Siphon

From DDL Wiki

| Line 1: | Line 1: | ||

| - | [[Image:Siphon_Main.jpg| | + | [[Image:Siphon_Main.jpg|center]] |

This product is a component of the analysis for the [[aquarium pump]] project. | This product is a component of the analysis for the [[aquarium pump]] project. | ||

Revision as of 16:40, 23 September 2007

This product is a component of the analysis for the aquarium pump project.

Contents |

Product Purpose

[Copy corresponding section from aquarium pump front page once proofread]

Customer Needs

[Copy corresponding section from aquarium pump front page once proofread]

Stakeholders

[Copy corresponding section from aquarium pump front page once proofread]

Consumer Demographics

[Copy corresponding section from aquarium pump front page once proofread]

Product Function

[Copy corresponding section from aquarium pump front page once proofread]

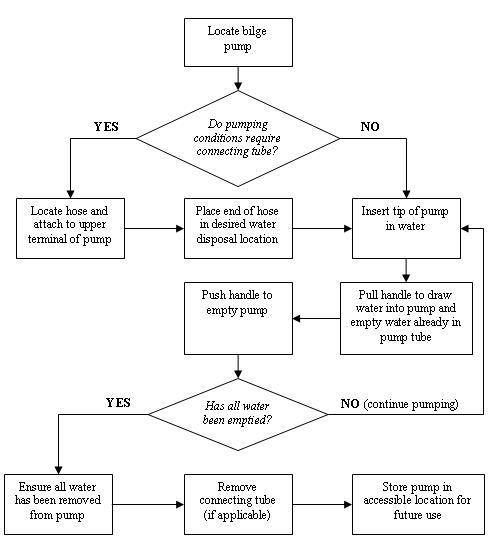

Product Use

In order to demonstrate the use and operation of the siphon, our group made the following video:

Bill of Materials

Failure Mode and Effects Analysis (FMEA)

The table below details our assessment of the most common failures that we anticipate the bilge pump to experience. This assessment explains how product parts may fail and what the consequences, detectability, and probability of occurence those failures implicate. Addressing these possibilities will allows future designs of this product to be more reliable. Using the Suggested Evaluation Criteria (as found on the FMEA wiki page), we were able to rank the severity from 1-10 (10 being the highest). For the occurrence parameter, we then were able to rank the probability of failure again from 1-10 (with 10 being the highest). Finally, we were able to rank detectability from 1-10 (with 1 being the most detectable). From these three numbers, we were able to multiply them together, which results with the Risk Priority Number (RPN).

| Item and Function | Failure Mode | Effects of Failure | S | Causes of Failure | O | Design Controls | D | RPN | Recommended Actions | Responsibility | Actions Taken | S* | O* | D* | RPN* |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Siphon Attachment Converger

| Blockage | Erratic operation; fluid movement impinged | 7 | Sediment buildup; insufficient room for large objects (e.g., aquarium stones); fish or marine life impingement | 6 | Siphon flows with suspensions of large objects of varying geometries | 2 | 84 | Allow greater curvature in converger design; creating brush to facilitate cleaning | Design engineer | - | - | - | - | - |

Attachment

| Cracking or fracture | Rocks may exit attachment and would not be cleaned properly | 6 | Overstressing; applying large forces to plastic outside of normal use | 3 | Test material strength under high loads | 3 | 54 | Improve material strength tests; use more durable plastic | Materials engineer | - | - | - | - | - |

Tube

| Deterioration or melting | Pump will lose efficiency | 6 | Siphoning corrosive substances or hot liquids; exposure to excessive heat | 4 | Test under extreme temperature conditions with range of substances | 4 | 80 | Use material with greater resistance to high temperatures | Materials engineer | - | - | - | - | - |

| Deformation | Tube may not connect to converger properly or may become dislodged during use | 6 | Excessive use causes tube diameter stretching | 3 | Subject tube to repeated tests with larger diameter | 2 | 36 | Use material that better permits repeated wear without deformation | Materials engineer | - | - | - | - | - | |

| Wear | Hole or rip | 7 | Overuse; contact with sharp edges (e.g., tank) | 5 | Test material under extreme use conditions | 3 | 105 | Use more durable material in tube construction | Materials engineer | - | - | - | - | - |

The highest RPN value for this analysis was 105, which would be caused by overuse. This mode of failure would lead to a hole or rip in the main tube, which transfers fluid from the aquarium to the output source. This failure received a 7 for severity, a 5 for probability of occurrence, and a 3 for detectability. The result of this failure would be the siphon operating inefficiently but perhaps would lead to a complete loss of functionality. From this analysis, it can be concluded that even the most catastrophic failure is not detrimental to the user with respect to his or her physical safety and wellbeing. The worst case scenario is that the siphon would lose its functionality, causing the user to have to purchase another such pump. To fix this failure mode, a possible solution would be to use more durable material in the tube. This example illustrates the fact that the FMEA analysis diagnoses some room for improvement in the overall design of the siphon.

Design for X (DFX)

The concept of DFX refers to considering a specific variable X in the design of a product. Some common variables that are considered are ease of: manufacturing, assembly, use, and maintainability.

Design for Manufacturing and Assembly (DFMA)

DFM and DFA refer to analysis and design strategies that aim to understand how a product is made and how the manufacturing and assembly steps in its production can be improved. The DFMA process is advantageous for a designer’s consideration due to the tremendous cost benefits that accompany the simultaneous analysis of DFM and DFA and the interface between the two methods. The use of these methodological tools can reduce costs, decrease labor, cut production times, decrease part counts, and improve the overall design quality.

Design for Manufacturing (DFM)

The primary goal of the DFM process is to analyze the manner in which the component parts of a product are made. By examining how things are manufactured, this process can be optimized so that parts can be produced efficiently and economically while adhering to design constraints. In order to optimize a manufacturing process, cost factors must be taken into account along with time, labor, environmental, and quality concerns. The list below details some of the ways in which DFM was likely incorporated into the design of the siphon:

- Tube and attachment are both extruded, which allows for less wasted plastic and ultimately greater efficiency and lower cost in mass production

- Tolerance between siphon attachment converger and tube is loose enough to allow small expansions of plastic tubing for tight fit in assembly, which prevents parts from being discarded owing to fitting problems

- Product contains no materials that are difficult or expensive to manipulate in manufacturing process (e.g., rubber, glass, metal)

The analysis above suggests that the product has been designed well for manufacturing. Despite its simplicity, the siphon design manages to reduce manufacturing costs through its choice of materials yet retains a high degree of durability. However, one improvement that might be made is to use an injection molding process to make the siphon attachment converger instead of forging, as this manufacturing switch would allow the process to become more cost effective.

Design for Assembly (DFA)

The objective of DFA is to improve product quality and reduce costs by optimizing a product's design and assembly process. DFA goals are predominantly achieved through simplifying a product, reducing part counts, and designing components that can be easily managed and installed. The follow list describes how DFA was probably applied to the design of the siphon:

- Product design uses sleeve fitting instead of fasteners to reduce part count, thereby decreasing cost and complexity

- All components are axisymmetric about radial axis and have enough friction to facilitate handling and manipulation

- Parts are not too big or heavy due to light plastics used in design, which makes handling easier

- Stackable nature of siphon attachment converger reduces storage space through compact design

- Simple and clear product design (with terminals that can only be connected with correct parts) facilitates assembly

From the aforementioned analysis, it is evident that great care has been taken to optimize the assembly process for the siphon. Owing to the straightforward nature of the product design, the design for assembly of the siphon is nearly optimal, as it avoids superfluous complexities and allows for easy handling.

Design for Environment (DFE)

Economic Input-Output Life Cycle Assessment (EIO-LCA)

Quantitative Analyses

To pass through the siphon system the fluid will:

1. Enter attachment

2. Pass through contraction to enter siphon tube

3. Flow through siphon tube

4. Exit siphon tube

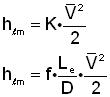

In order for the fluid to pass through this system, the fluid will have to overcome a head loss. Most of the head loss in this system comes from what is called minor head losses associated with expansions and contractions in the flow path. The below equations represent the two ways of calculating minor head loss when the mean velocity of the flow is known. Since the velocity of fluid passing through the system may vary depending on the user, the actual head loss of the system cannot be calculated explicitly.

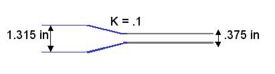

In the first equation, K is the head loss coefficient. In the second equation, f is the friction factor (which varies with velocity of the flow), the quantity Le is the equivalent length of an elbow, and the quantity D is the inner diameter of the pipe. The relevant values for the siphon system are shown in the image to the right.