Milling

From DDL Wiki

| Line 6: | Line 6: | ||

Milling is a subtractive process that can be used to create intricate shapes and cuts. A rotating multi-toothed bit can either be moved around a stationary object or the object can be moved to make cuts on a stationary cutter. The cutter can be right hand by turning clockwise and the left hand by turning counterclockwise. | Milling is a subtractive process that can be used to create intricate shapes and cuts. A rotating multi-toothed bit can either be moved around a stationary object or the object can be moved to make cuts on a stationary cutter. The cutter can be right hand by turning clockwise and the left hand by turning counterclockwise. | ||

| + | |||

| + | For a vertical mill, the spindle axis is vertically oriented. The cutters are i the spindle and rotates on the axis. The spindle can be extended for drilling and plunge cuts. In this process, there are subprocesses such as turretmills and bedmills. For a bedmill, the table moves perpendicular to the spindle's axis and the spindle moves parallel to its own axis. On the other hand, for a turretmill, the spindle is stationary and the table is moved both perpendicular and parallel to the spindle's axis. | ||

| + | |||

| + | A horizontal mill require a different process. The cutters for this mill are oriented horizontally across the table. The two subcomponents for this mill is the facemills and the sidemills. These cutters can groove drills and slots. | ||

'''Kind of material/size/shape/precision''' | '''Kind of material/size/shape/precision''' | ||

| Line 15: | Line 19: | ||

'''Relevance of the process to a design''' | '''Relevance of the process to a design''' | ||

| + | |||

| + | A component of a design may ned to be milled if it is a metal of complex shaping. A milling machine can do many complex operations such as planing, slot cutting, drilling, routing and rebating. | ||

'''Relative cost''' | '''Relative cost''' | ||

Revision as of 01:51, 12 February 2007

Tagged by Team 12.

Process

Milling is a subtractive process that can be used to create intricate shapes and cuts. A rotating multi-toothed bit can either be moved around a stationary object or the object can be moved to make cuts on a stationary cutter. The cutter can be right hand by turning clockwise and the left hand by turning counterclockwise.

For a vertical mill, the spindle axis is vertically oriented. The cutters are i the spindle and rotates on the axis. The spindle can be extended for drilling and plunge cuts. In this process, there are subprocesses such as turretmills and bedmills. For a bedmill, the table moves perpendicular to the spindle's axis and the spindle moves parallel to its own axis. On the other hand, for a turretmill, the spindle is stationary and the table is moved both perpendicular and parallel to the spindle's axis.

A horizontal mill require a different process. The cutters for this mill are oriented horizontally across the table. The two subcomponents for this mill is the facemills and the sidemills. These cutters can groove drills and slots.

Kind of material/size/shape/precision

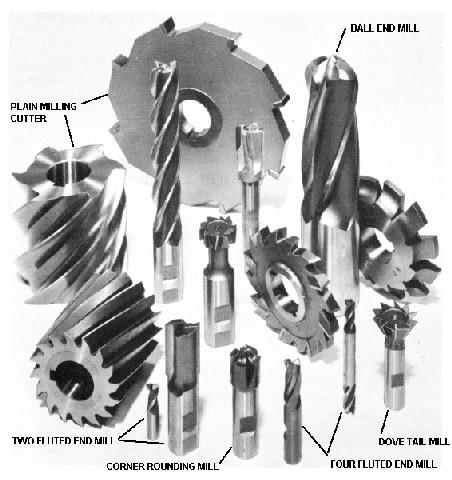

Usually, milling is used for metal and possibly some other materials. The surface being cut can be flat, curved or angular. There are many types and sizes of milling cutters. The picture below show a few of the cutters.

Relevance of the process to a design

A component of a design may ned to be milled if it is a metal of complex shaping. A milling machine can do many complex operations such as planing, slot cutting, drilling, routing and rebating.

Relative cost

References