RC rock crawler truck redesign

From DDL Wiki

(→Concept Evaluation) |

|||

| Line 63: | Line 63: | ||

Using a Pugh chart, we were able to asses our design concepts in comparison with existing products. This also showed us the positive and negative points between each characteristic of each design choice. When evaluating each design, we took into account criteria that were important to the manufacturer, and more importanly, the consumer. These criteria are weighted in accordance with our groups opinion as to how important they should weigh in the selection of the proper design. The picture below is our Pugh chart comparing the different products. First seen is our benchmark product, the off-the-shelf Wheeley King. The next product compared is an existing kit provided by HPI made for our truck. This product it mainly plastic components with very few parts made out of durable materials. Next in the chart are our two desgin concepts. The second concpet varies from the first as it has a new chasis and skid plate. Our team then evaluated each of the concepts as if they were in use on the truck. From our evaluations, the chart shows that the our second design concept with the chasis and skid plate offer us the best solution, and therefore this concept will be the one we choose to investigate further. | Using a Pugh chart, we were able to asses our design concepts in comparison with existing products. This also showed us the positive and negative points between each characteristic of each design choice. When evaluating each design, we took into account criteria that were important to the manufacturer, and more importanly, the consumer. These criteria are weighted in accordance with our groups opinion as to how important they should weigh in the selection of the proper design. The picture below is our Pugh chart comparing the different products. First seen is our benchmark product, the off-the-shelf Wheeley King. The next product compared is an existing kit provided by HPI made for our truck. This product it mainly plastic components with very few parts made out of durable materials. Next in the chart are our two desgin concepts. The second concpet varies from the first as it has a new chasis and skid plate. Our team then evaluated each of the concepts as if they were in use on the truck. From our evaluations, the chart shows that the our second design concept with the chasis and skid plate offer us the best solution, and therefore this concept will be the one we choose to investigate further. | ||

| + | |||

| + | =Appendix= | ||

| + | ==Concept Brainstorming== | ||

| + | 1. reverse chassis to redistribute weight to front to improve rock crawling ability<br /> | ||

| + | 2. lengthen wheelbase to increase ground clearance<br /> | ||

| + | 3. fabricate aluminum sway bars<br /> | ||

| + | 4. remove rear rod balance for flexibility<br /> | ||

| + | 5. lock differentials<br /> | ||

| + | 6. redesign chassis to reduce fasteners and improve handling<br /> | ||

| + | 7. reverse tires for better traction<br /> | ||

| + | 8. down gear for improved torque<br /> | ||

| + | 9. re-fab steering components<br /> | ||

| + | 10. solid driving axle<br /> | ||

| + | 11. fabricate aluminum suspension links<br /> | ||

| + | 12. redesign suspension links (tube shaped) to increase yield stress while maintaining factor of safety<br /> | ||

| + | 13. Additional body mounts to change body on chassis (aesthetics) <br /> | ||

| + | 14. better esc<br /> | ||

| + | 15. mount servos on both front and rear axles for low cg<br /> | ||

| + | 16. increase tire weight to lower cg<br /> | ||

| + | 17. change shock spring<br /> | ||

| + | 18. change shock fluid<br /> | ||

| + | 19. upgrade motor<br /> | ||

| + | 20. cast new body<br /> | ||

| + | 21. convert to tank tracks<br /> | ||

| + | 22. insert memory foam into tires<br /> | ||

| + | 23. upgrade bearings<br /> | ||

| + | 24. upgrade steering servo<br /> | ||

| + | 25. add solenoid to front suspension for “jumping” onto obstacles/rocks<br /> | ||

| + | 26. bug metal gears<br /> | ||

| + | 27. rearrange cells in battery pack for better weight distribution<br /> | ||

| + | 28. metal wheel rims for lower center of gravity<br /> | ||

| + | 29. get metal drive shafts<br /> | ||

| + | 30. increase cells in batter for longer lifespan<br /> | ||

| + | 31. bend a tube chassis<br /> | ||

| + | 32. dual motor<br /> | ||

| + | 33. mount servo to differential: lower COM and less complicated steering linkage<br /> | ||

| + | 34. build tube frame chassis<br /> | ||

| + | 35. waterproof electronics<br /> | ||

| + | 36. remount lower sway bars for increased ground clearance<br /> | ||

| + | 37. mount servo above knuckle for greater ground clearance and stronger steering<br /> | ||

| + | 38. increase servo arm length<br /> | ||

| + | 39. add functional headlights (aesthetics) <br /> | ||

| + | 40. add spare tire in bed (aesthetics) <br /> | ||

| + | 41. repaint body for realism (aesthetics) <br /> | ||

| + | 42. add roof rack (aesthetics) <br /> | ||

| + | 43. upgrade tires for better tread grip<br /> | ||

| + | 44. use sheet metal (~1/8 in)to redesign parts (easy manufacture) <br /> | ||

| + | 45. add sheet metal skid plates<br /> | ||

| + | 46. substitute delrin for aluminum in places where the weight would raise the COM<br /> | ||

| + | 47. cast another larger, more proportional body (realism, aesthetics) <br /> | ||

| + | 48. combine upper suspension links and battery mount into one part (also moves battery) to a more desirable location<br /> | ||

| + | 49. add rear view mirrors (aesthetics) <br /> | ||

| + | 50. incorporate skid plate into chassis redesign<br /> | ||

| + | 51. add ballast in tires<br /> | ||

| + | 52. design snap fastener body mount<br /> | ||

| + | 53. make chassis solid plate<br /> | ||

| + | 54. make chassis of a rigid non-metal (carbon fiber) <br /> | ||

| + | 55. make suspension and steering components of carbon fiber tubing<br /> | ||

| + | 56. attach skid plate to front diff for steering protection<br /> | ||

| + | 57. bend a scale brush guard<br /> | ||

| + | 58. design adapter to fit between diff and sway bar to allow sway bar to be made of rod and rod end like the suspension links (DFMA+ for us as conversion kit manufacturers) <br /> | ||

| + | 59. make steering linkages from rod and rod ends (also DFMA+, maybe thinner rod though) <br /> | ||

| + | 60. zip tie electronics cords to chassis/components to keep them out of the way<br /> | ||

| + | 61. put additional holes on redesigned chassis to allow for adjustments and to work with a larger range of existing components on the market<br /> | ||

| + | 62. integrate plastic "windshield" into body<br /> | ||

| + | 63. change shock spring color for aesthetics<br /> | ||

| + | 64. design a one piece chassis<br /> | ||

| + | 65. make wheels larger than body so it can flip over and still maintain traction<br /> | ||

| + | 66. give a full 180 degrees of rotation between front and rear axle<br /> | ||

| + | 67. change truck to a ball that can just roll over obstacles<br /> | ||

| + | 68. less fasteners<br /> | ||

| + | 69. air freshener in cab<br /> | ||

| + | 70. missiles<br /> | ||

| + | 71. american flag<br /> | ||

| + | 72. missiles AND american flag<br /> | ||

| + | 73. convert to robotic "spider" legs instead of wheels<br /> | ||

| + | 74. attached cup holder for beverage retrieval<br /> | ||

| + | 75. plow or cow catcher mounted to front<br /> | ||

| + | 76. increase scale and power to provide for sidewalk shoveling in winter<br /> | ||

| + | 77. controller that is an actual steering wheel<br /> | ||

| + | 78. "nitrous" button on controller for increased speed<br /> | ||

| + | 79. change to three wheel ("omniwheel") design that allows travel in any direction<br /> | ||

| + | 80. increase battery life<br /> | ||

| + | 81. wheels with cleats<br /> | ||

| + | 82. tires equipped with chains for better snow traction<br /> | ||

| + | 83. convert to half track system (two front tires and tank tracks in the back) <br /> | ||

| + | 84. make components from reused/recycled material (green machine) <br /> | ||

| + | 85. put a remote camera in the truck to improve performance for rock crawling competitions<br /> | ||

| + | 86. actuated arms to move obstacles from truck's path<br /> | ||

| + | 87. launchable cable grabber to drag itself through obstacles<br /> | ||

| + | 88. functional winch on the front<br /> | ||

| + | 89. aesthetic muffler or exhaust system<br /> | ||

| + | 90. novelty "la cuca racha" horn<br /> | ||

| + | 91. carrying case/storage box<br /> | ||

| + | 92. cleaning kit<br /> | ||

| + | 93. oil slick squirter<br /> | ||

| + | 94. actuated arms on the side so it can right itself if rolled<br /> | ||

| + | 95. add mud flaps<br /> | ||

| + | 96. ability to do burnouts<br /> | ||

| + | 97. place to store antenna<br /> | ||

| + | 98. adjustable antenna to cover different ranges<br /> | ||

| + | 99. fixed antenna<br /> | ||

| + | 100. carbon fiber body (aesthetics) <br /> | ||

Revision as of 21:04, 8 October 2008

Contents |

Executive Summary

This stage of our project required our group to analyze opportunities for improvement. We went about collecting data and observations in many various ways in order to diversify our understanding of the problems. Our first action towards product improvement was a basic brainstorming session where our group came up with 100 possible ideas from improvement, ranging from technical improvements such as higher torque to aesthetic changes such as having colored wheels. We wanted our improvements to intrigue both the amateur and the professional.

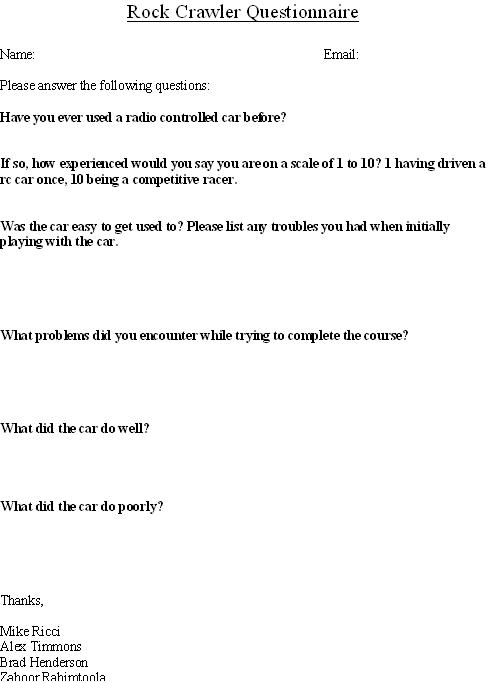

Next, our group conducted novice testing. In order to expand our consumer market base we have decided to create a product that can be used by everyone, not just the professional. In order to examine novice consumer needs, a 10 foot long rock crawling course was constructed. The course consisted of varying sized rocks followed by an incline. All participants were asked to fill out a questionnaire regarding their experience. (i.e.: what problems did you encounter while trying to complete the course?) From this data we realized that the most common problems for the amateur user was the car flipping over.

In order to obtain findings on a professional level, our group went to an indoor rock crawling facility. Two hours were spent watching competitions and talking with professional rock crawlers. Here we obtained more detailed findings that were all technically related. We talked to five professionals throughout the time spent at the facility, all having a very good knowledge of the HPI Wheely King. For the professional, the main problems with the stock Wheely King are its poor weight distribution, flimsy parts, and lack of a locked differential.

From all of the data and user opinions collected over the last three weeks our group was able to come up with …..x…..design improvements which we studied through the use of a Pugh chart. Brad/Zahoor….. can you put 2-3 sentences here about the pugh chard……From this study we concluded that ……….. are the best design improvements b/c…..

Research and Observations

For our research, we decided to get as many varying opinions as possible. We wanted to know what the novice thinks of the original car as well as a professional. (For the sake of simplicity, we decided to call anyone that competes at rock crawling a professional) For the novice research, our group set up a simple course that every participant was instructed to use. The course was 10 feet long and consisted of varying sized rocks as well as a slippery incline. The goal was to make it across the course without flipping the car or having to use reverse. Time was not a measured factor. Each participant was given 2 minutes before attempting the course to familiarize themselves with the car. After completing the course the participants were then asked to fill out a questionnaire so we could obtain feedback on the cars performance. From our novice research we found that the most common problem was the car tipping. The second most common problem was the need to reverse because the car could not climb over bigger rocks. This suggests to us that the car needs to have a more flexible chassis in order to keep its balance when going over uneven surfaces.

For our professional research our group went to an indoor rock crawling facility located in Beaver Falls, Pennsylvania. We were invited by the owner of the hobby shop where we purchased our car. The facility was an empty warehouse that was rented out for the weekend. We spent two hours at the facility watching competitions and talking with numerous professionals. As we had previously thought, everyone in the facility knew of the HPI Wheely King and everyone was quick to offer their opinion of the car. It was the general consensus that it was a good base model to transform into a rock crawler, but had some distinct flaws. Everyone first mentioned its weight imbalance, saying that a car designed to do wheelies is not designed to crawl rocks or go up steep inclines. Second, its flexibility was mentioned, saying that it had decent flexibility for a stock model but needed more axle freedom in order to climb the larger rocks without flipping.

Overall our research was very beneficial. We were able to identify the needs of both the amateur and the professional, giving us the advantage of designing an improvement kit that can be sold to a very diverse market. As well as being able to identify needs, our research provided us with professional advice that is now directing us to an improved product.

User Study

Design Concepts

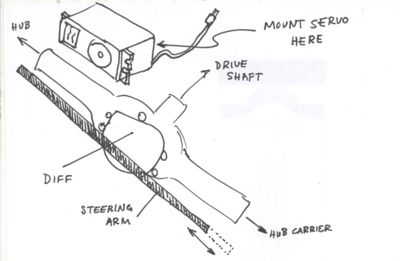

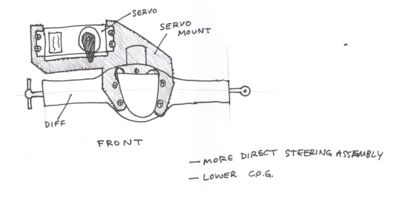

Servo Mount

On the stock Wheely King, the servo is mounted to the chassis toward the top, behind the front shock tower. The steering power, is translated to the front differential through a five part linkage. The weight of the servo and linkage components is not necessary to have up top (poor effect on COG) when we can mount the servo elsewhere, lower on the truck. By mounting the servo directly above the steering rod, on the differential, we can lower the COG a great deal.

Another disadvantage to having the servo connected through a linkage is that any deformation in the linkage components results in inaccurate steering. Many times in rock crawling, the steering system will have to overcome large load, such as when the trucks weight rests on the side of the front wheels. With the servo connected more directly through a one part linkage as opposed to a five part linkage, the steering system has greater strength. Reducing the part count is a good thing in this case as the added components can only introduce more modes of failure or weaken the steering system.

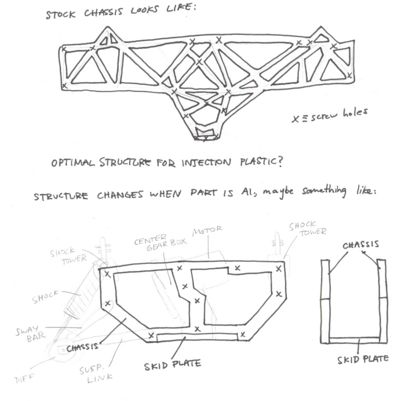

Redesigned Chassis

Many major component assemblies are attached to the chassis. The center gearbox and battery housing, for example, are two high-mass assemblies whose positions are dictated only by the anchor points to the chassis. By redesigning the chassis and moving these components around as we wish, we can lower the truck's COG without compromising ground clearance. The improved chassis can also facilitate the extension of the wheelbase, further increasing the vehicle's stability.

Manufacturing the chassis from machined aluminum plate can be accomplished realistically with either manual milling for prototypes or CNC milling for large batch production. Aluminum has many advantages over plastic in this application. The increased strength of the metal allows much less material to be used while still increasing overall chassis rigidity.

Sway Links

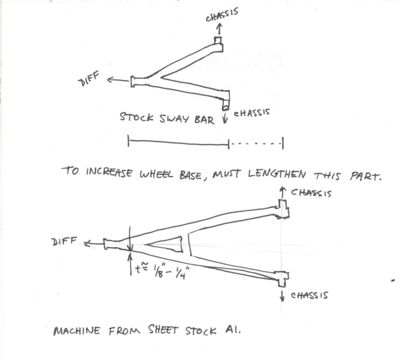

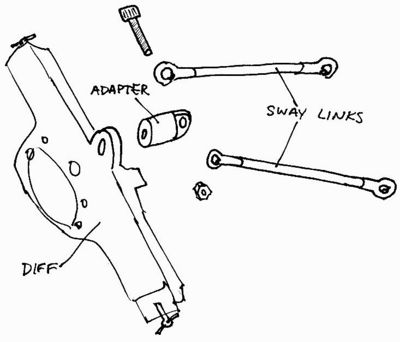

In order to lengthen the wheelbase, the sway bars must be replaced as well. This could be accomplished with machined plate aluminum, but the alternative we'll more likely choose is to design a small adapter component that will allow us to use aluminum rod and ball-pivoting rod ends. These can be the same materials as will be used in the suspension links and steering components. In this case, increasing the part count makes sense because we can reduce the amount of machining required for our components; rod and rod ends will be much easier to implement.

Concept Evaluation

Using a Pugh chart, we were able to asses our design concepts in comparison with existing products. This also showed us the positive and negative points between each characteristic of each design choice. When evaluating each design, we took into account criteria that were important to the manufacturer, and more importanly, the consumer. These criteria are weighted in accordance with our groups opinion as to how important they should weigh in the selection of the proper design. The picture below is our Pugh chart comparing the different products. First seen is our benchmark product, the off-the-shelf Wheeley King. The next product compared is an existing kit provided by HPI made for our truck. This product it mainly plastic components with very few parts made out of durable materials. Next in the chart are our two desgin concepts. The second concpet varies from the first as it has a new chasis and skid plate. Our team then evaluated each of the concepts as if they were in use on the truck. From our evaluations, the chart shows that the our second design concept with the chasis and skid plate offer us the best solution, and therefore this concept will be the one we choose to investigate further.

Appendix

Concept Brainstorming

1. reverse chassis to redistribute weight to front to improve rock crawling ability

2. lengthen wheelbase to increase ground clearance

3. fabricate aluminum sway bars

4. remove rear rod balance for flexibility

5. lock differentials

6. redesign chassis to reduce fasteners and improve handling

7. reverse tires for better traction

8. down gear for improved torque

9. re-fab steering components

10. solid driving axle

11. fabricate aluminum suspension links

12. redesign suspension links (tube shaped) to increase yield stress while maintaining factor of safety

13. Additional body mounts to change body on chassis (aesthetics)

14. better esc

15. mount servos on both front and rear axles for low cg

16. increase tire weight to lower cg

17. change shock spring

18. change shock fluid

19. upgrade motor

20. cast new body

21. convert to tank tracks

22. insert memory foam into tires

23. upgrade bearings

24. upgrade steering servo

25. add solenoid to front suspension for “jumping” onto obstacles/rocks

26. bug metal gears

27. rearrange cells in battery pack for better weight distribution

28. metal wheel rims for lower center of gravity

29. get metal drive shafts

30. increase cells in batter for longer lifespan

31. bend a tube chassis

32. dual motor

33. mount servo to differential: lower COM and less complicated steering linkage

34. build tube frame chassis

35. waterproof electronics

36. remount lower sway bars for increased ground clearance

37. mount servo above knuckle for greater ground clearance and stronger steering

38. increase servo arm length

39. add functional headlights (aesthetics)

40. add spare tire in bed (aesthetics)

41. repaint body for realism (aesthetics)

42. add roof rack (aesthetics)

43. upgrade tires for better tread grip

44. use sheet metal (~1/8 in)to redesign parts (easy manufacture)

45. add sheet metal skid plates

46. substitute delrin for aluminum in places where the weight would raise the COM

47. cast another larger, more proportional body (realism, aesthetics)

48. combine upper suspension links and battery mount into one part (also moves battery) to a more desirable location

49. add rear view mirrors (aesthetics)

50. incorporate skid plate into chassis redesign

51. add ballast in tires

52. design snap fastener body mount

53. make chassis solid plate

54. make chassis of a rigid non-metal (carbon fiber)

55. make suspension and steering components of carbon fiber tubing

56. attach skid plate to front diff for steering protection

57. bend a scale brush guard

58. design adapter to fit between diff and sway bar to allow sway bar to be made of rod and rod end like the suspension links (DFMA+ for us as conversion kit manufacturers)

59. make steering linkages from rod and rod ends (also DFMA+, maybe thinner rod though)

60. zip tie electronics cords to chassis/components to keep them out of the way

61. put additional holes on redesigned chassis to allow for adjustments and to work with a larger range of existing components on the market

62. integrate plastic "windshield" into body

63. change shock spring color for aesthetics

64. design a one piece chassis

65. make wheels larger than body so it can flip over and still maintain traction

66. give a full 180 degrees of rotation between front and rear axle

67. change truck to a ball that can just roll over obstacles

68. less fasteners

69. air freshener in cab

70. missiles

71. american flag

72. missiles AND american flag

73. convert to robotic "spider" legs instead of wheels

74. attached cup holder for beverage retrieval

75. plow or cow catcher mounted to front

76. increase scale and power to provide for sidewalk shoveling in winter

77. controller that is an actual steering wheel

78. "nitrous" button on controller for increased speed

79. change to three wheel ("omniwheel") design that allows travel in any direction

80. increase battery life

81. wheels with cleats

82. tires equipped with chains for better snow traction

83. convert to half track system (two front tires and tank tracks in the back)

84. make components from reused/recycled material (green machine)

85. put a remote camera in the truck to improve performance for rock crawling competitions

86. actuated arms to move obstacles from truck's path

87. launchable cable grabber to drag itself through obstacles

88. functional winch on the front

89. aesthetic muffler or exhaust system

90. novelty "la cuca racha" horn

91. carrying case/storage box

92. cleaning kit

93. oil slick squirter

94. actuated arms on the side so it can right itself if rolled

95. add mud flaps

96. ability to do burnouts

97. place to store antenna

98. adjustable antenna to cover different ranges

99. fixed antenna

100. carbon fiber body (aesthetics)