Stamping

From DDL Wiki

| Line 84: | Line 84: | ||

Posted by Team 1: Jeff Polack, Kevin Pruzinsky, Davey Quinn and Russel Verbofsky<br /> | Posted by Team 1: Jeff Polack, Kevin Pruzinsky, Davey Quinn and Russel Verbofsky<br /> | ||

| + | |||

| + | [[category:manufacturing]] | ||

Revision as of 01:54, 14 February 2007

Process

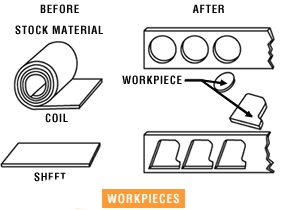

Stamping is the manufacturing process by which sheet metal is deformed via a die and punch into a desired shape. It is a very versatile process capable of many different form operations such as piercing, drawing, bending, etc. Progressive-die operations is when a stamped shape require a combination of these various operations or even just multiple stations of the same operation.

PIERCING

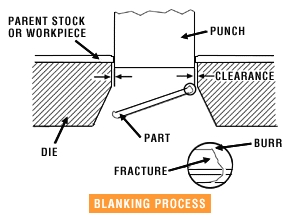

Blanking

The process by which a punch and die apply pressure to sheet metal to shear it and obtain a desired shape (blank) that is removed from the sheet which is now considered scrap.

Punching

The same process as blanking, except that removed material is scrap, and the remaining sheet is the workpiece.

DRAWING

Deep drawing

The process by which a sheet metal blank is formed into a cylindrical or box-shaped part by the punch pressing the blank into the die cavity.

Ironing

The same process as deep drawing, except that the die cavity has less clearance forcing the resulting cup to have a constant wall thickness.

BENDING

Air bending

The process by which sheet metal is plastically deformed to a desired angle.

Bottoming

The same process as air bending, except that the workpiece reaches the bottom of the die.

Coining

The same process as bottoming, except that the punch tip penetrates the neutral axis of the material.

Flanging

Another variation of bending in which the edges of the sheet metal are bent to create a flange.

BULGING

Embossing

The process of forming shallow shapes, like letters, numbers or designs on sheet metal.

Capabilities

MATERIALS

More Common

Aluminum (T1, T2, All alloys), Steel (Cold/Hot rolled, Galvanized, All alloys)

Less Common

Brass, Copper, Titanium, Zinc

SIZES

Sheet thickness typically varies from .005" to .075"

Sheet widths are typically no greater than 4 feet.

SHAPES

As you can see from the above processes both simple and complex shapes can be made by combinging different stamping operations. Some basic shapes include cups by drawing, flanges by bending, almost any 2-D shape by blanking, and a variety of hole shapes by punching.

PRECISION

The precision of a stamed part depends largely on the specific stamping process that was performed on it. In general however stamped parts are not created as precisely as machined parts and typically have somewhat larger tolerances.

Use

Stamping is generally used to create simple or complex shapes with a high surface area to volume ratio at high production rates.

COMMON EXAMPLES

Aluminum soda cans

Automobile body panels

Metal desks

Hubcaps

Kitchen utensils

Plumbing fittings

DESIGN CONSIDERATIONS

Blank design - Material scrap is a major concern of stamping, so it is important that blanks be designed so that they can be easily nested in order to reduce scrap.

Bending - Bending creates large distortions of the stress concentration within the sheet metal. At times these concentrations can become large enough to create wrinkling, buckling or even fracture. One common practice to reduce these effects is the incorporation of carefully located notches in the design of the part. These notches can help avoid tearing and wrinkling in right angle bending operations. It is also important to avoid placing holes too close to a bend, since holes already create areas of higher stress concentration.

Progressive die operations - Tooling costs can become somewhat expensive in stamping operations, so it is important to design the part with as few features as possible, or features that require few stamping stations. If two features are placed too closely together, there might be to small of a clearance for simultaneous punches, thus adding unnecessary tooling costs to the process.

Springback - Plastic deformation of a material is always followed by elastic recovery once the load causing the deformation is removed. A common fix of this phenomenon is simply overbending the part, so it springs back to the desired angle.

Cost

Tooling and equipment costs for stamping operations can be somewhat high, whereas labor costs are typically very low. However stamping dies can cost reasonably less than tooling used in molds, forging and casting because of the repetitive nature of combined forming operations that stamping allows. Many of the products created with those methods could be easily redesigned for stamping instead. One of the advantages of switching to stamping operations is the higher productions rates that can be achieved resulting in lower manufacturing costs. The cost of secondary operation can also be reduced with stamping, since many stamped parts require no machining. Scrap production from stamping operations is typically on the order of magnitude of 10% to 25% of the original material which is on the low end of most manufacturing processes, with some ranging as high as 60%.

References

1. http://en.wikipedia.org/wiki/Stamping_%28metalworking%29

2. http://www.beststampings.com/index.htm

3. http://www.engineersedge.com/manufacturing/metal_stamping.htm

4. http://www.mfgquote.com/process_metal_stamping.cfm

5. http://www.visionsenterprises.com/mastertool/definitions.htm

Posted by Team 1: Jeff Polack, Kevin Pruzinsky, Davey Quinn and Russel Verbofsky