Sand casting

From DDL Wiki

(→Process) |

(→Process) |

||

| Line 20: | Line 20: | ||

There are several stages that make up a typical sand casting system. | There are several stages that make up a typical sand casting system. | ||

| - | 1. | + | 1. Pattern construction- |

| - | The | + | The object to be cloned is made of different materials such as wood or metals. They are used to create the sand mold. |

<br /> | <br /> | ||

| - | 2. | + | 2. Molding- |

| - | + | Sand which is self-hardening, air-setting is used and is imprinted by the pattern | |

<br /> | <br /> | ||

| - | 3. | + | 3. Pouring- |

| - | The | + | The material of which the copy is to be made of is then poured into the hardened sand mold. The mold is filled using a network of runner troughs designed in accordance to the specifications of each casting. |

<br /> | <br /> | ||

| - | 4. | + | 4. Removal and Cleaning- |

| - | + | Once the material has solidified and cooling period is over, the casting is lifted out of the mold and the sand is recovered to start the molding cycled again. | |

<br /> | <br /> | ||

| - | 5. | + | 5. Final Treatment- |

| - | + | The casting is then further finalized by processes such as thermal treatment, machining, and painting depending on what the design calls for. | |

<br /> | <br /> | ||

---- | ---- | ||

Revision as of 06:29, 12 February 2007

Definition

What & How:

Casting is a manufacturing process used to produce objects by pouring molten material in to a cavity called a mold which is the negative of the object, and allowing it to cool and solidify. Sand casting is the specific casting process in which the mold is usualy made from sand formed around the object to be copied.

Top and bottom halves of a sand mold.

Two sets of castings (bronze and aluminum) from the above sand mold.

Process

Steps of Sand casting: There are several stages that make up a typical sand casting system.

1. Pattern construction-

The object to be cloned is made of different materials such as wood or metals. They are used to create the sand mold.

2. Molding-

Sand which is self-hardening, air-setting is used and is imprinted by the pattern

3. Pouring-

The material of which the copy is to be made of is then poured into the hardened sand mold. The mold is filled using a network of runner troughs designed in accordance to the specifications of each casting.

4. Removal and Cleaning-

Once the material has solidified and cooling period is over, the casting is lifted out of the mold and the sand is recovered to start the molding cycled again.

5. Final Treatment-

The casting is then further finalized by processes such as thermal treatment, machining, and painting depending on what the design calls for.

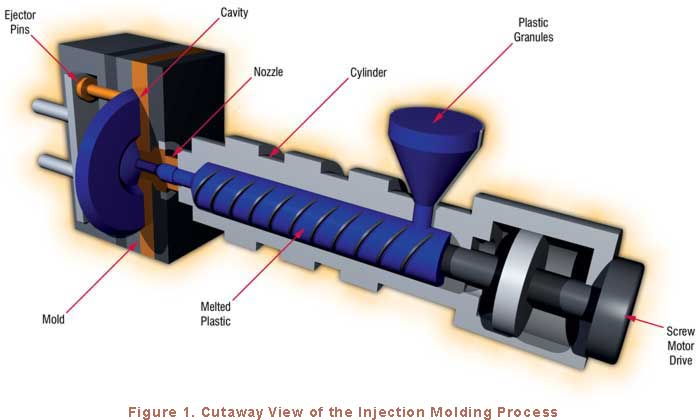

A diagram of injection molding