of the Main Gear

- see picture for detail

Sub-Assembly Analysis of Paper Roller Encoder System

Subassembly analysis of paper roller encoder system: The subassembly consists of three main components that act as a feedback control system: 1- The encoder circuit 2- The driving motor 3- The encoder gear

1- The Encoder Circuit This circuit is responsible for sending information the to the main printer circuit board. The circuit board sends information about many degrees did the paper roller turn. With this information the main circuit board can keep track of where the sheet of paper is inside the printer. The Encoder Circuit determines this information by using an infrared laser that monitors the movement of the encoder gear.

2- Encoder Gear This gear is directly attached to the Paper Rollers. There is a plastic disc with several small black lines along its circumference. The purpose of the black lines is provide a reference for the infrared laser. As the encoder gear moves the black lines are seen by the infrared laser to as a series of ones and zeros or black line and no black lines. By counting the number of black lines that were crossed the encoder can determine the number of degrees that the encoder gear turned. Using this and by knowing the size of the gears the main circuit board can determine the distance that the sheet of paper has traveled in the printer.

3- Driving Motor The driving motor is the final part of the feedback control system. The motor receives signals from the Encoder Circuit that tells it when to start moving and stop moving. The motor is also geared up to provide additional torque for moving the paper.

Design Considerations

Design for Assembly

- Visible and hidden screws are presented in many areas among the brackets/chip-circuit board/etc to secure every major parts onto the base

- Brackets/major assemblies are positioned in a way that they have to be put on/off together

- Many of the parts are designed with an interlock which is held in place by one screw. This reduces the number of screws and bolts which makes assembly much simpler and inexpensive.

- Almost all of the plastic parts, from the lid to the gears, have snaps that allow them to be easily attached to the main body.

Design for Disassembly

- Primary bracket has to be loosen before any other major components can be disassemble/removed from the base

- Difficult to assemble the pieces back to the original state once disassembled

- Great amount of sub-assemblies present throughout the unit

- Many of the plastic snap pieces are not easy to remove once they are in place. Many of the clips are on the inside or out of sight, making it much tougher to see and release them.

Design for Environment

- Plastics are not biodegradable

- The overall reliability of the product is good enough for the unit to last long enough time to make up for the main materials' harmful environment effects

Design for Manufacturing

- Brackets and major componets are placed in a way that they must all be at the correct position before being fastened with screws to ensure a secure overall fit

Design for Reliability

- With proper care/upgrades, the product has a very long life

- Nearly impossible to take apart without proper tools and dedicated intention

- The main wearing component- ink catridge, is very replaceble

Design for Saftety

- Proper covers/lids prevent unwanted interaction between human hands and running machinaries

- Sensors prevent excessive/active interaction between hands and mechanical components once they are exposed

Design Usability

- CPU/other wirings must be present for input purpose

- Paper tray assemblies' straight shapes helps to position the papers

FMEA chart

- S: Severity of failure

- O: Occurance probability

- D: ease of Detection

| Part | Failure Mode | Failure Effects | S | Causes of Failure | O | Design Controls | D | RPN | |

|---|---|---|---|---|---|---|---|---|---|

| Main Chip Board | Breaking/Loosening of chips/etc. | Unable to transfer the input data properly; unable to exercise proper printing actions | 9 | Excessive vibrations possibly through dropping | 2 | Notify the users on proper resting position of the printer | 5 | 90 | |

| Catridge Assembly | Blockage of Ink | Ink not able to come out of the catridge | 6 | Excessive dust cumulated at the ink openings; subpar ink quality | 4 | Quality control; limited chance of exposing the catridge assembly | 5 | 100 | |

| Primary Roller Assembly | Mechanical Failure | Paper Jammed/Stucked | 4 | Incorrect position of printing papers | 7 | Test paper tray assembly's position before entering actual printing process | 5 | 140 |

Modification

Our current analysis have generate the following list of components for possible future development:

- Part 4- Input Buttons

- Part 5- Rear Cover Assembly

- Part 6 through 8- Main Roller/Supporter Assembly

- Part 9 & 10- Springs and their resting plate

- Part 12- Rear Paper Roller Assembly

- Part 14- Main Bracket

Areas of Possible Improvement

The list of parts under Modification will be directly affected by the additional functionality we are currently planning to design. Other than Part 4, all the parts have to be either re-positioned or modified to generate the required space for additional components resulting from the next stage of design. For example, we might have to cut a hole/slot in Part 5 and attach an additional tray to it for CD/other hard materials' input. Vertical space is the most obvious issue as of now, and we will address these areas as we progress this project to the next stage.

Notes/Others

This section serves as our preliminary analysis information data base as of 02/12/07.Parts:

1.

Printer

2.

Lid/Paper Tray 1/ Paper Tray 2/ Input Buttons

Lid: prevents dust, allows ink replacement & paper adjustment

Paper Tray 1: holds pre-printed paper in straight position

Paper Tray 2: holds printed paper

Input Buttons: lets users input basic commands

Design Potential: *none

3.

Rear Cover(w/ 6 rollers)

Rear Cover: The 6 rollers located on it assist the paper movement inside of the printer

Design Potential: It might be one of the potential location for our rear slot (for CD or other hard materials).

4.

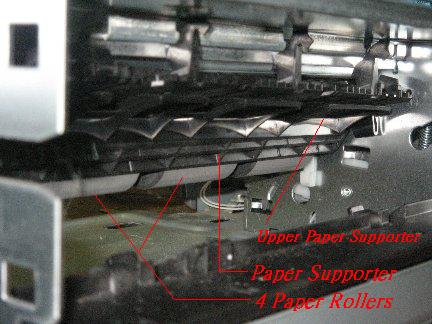

Upper Paper Supporter/Paper Supporter/Paper Rollers

Upper Paper Supporter: holds the printing paper in the y-direction

Paper Supporter: supports the printing paper upward

Paper Rollers: are the main rollers for paper movement

Design Potential: The two supporters need to be repositioned to create enough vertical space for the insertion of materials like CD.

5.

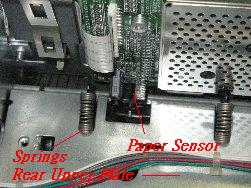

Springs/ Rear Upper Plate/ Paper Feed Sensor

Springs: acts as an simple shock absorber for the interior supporters

Rear Upper Plate: serves as the provider of opposite force on the Springs against the interior paper supporter; wirings attached on top

Paper Feed Sensor: senses the paper right before being printed

Design Potential: All three components will be repositioned to generate space for rear slot.

6.

Rear Paper Roller

Rear Paper Roller: rolls the paper into the actual printing process

Design Potential: It might be another target for repositioning to create vertical space; it might have to be adjusted to work with materials that are much thicker than paper.

7.

Lid Sensor

Lid Sensor: senses the opening and closing of the lid to trigger the movement of other interior components such as the cartridge

Design Potential: *none

8.

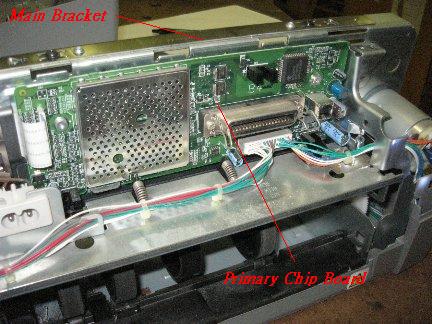

Main Bracket/ Primary Chip Board

Main Bracket: holds all the other major components in place, including the brackets for holding the motor and rear supporters

Primary Chip Board: responsible for input/output/power signals; connects to the main bracket

Design Potential: It will be relocated for the parts under it to be lifted up for additional vertical space

9.

AC Power Supply Input

AC Power Supply Input Takes in 120V AC and supplies it to the power supply of the printer to be converted into DC for the circuit board to use

Design Potential: None

10.

Power Supply

Power Supply: Converts the voltage supplied by the Power Supply Input from AC to DC

Design Potential: None

11.

Inkjet Cleaner Unit

Inkjet Cleaner Unit: Responsible for keeping the head of the inkjet cartridge clean in between operations to prevent the hardening of ink and jamming of the cartridge

Design Potential: None

12.

4 Paper Rollers

4 Paper Rollers: Responsible for moving the paper during the printing process

Design Potential: May need relocation to adapt to different page thicknesses

13.

Inkjet Cartridge Craddle

Inkjet Cartridge Craddle: Holds the Inkjet Cartridge and transports it during the printing process

Design Potential: None, it will operate in the same fashion after redesign

14.

Paper Roller Encoder Gear

Paper Roller Encoder Gear: Sends information to an encoder (not visible) so that the printer knows how far the paper has traveled inside the printer

Design Potential: Physically the part will remain the same, but will need correction in the printing software to accommodate longer sheets of paper

15.

Paper Roller Motor

Paper Roller Motor: Supplies the mechanical energy to the paper rollers so that they can move

Design Potential: We intend to leave this part the same but we may need to replace with a higher torque motor in order to move heavier sheets of paper

16.

Inkjet Cartridge Craddle Motor

Inkjet Cartridge Motor: Supplies mechanical energy to the Inkjet Cartridge Craddle so that it can move

Inkjet Cartridge Encoder Strip: Allows the Inkjet Cartridge Craddle encoder to determine its position laterally across the paper.

Design Potential: None

17.

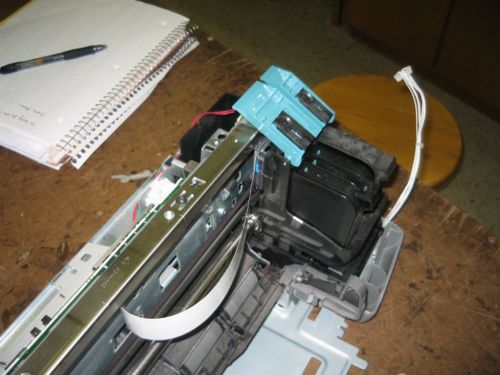

Print Cartridges

Print Cartridges: These cartridges hold the ink and the jets which place the ink on the paper.

Print Cartridge Slots: The slots which hold the cartridges can be seen in this view. The aqua-colored tabs at the top flip down to secure the cartridges in the slots.

Main Vertical Support: The main vertical support can be seen in this picture. It is a metal plate that is secured between two other supports which are in-turn stamped into the base plate. The support is the metal bar that comes up from the bottom left.

User Input Wires: The white bundle of wires at the right of the picture is the connection to the buttons on the top cover of the printer.

Design Potential: *none

18.

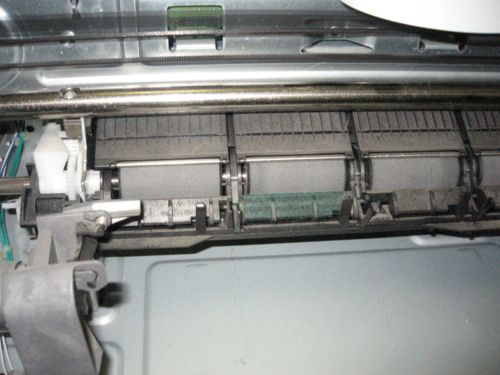

Inside of Top Cover

Print Cartridge Slots: The tabs which hold the print cartridges in can be seen in the locked position here.

User Input Wires: The white bundle of wires which was unplugged in the previous picture can be seen here plugged into the circuit board containing the user interface buttons.

Design Potential: *none

19.

Paper Tray

Paper Tray: This tray holds the paper before and after it has been printed. The lower section holds blank paper ready to be printed, the upper tray holds the paper after it has gone through the rollers and been printed on.

Letter Feed: The slot in the top tray can be used to feed envelopes and other irregularly sized paper into the rollers.

Paper Placement Tabs: The two aqua tabs are used to keep the paper stacked neatly and in place for the rollers. These tabs can be moved in or out depending on what size paper is put into the tray.

Design Potential: *none

20.

User Input Buttons

Cancel Button: The left-most button is the "Cancel" button. It cancels the current print job.

Paper Feed Button: The middle button is the "Paper Feed" button. This button feeds through any paper that has stopped part way in the rollers. It also must be pressed to reset a print job if there was a paper jam in the middle.

Power Button: The right-most button is the "Power" button. It does just what it says, it turns the power on or off. It is not a "hard" switch though (i.e. it won't turn the printer off without feeding any paper through the rollers first or returning the print cartridges to their docking position).

Design Potential: Possibly make the buttons more functional and less obscure.

21.

Print Cartridges in Docking Position

This is a picture of the print cartridges and slots in their docking position. When the printer is off or not in use they move to a protected position under the user buttons. The cartridges become locked in this position so that they are not damaged while the printer is not in use. The ribbon cable connecting the cartridges to the main processing circuit board can also be seen in this picture.

Design Potential: *none

22.

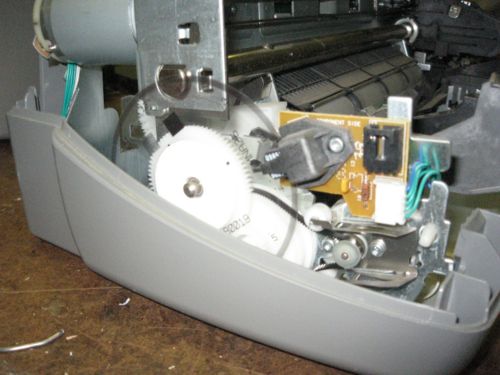

Roller Gears and Motor

In this picture one of gears which turns the rollers can be seen as well as the plastic disk which has the radial lines used by the encoder to determine the roller movement. The motor which controls the rollers can also be seen as well as the circuit board with the encoder and motor controller. The guide rail and linear encoder ribbon can be seen coming from the bottom right. The ribbon is used by an encoder on the print cartridge mechanism to determine its left-to-right position along the paper.

Design Potential: *none