Stamping

From DDL Wiki

| Line 3: | Line 3: | ||

''Blanking''<br /> | ''Blanking''<br /> | ||

The process by which a punch and die apply pressure to sheet metal to shear it and obtain a desired shape that is removed from the sheet which is now considered scrap.<br /> | The process by which a punch and die apply pressure to sheet metal to shear it and obtain a desired shape that is removed from the sheet which is now considered scrap.<br /> | ||

| - | [[Image: | + | [[Image:BlankingProcess.jpg]]<br /> |

''Punching''<br /> | ''Punching''<br /> | ||

The same process as blanking, except that removed material is scrap, and the remaining sheet is the workpiece.<br /> | The same process as blanking, except that removed material is scrap, and the remaining sheet is the workpiece.<br /> | ||

Revision as of 00:48, 12 February 2007

Process

Stamping is the manufacturing process by which sheet metal is deformed via a die and punch into a desired shape. It is a very versatile process capable of many different form operations such as:

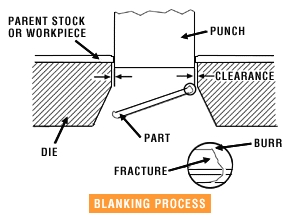

Blanking

The process by which a punch and die apply pressure to sheet metal to shear it and obtain a desired shape that is removed from the sheet which is now considered scrap.

Punching

The same process as blanking, except that removed material is scrap, and the remaining sheet is the workpiece.

Drawing

Ironing

Embossing

Bending

Flanging

Coining

Capabilities

Use

Simple or complex shapes at high production rates

Cost

High tooling and equipment costs

Low labor costs

References

1. http://en.wikipedia.org/wiki/Stamping_%28metalworking%29

2. http://www.beststampings.com/index.htm

3. http://www.engineersedge.com/manufacturing/metal_stamping.htm

4. http://www.mfgquote.com/process_metal_stamping.cfm

5. http://www.visionsenterprises.com/mastertool/definitions.htm