Soda gun opportunity

From DDL Wiki

(→Appendix) |

(→Stakeholder Interviews) |

||

| Line 88: | Line 88: | ||

The scope was to call different companies selling soda gun systems as well as the maintenance companies suggested on [http://www.wunderbar.com/wunderbar-technical-support/service-agent/Pennsylvania wunderbar.com] to get their feedback on soda gun systems. | The scope was to call different companies selling soda gun systems as well as the maintenance companies suggested on [http://www.wunderbar.com/wunderbar-technical-support/service-agent/Pennsylvania wunderbar.com] to get their feedback on soda gun systems. | ||

| + | |||

| + | <u>Strategies adopted on the phone while calling on Feb 7</u> | ||

| + | |||

| + | First, the interlocutor was exactly told who was calling : a student in Mechanical Engineering, doing a project involving a soda gun. This turned out to be a bad approach because I simply could not get through on the phone, or because they did not want to waste time with a student. | ||

| + | After a few setbacks, I turned into a customer or potential customer : at that point, I was able to get some answers but they were sometimes distorted by the sales-men's ability to prettify the situations. In the end, I even turned into a potential bar manager having some technical questions about the systems. | ||

<u>'''Summary'''</u> | <u>'''Summary'''</u> | ||

| - | The | + | The notes made during this research are in the appendix. The key findings are the following : |

*Most of the bars rent the system and therefore have a contract with the company regarding the maintenance : if they have a problem, they just call and they fix it. | *Most of the bars rent the system and therefore have a contract with the company regarding the maintenance : if they have a problem, they just call and they fix it. | ||

*The gun itself is pretty reliable : o-rings and valves are the only things that generally need replacement. The flow rate of the gun is commonly found to be rather poor compared to a soda fountain. | *The gun itself is pretty reliable : o-rings and valves are the only things that generally need replacement. The flow rate of the gun is commonly found to be rather poor compared to a soda fountain. | ||

| Line 98: | Line 103: | ||

*A common reason for bars to call a service company is because of a wrong syrup ratio ! | *A common reason for bars to call a service company is because of a wrong syrup ratio ! | ||

*The system sellers emphasize the fact that the system can be repaired and maintained by anyone. The service companies say it’s impossible to do it yourself. | *The system sellers emphasize the fact that the system can be repaired and maintained by anyone. The service companies say it’s impossible to do it yourself. | ||

| - | |||

| - | |||

| - | |||

| - | |||

| - | |||

| - | |||

| - | |||

| - | |||

| - | |||

| - | |||

| - | |||

| - | |||

| - | |||

| - | |||

| - | |||

| - | |||

| - | |||

| - | |||

| - | |||

| - | |||

| - | |||

| - | |||

| - | |||

| - | |||

| - | |||

| - | |||

| - | |||

| - | |||

| - | |||

| - | |||

| - | |||

==Product Reviews== | ==Product Reviews== | ||

Revision as of 14:11, 21 February 2014

Contents |

Executive Summary

Market Research

Conducting research on the soda gun was an interesting task because it is not a common consumer product. We visited local restaurants and bar areas to conduct anthropological research, as well as call and email a variety of companies and maintenance corporations.

Product reviews and secondary research were also conducted, which provided us with a variety of information ranging from homemade soda guns to intricate bar set up reviews.

We geared away from surveys and use studies because the soda gun is an uncommon consumer product. Often, users receive waitress or bar tending training before using the product and are instructed on how it functions. Use studies would be difficult to set up because the full system is very difficult to acquire. It is important to note these inconveniences when developing new opportunities. Perhaps our new product could function without the need of training. Perhaps we could condense the system, making it more transportable.

- "SUMMARIZE TOP STAKEHOLDER NEEDS IN A LIST"

Anthropological Study: Friday Afternoon

Two of our group members walked to Oakland on Friday afternoon to visit bars (Hemingway's) and restaurants (Noodles & Co. and Fuel & Fuddle) during off hours. The goal of this study was to interview bartenders, and get insider opinions on how a user interacts with a soda gun system.

We learned that the plastic pieces on the soda gun are colored either red (if the establishment sells Coke) or blue (if the establishment sells Pepsi). Further, the decision of which brand to sell is based mostly on customer demand.

We also learned that almost none of the restaurant owners/bartenders knew how to fix the gun if there was a problem. All maintenance was handled by an outside maintenance man even for problems as simple as a leaky O-ring or bad syrup ratio. Also, all the ratios are set by the installer.

Specifics to Hemingway's:

There are two stations behind the bar with three soda guns each: juices, sodas, and red bull. This is so the bartender can make a mixed drink pitcher more quickly by using two soda guns at once (say to combine cranberry juice and sprite).

The CO2 tanks and syrup boxes were located underneath a trapdoor behind the bar.

There was also a soda dispenser that was used mostly by the waiters. The bartender said she also preferred to use the soda dispenser to get cups of soda because it filled glasses faster than the soda gun.

Bartenders were responsible for changing the syrup boxes out (which happened on average once a week). The biggest problem was that the soda syrup boxes were incredibly heavy for the bartender to lift onto the rack. The syrup was siphoned out by a vacuum system so there was almost no waste. Each box made around 10,000 glasses of soda and cost around $4. The large 50-liter CO2 tanks were refilled by the distributor about every two weeks.

Likes: Can Duel-Wield Soda Gun, Stations set up to quickly fill shot pitchers

Dislikes: Very slow compared to soda machine, Pushing multiple buttons at once doesn't work, Short Leash, Metal tube is sometimes too stiff and causes the gun to twist out of the holster

Specifics to Fuel & Fuddle:

There are two stations with one 12-button gun, both for soda. This is a smaller bar and the soda gun was liked much less by everyone who worked there. It was very slow, and the syrup ratios were off. In general, the entire bar/waiting staff would prefer a soda dispenser for its speed and ease of use.

Anthropological Study: Saturday Night

Two of our group members walked down to Shadyside on Saturday night to visit bars(Mario's) and restaurants (Steel Cactus) during prime hours. The goal of this study was to observe how bartenders and waiters/ waitresses used the soda gun in a high stress environment.

Unfortunately, because the bartenders and waitresses were very busy, we could not conduct an interview with them. To continue the study, we sat close to the soda guns and made observations on how the employees interacted with the product.

We learned that longer bars have more than one gun attached. Steel Cactus serves Pepsi products, which we could notice through the blue plastic nozzle and handle. When the bar tender utilized the soda gun, he seemed to understand what buttons produced each syrup, even though they weren't labelled with brand names or icons. We assumed this intuitive state of thinking came from experience. We also noticed that only one button was pressed at a time. The bartender would often combine carbonated soda and a juice. To do so, he had to press the carbonated soda button, release it, then press the juice button.

On average, a drink would take 4-5 seconds to pour. Before mixing a drink, the bartender would grab the liquor bottle, walk over to the soda gun, use one hand to release the soda and the other hand to pour the liquor. This maximized the bartender's efficiency so he wasn't standing idle waiting for the glass to fill with soda. It is also important to note that the bartender would walk to the gun. He never fully utilized the extension of the gun. This occurred because the soda gun was re-holstered after every use. We were curious as to why the bartender would walk half way around the bar to utilize the soda gun instead of pulling it towards them. When we leaned closer, we realized the holster multi-functioned as a draining device. Any residue from the soda nozzle would drip into the holster down into a drain. The bartenders walked to the gun to maximize cleanliness, even if it cost them an extra five seconds.

On a busy night, bartenders utilize the soda gun 4-5 times per minute. Assuming busy hours at a bar in Shadyside to be between 11pm and 2am, the soda gun is used roughly 800 times per night. Rapid use and durability are significant factors to consider during design.

Anthropological Study: Soda Fountains

Our team also explored the soda gun's brother- the soda fountain. We visited a Carnegie Mellon University dining hall to explore how the soda fountain works and is utilized.

We spoke with one of the employees at Skibo Cafe, who took us behind the counter to see how the soda fountain is set up. The syrup boxes are aligned on shelves next to several Carbon Dioxide tanks. Only one tank is connected to the system, but there are extra tanks sitting idle in case the current tank runs out before another order is placed. All of the syrups are attached to tubes with a plastic nozzle and clamp very similar to those seen on the soda gun. We wonder if these are the same parts? This would reduce part numbers sold by the fountain manufacturer.

The syrup tubes run an extremely long line. The tubes are gathered together and filtered through a long piece of PVC that runs up the wall, through the ceiling, and down another wall. The tubes exit right below the soda fountain. At this point, the tubes containing syrup run directly up into the soda machine and are connected to their labeled taps. The carbon dioxide and water tubes run into the carbonator where the carbonated soda is made. This is then pumped through the larger, clear tube into the fountain.

After speaking with the employees at Skibo Cafe, we uncovered these key points

- Pepsi Co. installed this entire system. They also maintain the system, replace damaged parts, and restock syrups and carbon dioxide tanks. Skibo employees only responsibility is to call in when they need refills or if a part is damaged.

- Employee has been working in the cafe for over a year and has never seen a part malfunction

- Employee doesn’t know how to regulate the flow of syrup- Pepsi company takes care of that as well

- Employee didn’t have any significant complaints about the product

- Non-carbonated beverages run out faster than carbonated ones (could be a CMU statistic)

- Ice container chills syrup and soda in tubes only

- Cold plate on bottom of ice container

- It’s easy to screw on the nozzle to the syrup containers

- Pump is activated entirely through pressure because there are no wires

After observing students use the soda machine, we recorded:

- The tray under the nozzles isn’t connected to a drain- it’s just a collection bin that must be emptied out every evening

- Soda comes out of a fountain much faster than it comes out of a soda gun

- More carbonation is produced from a soda fountain than a soda gun

- Users can fill their cup with one hand, but cannot leave the machine unattended

- It is difficult to multitask when filling a drink at a soda fountain

- Multiple sodas can be pressed at a time

Stakeholder Interviews

The scope was to call different companies selling soda gun systems as well as the maintenance companies suggested on wunderbar.com to get their feedback on soda gun systems.

Strategies adopted on the phone while calling on Feb 7

First, the interlocutor was exactly told who was calling : a student in Mechanical Engineering, doing a project involving a soda gun. This turned out to be a bad approach because I simply could not get through on the phone, or because they did not want to waste time with a student. After a few setbacks, I turned into a customer or potential customer : at that point, I was able to get some answers but they were sometimes distorted by the sales-men's ability to prettify the situations. In the end, I even turned into a potential bar manager having some technical questions about the systems.

Summary

The notes made during this research are in the appendix. The key findings are the following :

- Most of the bars rent the system and therefore have a contract with the company regarding the maintenance : if they have a problem, they just call and they fix it.

- The gun itself is pretty reliable : o-rings and valves are the only things that generally need replacement. The flow rate of the gun is commonly found to be rather poor compared to a soda fountain.

- The other parts of the system (carbonator, pumps, ...) may be subject to failure during normal operation, as expected.

- The lifespan of a system can be from 10 to 30 years depending on the level of maintenance.

- A common reason for bars to call a service company is because of a wrong syrup ratio !

- The system sellers emphasize the fact that the system can be repaired and maintained by anyone. The service companies say it’s impossible to do it yourself.

Product Reviews

Key Points:

- There appears to be some demand for in-home soda dispensing systems

- Average annual consumption of carbonated soft drinks in America is 44.7 gallons per person, per year. (http://www.huffingtonpost.com/2011/06/27/americans-soda-beer_n_885340.html)

- There are current products in the market that allow for the adaptation of a Wunderbar system into a home system (Bar Bandit)

- Uses 2-liter bottles and CO2 to power soda through a Wunderbar gun, allowing for off-counter storage of bottles

- Benefits include portability, integrate-ability into current CO2 line set ups, low cost, increased work space, and professionalism (http://www.youtube.com/watch?v=ZE9kaeB_Bd4)

- Wholesale distributors allow you to buy soda syrup directly (http://www.markpowers-and-company.com/Wunder-Bar%20Setup.htm)

- A home user may not drink a 2L bottle of soda fast enough to prevent it from going flat, adding a CO2 component to preserve carbonation is attractive to consumers

- Purchasing the equipment (gun) especially new, is expensive and requires some know-how of how the set-up should work

- Bar guns should be cleaned daily to prevent contamination in the lines

- Our dissection product was a hydraulic post-mix gun, but most home consumers prefer pre-mix because it is easier and there is no syrup mixing involved (brixing etc.) (http://www.homebrewtalk.com/f51/soda-gun-anyone-used-one-these-35702/)

- The presence of a bar gun gives a bar, both in commercial and home settings, a sense of authenticity, a desired trait for many (http://www.hometheaterforum.com/topic/295421-should-i-get-a-soda-gun/)

- The bar gun allows users to “custom-set” their own preferences for brixing based on how they think the soda should taste

- Syrup attracts flies, ants, etc.

- Pre-mix guns can dispense beer, but post-mix guns can’t (all foam, wrong carbonation levels, mixer in gun prevents it) (http://www.homebrewtalk.com/f11/can-soda-bar-gun-dispense-beer-259425/)

- Financially, you will save money buying syrup and CO2 rather than soda itself (http://www.city-data.com/forum/house/579747-home-soda-fountain.html)

- Commercially, soda guns/fountains are preferable to bottles, but when maintenance and portability are brought into the picture, the advantage is reduced (http://www.roadfood.com/Forums/Coke-Dispensing-Machine-m551245.aspx)

General Impression:

- Many users express interest in a home soda gun for a variety of purposes, but the complexity of the set-up, the maintenance required, and the cost of commercial systems are major deterrents

Relevant Competitor Products

- Soda Stream (http://www.sodastreamusa.com/carbonators.aspx)

- Light-weight, smaller CO2 bottles

- Uses tap water and soda syrups to carbonate soda in the home

- Counter top device, no hoses or expected know-how

- Must be set-up for each serving/use

- Easy to clean

- Relatively low up-front costs ($79-$200)

- PUR Flavor Options (http://www.amazon.com/PUR-Flavor-Options-Faucet-FM-5050B/dp/B000QIYIA4)

- Uses tap water with a small amount of flavoring to lightly flavor water (4 flavor options sold separately)

- Also Filters water

- Biggest Problem = falling off the faucet

- Customers complained of cheap manufacturing by P&G

- Easy to Install

- No electricity necessary

- Attaches to any faucet

- $40-$100

- Everpure Exubera Chiller/Carbonator (http://www.freshwatersystems.com/c-630-everpure-exubera-chillercarbonator.aspx)

- Faucet system that dispenses chilled carbonated or still water

- Amount of fizz is adjustable

- Complicated installation

- Difficult to Remove

- Must also buy custom faucet ($600)

- Very Expensive ($2000)

Design Concepts

"Provide sketches and descriptions of your top 3-5 design concepts, describing what opportunities have been identified and how they will be addressed."

" Summarize your findings and recommendations. In particular, identify which concept you recommend pursuing for the remainder of the semester. Provide a hypothetical before & after user scenario representative of your target market from your research findings to motivate your top solution concept."

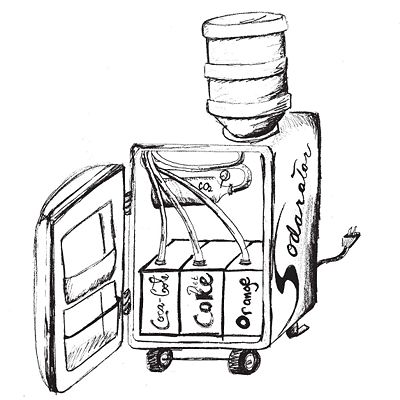

SODARATOR -

Personal, Portable Soda Dispenser Built Inside a Mini-Fridge

SODARATOR -

Personal, Portable Soda Dispenser Built Inside a Mini-Fridge

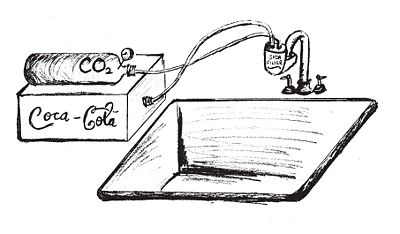

SODA FILTER -

Faucet + CO2 Tank + Box of Syrup = Cup of Inexpensive Soda

SODA FILTER -

Faucet + CO2 Tank + Box of Syrup = Cup of Inexpensive Soda

Pugh Chart

" Identify relevant competitor products from your patent searches, commercial searches, web searches, and expert interviews. Compare pros and cons of each of your concepts on a standard Pugh chart against your top stakeholder needs, and benchmark against the most relevant competitors. If your concepts are better on some attributes and worse on others,identify any market segments likely to value the tradeoffs you can offer."

Gantt Chart

Team Members

Appendix

List of Interview Questions for the User

- What do you like about your soda gun?

- What don’t you like about your soda gun?

- Has your soda gun ever broken? If so, how?

- What parts of the soda gun are tedious?

- Have you ever lost a customer because of soda gun malfunction?

- Have you ever used the shut off screw?

- What’s the most creative way you use the soda gun?

- Are there any quick fixes you have applied to the device to make it easier?

- How often does the product require maintenance?

- How easy is the product to maintain?

- How often do you clean the product? How? Issues?

- Can you personally maintain or do you need to call for assistance?

- Do you know how to adjust the soda ratio?

- Can you notice the difference between fountain soda and pre-bottled soda?

- Is the gun long enough to reach the full bar?

- Are the buttons hard to press?

- Are the buttons intuitive?

- Do you know how to refill the syrups?

- Where is the product from?

- What is the lifespan of the product?

- Is the product owned or licensed?

List of Interview Questions for Stakeholders and Experts

- What part of this product is the most difficult to produce?

- What part of this product is the easiest to produce?

- Where do you see the most failures in the product?

- Where do you see the least amount of failures in the product?

- Can you reduce part numbers?

- What part of this product is the most difficult to maintain?

- What part of this product is the easiest to maintain?

- How often are you called in to maintain the product?

- What replacement parts are purchased the most?

- What parts can be replaced individually? What failures require full system replacement?

- What is the lifespan of the product?

- Is the system transferable? Is the system worth transferring?

Notes from the phone calls

Random companies found on the internet :

- sodadispenserdepot.com

- Call : no answers

- Live chat : first ended by the agent because I wasn't a customer. Later, I pretended to be a potential customer : System lasts “several years”. Weak points are o-rings and syrup pumps that don’t last forever. Flow rate is rather poor vs fountain. Everything is easy to repair, they provide guides, videos, etc.

- sodadispensers.com : no answer

- sodabarsystem.com : they don’t do maintenance

- Willtec Home Soda : he doesn't do any maintenance but he has a system at home for 10 years w/o a problem. “Damn reliable”. Sometimes o-ring or valve have to be changed. He says bars have several guns to change them if there’s a problem.

- Kint : can’t join a technician, “time is money”.

Service companies from Wunder-bar website :

- R.S. Sales : don’t do soda guns -> Recommended to get in contact with Philadelphia Extract (215-548-5225)

- Philadelphia Extract : 99% of bars rent the system from them. They usually call once every month / 3 months for a problem, depending on the place. If maintained, system -> 20 years. Syrup pumps -> 5,6 years. Every system is likely to leak/break, but it’s less about the gun itself.

- Kapco Service : no answers

- Cameron Supply : What can fail : carbonator, pump. Problems : leaks on gun, connectors are bad. Most occurring problem : wrong syrup ratio. Lifespan up to 30 years.

- Polar Bear : can’t get through the answering machine w/o leaving my coordinates and detailing the problem.

- Glen Carbonic : they don’t do Coke/Pepsi and he doesn’t want to answer my questions anymore.

Additional notes :

The system sellers emphasize the fact that the system can be repaired and maintained by anyone. The service companies say it’s impossible to do it yourself.