Sand casting

From DDL Wiki

(→Design Considerations) |

Current revision (01:53, 14 February 2007) (view source) |

||

| Line 82: | Line 82: | ||

http://www.casting-source.com/sand-castings.htm | http://www.casting-source.com/sand-castings.htm | ||

| + | |||

| + | [[category:manufacturing]] | ||

Current revision

Contents |

Definition

What & How:

Casting is a manufacturing process used to produce objects by pouring molten material in to a cavity called a mold which is the negative of the object, and allowing it to cool and solidify. Sand casting is the specific casting process in which the mold is usualy made from sand formed around the object to be copied. This technique is generally used for high-volume production.

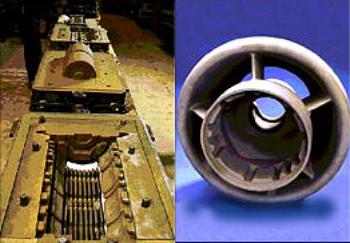

Top and bottom halves of a sand mold.

Two sets of castings (bronze and aluminum) from the above sand mold.

Parts made by sand casting

Process

Steps of Sand casting: There are several stages that make up a typical sand casting system.

1. Pattern construction -

A master object to be cloned is made of different materials such as wood or metals. They are used to create the sand mold.

2. Molding -

Sand which is self-hardening, air-setting is used and is imprinted by the pattern

3. Pouring -

The material of which the copy is to be made of is then poured into the hardened sand mold. The mold is filled using a network of runner troughs designed in accordance to the specifications of each casting.

4. Removal and Cleaning -

Once the material has solidified and cooling period is over, the casting is lifted out of the mold and the sand is recovered to start the molding cycled again.

5. Final Treatment -

The casting is then further finalized by processes such as thermal treatment, machining, and painting depending on what the design calls for.

Half mold with cores and an example of a cast air intake for a turbocharger

Costs

The principle cost in sand casting is low. The mold, which is the main cost of the process, is created out of reused sand. Since sand is easily formable, the cost varies little with different shapes and sizes. The mold is not permanent either so it is relatively inexpensive to cast different objects.

Design Considerations

The sand casting process is used when the volume of the parts justifies the creation of a molds. As the accuracy of the casting is limited by imperfections in the mold making process there will be extra material to be removed by grinding or machining, more than is required by other casting processes. Sand casings not further worked by polishing or machining are recongnized by the sand-like texture imprinted by the mold.

Advantages:

Least expensive casting process

Castings can be up to several tons

Can cast intricate shapes

Can be used with most pourable metals and alloys

Disadvanatages

Can only cast part shapes

Castings require secondary machining

Rough surface finish

External References

http://www.efunda.com/processes/metal_processing/sand_casting_intro.cfm